7

Do not use the furnace closet or area next to the

furnace as a storage area. This area must be

kept clear, clean, and free of lint. The furnace

must also be kept clear of loose or exposed

insulation materials. Examine the furnace area

when the furnace is installed or when insulation

is added. Some insulation materials may be

combustible.

For proper and safe operation, the furnace

needs air for combustion and ventilation. Do not

block or obstruct air openings on the furnace,

or any air openings where the furnace may be

installed, including any surrounding spaces.

Should the gas supply fail to shut off or if

overheating occurs, shut off gas valve to

the furnace before shutting off electrical

supply.

Do not use this furnace if any part has been

under water. A fl ood-damaged furnace is

extremely dangerous. Attempts to use the

furnace can result in fi re or explosion. A

qualifi ed service agency should be contacted

to inspect the furnace and to replace all gas

controls, control system parts, electrical parts

that have been wet or the furnace if deemed

necessary.

Familiarize yourself with the controls that

shut off the gas and electrical power to the

furnace. If the furnace is to be shut down for an

extended period of time, turn off both the gas

and electrical power. For your safety always

turn off both the gas and electrical power

before performing service or maintenance on

the furnace.

For 2-Stage and 95+ Models Only

For 80+ and 90+ Single Stage

Models Only

1. STOP! Read the safety information above on this label.

2. Set the thermostat to the lowest setting.

3. Turn off all electrical power to the appliance.

4. The appliance’s ignition device automatically lights the

burner. Do not try to light burner by hand.

5. Remove the control access door/panel (upper door if

two-door model).

6. Move the gas control switch to the “OFF” position.

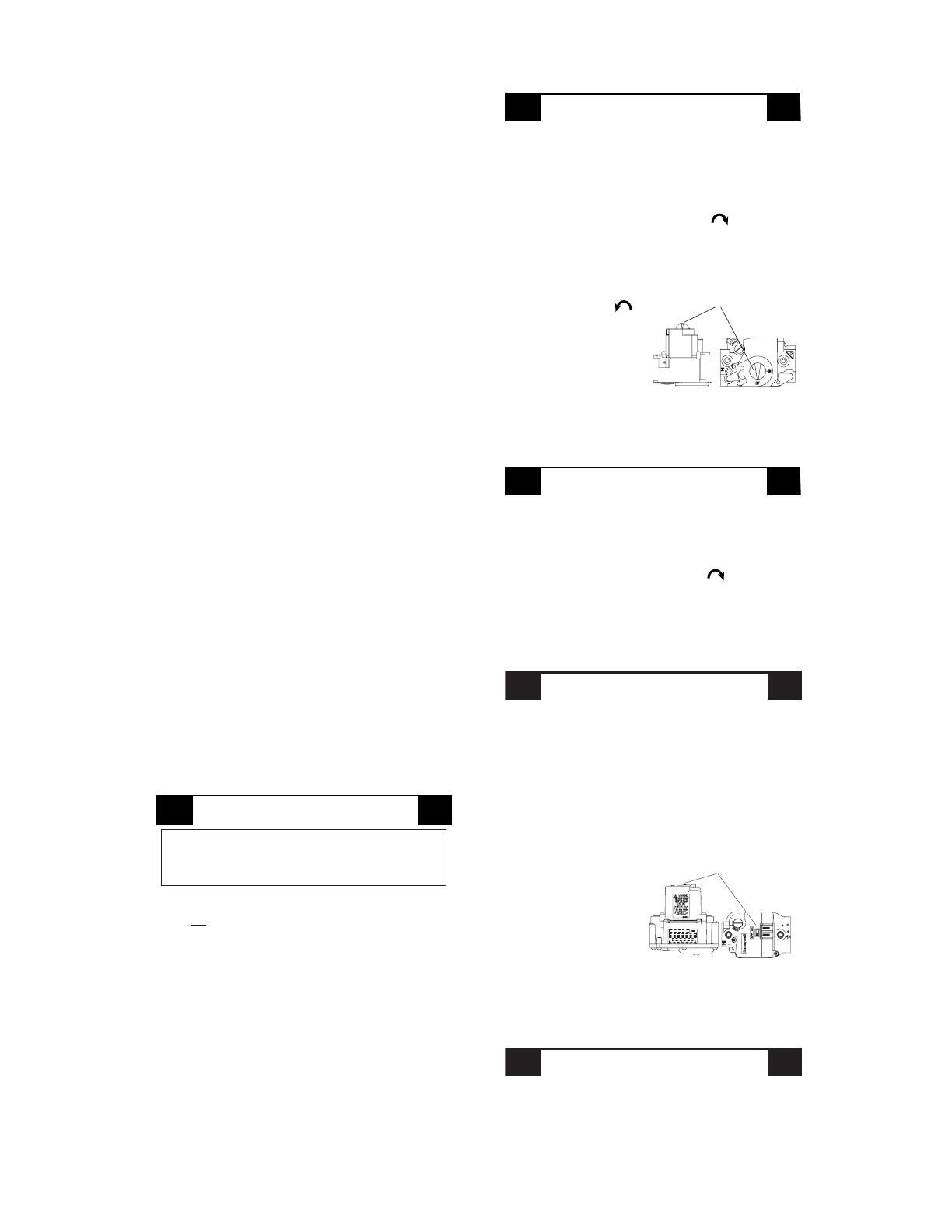

(See Figure 1)

7. Wait five (5) minutes to clear out any gas. Then

smell for gas, including near the floor. If you

smell gas, STOP! Follow “B”

in above information. If

you don’t smell gas, go

to the next step.

8. Move the gas control

switch to the “ON”

position. (See Figure 1)

9. Replace the control

access door/panel

(upper door if two-door

model).

10. Turn on all electrical power to the appliance.

11. Turn the thermostat to a desired setting.

12. If the appliance will not operate, follow the instructions

“To Turn Off Gas To Appliance” and call your service

technician or gas supplier.

1. Set the thermostat to the lowest setting.

2. Turn off all electrical power to the appliance if service is

to be performed.

3. Remove the control access door/panel (upper door if

two-door model).

4. Move the gas control switch to the “OFF” position. Do

not use force. (See Figure 1)

5. Replace the control access door/panel (upper door if

two-door model).

TO TURN OFF

GAS TO APPLIANCE

OPERATING INSTRUCTIONS

SWITCH

(INTERRUPTEUR)

Figure 1

A. This appliance does not have a pilot. It is equipped with

an ignition device which automatically lights the burner.

Do

not try to light the burner by hand.

B. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

C.Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

move by hand, do not try to repair it, call a qualified

service technician. Force or attempted repair may result

in a fire or explosion.

D.Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

FOR YOUR SAFETY READ

BEFORE OPERATING

WARNING:

If you do not follow these instructions

exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

1. STOP! Read the safety information above on this label.

2. Set the thermostat to the lowest setting.

3. Turn off all electrical power to the appliance.

4. The appliance’s ignition device automatically lights the

burner. Do not try to light burner by hand.

5. Remove the control access door/panel (upper door if

two-door model).

6. Move the gas control knob clockwise

to “OFF”.

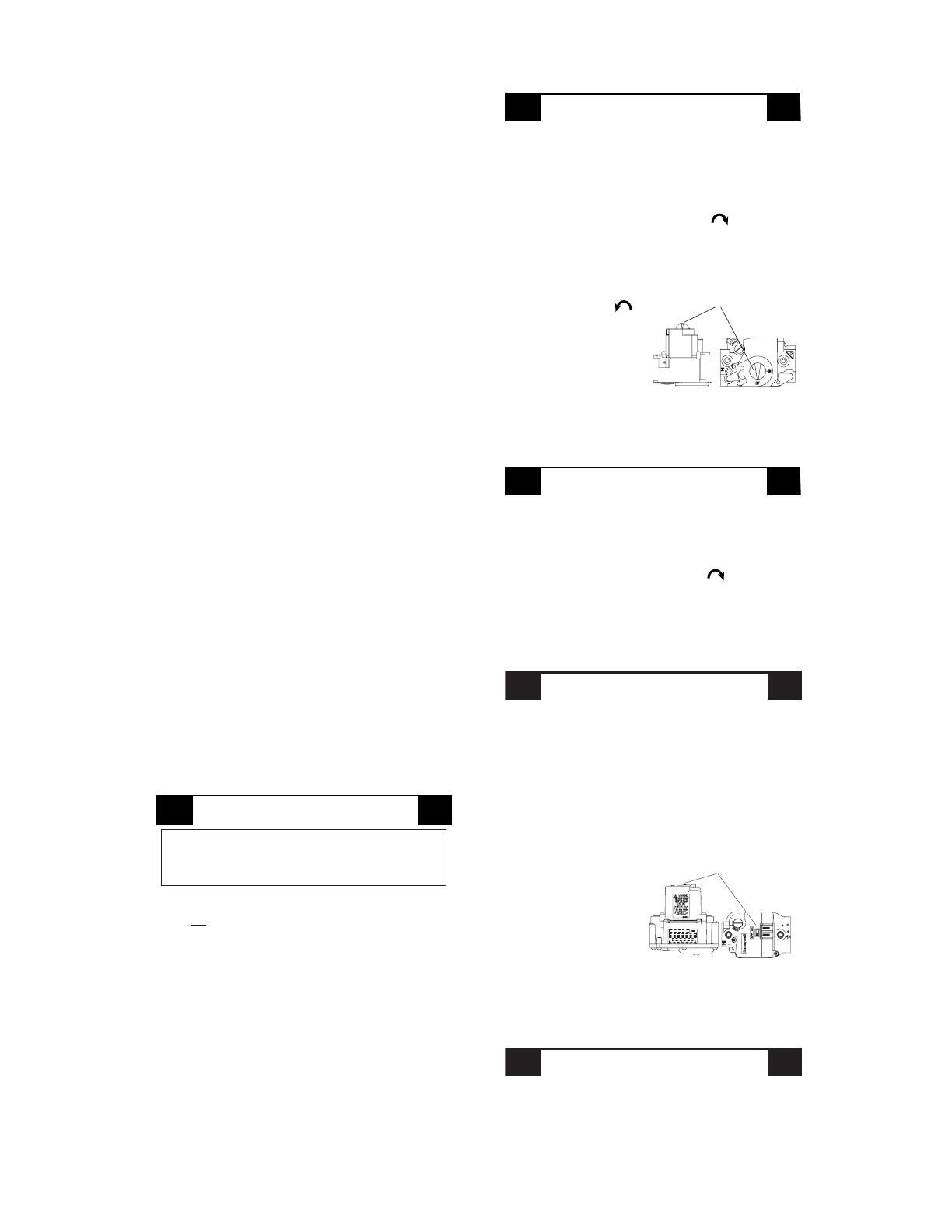

(See Figure 1)

7. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you smell gas,

STOP! Follow “B” in above information. If you don’t

smell gas, go to the next step.

8. Move the gas control knob

counterclockwise

to “ON”.

(See Figure 1)

9. Replace the control

access door/panel

(upper door if two-door

model).

10. Turn on all electrical

power to the appliance.

11. Turn the thermostat to a

desired setting.

12. If the appliance will not operate, follow the instructions

“To Turn Off Gas To Appliance” and call your service

technician or gas supplier.

1. Set the thermostat to the lowest setting.

2. Turn off all electrical power to the appliance if service is

to be performed.

3. Remove the control access door/panel (upper door if

two-door model).

4. Move the gas control knob clockwise

to “OFF”. Do

not use force. (See Figure 1)

5. Replace the control access door/panel (upper door if

two-door model).

TO TURN OFF

KNOB

(ROBINET)

Figure 1

OPERATING INSTRUCTIONS

GAS TO APPLIANCE