Nilfisk SW5500 60 B Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

SW5500

Instructions for use

LPG

09/2016 Revised 04/2018

(B)

FORM NO. 1467287000

English

Français

Español

Português

Instructions d’utilisation

Instrucciones de uso

Instruções de uso

Model No.:

9084417010

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 1

09/2016

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................................................................. 2

MANUAL PURPOSE AND CONTENTS .......................................................................................................................................... 2

TARGET ........................................................................................................................................................................................... 2

HOW TO KEEP THIS MANUAL ....................................................................................................................................................... 2

IDENTIFICATION DATA ................................................................................................................................................................... 2

OTHER REFERENCE MANUALS ................................................................................................................................................... 3

SPARE PARTS AND MAINTENANCE ............................................................................................................................................. 3

CHANGES AND IMPROVEMENTS ................................................................................................................................................ 3

OPERATION CAPABILITIES ........................................................................................................................................................... 3

CONVENTIONS .............................................................................................................................................................................. 3

UNPACKING/DELIVERY ................................................................................................................................................. 3

SAFETY ........................................................................................................................................................................... 3

VISIBLE SYMBOLS ON THE MACHINE ......................................................................................................................................... 4

SYMBOLS THAT APPEAR ON THIS MANUAL ............................................................................................................................... 4

GENERAL INSTRUCTIONS ............................................................................................................................................................ 4

MACHINE DESCRIPTION ............................................................................................................................................... 8

MACHINE STRUCTURE ................................................................................................................................................................. 8

CONTROL PANEL ..........................................................................................................................................................................11

ACCESSORIES/OPTIONS ............................................................................................................................................................ 12

TECHNICAL DATA ......................................................................................................................................................................... 12

WIRING DIAGRAM ........................................................................................................................................................................ 14

USE ................................................................................................................................................................................ 16

FUEL .............................................................................................................................................................................................. 16

BEFORE MACHINE START-UP .................................................................................................................................................... 17

STARTING AND STOPPING THE MACHINE ............................................................................................................................... 17

PARKING BRAKE .......................................................................................................................................................................... 18

MACHINE OPERATION ................................................................................................................................................................ 19

HOPPER DUMPING ...................................................................................................................................................................... 20

AFTER USING THE MACHINE ..................................................................................................................................................... 21

MACHINE LONG INACTIVITY ...................................................................................................................................................... 21

MAINTENANCE ............................................................................................................................................................. 21

SCHEDULED MAINTENANCE TABLE ......................................................................................................................................... 21

MULTIFUNCTION DISPLAY SERVICE SCREENS ....................................................................................................................... 23

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT .................................................................................................................. 25

MAIN BROOM REPLACEMENT ................................................................................................................................................... 26

SIDE BROOM HEIGHT CHECK AND ADJUSTMENT .................................................................................................................. 27

SIDE BROOM REPLACEMENT .................................................................................................................................................... 28

PANEL DUST FILTER CLEANING AND INTEGRITY CHECK ...................................................................................................... 29

SKIRT HEIGHT AND OPERATION CHECK .................................................................................................................................. 30

DUSTGUARD™ SYSTEM WATER FILTER CLEANING (OPTIONAL) ......................................................................................... 31

HYDRAULIC SYSTEM OIL LEVEL CHECK .................................................................................................................................. 31

ENGINE OIL LEVEL CHECK AND REPLACEMENT .................................................................................................................... 32

ENGINE AIR FILTER CHECK/CLEANING .................................................................................................................................... 33

ENGINE SPARK PLUG CHECK/REPLACEMENT ........................................................................................................................ 34

BATTERY CHARGING (only for version with optional hybrid KIT installed) .................................................................................. 35

FUSE CHECK/REPLACEMENT .................................................................................................................................................... 36

SAFETY FUNCTIONS ................................................................................................................................................... 36

EMERGENCY PUSH-BUTTON ..................................................................................................................................................... 36

DRIVER’S SEAT MICROSWITCH ................................................................................................................................................. 36

ANTI-SKID SAFETY SYSTEM ...................................................................................................................................................... 36

MACHINE ANGLE SENSOR ......................................................................................................................................................... 36

HOPPER POSITION SENSOR ..................................................................................................................................................... 36

HOPPER SAFETY VALVE ............................................................................................................................................................. 36

TROUBLESHOOTING ................................................................................................................................................... 37

SCRAPPING .................................................................................................................................................................. 38

ENGLISH INSTRUCTIONS FOR USE

2SW5500 - 1467287000 09/2016

INTRODUCTION

NOTE

The numbers in brackets refer to the components shown in Machine Description chapter.

MANUAL PURPOSE AND CONTENTS

The purpose of this Manual is to provide the operator with all necessary information to use the machine properly, in a safe and

autonomous way. It contains information about technical data, safety, operation, storage, maintenance, spare parts and disposal.

Before performing any procedure on the machine, the operators and qualied technicians must read this Manual carefully. Contact

Advance in case of doubts regarding the interpretation of the instructions and for any further information.

TARGET

This Manual is intended for operators and technicians qualied to perform the machine maintenance.

The operators must not perform procedures reserved for qualied technicians. Advance will not be responsible for damages coming

from failure to follow these instructions.

HOW TO KEEP THIS MANUAL

The Instructions for Use Manual must be kept near the machine, inside an adequate case, away from liquids and other substances

that can cause damage to it.

IDENTIFICATION DATA

The machine serial number and model name are marked on the plate (30).

Product code and year of production are marked on the same plate.

The engine model and serial number are shown on the engine plate (see the engine manual).

This information is useful when ordering machine and engine spare parts. Use the following table to write down the machine and

engine identication data for any further reference.

MACHINE model ...............................................................................

PRODUCT code ................................................................................

MACHINE serial number ...................................................................

ENGINE model ..................................................................................

ENGINE serial number ......................................................................

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 3

09/2016

OTHER REFERENCE MANUALS

– Spare Parts List (supplied with the machine)

– Engine Manual (Honda iGX 270)

– Service Manual (that can be consulted at Advance Service Centers)

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair procedures must be performed by qualied personnel or by Advance Service

Centers. Only original spare parts and accessories must be used.

Contact Advance for service or to order spare parts and accessories, specifying the machine model, product code and serial

number.

CHANGES AND IMPROVEMENTS

Advance constantly improves its products and reserves the right to make changes and improvements at its discretion without being

obliged to apply such benets to the machines that were previously sold.

Any change and/or addition of accessories must be approved and performed by Advance.

OPERATION CAPABILITIES

This sweeper has been approved to clean (sweeping and vacuuming) compact and solid oors, in commercial or industrial

environments, under safe operation conditions by a qualied operator.

CONVENTIONS

Forward, backward, front, rear, left or right are intended with reference to the operator’s position, that is to say on the driver’s seat

(3).

UNPACKING/DELIVERY

CAUTION!

To unpack the machine, carefully follow the instructions on the packing.

Upon delivery carefully check that the machine and its packing have not been damaged during transportation. In case of visible

damages, keep the packing and have it checked by the carrier that delivered it. Call the carrier immediately to ll in a damage claim.

Check that the machine is equipped with the following features:

– Technical documents:

• Sweeper Instructions for Use Manual (this document)

• Engine Manual (Honda iGX 270)

• Sweeper Spare Parts List

– No. 1 10 A fuse

SAFETY

The following symbols indicate potentially dangerous situations. Always read this information carefully and take all necessary

precautions to safeguard people and property.

The operator’s cooperation is essential in order to prevent injury. No accident prevention program is eective without the total

cooperation of the person responsible for the machine operation. Most of the accidents that may occur in a factory, while working

or moving around, are caused by failure to comply with the simplest rules for exercising prudence. A careful and prudent operator is

the best guarantee against accidents and is essential for successful completion of any prevention program.

ENGLISH INSTRUCTIONS FOR USE

4SW5500 - 1467287000 09/2016

VISIBLE SYMBOLS ON THE MACHINE

WARNING!

Carefully read all the instructions

before performing any operation on the

machine.

DANGER!

Internal combustion engine.

Do not inhale exhaust gas fumes.

Carbon monoxide (CO) can cause brain

damage or death.

WARNING!

Do not wash the machine with direct or

pressurized water jets.

X

%

WARNING!

Do not use the machine on slopes with

a gradient exceeding the specications.

WARNING!

Hot parts, danger of burns.

WARNING!

Moving parts.

WARNING!

Moving parts. Danger of crushing.

WARNING!

Parts under voltage. Presence of

corrosive uids.

SYMBOLS THAT APPEAR ON THIS MANUAL

DANGER!

It indicates a dangerous situation with risk of death for the operator.

WARNING!

It indicates a potential risk of injury for people or damage to objects.

CAUTION!

It indicates a caution or a remark related to important or useful functions. Pay careful attention to the

paragraphs marked by this symbol.

NOTE

It indicates a remark related to important or useful functions.

CONSULTATION

It indicates the necessity to refer to the Instructions for use Manual before performing any procedure.

GENERAL INSTRUCTIONS

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

–Carbon monoxide (CO) can cause brain damage or death.

–The internal combustion engine of this machine can emit carbon monoxide.

–Do not inhale exhaust gas fumes.

–Only use indoors when adequate ventilation is provided, and with the help

of an assistant who can monitor the operator’s health.

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 5

09/2016

DANGER!

–Before performing any maintenance, repair, cleaning or replacement procedure disconnect the batteries,

remove the ignition key and engage the parking brake.

–This machine must be used by properly trained operators only.

–Sharp turns must be made in safe conditions. Avoid abrupt turns, particularly on slopes, and turns with the

hopper lifted.

–Do not lift the hopper when the machine is on a slope.

–Keep the batteries away from sparks, ames and incandescent material.

–Do not wear jewels when working near electrical components.

–Do not work under the lifted machine without supporting it with safety stands.

–When working under the open hood, ensure that it cannot be closed by accident.

–Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids or vapors:

This machine is not suitable for collecting dangerous powders.

–Be careful: fuel is highly ammable.

–Do not smoke or bring naked ames in the area where the machine is refueled or where the diesel fuel is

stored.

–Refuel outdoors or in a well-ventilated area, with the engine o.

–Leave at least a space of 4 cm in the ller to allow the fuel to expand.

After refueling, check that the fuel tank cap is rmly closed.

–If any fuel is spilled while refueling, clean the tank area and allow the vapors to evaporate before starting

the engine.

–Do not let fuel come into contact with the skin; do not breathe fuel vapors. Keep out of reach of children.

–Do not tilt the engine or the machine too much to avoid fuel spillage.

–When moving the machine, the fuel tank must not be full and the fuel valve must be closed.

–Do not lay any object on the engine.

–Stop the engine before performing any procedure on it. To avoid any incidental start, disconnect the spark

plug cap or disconnect the battery negative terminal.

–See also the SAFETY RULES in the Engine Manual, which is to be considered an integral part of this

Manual.

–Lead batteries (WET) are installed on this machine, do not tilt the machine more than 30° from its horizontal

position to prevent the highly corrosive acid to leak out of the batteries. When the machine is to be tilted to

perform maintenance procedures, remove the batteries.

–Do not use the machine in case of gas leaks. Disconnect the hose and replace the LPG tank. If the gas leak

persists, disconnect the hose and contact the Advance Service Center.

WARNING!

–Carefully read all the instructions before performing any maintenance/repair procedure.

–The machine must be regularly inspected by qualied personnel, especially the LPG tank and its

connections to grant a safe use, as stated by the local laws in force.

–When working near the hydraulic system, always wear protective clothes and safety glasses.

–This machine is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the machine by a person responsible for they safety.

Children should be supervised to ensure that they do not play with the machine.

–Close attention is necessary when used near children.

–Use only as shown in this Manual. Use only Advance’s recommended accessories.

–Check the machine carefully before each use, always check that all the components have been assembled

before use. If the machine is not perfectly assembled it can cause damages to people and properties.

–Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the machine

moving parts.

–To avoid any unauthorized use of the machine, remove the ignition key.

–Do not leave the machine unattended without being sure that it cannot move independently.

–The machine must be safely parked (considering the pressurized LPG on board).

–Do not use the machine on slopes with a gradient exceeding the specications.

ENGLISH INSTRUCTIONS FOR USE

6SW5500 - 1467287000 09/2016

WARNING!

–Do not tilt the machine more than the angle indicated on the machine itself, in order to prevent instability.

–Use only brooms supplied with the machine or those specied in the Instructions for Use Manual. Using

other brooms could reduce safety.

–This is a class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

–Before using the machine, close all doors and/or covers as shown in the Instructions for Use Manual.

–Do not wash the machine with direct or pressurized water jets, or with corrosive substances.

–Use the machine only where a proper lighting is provided.

–Working lights (optional) have to be used only to enhance visibility on the oor to be cleaned, but they do

not authorize anyone to use the sweeper in dark environments.

–While using this machine, take care not to cause damage to people or objects.

–Do not bump into shelves or scaoldings, especially where there is a risk of falling objects.

–If the proper protective guard (FOPS)(optional) is not installed, do not use the machines in areas where

there is the risk of falling objects.

–Do not lean liquid containers on the machine, use the relevant can holder.

–The machine storage temperature must be +32 °F to 104 °F (0 °C to +40 °C).

–The machine working temperature must be +32 °F to 104 °F (0 °C to +40 °C).

–The humidity must be between 30 % and 95 %.

–Always protect the machine against the sun, rain and bad weather, both under operation and inactivity

condition. Store the machine indoors, in a dry place. (If applicable) This machine must be used in dry

conditions, it must not be used or kept outdoors in wet conditions.

–Do not use the machine as a means of transport, or for pushing/towing.

–The machine maximum capacity, operator’s weight not included, is 529 lb (240 kg) (the weight of waste).

–In case of re, use a powder re extinguisher, not a water one.

–Adjust the operation speed to suit the oor conditions.

–Avoid sudden stops when the machine is going downhill. Avoid sharp turns. Drive at slow speed when

going downhill.

–This machine cannot be used on roads or public streets.

–Do not tamper with the machine safety guards.

–Follow the routine maintenance procedures scrupulously.

–Do not allow any object to enter into the openings. Do not use the machine if the openings are clogged.

Always keep the openings free from dust, hairs and any other foreign material which could reduce the air

ow.

–(Only for versions equipped with DustGuard™ system). Pay attention during machine transportation

when temperature is below freezing point. The water in the tank or in the hoses could freeze and seriously

damage the machine.

–Do not remove or modify the plates axed to the machine.

–When the machine is to be pushed for service reasons (lack of fuel, etc.), the speed must not exceed 4

km/h.

–In case of machine malfunctions, ensure that these are not due to lack of maintenance. If necessary,

request assistance from the authorized personnel or from an authorized Service Center.

–If parts must be replaced, require ORIGINAL spare parts from an Authorized Dealer or Retailer.

–To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant chapter of

this Manual, must be performed by the authorized personnel or by an authorized Service Center.

–The machine must be disposed of properly, because of the presence of toxic-harmful materials (batteries,

oils, etc.), which are subject to standards that require disposal in special centers (see the Scrapping

chapter).

–While the engine is running, the silencer warms up; do not touch the silencer when it is hot to avoid burns

or res.

–Running the engine with an insucient quantity of oil can seriously damage the engine. Check the oil level

with the engine o and the machine on a level surface.

–Never run the engine if the air lter is not installed, because the engine could be damaged.

–Technical service procedures on the engine must be performed by an authorized Dealer.

Only use original spare parts or parts of matching quality for the engine. Using spare parts of lower quality

can seriously damage the engine.

–See also the SAFETY RULES in the Engine Manual, which is to be considered an integral part of this

Manual.

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 7

09/2016

Guide lines to bacteria control and other dangers coming from the presence of microbes in the DustGuard™

system (optional).

WARNING!

To prevent the operators and other people from developing infections caused by microbes and Legionella that

may ourish in the dust guard system, take the following precautions:

–If possible, ll the tank with cold water [< 68 °F (< 20 °C)].

–DO NOT use stagnant water to ll the tank.

–DO NOT use recycled water, undrinkable water or water that has been in contact with the soil.

–Adjust and turn the nozzles towards the oor only, from preventing possible inhaling.

–Do not store the machine outdoors or near sources of heat.

–Do not over-ll the tank. Fill the tank suciently so that it can be emptied by using the system.

–Empty the tank every 10 hours or once a week, according to the use.

–If the machine is not used for more than one week, empty the tank completely, and let it dry before storing

it.

–If the tank cannot be cleaned regularly, consider using a biocide that can kill or exert a controlling eect on

Legionella bacteria. Biocide must be chosen according to the local regulations and must be used according

to the relevant instructions and cautions, to avoid that the personnel gets aected by dangerous chemical

substances.

–If chemical products have to be used in the water tank, it is mandatory to apply the relevant information and

caution labels of the product.

ENGLISH INSTRUCTIONS FOR USE

8SW5500 - 1467287000 09/2016

MACHINE DESCRIPTION

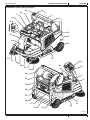

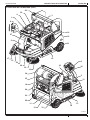

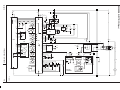

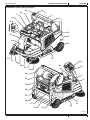

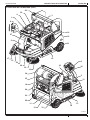

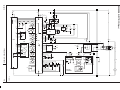

MACHINE STRUCTURE

1. Steering wheel

2. Control panel (see the following paragraph)

3. Driver’s seat with safety microswitch

4. Seat position adjusting lever

5. Accelerator pedal

6. Service brake pedal

7. Parking brake lever: press both the service brake (6) and the lever (7) to switch from the service brake to the parking brake

8. Front skirt lifting pedal

9. Main broom height adjusting knob:

• Turn it counter-clockwise to increase the broom pressure on the oor

• Turn it clockwise to decrease the broom pressure on the oor

10. Vacuum system rear hood

11. Vacuum system hood release lever

12. Hopper (empty it when it is full)

13. Right door (to be opened for performing maintenance procedures only)

14. Left door (for main broom removal)

15. Right side broom

16. Left side broom (optional)

17. Side broom guards (optional)

18. Main broom

19. Engine compartment hood

20. Can holder

21. Rear wheels

22. Front driving and steering wheel

23. Dust lter container / Dust guard system water tank (optional)

24. Panel lter

25. Dust guard system water ller neck plug (optional)

26. Dust guard system nozzles (optional)

27. Front column

28. Working lights

29. Flashing light (always on when the ignition key is turned to “I”)

30. Serial number/technical data/conformity certication plate

31. Removable right side panel

32. Removable left side panel

33. Anchoring slots for transport (not for lifting)

34. LPG cylinder

35. LPG tank fastening band

36. Engine o push-button (optional, only for hybrid version)

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 9

09/2016

MACHINE STRUCTURE (Continues)

17

5

27

1

20

3

30

21

6

7

8

14

24

25

12

18

13

9

4

29

2

36

5

15

28

22

26

16

11

23

10

35

34

33

19

32

31

P100919

revised 04/2018

ENGLISH INSTRUCTIONS FOR USE

10 SW5500 - 1467287000 09/2016

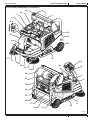

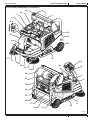

MACHINE STRUCTURE (Continues)

41. Engine compartment hood (open)

42. LPG engine

43. Hydraulic unit with tank for hopper lifting

44. Open hood safety rod

45. Alternator

46. Cooling fan

47. Batteries

47

41

44 43 42 45 46

P100920

revised 04/2018

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 11

09/2016

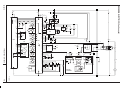

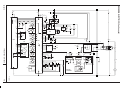

CONTROL PANEL

51. Ignition key:

• When turned to “0”, it turns the electrical system o and

disables all machine functions

• When turned to “II”, it starts the machine When the

machine starts, release the key, which will return to “I”

(machine ON)

52. One-Touch sweeping/vacuuming push-button

53. Right side broom push-button

54. Left side broom push-button

55. Side broom rotation speed adjustment push-buttons

56. Vacuum push-button

57. Filter shaker push-button

58. Increase maximum running speed push-button

59. Decrease maximum running speed push-button

60. Hopper lifting push-button

61. Hopper lowering push-button

62. Hopper dumping push-button

63. Hopper reset push-button

64. Reverse gear/forward gear reset push-button

65. Horn push-button

66. Hopper movement enabling push-button

67. Working light push-button (optional)

68. DustGuard™ system push-button (optional)

69. Emergency push-button. Press it in case of emergency to

stop all the machine functions.

To deactivate the emergency push-button, turn it in the

direction shown by the arrow.

70. USB socket (optional)

71. Multifunction display

Items displayed:

A) Working hours

B) Battery type

C) Maximum running speed setting

D) Work screen

E) Main broom activation

F) Side brooms activation

G) Vacuum activation

H) Reverse gear activation

I) Side brooms speed setting

J) Auto-shut o timer

K) Hopper opening warning

L) DustGuard™ system

M) Work light turned on

N) Main broom worn out

O) Service call

P) Fuel reserve warning

Q) Engine overheat warning

R) Engine oil pressure warning

S) Alternator warning

54

51

57

56

52

65

68 66 67

70 69

63

62

64

59

58

61

60

55 53

71

AB

H

IJK

LMNO

PQRS

D

E

C

F

G

P100921

revised 04/2018

ENGLISH INSTRUCTIONS FOR USE

12 SW5500 - 1467287000 09/2016

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can be equipped with the following accessories/options, according to the

machine specic use:

– Left side broom

– Main and side brooms with harder or softer bristles

– Paper dust lter

– Non-marking skirts

– Safety belts

– Right and left armrests

– Non-marking wheels

– FOPS protective roof

– Roof cover

– Side broom guards

– DustGuard™ system

– USB™ socket

– Hybrid motor

For further information concerning the optional accessories, contact an authorized Retailer.

TECHNICAL DATA

Model SW5500 LPG

Cleaning width with one side broom 46.2 in (1,175 mm)

with two side brooms 59 in (1,500 mm)

Main broom size (length x diameter) 33.5 x 14.2 in (850 x 360 mm)

Side broom diameter 19.7 in (500 mm)

Hopper capacity 39.6 US gal (150 liters)

maximum liftable weight 529 lb (240 kg)

maximum lifting height 70 in (1,650 mm)

Filter cleaning system Electrical lter shaker

area 10850 ft2 (7 m2)

lter eciency 77 % @ 0,8 µm

Power 6.3 kW (8.4 hp) @ 3,600 rpm

Engine model Honda iGX 270

Fuel type LPG

Fuel tank capacity 15 Kg

Type of engine oil SAE 10W30

hopper hydraulic lifting system Arnica 46

Main broom motor power 1.7 hp (1,250 W)

speed 4,800 rpm

Side broom motor power 0.16 hp (120 W)

speed (variable) 40/155 rpm

Vacuum motor power 0.35 hp (260 W)

Drive type Electrical on the front wheel

gearmotor power 1.6 hp (1,200 W)

forward speed 6.2 mi/h (10 km/h)

reverse speed 2.8 mi/h (4.5 km/h)

Maximum gradient when working 20 %

Hopper hydraulic control unit 1.1 hp (800 W)

Filter shaker motor 2 x 0.016 hp (2 x 12 W)

Total absorbed power 3.5 hp (2.6 kW)

Dimensions

(length x width x height)

machine body 73.8 x 47.2 x 61.6 in

(1,875 x 1,200 x 1,564 mm)

machine with side brooms 73.8 x 51.2 x 61.6 in

(1,875 x 1,300 x 1,564 mm)

machine with FOPS protective roof (optional) 73.8x47.2x78.5/81.7 in

(1,875x1,200x1,995/2,075 mm)

LPG tank maximum size (length x diameter) 34.9 x 12 in

(886 x 306 mm)

revised 04/2018

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 13

09/2016

TECHNICAL DATA (Continues)

Model SW5500 LPG

Weight kerb weight 1684 lb (764 Kg)

total kerb weight (*) 1920 lb (871 Kg)

front axle kerb weight (*) 804 lb (365 Kg)

rear axle kerb weight (*) 1115 lb (506 Kg)

gross vehicle weight (GVW) 2846 lb (1,291 Kg)

Wheel specic pressure on the oor (front - rear wheels, in running conditions) (0.7 - 0.5 N/mm2)

Sound pressure level at workstation (ISO 11201, ISO 4871, EN 60335-2-72) (LpA) 79 dB(A) ± 3 dB(A)

Machine sound pressure level (ISO 3744, ISO 4871, EN 60335-2-72) (LwA) 98 dB(A)

IP protection class X3

Dust guard system water tank (optional) capacity 8.4 US gal (32 liters)

U-turn space (right - left) 91 - 93.5 in (2,310 - 2,375 mm)

Vibration level at the operator’s arms (ISO 5349-1) (**) <98.4 in/s2 (<2.5 m/s2)

Vibration level at the operator’s body (ISO 2631-1) (**) 31.5 in/s2 (0.8 m/s2)

(*) With operator on board, fuel tank and hopper empty.

(**) Under normal working conditions, on a level asphalt surface.

Machine Material Composition and Recyclability

Type Recyclable

percentage SW5500 LPG weight percentage

Aluminum 100 % 0.1 %

Electric motors - various 29 % 20.4 %

Ferrous materials 100 % 61.1 %

Wiring harnesses 80 % 0.0 %

Liquids 100 % 0.6 %

Plastic - non-recyclable material 0 % 0.0 %

Plastic - recyclable material 100 % 0.8 %

Polyethylene 92 % 8.1 %

Rubber 20 % 8.7 %

Cardboard - paper - wood 100 % 0.1 %

Hydraulic oil technical data

Viscosity at 104 °F (40 °C) in2/s (mm2/s) 0.07 (45) 0.05 (32)

Viscosity at 212 °F (100 °C) in2/s mm2/s (7.97) (6.40)

Viscosity index / 150 157

Flash point COC °F (°C) 419 (215) 396 (202)

Pour point °F (°C) -33 (-36) -33 (-36)

Density at 15 °C (59 °F) lb/US gal (kg/l) (0.87) (0.865)

CAUTION!

If the machine is to be used at ambient temperatures below 50 °F (+10 °C), the oil should be changed with

equivalent oil having a viscosity of 32 cSt. For temperatures below 32 °F (0 °C), use an oil with lower viscosity.

ENGLISH INSTRUCTIONS FOR USE

14 SW5500 - 1467287000 09/2016

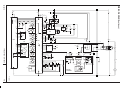

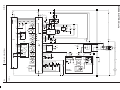

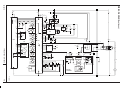

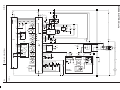

WIRING DIAGRAM

Key

A1 Main broom actuator

A2 Right side broom actuator

A3 Left side broom actuator (optional)

ALT Alternator

BAT1 12 V batteries

BAT2 12 V batteries

BZ Reverse gear buzzer

BE Flashing light

CCOIL Charging coil

CH Hybrid battery charger (optional)

D1..D3 Diode

EB1 Function electronic board

EB2 Drive system electronic board

EB3 Display board

EB4 Dashboard electronic board

EB5 Seat dashboard electronic board

EB6 Honda engine ECM

EB7 Honda engine ignition coil

ECN Encoder

ES1 Function electronic board contactor

ES2 Drive system electronic board contactor

ES3 Engine on/o relay

ES4 Engine RPM relay

ES5 Engine start relay

ES6 Fan relay

ES8 Drive system enabling relay

ES9 Horn relay

ES10 Charging system electromagnetic switch

ES11 Hybrid charging system relay

EV1 Hopper raising solenoid valve

EV2 Hopper lowering solenoid valve

EV3 Hopper solenoid valve

EV4 Fuel solenoid valve

F0 Battery fuse

F1 Function electronic board fuse

F2 Ignition key fuse

F3 Drive system fuse

F4 Alternator fuse

F5 Engine fuse

F6 Engine start fuse

F7 Fan fuse

F8 Horn fuse

HN Horn

KEY Ignition key

L1 Working light (optional)

M0 Driving wheel

M1 Vacuum system motor

M2 Filter shaker motor

M3 Hopper pump motor

M4 Main broom motor

M5 Right side broom motor

M6 Left side broom motor (optional)

M7 Engine compartment fan

MST Starter

P1 Dust guard system pump motor (optional)

R1 Accelerator pedal

R2,...4 Resistance

S1 Opened hopper sensor

S2 High hopper sensor

S3 Rotated hopper sensor

S4 Main broom wear sensor

S5 Driving wheel temperature sensor

S6 Fuel reserve sensor

S7 Oil alert sensor

S8 Diode jumper temperature sensor

SPK Engine spark plug

SW0 Emergency push-button

SW1 Driver’s seat safety microswitch

TU Trackunit (optional)

USB USB port (optional)

Color codes

BK Black

BU Blue

BN Brown

GN Green

GY Grey

OG Orange

PK Pink

RD Red

VT Violet

WH White

YE Yellow

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 15

09/2016

WIRING DIAGRAM (Continues)

F2

S1 S2

P2

P1

P0

30/1

15

30

5015/54

KEY

SW0

BE

+

ES1

EB1

RD

BK

B+

F1

RD RD

BZ

J2.4

J1.5

J1.6

J2.15

J1.11

BK

J2.8

EV2

ES1

J4.1

J4.2

M5

M4

M2

M1

M6

P1

FS-

FS+

VA-

VA+

BR-

BR+

RSB-

RSB+

LSB-

LSB+

WP1

M3

PM-

PM+

EB5

J1.2

J1.3

J2.7

J1.4

WP2

R2

+

L1

J2.12

-B

J1.9

J1.10

S4

J1.19

J1.15

J1.12

J1.20

S3

EV3EV1

J2.3

J2.2

J2.1

J2.9

12V

BATT1

B+

B-

BK

BK

RD

F4

RD

S6

J2.6

J2.14

J1.8

J1.18

J1.16

ES3

M

MST

WH

F5

-

+

REG

GY

GY GY

WHGN

GY

BK WH

CCOIL

BK

ES4

S7

ES3

WHBK

YEBK LIGHTGNBK RDYE

SPK

ENGINE

CH

EB6EB7

B+

ALT

B-

BK

J1.14

ASSEMBLY

M2

A2

A1

A3

A2.4

A2.1

A1.1

A3.1

A3.4

A1.4

EB3

EB4

J1.3

J1.1

J3.4

J2

J3.2

16

J1.1

J1.4

J1.5

J1.2J3.1

ES5

ES5 F6

RD

EB2

SW1

BK

+

ES2

ES2

F3

3

M0

ENC

JD.5

JD.1

JD.4

RD

JD.6

JD.3

S5

JC.6

JC.1

JB.6

B+

BF+

B-

JB.2

W

V

U

USB

0V

JC.10(CAN_L)

JC.9 A4.3

J7.2(CAN_L)

JC.5(CAN_H) J7.1(CAN_H)

JB.8 A4.1

JD.2

F7

RD

ES6

M7

JC.4

JC.3

R1

JB.4

J1.1

J1.2

J1.3

J2.2 J2.1

GY

TU

J6.1

J6.3

J6.4

J6.5

J6.6

BN

PK

WH

YE

BU

F0

12V

BATT2

FR FR FR

FR

JC.8

S8

J1.13

D2

ES4

J2.13

J2.5

+

ES6ES10

R3

+

ES10

TU.RD

HN

0V

ES9

F8

ES9

TU.RD

RD

-

+

D1

0V

ES11

ES11

0V

COMM.4

COMM.3

BK

RD

BK

RD

BK

RD

BK

RD

BK

RD

BK

RD

BK

RD

OGBK

BK

RD

GY

BU

OGBK

BK

RD

GY

BU

GN

WH

BN

YE

VTBK

OGBK

BK

RD

BK

BU

WH

YEBK

YE

BK

BK

BK

BK

RD

BK

RD

VT

YE

YEBK

VTBK

OG

BK

PK

RDWH

BUWH

GN

YE

BU

BK

RD

RD

RD

BU

RD

RD

WH

OG OG OG

GNBK

BNBK

BUBK

RD

BNWH

VTWH

BUWH

GNWH

GN

BU

VT

BN

RD VT

BNBK

PKBK

YE

BK

OGBK OGBK

OGBK

BUBK

BK

RD

BK

RD

RDBK RDBK RDBK RDBK

GY

GYBK GYBK GYBK

RD RD

BK BK BK BK BK

RD

RD

RD

BK

WHBK

GNBK RD

RD

RD

SW2

EV4

PKBK

RDWH

D3 D4

PKBK

GN

WH

BN

SK

3

A4.4

VTVT

JC.2

0V

J1.1

J1.2

J1.3

J1.4

J1.5

P16

P17

P18

LD1

P100923

ENGLISH INSTRUCTIONS FOR USE

16 SW5500 - 1467287000 09/2016

USE

WARNING!

On some points of the machine there are some adhesive plates indicating:

–DANGER

–WARNING

–CAUTION

–CONSULTATION

While reading this Manual, the operator must pay particular attention to the symbols shown on the plates (see the Visible Symbols

On The Machine paragraph).

Do not cover these plates for any reason and immediately replace them if they are damaged.

If the machine has not been used after being transported, check that all the blocks have been removed.

FUEL

DANGER!

–Carbon monoxide (CO) can cause brain damage or death.

–The internal combustion engine of this machine can emit carbon monoxide.

–Do not inhale exhaust gas fumes.

–Only use indoors when adequate ventilation is provided, and with the help

of an assistant.

DANGER!

Before replacing the LPG tank, close the safety valve and disconnect the hose.

1. Install an LPG tank (34) having characteristics which comply with the laws in force in the country where it is used.

2. Fasten the tank with a fastening band (35).

3. Connect the hose and open the cut-o valve on the LPG tank. Always wear gloves when connecting and disconnecting the

hose. When the machine is not operating, close the LPG tank cut-o valve.

NOTE

Place the LPG tank in a proper horizontal position. Connect the hose to the tank and check that there are no gas leaks.

DANGER!

Do not use the machine in case of gas leaks. Disconnect the hose and replace the LPG tank. If the gas leak

persists, disconnect the hose and contact the Advance Service Center.

INSTRUCTIONS FOR USE ENGLISH

1467287000 - SW5500 17

09/2016

BEFORE MACHINE START-UP

Checklist

1. Have a full knowledge of the machine operating controls and their functions.

2. Insert the key (51) and start the machine (see the procedure in the following paragraph).

3. In the rst 2 seconds after turning on, the multifunction display (71) shows the machine working hours (71-A), the type of

batteries set (71-B) and the current maximum machine speed setting (71-C).

4. Check the fuel reserve icon (71-P); if it is lit, range will be limited. Replace the LPG tank (see previous paragraph).

5. Check the horn with switch (65), the reverse gear buzzer with switch (64) and the working light switch (67, optional) for proper

operation.

6. Check the parking brake (7 and 6). The brake must hold its (locked parked) setting rmly without easily being released (report

all defects immediately to Advance Service Center).

7. Check the service brake pedal (6) for proper operation.

WARNING!

If the pedal is “spongy” or fades under pressure without an ecient braking force, do not drive the machine

(report all defects immediately to Advance Service Center).

8. Make sure that there are no open doors/hoods and that the machine is in normal operating conditions.

Cleaning planning

1. Arrange long runs with a minimum of stopping or starting.

2. Allow a small amount of broom path overlap to ensure complete coverage.

3. Avoid making sharp turns, bumping or scraping the side of the machine.

Filling the DustGuard™ system water tank (optional)

1. Remove the plug (25) to reach the ller neck.

2. Fill the tank (24) with clean water. Do not ll the tank completely, leave a few centimeters from the edge.

STARTING AND STOPPING THE MACHINE

Starting the machine

1. Sit on the driver’s seat (3) and adjust it with the lever (4) to allow easy reach of all controls.

NOTE

The driver’s seat (3) is equipped with a safety sensor, which allows the machine to be driven only when the operator is

on the driver’s seat.

2. Turn the ignition key (51) clockwise to the “I” position.

3. Wait for the multifunction display to show the work screen (71-D).

4. Turn the ignition key (51) to the start position “II”, then release it when the engine starts.

5. After starting, let the engine idle for a few seconds.

CAUTION!

When starting do not press the accelerator pedal (5).

6. Disengage the parking brake.

7. Drive the machine to the working area, maneuvering it by turning the steering wheel with your hands (1) and pressing the

accelerator pedal (5).

The speed can be adjusted by applying more or less pressure to the accelerator pedal (5).

The maximum running speed can be set with push-buttons (58) and (59).

8. The forward/reverse direction is selected with the relevant push-button (64) on the dashboard. Activation of reverse gear is

indicated by the buzzer and on the display (71-H).

WARNING!

When steering, avoid abrupt direction changes, pay careful attention and drive the machine at slow speed,

especially when the hopper is full or when operating on inclines.

Drive the machine slowly on inclines. Use the brake pedal (6) to control machine speed while descending

inclines.

Do not turn the machine on an incline; drive straight up or down.

NOTE

The machine has an anti-skid safety system, which where necessary reduces speed when steering and when the

machine is driving on a camber, regardless of the pressure applied to the pedal.

This reduction in speed is therefore not a malfunction but a characteristic which increases the stability and safety of the

machine in all conditions.

ENGLISH INSTRUCTIONS FOR USE

18 SW5500 - 1467287000 09/2016

Hybrid motor (optional)

1. Perform steps 1 to 3 of the machine start-up paragraph.

2. Ignition of the engine is not necessary while the batteries retain a sucient level of charge.

3. Check the battery charge while working. While at least one segment of the battery icon

(A, Fig. 1) is lit and not ashing on the multifunction display (71), the machine can be used

with the engine o. When the battery icon (A) has only one ashing segment remaining ,

it is advisable to start the engine, or else to recharge the batteries using the on-board battery

charger (see procedure in the Maintenance chapter).

4. To start using the machine again with the engine o, press the push-button (36) and hold it

down until the engine turns o.

5. When the multifunction display shows screen (B), a complete battery charging cycle must be

performed using the on-board battery charger. Complete the job in progress before taking the

machine to the area for charging its batteries.

6. Perform a complete charging cycle before using the machine again (see procedure in the

Maintenance chapter).

A

B

P100924

Figure 1

Stopping the machine

1. To stop the machine, release the accelerator pedal (5).

2. To stop the machine quickly, also press the service brake pedal (6).

WARNING!

The machine regulates its speed in proportion to the pressure on the accelerator pedal, accelerating and

decelerating as a result. In some particular working and environmental conditions (e.g. steep descents), the

automatic deceleration may deactivate itself to protect the system. For this reason, always use the service brake

(6) to be sure of the machine’s stopping distance.

3. In case of emergency, press the emergency push-button (69) to immediately stop the machine.

To deactivate the emergency push-button (69), turn it clockwise.

WARNING!

The emergency push-button (69) also deactivates the machine’s automatic deceleration system; if operated

while moving, use the service brake (6) to stop the machine.

4. Turn the ignition key (51) to “0” and remove it.

PARKING BRAKE

1. Engage the parking brake by pressing the pedal (6) and engaging the lever (7).

2. Disengage the parking brake by pressing and releasing the pedal (6).

WARNING!

Before performing any maintenance, repair, cleaning or replacement procedure engage the parking brake.

Engage the parking brake when parking the machine on a slope.

WARNING!

Before leaving the machine unattained, be sure that the parking brake can stop the machine with a large safety

margin.

WARNING!

When using the machine on slopes, respect the maximum gradient values marked on the machine itself (see

technical characteristics table).

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

Nilfisk SW5500 60 B Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

dans d''autres langues

- English: Nilfisk SW5500 60 B Owner's manual

- español: Nilfisk SW5500 60 B El manual del propietario

- português: Nilfisk SW5500 60 B Manual do proprietário