Whirlpool WGD9371YW2 Guide d'installation

- Catégorie

- Sèche-linge

- Taper

- Guide d'installation

Ce manuel convient également à

Gas Dryer Installation Instructions

Canadian Electric Dryer Installation Instructions

Instructions pour l'installation de la s6eheuse h gaz

p

(E.-U. et Canada) et 61eetrique (Canada uniquement)

Table of Contents Table des matibres

DRYER SAFETY ................................................................ 2 SEGURITE DE LA SEGHEUSE ....................................... 17

iNSTALLATiON REQUIREMENTS .................................... 4

Tools and Parts .................................................................... 4

Location Requirements ...................................................... 5

Electric Dryer Power Hookup=Canada Only ..................... 7

Gas Dryer Power Hookup ................................................... 8

VENTING .................................................................................... 10

Venting Requirements ....................................................... 10

Plan Vent System ............................................................... 11

install Vent System ............................................................ 12

iNSTALL LEVELING LEGS ........................................................ 12

MAKE GAS CONNECTION ....................................................... 13

CONNECT iNLET HOSES ......................................................... 13

CONNECT VENT ....................................................................... 15

LEVEL DRYER ........................................................................... 15

COMPLETE iNSTALLATiON CHECKLIST ............................... 16

DOOR REVERSAL ..................................................................... 16

STACKING WASHER AND DRYER .......................................... 16

TROUBLESHOOTING ............................................................... 16

EXIGENCES D'INSTALLATION ...................................... 19

Outillage et pi_ces ............................................................ 19

Exigences d' emplacement ............................................... 20

Raccordement a I'alimentation _lectrique de

la s_cheuse 61ectrique - Canada seulement .................. 22

Raccordement d'une s6cheuse/_ gaz ............................. 23

UEVACUATION .......................................................................... 25

Exigences concernant I'_vacuation ................................ 25

Planification du syst_me d'_vacuation ........................... 26

Installation du circuit d'_vacuation ................................. 28

iNSTALLATiON DES PIEDS DE NIVELLEMENT ..................... 28

RACCORDEMENT AU GAZ ...................................................... 29

RACCORDEMENT DU TUYAU D'ARIVEE D'EAU ................... 29

RACCORDEMENT DU CONDUIT D'ISVACUATION ................ 31

REGLAGE DE L'APLOMB DE LA SLeCHEUSE ......................... 31

ACHEVER UINSTALLATION - LISTE DE VISRIFICATION ....... 32

iNVERSiON DE LA PORTE ....................................................... 32

LAVEUSE ET SIsCHEUSE SUPERPOSISES ............................. 32

D#PANNAGE ............................................................................. 32

iNSTALLATiON NOTES

Date of purchase:

Date of installation:

Installer:

Model number:

Serial number:

NOTES CONCERNANT L'INSTALLATION

Date d'achat :

Date d'installation :

Installateur :

Num6ro de module :

Num_ro de s6rie :

Para obtener acceso al manual de uso y cuidado en espaSol, o para obtener informaci6n adicional acerca de su

producto, visite:

www.whirlpool.com

Tenga listo su nOmero de modelo completo. Puede encontrar el nOmero de modelo y de serie dentro de la cavidad

superior de la puerta.

W10443045B

W10443046B=SP

DRYER S_ETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

WARNING - ...i.. ofFi,o..

- Clothes dryer installation must be performed by a qualified installer.

- install the clothes dryer according to the manufacturer's instructions and local codes,

= Do not install a clothes dryer with fle×ible plastic venting materials or flexible metal

(foil type) duct. if fle×ible metal duct is installed, it must be of a specific type identified

by the appliance manufacturer as suitable for use with clothes dryers. Fle×ible venting

materials are known to collapse, be easily crushed, and trap lint. These conditions will

obstruct clothes dryer airflow and increase the risk of fire.

= To reduce the risk of severe injury or death, follow all installation instructions.

= Save these instructions.

2

WARNING: For your safety, the information in this manual must be followed to minimize 1

the risk of fire or explosion, or to prevent property damage, personal injury, or death. 1

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

- WHAT TO DO iF YOU SMELL GAS:

®Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

®Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

= if you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the "What to do if you smell gas" instructions.

iMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSi Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

In the State of Massachusetts, the following installation instructions apply:

[] Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

[] if using a ball valve, it shall be a T=handle type.

[] A flexible gas connector, when used, must not exceed 3 feet.

I

iMPORTANT: When discarding or storing your old clothes dryer, remove the door.

I

IN$ LATION REQUIREMENTS

TOOLS AND PARTS

Gatherthe requiredtoolsand partsbeforestartinginstallation.

Tools needed for allinstallations:

Tools needed for gas installations:

8" or 10" pipe wrench 8" or 10" adjustable wrench

(for gas connections)

Flat-blade screwdriver

Wire stripper (direct wire

installations)

1/4" nut driver

recommended)

#2 Phillips screwdriver

Tin snips (new vent

installations)

Vent clamps

Pipe-joint compound

resistant to LP gas

Parts supplied (all models):

Leveling legs (4)

Parts supplied (steam models):

Tape measure

Pliers

&

"Y" connector Short inlet hose

4

Level

Adjustable wrench that

opens to 1" (25 mm) or

hex-head socket wrench

Caulking gun and compound

(for installing new exhaust vent)

Utility knife

Long inlet hose

Rubber washer

Parts package is located in dryer drum. Check that all parts

are included.

NOTE: If installing dryer on pedestal, do not use leveling legs.

Optional Equipment: (Not supplied with dryer)

Refer to your Use and Care Guide for information about

accessories available for your dryer.

Parts needed: (Not supplied with dryer)

Check local codes. Check existing electrical supply and venting.

See "Electrical Requirements" and "Venting Requirements"

before purchasing parts.

Check code requirements. Some codes limit, or do not permit,

installing dryer in garages, closets, mobile homes, or sleeping

quarters. Contact your local building inspector.

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from dryer.

Place dryer at least 18 inches (460 ram) above the floor

for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need:

[] A location allowing for proper exhaust installation.

See "Venting Requirements."

[] If using power supply cord, a grounded electrical outlet

located within 2 ft. (610 mm) of either side of dryer.

See "Electrical Requirements."

[] Floor must support dryer weight of 200 Ibs. (90.7 kg).

Also consider weight of companion appliance.

[] Cold water faucets located within 4 ft. (1.2 m) of the water fill

valves, and water pressure of 20-100 psi (137.9-689.6 kPa).

You may use the water supply for your washer using the "Y"

connector and short hose (if needed) which are provided.

[] 20-100 psi (138-690 kPa) for best performance.

[]

Level floor with maximum slope of 1" (25 mm) under entire

dryer. If slope is greater than 1" (25 mm), install Extended

Dryer Feet Kit, Part Number 279810. If not level, clothes

may not tumble properly and automatic sensor cycles may

not operate correctly.

[] For garage installation, place dryer at least 18" (460 mm)

above floor. If using a pedestal, you will need 18" (460 mm)

to bottom of dryer.

For each arrangement, consider allowing more space for ease

of installation and servicing; spacing for companion appliances

and clearances for walls, doors, and floor moldings. Space

must be large enough to allow door to fully open. Add spacing

on all sides of dryer to reduce noise transfer. If a closet door

or Iouvered door is installed, top and bottom air openings

in door are required.

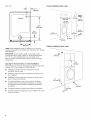

DRYER DiMENSiONS

Front view:

27"

(686 ram)

353/8"

(899 mm}

Side view:

29"

• (736 mrn)----------€_

Left or

right side

exhaust

31/2"

(89ram)

(41 ram)

Door open view:

-.q

-.q

48V8"

(1238 ram)

47V8"

(1197 ram)

©

Back view:

f

Electric

m

J

(358 ram)

6t/4,,

(159 ram)

T

28tA ''

(715 ram)

3t/2"

(89 ram)

NOTE: Most installations require a minimum of 5" (127 mm)

clearance behind dryer for exhaust vent with elbow. See "Venting

Requirements."

iMPORTANT: Do not operate, install, or store dryer where

it will be exposed to water, weather, or at temperatures below

45° F (7° C). Lower temperatures may cause dryer not to

shut off at end of automatic sensor cycles, resulting in longer

drying times.

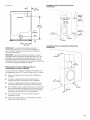

Spacing for recessed area or closet installation

All dimensions show recommended spacing allowed, with tested

spacing of 0" (0 mm) clearance on sides and rear.

[] Additional spacing should be considered for ease of

installation and servicing.

[] Additional clearances might be required for wall, door, and

floor moldings.

[] Additional spacing should be considered on all sides of the

dryer to reduce noise transfer.

[] For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilitation openings are

acceptable.

[] Companion appliance spacing should also be considered.

[] No other fuel-burning appliance may be installed in the same

closet as the dryer.

Closet installation (dryer only):

(102 mm)

34" recomrnende(

(864 turn)

I

18" rain.

1 ml

1" (25ram)

(25ram)

Cabinet installation (dryer only):

7 mm

(178 ram)

48 in.2

(310cm2)

24 in?

(155 cm_)

3""

(76ram)

A

18"

(480 ram)

6

Closet Installation (stacked washer and dryer):

6"

i............

51/2.

_ (25 ram)

] /[, ,

iiii /

_--1"

(25ram)

3 mm

(76 ram)

f

48 in.2

(310 cm2)

Custom under counter instaflation (dryer only):

I

o

39" min.

< (990 mm}

NOTE: Some models not recommended for undercounter

installation.

Mobile home = Additional installation requirements:

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured

Home Construction and Safety Standard, Title 24 CFR,

Part 3280 (formerly the Federal Standard for Mobile home

construction and Safety, Title 24, HUD Part 280) or Standard

CAN/CSA-Z240 MH.

Mobile home installations require:

All dryers:

[] Metal exhaust system hardware, available for purchase

from your dealer. For further information, see "Assistance

or Service" section in your Use and Care Guide.

[]

Special provisions must be made in mobile homes to

introduce outside air into dryer. Openings (such as a

nearby window) should be at least twice as large as

dryer exhaust opening.

For gas dryers mobile home installations:

[] Mobile Home Installation Hold-down Kit Part Number

346764 is available to order. For further information, see

"Assistance or Service" section in your Use and Care Guide.

ELECTRIC DR R

POWER HOOKUP - ONLY

ELECTRICAL REQUIREMENTS

Electrical Shock Hazard

Plug into a grounded 4 prong outlet.

Failure to do so can result in death or electrical shock,

It is your responsibility:

[] Tocontact a qualified electrical installer.

[]

[]

[]

To be sure that the electrical connection is adequate and in

conformance with Canadian Electrical Code, C22.1 - latest

edition and all local codes. A copy of above codes standard

may be obtained from: Canadian Standards Association,

178 Rexdale Blvd., Toronto, ON M9W 1R3 CANADA.

To supply the required 4-wire, single phase, 120/240 volt,

60 Hz, AC only electrical supply on a separate 30-amp

circuit, fused on both sides of the line. A time-delay fuse or

circuit breaker is recommended. Connect to an individual

branch circuit.

This dryer is equipped with a CSA

International Certified Power Cord

intended to be plugged into a standard

14-30R wall receptacle. The cord is 5 ft.

(1.52 m) long. Be sure wall receptacle is

within reach of dryer's final location.

4-wire receptacle

(14-30R)

If using a replacement power supply cord, it is recommended that

you use Power Supply Cord Replacement Part Number 9831317.

For further information, please reference service numbers located

in "Assistance or Service" section of your Use and Care Guide.

GROUNDING INSTRUCTIONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

GAS DR R POWER HOOKUP

ELECTRICAL REQUIREMENTS

[]

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

120 Volt, 60 Hz, AC only, 15- or 20- amp fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is also recommended that a separate

circuit serving only this dryer be provided.

GROUNDING iNSTRUCTiONS

[] For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or

breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipment-

grounding conductor and a grounding plug. The plug must

be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service representative

or personnel if you are in doubt as to whether the dryer is

properly grounded. Do not modify the plug provided with

the dryer: if it will not fit the outlet, have a proper outlet

installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

GAS SUPPLY REQUIREMENTS

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure

gas pressure does not exceed 13" (330 ram} water

column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion, or fire.

GAS TYPE

Natural Gas:

This dryer is equipped for use with Natural gas. It is

design-certified by CSA International for LP (propane or

butane) gases with appropriate conversion.

[]

Your dryer must have the correct burner for the type of gas

in your home. Burner information is located on the rating

plate in the door well of your dryer. If this information does

not agree with the type of gas available, contact your dealer

or call the phone numbers referenced in the "Assistance or

Service" section of your Use and Care Guide.

LP Gas Conversion:

IMPORTANT: Conversion must be made by a qualified

technician.

No attempt shall be made to convert the dryer from the gas

specified on the model/serial rating plate for use with a different

gas without consulting your gas company.

8

GAS SUPPLY LiNE

[] Must include 1/8" NPT minimum plugged tapping accessible

for test gauge connection, immediately upstream of the gas

connection to the dryer.

E

Ci_'x

B

[]

[]

[]

[]

[]

A. 3/8" flexible gas connector

B. 3/8" pipe to flare adapter fitting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shutoff valve

1/2" IPS pipe is recommended.

3/8" approved aluminum or copper tubing is acceptable for

lengths under 20 ft. (6.1 m) if local codes and gas supplier

permit.

If you are using natural gas, do not use copper tubing.

Lengths over 20 ft. (6.1 m) should use larger tubing and

a different size adapter fitting.

If your dryer has been converted to use LP gas, 3/8" LP

compatible copper tubing can be used. If the total length of

the supply line is more than 20 ft. (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON_'*_ttape.

[] Must include shut-off valve

in the U.S.A.:

An individual manual shut-off valve must be installed within

six (6) ft. (1.8 m) of the dryer in accordance with the National

Fuel Gas Code, ANSi Z223.1. The location should be easy to

reach for opening and closing.

In Canada:

An individual manual shut-off valve must be installed in

accordance with the B149.1, Natural Gas and Propane

installation Code. It is recommended that an individual

manual shut-off valve be installed within six (6) ft. (1.8 m) of

the dryer. The location should be easy to reach for opening

and closing.

GAS SUPPLY CONNECTION REQUIREMENTS

[] Use an elbow and a 3/8" flare x 3/8" NPT adapter fitting

between the flexible gas connector and the dryer gas pipe,

as needed to avoid kinking.

Use only pipe-joint compound. Do not use TEFLON _'*_ttape.

[]

[]

This dryer must be connected to the gas supply line with a

listed flexible gas connector that complies with the standard

for connectors for gas appliances, ANSi Z21.24 or CSA 6.10.

BURNER INPUT REQUIREMENTS

Elevations above 10,000 ft. (3,048 m):

[] When installed above 10,000 ft. (3,048 m) a 4% reduction

of the burner Btu rating shown on the model/serial number

plate is required for each 1,000 ft. (305 m) increase in

elevation.

Gas supply pressure testing

[] The dryer must be disconnected from the gas supply piping

system during pressure testing at pressures greater than

1/2 psi.

DRYER GAS PiPE

[] The gas pipe that comes out through the rear of your dryer

has a 3/8" male pipe thread.

"61/4"

(159 mm)

A

1 1/2"

138 mm)

A. 3/8" NPT dryer pipe

*NOTE: If the dryer is mounted on a pedestal, the gas pipe

height must be an additional 10" (254 ram) or 15.5" (394 mm)

from the floor, depending on the pedestal model. For a garage

installation, the gas pipe height must be an additional 18"

(460 mm) from the floor.

1®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

9

VENTING REQUIREMENTS

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

WARNING; To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT: Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a buildinc Only rigid or flexible metal vent shall be used for

exhaustinc

( (?,

(102ram)

i-

4" (102 ram) heaw metal exhaust vent

[] Only a 4" (102 mm) heavy metal exhaust vent and clamps

may be used.

[] Do not use plastic or metal foil vent.

Rigid metal vent:

[] Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent: (Acceptable only if accessible to clean)

[]

[]

Must be fully extended and supported in final dryer location.

Remove excess to avoid sagging and kinking that may

result in reduced airflow and poor performance.

[] Do not install in enclosed walls, ceilings, or floors.

[] The total length should not exceed 73/4ft. (2.4 m).

NOTE: If using an existing vent system, clean lint from

entire length of the system and make sure exhaust hood

is not plugged with lint. Replace plastic or metal foil vents

with rigid metal or flexible metal vents. Review "Vent System

Charts" and, if necessary, modify existing vent system to

achieve best drying performance.

Exhaust hoods:

[] Must be at least 12" (305 ram) from ground or any object that

may obstruct exhaust (such as flowers, rocks, bushes, or

snow).

Recommended Styles:

Louvered Hood

Acceptable Style:

Box Hood

Angled Hood

Elbows:

[] 45° elbows provide better airflow than 90° elbows.

Recommended Styles:

Clamps:

[]

[]

Be

Use clamps to seal all joints.

Exhaust vent must not be connected or secured with screws

or other fastening devices that extend into interior of duct

and catch lint. Do not use duct tape.

improper venting can cause moisture and lint to collect

indoors, which may result in:

[] Moisture damage to woodwork, furniture, paint, wallpaper,

carpets, etc.

[] Housecleaning problems and health problems.

Vent products can be purchased from your dealer. For more

information, see "Assistance or Service" section in your Use and

Care Guide.

10

PLAN SYSTEM

Recommended exhaust installations

Typical installations vent the dryer from the rear of the dryer.

Other installations are possible.

m

Alternate installations for close clearances

Venting systems come in many varieties. Select the type best

for your installation. Two close-clearance installations are shown.

Refer to the manufacturer's instructions.

Optional exhaust installations:

Fire Hazard

Use a heavy metal vent,

Do not use a plastic vent,

Do not use a metal foil vent.

Failure to follow these instructions can result in death

or fire.

If you prefer, dryer may be converted to exhaust out right side,

left side (all models except WGD9051Y), or through bottom.

You must contact your local dealer to have dryer converted.

Use 4-Way Exhaust Kit Part Number W10470674.

NOTE: On Model WGD9051Y only, do not exhaust out the

left side.

Special provisions for mobile homes:

Exhaust vent must be securely fastened to a noncombustible

portion of mobile home and must not terminate beneath the

mobile home. Terminate exhaust vent outside.

Over-The-Top installation (also available with one offset elbow)

J

Periscope installation

Mobile Home Exhaust installation

11

Determine vent path:

m Select route that will provide straightest and most direct

path outdoors.

m Plan installation to use fewest number of elbows and turns.

m When using elbows or making turns, allow as much room

as possible.

m Bend vent gradually to avoid kinking.

m Use as few 90° turns as possible.

Determine vent length and elbows needed for best

drying performance:

m Use the following "Vent System Charts" to determine type of

vent material and hood combinations acceptable to use.

NOTE: Do not use vent runs longer than those specified

in "Vent System Charts." Exhaust systems longer than those

specified will:

m Shorten life of dryer.

m Reduce performance, resulting in longer drying times

and increased energy usage.

The "Vent System Charts" provide venting requirements that

will help achieve best drying performance.

Standard Vent System Chart

Number of Type Box/Iouvered Angled

90 °elbows of vent hoods hoods

0 Rigid metal 64 ft. (20 m) 58 ft. (17.7 m)

1 Rigid metal 54 ft. (16.5 m) 48 ft. (14.6 m)

2 Rigid metal 44 ft. (13.4m) 38 ft. (11.6m)

3 Rigid metal 35 ft. (10.7 m) 29 ft. (8.8 m)

4 Rigid metal 27 ft. (8.2 m) 21 ft. (6.4 m)

Long Vent System Chart*

Number of

90 °elbows

0

1

2

3

4

Type

of vent

Rigid metal

Rigid metal

Rigid metal

Rigid metal

Rigid metal

*For Model WGD9051Y only.

Box/Iouvered Angled

hoods hoods

130 ft. (39.6 m) 129 ft. (39.3 m)

125 ft. (38.1 m) 119 ft. (36.3 m)

115 ft. (35.1 m) 109 ft. (33.2 m)

106 ft. (32.3 m) 100 ft. (30.5 m)

98 ft. (29.9 m) 92 ft. (28.0 m)

NOTE: Side and bottom exhaust installations have a 90° turn

inside the dryer. To determine maximum exhaust length, add one

90° turn to the chart.

12

INS%ALL ¥_NT SYSTEM

1, Install exhaust hood

12" rain.

(305 ram)

Install exhaust hood and use caulking compound to seal

exterior wall opening around exhaust hood.

2. Connect vent to exhaust hood

Vent must fit over the exhaust hood. Secure vent to exhaust

hood with 4" (102 mm) clamp. Run vent to dryer location

using straightest path possible. Avoid 90° turns. Use clamps

to seal all joints. Do not use duct tape, screws, or other

fastening devices that extend into interior of vent to secure

vent, because they can catch lint.

INSTALL LE¥_LING LEGS

Excessive Weight Hazard

Use two or more people to move and install dryer.

Failure to do so can result in back or other injury.

1. Prepare dryer for leveling legs

To avoid damaging floor, use a large flat piece of cardboard

from dryer carton; place under entire back edge of dryer.

Firmly grasp dryer body (not console panel) and gently lay

dryer down on cardboard.

2, Screw in leveling legs

Examine leveling legs, find diamond marking. Screw legs into

leg holes by hand, use a wrench to finish turning legs until

diamond marking is no longer visible.

Now stand the dryer on its feet. Slide the dryer until it is

close to its final location. Leave enough room for electrical

connection and to connect the exhaust vent.

r NE GAS CONNECTION

1, Connect gas supply to dryer

Flared

male fitting

Non-flared

male fitting

:2, Plan pipe fitting connection

B

A. 3/8" flexible gas connector C. 3/8" to 3/8" pipe elbow

B. 3/8" dryer pipe D. 3/8" pipe-to-flare adapter fitting

A combination of pipe fittings must be used to connect dryer

to existing gas line. A recommended connection is shown.

Your connection may be different, according to supply line

type, size, and location.

3. Open shut=off valve

Closed_

Open valve

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leaks found.

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-flared male fittings. If flexible metal

tubing is used, be sure there are no kinks.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON ®t tape.

CONNECT INLET HOSES

For non-steam models, skip to "Connect Vent" on page 15.

The dryer must be connected to the cold water faucet using the

new inlet hoses. Do not use old hoses.

f] J, Turn cold water off, remove and

replace rubber washer

®

®

®

Turn cold water faucet off and remove washer inlet hose.

Check and see if rubber washer is in the "Y" connector.

Remove old rubber washer from inlet hose and replace with

new rubber washer provided.

1®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

13

If space permits, attach the brass female end of the "Y"

connector to the cold water faucet. See figure A.

If "Y" connector cannot be attached directly to the cold water

faucet, the short hose must be used. See figure B. Attach

short hose to cold water faucet. Screw on coupling by hand

until it is seated on faucet. Then attach "Y" connector to

brass male end of the short hose. Screw on coupling by hand

until it is seated on connector.

One end of the long hose has a wire mesh strainer inside the

coupling. Attach this end to the "Y" connector. Attach washer

cold inlet hose to other side of "Y" connector. Screw on

coupling by hand until it is seated on connector. Using pliers,

tighten the couplings an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can

result.

Using pliers, tighten the couplings with additional

two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can

result.

and tighten coupling

Attach other end of long hose to

fill valve at bottom of dryer back

panel. Screw on coupling by hand

until it is seated on fill valve connector. Using pliers, tighten

the couplings an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the coupling can

result.

14

Check that the water faucets are turned on.

2, Move dryer to final location

Move dryer to final location. Avoid crushing or kinking vent.

After dryer is in place, remove cardboard from under dryer.

Check for leaks around "Y" connector, faucets, and hoses.

CONNECT _NT

, Connect vent to exhaust outlet

LEVEL DR_R

1, Level Dryer

Place

level here

Check levelness of dryer from side to side. Repeat from

front to back.

NOTE: The dryer must be level for the moisture sensing system

to operate correctly.

Not Level LEVEL Not Level

Using a 4" (102 mm) clamp, connect vent to exhaust outlet

in dryer. If connecting to existing vent, make sure vent is

clean. Dryer vent must fit over dryer exhaust outlet and inside

exhaust hood. Check that vent is secured to exhaust hood

with a 4" (102 mm) clamp.

15

If dryer is not level, prop up using a wood block, use wrench

to adjust legs up or down, and check again for levelness. Once

legs are level, make sure all four legs are snug against the floor.

COMPLETE INSTALLATION

[_ Check that all parts are now installed. Ifthere is an extra

part, go back through steps to see what was skipped.

[_ Check that you have all of your tools.

[_ Dispose of/recycle all packaging materials.

[_ Be sure the water faucets are on.

[_ Check for leaks around "Y" connector, faucets, and hoses.

[_ Check dryer's final location. Be sure vent is not crushed

or kinked.

[_ Check that dryer is level. See "Level Dryer."

[_ Remove film on console and any tape remaining on dryer.

[_ Wipe dryer drum interior thoroughly with a damp cloth to

remove any dust.

[_ Read "Dryer Use" in your Use and Care Guide.

[_ If you live in a hard water area, use of a water softener is

recommended to control the buildup of scale through the

water system in the dryer. Over time, the buildup of lime

scale may clog different parts of the water system, which will

reduce product performance. Excessive scale buildup may

lead to the need for certain part replacement or repair.

Electric Models:

[_ Plug into a grounded outlet.

Gas Models:

[_ Check that gas supply is on.

[_ Check for leaks.

All Models:

[_ Select a Timed Dry heated cycle, and start dryer. Do not

select Air Only Temperature setting.

If dryer will not start, check the following:

* Controls are set in a running or "On" position.

* Start button has been pushed firmly.

* Dryer is plugged into an outlet and/or electrical supply is

connected.

* Household fuse is intact and tight, or circuit breaker has

not tripped.

* Dryer door is closed.

This dryer automatically runs an installation diagnostic routine

at the start of its first cycle.

NOTE: You may notice an odor when dryer is first heated. This

odor is common when heating element is first used. The odor will

go away.

DOOR RE TRS,

If you prefer to reverse the door swing on your dryer: A door

reversal kit, Part Number W10277499, is available to order. For

further information, see "Assistance or Service" section in your

Use and Care Guide.

STACKING WASHER DRYER

If you prefer to stack your washer and dryer: A stack kit, Part

Number 8572546 is available to order. For further information,

see "Assistance or Service" section in your Use and Care Guide.

TROUBLESHOOTING

See the Use and Care Guide or visit our website and reference

"Frequently Asked Questions" to possibly avoid the cost of a

service call.

16

SECURIWE DE LA SECHEUSE

Votre s_curit_ et celle des autres est tr_s irnportante.

Nous donnons de nombreux messages de securit6 importants dans ce manuel et sur votre appareil m6nager. Assurez-vous de

toujours lire tousles messages de securit6 et de vous y conformer.

Voici le symbole d'alerte de s6curit&

Ce symbole d'alerte de s6curit6 vous signale les dangers potentiels de d6c_s et de blessures graves & vous

et & d'autres.

Tous les messages de s6curit6 suivront le symbole d'alerte de s6curit6 et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient :

Risque possible de d_c_s ou de blessure grave si vous ne

suivez pas irnm_diatement les instructions,

Risque possible de d_c_s ou de blessure grave si vous

ne suivez pas les instructions.

Tousles messages de securit6 vous diront quel est le danger potentiel et vous disent comment r6duire le risque de blessure et

ce qui peut se produire en cas de non-respect des instructions.

AVERT|SSEMENT d.i°oo°dio..

m

m

m

L'installation de la s_cheuse a linge dolt 6tre effectu_e par un installateur qualifi_.

Installer la s_cheuse conform_ment aux instructions du fabricant et aux codes Iocaux.

Ne pas instaJler de s_cheuse & linge avec des rnat_riaux d'_vacuation en plastique

souple ou un conduit rn_tallique souple (de type papier d'alurniniurn). Si un conduit

rnq#taJlique souple est instaJl_, ceJui-ci doit 6tre d'un type sp_cifique identifi_ par le

fabricant de I'appareil et convenir & une utiJisation avec les s_cheuses & linge. Les

rnat6riaux d'6vacuation soupJes sont connus pour s'affaisser, 6tre facilement _cras_s

et bJoquer la charpie. Ces situations obstrueront le d_bit d'air de la s_cheuse & linge et

augrnenteront le risque d'incendie.

Pour r_duire le risque de blessure grave ou de d_c_s, suivre routes

les instructions d'instailation,

Conserver ces instructions.

17

AVERTISSEIVlENT : Pour votre securite, les renseignements dans ce manuel doivent

_tre observes pour reduire au minimum les risques d'incendie ou d'explosion ou pour

eviter des dommages au produit, des blessures ou un deces.

- Ne pas entreposer ou utiliser de I'essence ou d'autres vapeurs ou liquides

inflammables a proximite de cet appareil ou de tout autre appareil electromenager.

-QUE FAIRE DANS LE CAS D'UNE ODEUR DE GAZ :

= Ne pas tenter d'allumer un appareil.

= Ne pas toucher a un commutateur electrique; ne pas utiliser le telephone se trouvant

sur les lieux.

= I'=vacuer tous les gens de la piece, de I'edifice ou du quartier.

= Appeler immediatement le fournisseur de gaz d'un telephone voisin. Suivre ses

instructions.

= h. defaut de joindre votre fournisseur de gaz, appeler les pompiers.

- L'installation et I'entretien doivent _tre effectues par un installateur qualifie, une

agence de service ou le fournisseur de gaz.

AVERTISSEMENT • L'odorat ne permet pas toujours la detection d'une fuite de gaz.

Les distributeurs de gaz recommandent remploi d'un d6tecteur de gaz (homologation UL ou CSA).

Pour d'autre information, contacter le fournisseur de gaz local.

En cas de detection d'une fuite de gaz, executer les instructions "Que faire dans le cas d'une odeur de gaz".

iMPORTANT : L'installation du gaz doit se conformer aux codes Iocaux, ou en I'absence de codes Iocaux, au code canadien

d'installation B149.1 du gaz naturel ou du propane.

La secheuse doit _tre electriquement reli6e Ala terre conform6ment aux codes Iocaux, ou en I'absence de codes Iocaux, au Code

canadien de 1'61ectricit6, CSA C22.1.

Dans I'Etat du Massachusetts, les instructions d'installation suivantes sont applicables :

[] Les travaux d'installation et reparation doivent 6tre execut6s par un plombier ou tuyauteur qualifie ou licenci6, ou par le

personnel qualifie d'une entreprise licenciee par I'Etat du Massachusetts.

[] Si une vanne & boisseau spherique est utilisee, elle dolt comporter une manette "T".

[] Si un conduit de raccordement flexible est utilis& sa Iongueur ne doit pas d6passer 3 pi.

I

IMPORTANT : En jetant ou en enregistrant votre vieille s6cheuse de v_tements, retirez la porte.

I

18

EXIGENCES D'IN$ LATION

OUTIL_GE ET PIEOES

Rassembler les outils et composants n6cessaires avant

d'entreprendre I'installation.

Outils n_cessaires pour toutes les installations :

@

Outils n6cessaires aux installations au gaz :

CI6 & tuyau de 8" ou 10"

CI6 & molette de 8" ou 10"

(pour le raccordement au gaz)

Tournevis & lame plate

Pince a d6nuder les fils

(pour les installations

raccordement direct)

Tourne-6crou de 1/4"

recommand6)

Tournevis Phillips n° 2

Cisaille de ferblantier

(pour I'installation d'un

nouveau conduit)

dS

Brides de serrage pour

conduit d'6vacuation

Compos6 d'6tanch6it6

des raccords filet6s -

r6sistant au gaz propane

Pi_ces fournies (tous les modules)

Pieds de nivellement (4)

Pi_ces fournies (modUles _ vapeur) :

Metre-ruban

Pince

&

Connecteur en "Y"

Tuyau d'alimentation court

Jr-@ ® @!

Niveau

016 & molette avec

ouverture jusqu'a

1" (25 mm) ou cl6

douille a t_te hexagonale

Pistolet a calfeutrage et

compos6 de calfeutrage

(pour I'installation d'un nouveau

conduit d'6vacuation)

Couteau utilitaire

Tuyau d'alimentation

long

Rondelle de caoutchouc

Le sachet de pieces se trouve dans le tambour de la s6cheuse.

V@ifier que toutes les pieces sont pr6sentes.

REMARQUE : Ne pas utiliser les pieds de nivellement si la

s6cheuse dolt #.tre install6e sur un pi6destal.

i_quiperaent facultatif • (Non fourni avec la s6cheuse)

Se r6f@er au Guide d'utilisation et d'entretien pour des

renseignements sur les accessoires disponibles pour la

s6cheuse.

19

Pi_ces n6cessaires : (Non fourni avec la s6cheuse)

Consulter les codes Iocaux. V6rifier I'alimentation 61ectrique et

le circuit d'6vacuation existants. Voir "Sp6cifications 61ectriques"

et "Exigences concernant 1'6vacuation" avant d'acheter les

pieces.

V6rifier les exigences des codes. Certains codes limitent ou

n'autorisent pas I'installation des s6cheuses dans un garage,

un placard, une maison mobile ou une chambre & coucher.

Contacter I'inspecteur en bfitiment local.

EXIGENCES D'EMPLACEMENT

DIMENSIONS DE LA SECHEUSE

Vue de face

353/8"

(899 mm)

27"

(686 ram)

[]

[]

Risque d'expJosion

Garder les mati_res et les vapeurs inflammables, telle

que I'essence, loin de la s6cheuse.

Placer la s6cheuse au moins 460 mm (18 po) au=dessus

du plancher pour une installation dans un garage.

Le non=respect de ces instructions peut causer

un d6c_s, une explosion ou un incendie.

II vous faudra :

Un emplacement permettant une 6vacuation appropri6e.

Voir "Exigences concernant 1'6vacuation".

[]

[]

[]

[]

Si on utilise un cordon d'alimentation, une prise 61ectrique

avec liaison & la terre situ6e & moins de 2 pi (610 ram) de I'un

des c6t6s de la s6cheuse. Voir "Sp6cifications 61ectriques".

Le plancher dolt supporter le poids de la s6cheuse de

200 Ib (90,7 kg). II faut 6galement prendre en compte le

poids des appareils m6nagers voisins.

Des robinets d'eau froide situ6s & 4 pi (1,2 m) maximum

des valves de remplissage, et une pression d'eau de 20 &

100 Ib/po 2(137,9 & 689,6 kPa). L'alimentation en eau de

la laveuse peut 6tre utilis6e avec le connecteur en "Y" et

le tuyau court (si n6cessaire) fournis.

20 & 100 Ib/po 2(138 & 690 kPa) pour un rendement optimal.

Un plancher de niveau ayant une pente maximale de

1" (25 mm) sous I'ensemble de la s6cheuse. Si la pente

est sup6rieure a 1" (25 mm), installer un ensemble de

pieds d'extension pour s6cheuse, piece n° 279810.

Si la s6cheuse n'est pas d'aplomb, le linge peut ne pas

culbuter convenablement, et les programmes automatiques

command6s par d6tecteur peuvent ne pas fonctionner

correctement.

[]

Pour I'installation dans un garage, placer las6cheuse

au moins 18" (460 mm) au-dessus du sol. En cas

d'utilisation d'un pi6destal, il faudra 18" (460 mm)

jusqu'au fond de la s6cheuse.

Pour chaque am6nagement, pr6voir davantage d'espace pour

faciliter I'installation et I'entretien; des espacements pour les

appareils voisins, les tours, les portes et les plinthes. L'espace

dolt 6tre assez grand pour ouvrir completement la porte. Ajouter

un espacement sur tousles c6t6s de la s6cheuse pour r6duire

le transfert du bruit. Si une porte de placard ou une porte &

claire-vole est install6e, des ouvertures de ventilation en haut

et en bas sont n6cessaires.

20

1"

(25 ram)

Vue lat6rale

Vue porte ouverte "

29"

(738 ram)----------_

Evacuation

la gauche ou

au cTt_ droit

31//2"

(89 ram)

(41 ram)

481/8"

(1238 ram)

471/8"

(1197 ram)

O j

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

Whirlpool WGD9371YW2 Guide d'installation

- Catégorie

- Sèche-linge

- Taper

- Guide d'installation

- Ce manuel convient également à

dans d''autres langues

Documents connexes

-

Whirlpool MGDX600XL0 Guide d'installation

-

Admiral NGD5100TQ2 spécification

-

Maytag YMEDB725BW0 Guide d'installation

-

Maytag YMED8200FW0 Guide d'installation

-

Whirlpool MGD3000BW1 Guide d'installation

-

Whirlpool 3DWGD4815FW0 Guide d'installation

-

Maytag WGD8200YW3 Guide d'installation

-

Maytag MGD7000XW2 Guide d'installation

-

Maytag 4KNED4400BQ1 Guide d'installation

-

Whirlpool WGD9400SZ1 Guide d'installation