Digital Monitoring Products 1183-135F Wireless Heat Detector Guide d'installation

- Catégorie

- Protection contre le feu

- Taper

- Guide d'installation

Ce manuel convient également à

1183 SERIES WIRELESS HEAT DETECTOR

Installation Guide

DESCRIPTION

The 1183 Series is available in two

models: 1183-135F and 1183-135R.

The 1183-135F is a fixed temperature

detector that reacts to heat by

responding to the fixed 135°

temperature setting. When

activated, an alarm is sent to

the control panel. The 1183-135F

model has a black dot on the heat

collector fin for identification.

The 1183-135R model is a

combination rate-of-rise and fixed

temperature detector that detects

heat quickly by responding to a

rapid temperature increase or a

fixed 135 ° temperature setting.

The element responds to a rapid

rise in temperature and sends an

alarm to the control panel when the

ceiling temperature increases at a

minimum rate of 15 ° F per minute.

An alarm is also sent to the panel if

the ceiling temperature reaches the

fixed 135 ° setting if the rate-of-rise

is not exceeded.

Compatibility

• All DMP 1100 Series Wireless

Receivers and Panels

What is Included?

• One 1183-135F or one 1183-135R

Heat Detector with DMP wireless

transmitter installed

• One 3V lithium CR123A battery

• Hardware pack

1PROGRAM THE TRANSMITTER

IN THE PANEL

1. Locate and record the detector serial number. This number

is required during programming.

2. Enter 6653 (PROG) at the keypad to enter the

PROGRAMMER menu.

3. Press CMD until ZONE INFORMATION displays. Press a

select key or area to enter the menu.

4. At ZONE NO:, enter the zone number.

5. At ZONE NAME, enter the zone name.

6. At ZONE TYPE, select FI (fire).

7. At NEXT ZONE?, select NO.

8. At SERIAL NUMBER, enter the eight-digit SERIAL NO found

on the device and press CMD.

9. At SUPVSN TIME, enter 3 and press CMD.

10. At BELL OPTIONS, press CMD until BELL OPTIONS displays,

and then press a select key or area.

11. At FIRE BELL ACTION FIRE TYPE:, select T (temporal) as

the action type.

12. Continue to program the zone as directed in the panel

programming guide.

Note: When a receiver is installed, powered up, or the panel is

reset, the supervision time for transmitters is reset. If the

receiver has been powered down for more than one hour,

wireless transmitters may take up to an additional hour to send

a supervision message unless tripped, tampered, or powered

up. This operation extends battery life for transmitters. A

missing message may display on the keypad until the

transmitter sends a supervision message.

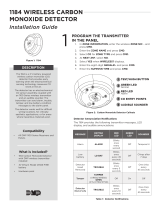

Transmitted Signal Outputs

The heat detector provides the signals listed in the table:

Signal Keypad Display

Alarm ALARM

Low battery LO BAT

Detector head removed TROUBLE

Figure 1: 1183 Series Wireless

Heat Detector

WARNING: 1183 Series Heat Detectors are single use

detectors. Do not test them with a heat source.

2 1183 INSTALLATION GUIDE | DIGITAL MONITORING PRODUCTS

3Install the transmitter away from large metal objects because metal

surfaces impairs performance. The 1183 Series transmitters allow one

person to confirm communication with the receiver while the cover is

removed

The 1183 Series Wireless Heat Detector provides a Survey LED

capability to allow one person to confirm communication with

the wireless receiver or panel while the cover is removed.

1. With the battery cover removed, hold the transmitter in

the exact desired location.

2. Press the survey button to send data to the panel and

determine if communication is confirmed or faulty.

Confirmed: If communication is confirmed, for each

press or release of the tamper switch, the LED blinks

immediately on and immediately o. Repeat this test

to confirm five separate consecutive LED blinks. Any

indication otherwise means proper communication

has not been established.

Faulty: If communication is faulty, the LED remains on for

about 8 seconds or flashes multiple times in quick

succession. Relocate the detector or receiver until the LED

confirms clear communication.

SELECT A LOCATION

Battery Compartment

Battery Cover

Battery

Figure 2: Battery Compartment

INSTALL THE BATTERY

2Observe polarity when installing the battery. Use only 3.0V lithium batteries, DMP Model CR123-FIRE or

Panasonic Model CR123A.

Note: When setting up a wireless system, it is recommended to program zones and connect the receiver

before installing batteries in the transmitters.

1. Slide the battery compartment cover away from the detector to unsnap it and lift it o. See Figure 2.

2. If replacing the battery, remove the old battery and dispose of them properly.

3. Observing correct polarity, insert the new 3V lithium battery into the battery compartment and replace

the cover. Use only new batteries when replacing old ones.

4. Reattach the detector to the mounting base. See Attaching and Removing the Detector.

5. Test the detector. See Test the Detector Alarm.

Caution: Properly dispose of used batteries. Do not recharge, disassemble, heat above 212 ° F (100°C),

or incinerate. Risk of fire, explosion, and burns.

Survey Button

Survey LED

SURVEY

Figure 3: Survey Button

1183 INSTALLATION GUIDE | DIGITAL MONITORING PRODUCTS 3

MOUNT THE DETECTOR

When setting up a wireless system, it is recommended to

program zones and connect the wireless receiver before

installing batteries in the transmitters.

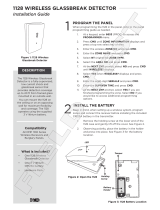

Install the Mounting Base

Using the two screws provided, mount the base in the

location previously surveyed for proper communication.

Attach the Detector

1. Using the alignment notch on the lip of the

mounting base as a guide, align the detector with

the alignment tabs.

2. Insert the detector into the mounting base and

turn clockwise approximately 15 degrees. It should

snap firmly into place.

Note: To remove the detector from the mounting

base, grasp the detector and turn it

counterclockwise approximately 15 degrees. The

detector should snap o of the mounting base.

See Figure 4.

4

5TEST THE DETECTOR ALARM

1. To test the detector alarm, enable Walk Test operation on the control panel. If the system is monitored,

the system sends a System Test Begin report (System message S66) to the central station.

To conduct the Walk Test, reset the control panel. From the keypad, enter the code 8144. The keypad

displays WALK TEST. Refer to the panel programming guide for complete information on Walk Test

operation.

2. For the XTL Series panels or XT30/XT50 Series panels, select STD (Standard Walk Test). For the

XR150/XR550 Series panels, select FI (Fire zones). A sensor reset occurs after each detector tested.

3. Remove the heat detector from the mounting base. See Attaching and Removing the Detector.

Carefully short the two terminals (screw heads) momentarily to send an alarm signal to the control

panel. Verify that the walk test trip counter increments to indicate a successful test. Once testing is

completed, install the detector back onto the mounting base. Shorting the terminals does not aect

the standard operation of the detector.

4. Select END to stop the Walk Test. When the Walk Test ends or a 20-minute time-out expires, a final

Sensor Reset occurs. The System Test End message (System message S67) is sent to the central

station along with verify and fail messages for each zone under test. Faulted zones then display on the

keypad.

Note: The control panel alarm and all auxiliary functions should be verified for a complete test of the

system. See the panel programming guide for additional information.

Alignment

Tabs

Alignment

Tabs

Mounting Holes

Alignment

Notch

Figure 4: Mounting Base

General Location Guidelines

In addition to NFPA 72, use the following location guidelines to optimize performance and reduce the chance

of false alarms from the detector:

• Locate ceiling-mounted detectors in the center of a room or hallway at least 4 inches from any walls or

partitions

• Locate wall-mounted heat detectors so the top of the detector is 4 to 12 inches below the ceiling

• Mount the detector on a firm permanent surface

• Locate the detector in environmentally controlled areas where the temperature does not exceed 100

°

F

(37.8 ° C).

• In rooms with sloped, peaked, or gabled ceilings, locate detectors 3 feet (.9 meters) down or away from

the highest point of the ceiling

• When mounting to suspended ceiling tile, the tile must be secured with the appropriate fastener to

prevent tile removal

WARNING: 1183 Series Heat Detectors are single use detectors. Do not test them with a heat source.

Designed, engineered, and

manufactured in Springfield, MO

using U.S. and global components.

LT-1186 1.02 20461

1183 SERIES WIRELESS

HEAT DETECTOR

Specifications

Frequency Range 905 - 924 MHz

Battery Life 2 years

Dimensions 5.8” x 2.2”

(14.3 cm x 6.1 cm)

Heat Alarm Specifications:

Rate-of-Rise 15 ° F/min > 105 ° F

(8.3 ° C/min > 40.6 ° C)

Fixed 135 ° F ± 5 ° F

(57.2 ° C ± 2.8 ° C)

Patents

U.S. Patent No. 7,239,236

Certifications

California State Fire Marshal (CSFM)

FCC Part 15 Registration ID: CCKPC0134

New York City Fire Department (#6167)

Industry Canada Registration ID: 5251A-PC0134

Underwriters Laboratory (UL) Listed

ANSI/UL 521 Heat Detectors for Fire Protective Signaling Systems

INTRUSION • FIRE • ACCESS • NETWORKS

2500 North Partnership Boulevard

Springfield, Missouri 65803-8877

800.641.4282 | DMP.com

FCC INFORMATION

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1. This device may not cause harmful interference, and

2. this device must accept any interference received, including

interference that may cause undesired operation.

The antenna used for this transmitter must be installed to provide a separation distance of at least 20 cm (7.874 in.) from all persons. It

must not be located or operated in conjunction with any other antenna or transmitter.

Changes or modifications made by the user and not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment o and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

4. Consult the dealer or an experienced radio/TV technician for help.

INDUSTRY CANADA INFORMATION

This device complies with Industry Canada Licence-exempt RSS standards. Operation is subject to the following two conditions:

1. This device may not cause interference, and

2. this device must accept any interference, including interference that may cause undesired operation of the device.

This system has been evaluated for RF Exposure per RSS-102 and is in compliance with the limits specified by Health Canada Safety

Code 6. The system must be installed at a minimum separation distance from the antenna to a general bystander of 7.87 inches (20 cm)

to maintain compliance with the General Population limits.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes:

1. l’appareil ne doit pas produire de brouillage, et

2. l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en

compromettre le fonctionnement.

L’exposition aux radiofréquences de ce système a été évaluée selon la norme RSS-102 et est jugée conforme aux limites établies par le

Code de sécurité 6 de Santé Canada. Le système doit être installé à une distance minimale de 7.87 pouces (20 cm) séparant l’antenne

d’une personne présente en conformité avec les limites permises d’exposition du grand public.

ADDITIONAL INFORMATION

Heat Collector Fin

The 1183 Series heat detectors use a heat collector fin (See Figure 5) to

detect temperature changes. The fin is spring loaded and sensitive to

handling. Do not set the detector on the collector fin or put pressure on the

fin while handling as this could cause damage to the internal operation.

Mounting Base

Alignment Notch

Tamper Post

Detector Cover

Battery Compartment

Heat Collector Fin

Figure 5: Heat Detector Exploded View

-

1

1

-

2

2

-

3

3

-

4

4

Digital Monitoring Products 1183-135F Wireless Heat Detector Guide d'installation

- Catégorie

- Protection contre le feu

- Taper

- Guide d'installation

- Ce manuel convient également à

dans d''autres langues

Documents connexes

Autres documents

-

DMP Electronics 1183 Series Guide d'installation

DMP Electronics 1183 Series Guide d'installation

-

DMP Electronics 1100DH Series Guide d'installation

DMP Electronics 1100DH Series Guide d'installation

-

DMP Electronics 1100d Guide d'installation

DMP Electronics 1100d Guide d'installation

-

DMP Electronics 1100DI Guide d'installation

DMP Electronics 1100DI Guide d'installation

-

AJAX 9NA MotionProtect Plus Pet Immune Motion Detector Mode d'emploi

-

DMP 1184 Guide d'installation

DMP 1184 Guide d'installation

-

DMP Electronics 1128 Guide d'installation

DMP Electronics 1128 Guide d'installation

-

Apollo 51000-305 Guide d'installation

-

QOLSYS QS5210-840 Guide d'installation