— WHATTODOIFYOUSMELLGAS

• OpenWindows

• DO NOTtrytolightanyappliance.

• DO NOTuseelectricalswitches.

• DO NOTuseanytelephoneinyourhouse.Immediatelycallyourlocalgassupplierfromaneighbor’stelephone.

Followthegassupplier’sinstructions.

• Do nottouchanyelectricalswitch;donotuseanyphoneinyourbuilding.

• Installationandservicemustbeperformedbyaqualifiedinstaller,serviceagencyorthegassupplier.

• Ifyoucannotreachyourgassupplier,calltheFireDepartment.

FOR YOUR SAFETY:

Donotstoreorusegasolineorotherflammablevaporsandliquidsinthevicinityofthisoranyotherappliance.

WARNING: Iftheinformationintheseinstructionsarenotfollowedexactly,afireorexplosionmayresultcausing

propertydamage,personalinjuryorlossoflife.

18677XL2017CB

ENERCOGroup,Inc.,4560W.160THST.,CLEVELAND,OHIO44135•866-447-2194

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury, or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions.

Place instructions in a safe place for future reference. Do not allow anyone who

has not read these instructions to assemble, light, adjust or operate the heater.

Model#

XL

ER

LANGUAGES INCLUDED

•ENGLISH

•FRENCH

•SPANISH

Heatstar ERXL

Gas-Fired Low-Intensity Infrared Heaters Approved For

Residential Garage/Commercial Applications

ERXL-40ERXL-60

ERXL-80ERXL-100

ERXL-125ERXL-150

ERXL-175

2

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

SECTION 1:Introduction

HeatstarERXLmodelsarelow-cost,fieldassembledinfrared

heatersthatareeasytoinstallandrequireonlyminimal

maintenance.Theyaredesignedtoprovideyearsofeconomical

operationandtrouble-freeservice.

Checking Shipment

ChecktheshipmentagainsttheBillofLadingforshortages.

Also,checkforexternaldamagetocartons.Noteany

shortages,and/orexternaldamagetocartonsontheBillof

Ladinginthepresenceofthedeliverytrucker.Thedelivery

truckershouldacknowledgeanyshortagesordamageby

initializingthis“noted”BillofLading.Immediatelyreport

anyclaimsfordamagedmaterial,orshortagesthatwerenot

evidentatthetimeofshipment,tothecarrierandyourEnerco

Group,IncFactoryRepresentative.

Installer Responsibility

Allheatersandassociatedgaspipingshouldbeinstalledin

accordancewithapplicablespecificationsandthisinstallation

madeonlybyfirms(orindividuals)wellqualifiedinthistypeof

work.Consultlocalbuildinginspectors,FireMarshalsoryour

localEnercoGroup,IncFactoryRepresentativeforguidance.

HeatstarERXLheatersareinstalledonthebasisofinformation

giveninalayoutdrawing,whichtogetherwiththecitedcodes

andregulations,comprisethebasicinformationneededto

completetheinstallation.Theinstallermustfurnishallneeded

materialthatisnotfurnishedasstandardequipment,andit

ishisresponsibilitytoseethatsuchmaterials,aswellasthe

installationmethodsheusesresultinajobthatisworkmanlike

andincompliancewithallapplicablecodes.

EnercoGroup,IncFactoryRepresentativeshavehadtraining

andexperienceintheapplicationofthisequipmentandcan

becalledonforsuggestionsaboutinstallationwhichcansave

materialandmoney.

WARNING:

FIRE,BURN,INHALATION,ANDEXPLOSIONHAZARD.KEEP

SOLIDCOMBUSTIBLES,SUCHASBUILDINGMATERIALS,

PAPERORCARDBOARD,ASAFEDISTANCEAWAYFROM

THEHEATERASRECOMMENDEDBYTHEINSTRUCTIONS

NEVERUSETHEHEATERINSPACESWHICHDOORMAY

CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES,

ORPRODUCTSSUCHASGASOLINE,SOLVENTS,PAINT

THINNER,DUSTPARTICLESORUNKNOWNCHEMICALS.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF

FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON

MONOXIDEPOISONING,AND/ORELECTRICALSHOCK.

ONLYPERSONSWHOCANUNDERSTANDANDFOLLOW

THEINSTRUCTIONSSHOULDUSEORSERVICETHIS

HEATER.

IFYOUNEEDASSISTANCEORHEATERINFORMATION

SUCHASANINSTRUCTIONSMANUAL,LABELS,ETC.

CONTACTTHEMANUFACTURER.

WARNING:

YOURSAFETYISIMPORTANTTOYOUANDTOOTHERS,

SOPLEASEREADTHESEINSTRUCTIONSBEFOREYOU

OPERATETHISHEATER.

CONTENTS

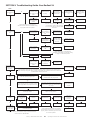

Section1INTRODUCTION.........................................................2

Section2PLANNING.................................................................3

Section3INSTALLATION&ASSEMBLY.......................................6

Section4EngineeringSpecifications.......................................13

Section5VENTING/DUCTING…………………………………………14

Section6GASPIPING..............................................................17

Section7WIRING....................................................................18

Section8OPERATIONMAINTENANCE.....................................19

Section8TROUBLESHOOTING.................................................21

Section9REPLACEMENTPARTS..............................................22

WARRANTYINFORMATION.....................................................28

WARNING:

The State of California requires the following warning:

COMBUSTIONBY-PRODUCTSPRODUCEDWHENUSING

THISPRODUCTCONTAINCARBONMONOXIDE,A

CHEMICALKNOWNTOTHESTATEOFCALIFORNIA

TOCAUSECANCERANDBIRTHDEFECTS(OROTHER

REPRODUCTIVEHARM).

3Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

SECTION 2: Planning

Thefollowingcodesandinstructionsshouldbefollowed

whenplanningtheinstallationoftheHeatstarERXLheater.In

additiontotheseinstructions,thewarningsin(Section1)must

becarefullyadheredtosinceimproperinstallationmayleadto

propertydamage,injury,ordeath.

National Standards and Applicable

Codes

Gas Codes:

Thetypeofgasappearingonthenameplatemustbe

thetypeofgasused.Installationmustcomplywithlocal

codesandrecommendationsofthelocalgascompany,

andtheNationalFuelGasCode,ANSIZ223.1–latest

revision,(sameasNFPABulletin54)ortheNaturalGas

andPropaneInstallationCode,CSAB149.1.

•Clearancebetweentheheateranditsventandadjacent

combustiblematerial(whichispartofthebuilding

oritscontents)shallbemaintainedtoconformwith

theStandardforInstallationofGasAppliancesand

GasPiping,NFPA-54/ANSIZ223.1–latestrevision,

NationalFuelGasCodeortheNaturalGasandPropane

InstallationCode,CSAB149.1.

Aircraft Hangers:

Installationinaircrafthangersmustbeinaccordance

withtheStandardforAircraftHangers,ANSI/NFPA-409

–latestrevision.

• Heatersinaircraftstorageorserviceareasshallbe

installedataheightof10feetabovetheuppersurface

ofwingsorengineenclosuresofthehighestaircraft

whichmaybehousedinthehanger.(Thisshouldbe

measuredfromthebottomoftheheatertothewingor

engineenclosure,whicheverishighestfromthefloor.)

• Inothersectionsofaircrafthangers,suchasshopsor

offices,heatersmustnotbeinstalledlessthan8feet

abovethefloor.

• Heatersinstalledinaircrafthangersshallbelocated

soasnottobesubjecttodamagebyaircraft,cranes,

moveablescaffoldingorotherobjects.

Public Garages:

Installationsingaragesmustbemadeinaccordance

withtheStandardforParkingStructures,NFPA-88A–

latestrevisionortheStandardforRepairGarages,NFPA-

88B–latestrevision.

• Heatersmustnotbeinstalledlessthan8feetabove

thefloor.Minimumclearancestocombustiblesmustbe

maintainedfromvehiclesparkedbelowtheheater.

• Wheninstalledoverhoists,minimumclearancesto

combustiblesmustbemaintainedfromtheuppermost

pointonthehoist.

Venting:

TheventingmustbeinstalledinaccordancewithNFPA-

54/ANSIZ223.1orCSA149.1–latestrevision,National

FuelGasCode.Partialinformationwithregardtothis

codeisprovidedin(Section5)ofthisinstallationmanual

withregardtosizeandconfigurationsforventing

arrangements.

• Anyportionoffluepipepassingthroughacombustible

wallmustbedualinsulatedorhaveanapprovedthimble.

RefertoANSI-Z223.1orCSA149.1–latestrevision.

Hazardous Locations:

Wherethereisthepossibilityofexposuretocombustible

airbornematerialorvapor,consultthelocalFireMarshal,

thefireinsurancecarrierorotherauthoritiesforapproval

oftheproposedinstallation.

Critical Considerations

HeatstarERXLisasuspendedheater.Therefore,its

stability,flexibility,andsafetyareveryimportant.Before

startinginstallation,besurethesystemcanmeetthe

followingrequirements.

• Maintainspecifiedclearancestocombustibles,andsafe

distancefromtheheat-sensitivematerial,equipmentand

workstations.

• Thestatedclearancestocombustiblesrepresent

asurfacetemperatureof90°F(30°C)aboveroom

temperature.Buildingmaterialswithlowheattolerance

(suchasplastic,vinylsiding,canvas,etc.)maybesubject

todegradationatlowertemperatures.Itistheinstallers

responsibilitytoassurethatadjacentmaterialsare

protectedfromdegradation.

• Provideasuspensionwithverticallengthofchainor

swingingrodwhichhasatleast2inchesofhorizontal

travelforeachburnerinastraightrun.Besurethe

suspensionsystemissufficientlyflexibletoaccommodate

thermalexpansionwhichoccursasthesystemheatsup

(seeFigure6onpage12).

• Provideaccesstoburnersforservicing,preferableon

bothsides,aboveandbehindtheburnerforremoval.

• Provideaminimumof18inchesofclearancebetween

burnersandbuildingwalls.(Alwaysobserveminimum

clearancestocombustibles.)

• Besuretheheaterhasadownwardpitchofone-half

inchper20feetawayfromtheburner.

• Providesignsinstorageareastospecifymaximum

stackingheighttomaintainrequiredclearancesto

combustibles.

• Planlocationsupports(seeFigure2A-Fstartingonpage

8).Locateasupportnearallelbows.

• Theinstallationmustconformwithlocalbuildingcodes

orintheabsenceoflocalcodes,withtheNationalFuel

GasCode,ANSIZ223.1/NFPA54ortheNaturalGas

andPropaneInstallationCode,CSAB149.1.

• Ifanexternalelectricalsourceisutilized,theheater,

wheninstalled,mustbeelectricallygroundedin

accordancewiththeNationalElecticalCode,ANSI/

NFPA70orcurrentCanadianElectricalCode,CSA

C22.1.

4

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

Clearances To Combustibles

TABLE 1:MinimumClearancestoCombustibles(UseFigure1onpage5asaGuide)

Reflector Type Position ERXL-40 ERXL-60 ERXL-80 ERXL-100 ERXL-125 ERXL-150 ERXL-175

Standard

Reflector

(Horizontal)

A

B

C

D

6”

30”

55”

30”

6”

30”

55”

30”

6”

36”

55”

36”

6”

36”

74”

36”

6”

36”

87”

36”

6”

36”

87”

36”

8”

36”

87”

36”

45°ReflectorTilt

A

B

C

E

F

12 ”

30”

55”

36”

60”

12 ”

30”

55”

36”

60”

18”

36”

55”

36”

60”

18”

36”

74”

36”

60”

18”

36”

87”

36”

60”

18”

36”

87”

36”

60”

18”

36”

87”

36”

60”

U-TubeStandard

(Horizontal)

A

B

C

D

6”

30”

55”

30”

6”

30”

55”

30”

6”

36”

55”

36”

6”

36”

74”

36”

6”

36”

87”

36”

6”

36”

87”

36”

8”

36”

87”

36”

U-TubeOpposite

45°

A

B

C

F

12 ”

30”

55”

60”

12 ”

30”

55”

60”

18”

36”

55”

60”

18”

36”

74”

60”

18”

36”

87”

60”

18”

36”

87”

60”

18”

36”

87”

60”

U-TubeFull45°

A

B

C

E

F

12 ”

30”

55”

36”

60”

12 ”

30”

55”

36”

60”

18”

36”

55”

36”

60”

18”

36”

74”

36”

60”

18”

36”

87”

36”

60”

18”

36”

87”

36”

60”

18”

36”

87”

36”

60”

Unvented AboveA 36” 36” 36” 36” 36” 36” 36”

WARNING:

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE INJURY OR DEATH.

Inallsituations,clearancestocombustiblesmustbemaintained.Failuretoobserveclearancestocombustiblesmayresultinproperty

damage,severeinjury,ordeath.

Minimumclearancesmustbemaintainedfromvehiclesparkedbelowtheheater.Signsshouldbepostedinstorageareastospecify

maximumstackingheighttomaintainrequiredclearancestocombustibles.

Cautionshouldbeusedwhenrunningthesystemnearcombustiblematerialssuchaswood,paper,rubber,etc.Considerationshouldbe

giventopartitions,storageracks,hoists,buildingconstruction,etc.

TABLE1givesminimumacceptableclearancestocombustibles.ClearancesasshowninTABLE1arenotforuseinfour-sidedenclosures.

5Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

D

A

C

STANDARD REFLECTOR

A

E

C

E

45 DEGREE REFLECTOR TILT

C

A

EF

U-TUBE OPPOSITE 45 DEGREE

A

CD

U-TUBE STANDARD

C

E

A

E

U-TUBE FULL 45

BE

FRONT AND BACK CLEARANCE

Clearances To Combustibles

Figure 1: ClearancesToCombustibles(RefertoTABLE1onpage4)

A

C

EF

STANDARD REFLECTOR

D

A

C

A

C

D

“U”-Tube,Standard

A

C

D

F

“U”-Tube,Opposite45°

F

C C

AA

E

A

F

“U”-Tube,Full45°

C

AC

B

B

FrontandBackClearance

6

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

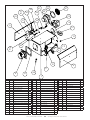

SECTION 3: Installation & Assembly

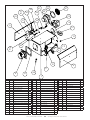

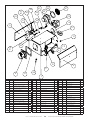

TUBECOUPLING(14612)

KEYFORTUBECOUPLING

(14616)

TUBEHANGER

(14585P)

HEATEXCHANGERTUBE10'

(06413)

TURBULATORBAFFLE10'(03445)

TURBULATORBAFFLE5'(03447)

**NOTINCLUDEDWITHALLMODELS**

**ONLYHEATERS30'LENGTHANDUNDER**

REFLECTOR10'

(00418A)

VENTADAPTER

(19021)

BURNERBOX

7Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Installation Procedure

Takemaximumadvantageofthebuildingupper

structure,beams,joists,purlins,etc.,fromwhichto

suspendtheheater.Thereisnouniquesequencefor

installationofthetubing.On-siteobservationwillusually

revealalogicalsequence.Begintheinstallationatthe

mostcriticaldimension.Thiscouldsavetime.Watchfor

swingingdoors,overheadcranes,carliftsetc.Reflectors

andtubingcanbeinstalledasyoumovealong.Carefully

adjustsystempitchateachpositiontoleveltheheater.

Pitchdownone-halfinchin20feet(awayfromburner).

DON’TPressuretestthegaslineusinghighpressure(greater

than½PSIG)withoutclosingthehigh-pressureshutoff

cocks.Failuretodosowillresultindamagetothe

burners.

DO Familiarizeyourselfwithlocalandnational

codes.

Burner Housing

Mustalwaysbe

installedhorizontally.

Tube and Reflector Hanger

Installimmediatelyafterfirst

coupling.

Turbulator Assembly

EnercoGroup,IncnormallyshipsEner-Radiantheaters

withturbulatorsassembledintoappropriatetubes.

Tube and Reflector Hanger

Suspendsystemfromthesehangers.

Minimumtwo(2)requiredpertube.

Reflectors

Alternateoverlapasshown

onoverview.Lengthof

reflectorandamountof

overlapisindicated.

10'2-1/2" ALUMINIZED

Heat Exchange Tubes

Suppliedin10ft.lengths.

Tube Coupling Assembly

Couplingshouldbeorientedwith

slidebarontop,andallcouplings

should“point”inthesamedirection.

Where Field Changes Occur

TurbulatorSectionsandAdapterareavailablein

sectionsandmustbeassembledbeforeinstallation

(SeeFigure3fordetails).Thenumberofsections

requiredisindicated.

AssembletheheatercomponentsasshowninFigures2A,2B,2C,2D,2E,2Fand2G.Optionalreflectorconfigurationsareshownin(Figure

1).Installappropriatedsuspensionhardware,beamclamps,chainorrodatpredeterminedlocations.Adjustmentofchainlengthwillprovide

uniformpitch.

Developaplannedprocedurewhichwillconservematerial

andlaboronthejob.

Checktoseethatallmaterialandequipmentisonthejob

beforestartinginstallation.

Allowforthermalexpansionofthehottube.

Installthegasconnectoronlyasshownininstructions(see

Figure14onpage17).

Haveslipjointswhererequiredbetweenreflectorstokeep

themfrombucklingorcomingapart.

Provide1sq.inchoffreeairopeningtoeach1,000BTU/hr.

ofheaterinput(butnotlessthan100sq.inches)inenclosed

spaces.Oneopeningshouldbewithin12inchesofthetop

andonewithin12inchesofthebottomoftheenclosure.

FIGURE 2: Ener-Radiant XL Overview

Vent Adapter

Usedtoattachtheheat

exchangertubingtoventpipe.

8

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

HANGER HANGER

18” 18”

10’ 2-1/2” ALUMINIZED

ALUMINIZED

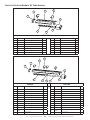

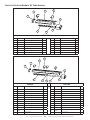

FIGURE 2B: Ener-Radiant XL Model ERXL-60, ERXL-80, Assembly Overview

20 ft. Exchanger length. 21 ft. - 4 in. Total Heater length. 4 Suspensin points indicated.

FIGURE 2A: Ener-Radiant XL Model ERXL-40

10 ft. Exchanger length. 11 ft. - 4 in. Total Heater length. 2 Suspension points as indicated.

HANGER HANGER HANGER HANGER

18” 18” 18” 18”

10’ 2-1/2” 10’ 2-1/2”

ALUMINIZED

2-1/2” OVERLAY TYP

(1) Turbulator Sections

ALUMINIZED

FIGURE 2D: Ener-Radiant XL Model ERXL-100 Assembly Overview

30 ft. Exchanger length. 31 ft. - 4 in. Total Heater length. 6 Suspension points as indicated.

FIGURE 2C: Ener-Radiant XL Model ERXL-80, Assembly Overview

30 ft. Exchanger length. 31 ft. - 4 in. Total Heater length. 6 Suspension points as indicated

18” 18” 18” 18” 18” 18”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

(1) Turbulator Sections

HANGER HANGER HANGER

Typ.

HANGER

ALUMINIZED ALUMINIZED

9' Long Turbulator Section

10' Long Turbulator Section

5' Long Turbulator Section

10' Long Turbulator Section

9Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

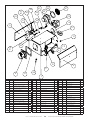

FIGURE 2E: Ener-Radiant XL Model ERXL-100, ERXL-125

40 ft. Exchanger length. 41 ft. - 4 in. Total Heater length. 8 Suspension points as indicated.

FIGURE 2F: Ener-Radiant XL Model ERXL-125, ERXL-150, ERXL-175

50 ft. Exchanger length. 51 ft. - 4 in. Total Heater length. 10 Suspension points as indicated.

FIGURE 2G: Ener-Radiant XL Model ERXL-150, ERXL-175

60 ft. Exchanger length. 61 ft. - 4 in. Total Heater length. 12 Suspension points as indicated.

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

10’ 2-1/2”

10’ 2-1/2”

18”

Typ.

ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED

18” 18” 18” 18” 18” 18” 18” 18” 18”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

18”

Typ.

ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZEDALUMINIZED

18” 18” 18” 18” 18” 18” 18” 18” 18” 18” 18”

ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED

18”

Typ.

18” 18” 18”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

18" 18" 18" 18" 18" 18" 18"

10

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

FIGURE 3: Ener-Radiant XL Dimensions & Suggested Mounting Heights

(someModels)

Turbulator

HeatExchanger Tubing (someModels)

Turbulator

HeatExchanger Tubing

MinimumTotalLength(seechartbelow)

Burner Side View

Burner Ratings and Heat Exchanger Lengths: (NG and LP) Suggested Mounting Heights

Model # Rate (BTU/Hr.) Heat Exchanger

Length Turbulator Minimum

Total Length

Suggested

Min. Space

Typical

Mounting

Height Spot

ERXL-40 40,000 10ft. 9ft. 10'-4' 8'-10' 10’-14'

ERXL-60 60,000 20ft. 10ft. 21'-4' 10’-12’ 10’-14’

ERXL-80 80,000 20ft. 10ft. 21'-4' 12’-15’ 12’-15’

ERXL-80 80,000 30ft. 10ft. 31'-4' 12’-15’ 12’-15’

ERXL-100 100,000 30ft. 5ft. 31'-4' 12’-15’ 12’-15’

ERXL-100 100,000 40ft. None 41'-4' 15’-18’ 12"-15'

ERXL-125 125,000 40ft. None 41'-4' 15’-20’ 14’-19'

ERXL-125 125,000 50ft. None 51'-4' 15’-18’ 14’-19'

ERXL-150 150,000 50ft. None 51'-4' 20’-23’ 15’-25'

ERXL-150 150,000 60ft. None 61'-4' 20’-25’ 15’-25'

ERXL-175 175,000 50ft. None 51'-4' 20’-23’ 15’-25'

ERXL-175 175,000 60ft. None 61'-4' 20’-25’ 15’-25'

Burner Rear View

9.25"(23.49cm)

9.25"(23.49cm)

17.75"(45.08)

11 Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Couplings: Tubeandtubefittingsareconnectedbywrap-

aroundcouplingswhichclampbymeansof

atapered,hammer-drivenlockmember.The

startingendsofthecouplingandlockmember

areidentifiedby1/4”holeswhichareput

togetherwhenstartingassembly.Besurethe

tubeendsareinlineandtubeendsbuttagainst

stoppin(s)insidecoupling.Theslidebaristobe

hammer-driventoapointofsecuringthecoupling

snuglytothetubes.Over-drivingwillresultin

distortionofthecouplingorslidebarliptoa

pointdecreasingtheholdingthecapabilityofthe

coupling.(SeeFigure4)

ElbowFittingDimensions

FIGURE 5: Installation of Elbow & Coupling

ElbowPackage: Stk.#F106415ElbowPackageincludes:

(1)elbow,(1)coupling.Installelbow

intoradianttubesequencewhereplans

indicatea90°bend(seeFigure4).

U-TubeFittingDimensions 180°U-Tube

Stk.#i ncludes:F106414U-TubePackage

radianttubesequencewhereplans

indicatea180°bend

(seeFigure4).

COUPLING ASSEMBLY

Plain Coupling - 14612

Key for Coupling - 14616

Tighten

Loosen

Hole 1

Coupling

Assembly

Impact

Block

Hole 2

Whenassemblingcouplingnote

thelocationofHole1andHole2

Orientcouplingsothat

theimpactblockisabove

tubecenterline.

TUBECOUPLING

KEYforCOUPLING

FIGURE 4:

(38.73 CM)

(15.24 CM)

18" (45cm)

10"

(25cm)

(10cm)

(43cm)

9" (22cm) Radius

90°

(1) U-tube, (1) coupling

Install U-tube elbow into

12

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

A

Chainkit-Stk.#17370

Onechainkitwillsuspendone10ft.sectionoftubeandone10ft.

sectionofreflector.

FIGURE 7: Tube and Reflector Hanger

FIGURE 7: Mounting Flange / Tube Detail

1) Inserttube06413intofrontcastingtopoint(A).

2) Tighterallsetscrewsmarked(B)untilsnug.

3) Afterbothsetscrewsaresnug,turneach

additional1/4turntosecuretubeinplace.

FIGURE 8: Burner Box / Transition Tube Detail

FIGURE 6: Typical Suspension Details

Locknut

Washer

WoodBeam

Washer

ScrewHook

min.3/8"(10mm)

I-Beam

Beam

Clamp

AsReq'd

S-Hook

BarJoist

Clip

Truss

Concrete

Beam

Anchor

MountingFlange

CapScrew

Stk.98012

SplitLockWasher

Stk.#98527

Gasket

Stk.#12397

Burner Box

(flameobservation

windowfacingdown)

horizontal reflector position (standard)

angle mounting ring

radiant tube

horizontal mounting ring

hanger

reflector

top

side 45° reflector position (optional)

below

FIGURE 9: Reflector End Cap

Partslist

100419ReflectorEndCap(Qty1)

209369SpringClip(Qty4)

FlangeKit#06428XL

KitIncludes:Flange,Screws(4),LockWashers(4),Gasket(1)

B

B

13 Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

SECTION 4

Engineering Specifications

ThetotalheatingsystemsuppliedshallbedesigncertifiedbyCSA

underANSIZ83.20alatestrevisionandCGA2.34alatestrevision.

A. Burner & Burner Controls

1.Burnersshallbecapableoffiringwithoneofthefueloptionsas

specifiedonthepurchasedocuments:NaturalGasorLP.

2.Burnersshallbesuppliedtofireatanyoneoftheinputratesas

specified.

ERXL-40 40,000BTU/Hr. ERXL-125125,000BTU/Hr.

ERXL-60 60,000BTU/Hr. ERXL-150150,000BTU/Hr.

ERXL-80 80,000BTU/Hr. ERXL-175175,000BTU/Hr.

ERXL-100 100,000BTU/Hr.

3.Burnershallbeequippedwithadirectsensesilicon-carbidehot

surfaceignitioncontrolsystemwith100%shut-offignitiondevice.

Powersuppliedtoeachheatershallbe120V,60Hz,singlephase.

Burnersshallberatedfor1.0Amp(run)and5.0Amp(start.)

4.Burnershallbeequippedwiththermaloverloadmotor

protection,balancedairrotor,combustionairprovingsafety

pressureswitch,andviewingwindowforflameobservation.

5.Whenspecified,incontaminatedenvironments,theburnershall

becapableofsupplyingoutsideairtoeachburnerforthesup-

portofcombustion.

6.Allburnersshallbepre-wiredwithagroundedelectrical

cordandplug.

7.Atcustomer’schoice,burnersmaybecontrolledwitheither

anoptionallinevoltagethermostatorbyoptionallowvoltage

thermostatswithanappropriatelowvoltagetransformerrelay.

8.Gassupplytotheburnersshallconformtothefollowing:

1/2”NPTgasconnectorsize

NaturalGas: 4.6”W.C.MIN,7.0”W.C.MAX

LPGas: 11”W.C.MIN,14.0:W.C.MAX

B. Heat Exchanger

1.Radianttubingshallbe4”diameteraluminizedsteelsuppliedin

10ft.sections.Sectionsshallbejoinedwithstainlesssteelwrap-

aroundcouplings.

2.Reflectortobeofaluminummaterialanddesignedtodirectall

radiantoutputbelowhorizontalcenterlineofradianttube.

3.Heatersshallbeventedaccordingtomanufacturer’s

recommendations.

Gas pressure at MANIFOLD:

Natural Gas: 3.5” W.C.

LP Gas: 10.5” W.C.

1/2”NPTGasConnectorSize

Gas INLET pressure:

Natural Gas: 4.6” W.C. Min

11.0” W.C. Max

LP Gas: 11.0” W.C. Min

14.0” W.C. Max

1/2”NPTGasConnectorSize

Electrical Rating:(AllModels)

120V-60Hz

1.0AMP(Run)5.0AMP(Start)

Dimensions:

Flue Connection Size…………………4”

Outside Air Connection Size………4”

14

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

COMMON VENTING - (2) Heaters (Horizontal and Vertical)

Model# H=6ft. H=8ft. H=15ft.

ERXL-40 D=7" D=6" D=6"

ERXL-60 D=7" D=6" D=6"

ERXL-80 D=8" D=7" D=6"

ERXL-100 D=8" D=8" D=7"

ERXL-125 D=10" D=10" D=8"

ERXL-150 D=10" D=10" D=8"

ERXL-175 D=10" D=10" D=8"

SECTION 5

Venting / Ducting

General Requirements

Thisheatermustbeventedinaccordancewiththespecifications

containedinthismanualandwiththefollowingnationalcodes

andanystate,provincialorlocalcodeswhichmayapply:

•RefertoNationalFuelGasCodeNFPA54/ANSIZ223.1-latest

revision.

•CANADA:RefertoNaturalGasandPropaneInstallationCode

CSAB149.1-latestrevision.

Theheatermaybeventedtotheoutdoorseitherverticallyor

horizontally.

Optionaloutsideairsupplymaybedirectedtotheheater

horizontallyorvertically.

Besurethatthemethodselectedforventingheatercomplies

withallcodesasrequiredforeachparticularlocation

Theuseofsingle-wallventpipe(26gauge)isrecommended.A

sectionofdouble-wallventpipeisrecommendedwhenpassing

throughtherooforwall.

Exhaustendofheaterwillaccepta4'(10cm)ventpipeusing

theventadapter.Installtheventadapterwiththeseamontop,

secureallventjointswithaminimumof3#8x3/8"sheetmetal

screwsandsealalljointsusingahightemperaturesilicone

sealant.

Ifcondensationintheflueisaproblem,thefluelengthshould

beshortenedorinsulated.

Ventpipemustbeslopeddownwardawayfromtheburner

1/4"(.6cm)forever10'(3m).

VENTLENGTHS:

• Maximumtotalventlengthallowedinthirty(30’)feet.

• Maximumoutsideairsupplyductallowedthirty(30’)feet.

• Maximumtotalventlengthplusoutsideairsupplylength

shallnotexceedfifty(50’)feet.

NOTE:

Atotaloftwo(2)elbowsareallowedforventand

outsideairsupplycombination.Subtract5'feetperadditional

elbowfrommaximumlengthallowedif3ormoreelbowsare

used.

Installaminimum18"(30cm)straightlengthofductforair

intakeorventbeforeanyTeeorelbow.

Alternative Arrangements / Optional Equipment for Venting

Unvented Operation

a) Sufficientventilationmustbeprovidedintheamountof4

CFMper1,000BTU/hr.firingrate.

b) RefertoANSIZ223.1-latestrevision,NFPA-54andlocal

codesforadditionalinformation.

c) Useofoptionaloutsidecombustionairisnotrecommended

withunventedheatersduetopressureconsiderations.Refer

topage16

Horizontal Venting

a) Four(4”)inchO.D.fluepipeisrequired.Thirty(30’)feet

maximumlengthisrecommended.

b) Allfluejointsshouldbesealedusingsuitableproductsuch

asGeneralElectricRTV106orPermatexForm-A-GasketRed

HighTemperatureSiliconeAdhesiveSealant.

c) Donotinstallanyelbowor45fittingtobringventlower

thanthehorizontaltubesystem.

d) Ventterminalshouldbeinstalledataheightsufficientto

preventblockagebysnow.

1) Ventmustexitbuildingnotlessthanseven(7’)feet

abovegradewhenlocatedadjacenttopublicwalkways.

2) Ventmustterminateatleastthree(3’)feetaboveany

forcedairinletlocatedwithintenfeet(10’).

3) Ventmustterminateatleastfour(4’)feetbelow,four

(4’)feethorizontallyfrom,orone(1’)footaboveany

door,window,orgravityinletintoanybuilding.

4)Ventterminalshallbelocatedatleasttwelve(12”)inches

fromanyopeningthroughwhichventgasescouldenter

thebuilding.

5) Ventterminalmustbebeyondanycombustibleover

hang

Vertical Venting

a) Four(4”)inchO.D.fluepipe,maximumthirty(30’)feet

inlengthmaybeusedasshownwithapprovedventcap.

(SeeGeneralRequirementsonthispageforadditional

information.)

b) Aninsulatedthimblemayberequiredtopassthrough

combustiblestructures(checklocalcodes).

c) Allfluejointsshouldbesealedusingsuitableproducts(see

recommendationforhorizontalventing.)

Common Venting

a) Horizontalruntoventmustneverexceed75%ofthevertical

heightofthevent.RefertoANSIZ223.1-latestrevision,

NFA-54forproperventsizesandinstallation.

b) Openareaofcommonventmustequalthesumoftheopen

areaofindividualventsconnectedtoit.(Seechartbelow

anddiagrams-page14.)

c) Usedoublewallventasrequired(checkcodes.)

d) Alljointsmustbesealedusingsuitableproducts.

e) Connectionstocommonstackmustbepositionedtoavoid

directoppositionbetweenstreamsofcombustiongases.

15 Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

FIGURE 12: Common Roof Venting

HORIZONTAL COMMON VENTING

VERTICAL COMMON VENTING

SIDE VIEW

TOP VIEW

Type "B" Vent required outdoors.

Vent Adapter Stk. #19021

At least 1/4" per foot rise or pitch

must be maintained on horizontal

runs from heater to vent.

Roof

Secure all joints with 3 (minimum) #8 x 3/8"

sheet metal screws and seal all joints.

H

Approved Vent Cap

Type "B" Vent required outdoors.

Vent Adapter Stk. #19021

Outside Wall

H

Vent Cap

Flashing

Wall Thimble

(If Applicable)

Burner Box Burner Box

Burner Box

Burner Box

Burner Box

Burner Box

D

Burner Box Burner Box

D

4” Aluminized steel Heat Exchange Tube

4” Aluminized steel Heat Exchange Tube

Type"B"Ventrequiredoutdoors.

VentAdapterStk.#19021

OutsideWall

Securealljointswith3(minimum)#8x3/8"

sheetmetalscrewsandsealalljoints.

H

VentCap

WallThimble

(IfApplicable)

BurnerBox

BurnerBox

D

D

16

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

FIGURE 10: Unvented Operation

36”

36”

A

1. Ventilationequalto4CFMper1,000BTU/HRfiringratemust

beprovidedinunventedheaterinstallations

2. FordimensionsA"unvented"referto(Figure1-Minimum

ClearancestoCombustibles.)

FIGURE 10A: Single Wall

Singlewallventrun

Singlewallterminalend

FIGURE 10b: Double Wall

Doublewallventrun

Doublewallterminalend

FIGURE 11: Vertical Venting

18"(45cm)

18" (45cm) Min. 3'-0" (91cm) Min.

8"(20cm) to 10"(25cm) Max.

6' (182cm) Min.

18" (45cm) Min. 3'-0" (91cm) Min.

6' (182cm) Min.

2"(5cm) Clearance thimble

2"(5cm) Clearance thimble

required when u pipe

extends through

combustible materials

(91cm)

(91cm)

17 Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

Outside Combustion Air Supply

TheEner-RadiantXLheaterisapprovedforinstallationwith

anoutsideairsupplysystem.Somecompoundssuchas

halogenatedhydrocarbonsorothercorrosivechemicalsinthe

aircanbedrawnintotheequipmentandcauseanaccelerated

rateofcorrosionofsomeoftheheatercomponents.Theuse

ofsuchchemicalcompoundsneartheenclosureshouldbe

avoided.

IMPORTANT: If the building has a slight negative

pressure or contaminants are present in the air, an

outside combustion air supply to the heaters is strongly

recommended.

Foranoutsideairsupply,afour(4”)inchO.D.singlewallpipe

maybeattachedtotheheater.Theductmaybeuptoforty-five

(30’)ft.maximumlengthortwo(2’)ft.minimumlengthwith

nomorethantwo(2)elbows.(SeeGeneralRequirementson

page15foradditionalinformation.)

Theairsupplyductmayhavetobeinsulatedtoprevent

condensationontheoutersurface.Theoutsideairterminal

shouldbesecurelyfastenedtotheoutsidewallbydrillingfour

(4)1/4”diameterholesintheoutsideflange;woodscrewsor

boltsandexpansionsleevesmaybeusedtofastenterminal.

FIGURE 13: Non-Pressurized Outside Air Supply Duct

PVCPipe,“DryerHose”,orequivalentmaybeusedinsteadof

standardventpipe.

SECTION 6

Gas Piping

Readapplicablewarningsin(Section1)beforeproceedingwith

GasPipeinstallation.Improperinstallationmayresultinproperty

damage,severeinjury,ordeath.

Meterandservicemustbelargeenoughtohandlealltheburners

beinginstalledplusanyotherconnectedload.Thegaslinewhich

feedthesystemmustbelargeenoughtosupplytherequiredgas

withamaximumpressuredropof1/2”watercolumn.Whengas

pipingisnotincludedinthelayoutdrawing,thelocalgassupplier

willusuallyhelpinplanningthegaspiping.

A1/2”tappingateachburnerlocationmustbelocatedandoriented

asshownin(Figure14).Tochecksystempressure,putaplugged

1/8”NPTtappinginthegaslineattheconnectiontotheburner

farthestfromthesupply.Beforeconnectingtheburnerstothe

supplysystem,verifythatallhighpressuretestingofthegaspiping

hasbeencompleted.Donothighpressuretestthegaspipingwith

theburnersconnected.

Followtheseinstructionstoensureaprofessionalgassupply

installation:

• Supportallgaspipingwithsuitablepipehanging

materials.

• Usewroughtironorwroughtsteelpipeandmalleable

ironfitting.Allpipefittingsshouldbenewandfree

fromdefects.Carefullyreamthepipeandtubingends

toremoveobstructionsandburrs.

• UseL.P.gas-resistantjointcompoundonallpipe

threads.

• Checkthepipeandtubingendsforleaksbefore

placingheatingequipmentintoservice.When

checkingforgasleaks,usesoapandwatersolution:

NEVER USE AN OPEN FLAME.

Installtheflexgasconnectorasshown.Theflexgasconnector

accommodatesexpansionoftheheatingsystemandallowsforeasy

installationandserviceoftheburner.

FIGURE 14: Gas Line Connection with Stainless Steel Flex Gas

Connector

Shut-OffValvemustbeparallel

toburnergasinlet.The2”

displacementshownisforthecold

condition.Thisdisplacementmay

reducewhenthesystemisfired.

Shut–offValve

12 "

2"

1/2"StainlessSteelFlexGasConnector

Stk.#16401

90°

45°

0°

45°

4" (10 cm)

Seal All Joints

4"

Heater Movement

Heater Movement

Heater Movement

Heater Movement

Outside Air

Terminal

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

Outside Air

Terminal

NOTE:

Flue pipe requires additional

support. Flex pipe will not

support riser and outside

air terminal

Vertical Outside Air

Horizontal Outside Air

FIGURE 14A: Incorrect Gas Line Connection with Stainless

Steel Flex Gas Connector

18

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

SECTION 7

Wiring

Heatersarenormallycontrolledbythermostats.Linevoltage

thermostatsarewireddirectly(seeFigure15),24Vthermostatsare

wireddirectlyusingtheterminalsonburnerbox(seeFigure16).

HeatersmustbegroundedinaccordancewiththeNationalElectric

CodeANSI/NFPA-70orcurrentCanadianElectricalCode,CSA

C22.1.Heatersmayalsobecontrolledwithamanuallinevoltage

switchortimerswitchinplaceofthethermostat.

FIGURE 15: Line Voltage Thermostat Wiring

T

H

N

120v – 60 Hz

White

White

Green

Green

Supply Circuit

120v – 60 Hz

Supply Circuit

Burners

(Maximum – 2 per Thermostat)

Burners

(Maximum – 1 per Thermostat)

Black

Black

H

N

T

FIGURE 16: Low Voltage Thermostat Wiring

T

H

N

120v – 60 Hz

White

White

Green

Green

Supply Circuit

120v – 60 Hz

Supply Circuit

Burners

(Maximum – 2 per Thermostat)

Burners

(Maximum – 1 per Thermostat)

Black

Black

H

N

T

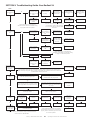

FIGURE 18: Ener-Radiant XL Burner Internal Wiring Ladder

FIGURE 17: Ener-Radiant XL Burner Internal Wiring

• Ifanyoftheoriginalwireassuppliedwiththe

appliancemustbereplaced,itmustbereplacewith

wiringmaterialhavingatemperatureratingofatleast

105°Cand600volts.

• Eachburnermustbeelectricallygroundedin

accordancewiththeNationalElectricCodeANSI/NFPA

-70orcurrentCanadianElectricalCode,CSAC22.1.

Diagram

VAC

120

120V 24V

Black

Black

Purple

Yellow

Yellow

Black

Black

Black

Green

Green

Orange

Transformer

White

White

White

THERMOSTAT

White

Blue

Gas Valve

Air Switch

Ignitor

Sensor

Motor / Blower Door Switch

Terminal

Bushing

120V

L2

(NEUTRAL)

White

White

White

White

White

White

Gray

Orange

Transfomer

Thermostat

Air Switch

Gas Valve

Door Switch Motor / Blower

Ignitor

Sensor

Blue

Yellow

Yellow

Purple

Black

Black

Black

Black

L2 (HOT)

24V

19 Operating Instructions and Owner’s ManualEnerco | Heatstar ERXL Series Heater

9. Aqualifiedserviceagencyshouldbecontactedforservice

otherthanroutinemaintenance.

10. Checkventterminalandfreshairinlettoseethattheyhave

notbeenblockedduringthenon-heatingseason.Ifeither

pipeisrestricted,theairswitchwon’tclose,resultingina

no-heatsituation.

Troubleshooting

CAUTION:BeforeopeningtheEner-RadiantXL

burnerdoorforanytypeofservice,besure

thegassupplyhasbeenshutoffattheheater

andtheelectricalcordfromtheburnerbox

hasbeenunplugged.

Blower Motor 1.Isthethermostatcallingforheat?Isthere

Fails to Run: 115Vattheburnerreceptacle?

2.Checkblowersidedoorforseal.Checkdoor

switch.Replaceifnecessary/

3.Checkblowerforobstructions.Replace

blowerifnecessary.

Igniter 1.Checkigniterfordamage.Replaceif

Does Not Glow: necessary.

2.Checkvoltageandresistanceatigniter.

(Voltageshouldbe115V.Resistanceshould

be40-75ohms.)

3.Checkforobstructionstotheairinletand

outlet.

4.Checkwiringandhoseconnectionstothe

airswitch.Replaceifnecessary.

5.Checkvoltagesattransformerprimaryand

secondary.Replacetransformerormoduleif

necessary.

Valve Does Not Gaspressuredownstreamofgascontrolcan

Come On: bemeasurebyusingamanometerand

connectingtopressuretaponcontrol/

1.ChecktoseeifmanualvalveheaterisON.

2.Checktoseeifmanualvalveknobonheater

gascontrolinON.

3.Supplygaspressurecanbecheckedat1/8”

NPTpressuretappingonheaterexternal

manualvalve.

4.Checktoseeifgascontrolisopening:no

manifoldpressureindicatesvalveisclosed.

Ifthevalveisclosed,eitherthegasvalveor

theignitionmoduleisfaulty.

WARNING:Donotdisconnectgroundleads

insideheater.Donotinterchangegrounded

andungroundedleadsontransformeror

ignitionmodule.

Burner Does Not 1.Checktoseeifgaslineswereproperly

Light: purgedofair.

2.Checkinletandoutletgaspressureduring

ignitionperiod.

Naturalinletpressureshouldbe4.6”

Naturaloutletpressureshouldbe3.5”

LPinletpressureshouldbe11.0”

LPoutletpressureshouldbe10.25”

3.Checkforproperorificeandairplate.

SECTION 8

Operation & Maintenance

Sequence of Operation

1. Turnthethermostatup.Whenthethermostatcallsforheat,

blowermotorwillenergize.

2. WhenthemotorapproachesnominalrunningRPM,theair

provingswitchclosesandactivatestheignitionmodule.

3. Theignitionmodulethenenergizesthehotsurfaceigniterfor

atimedwarm-upperiod(approximately45to60seconds.)

4. Afterthewarm-upperiod,thegasvalveisenergized.

5. Duringthelastpartofthesequence,theigniterisde-

energizedandisconvertedtoaflamesensingrod.

6. Ifaflameisdetected,thegasvalveremainsopen.Whenthe

callforheatissatisfied,andthesystemcontrolmechanism

de-energizestheburnerlinevoltagesupply,thegasvalvesare

turnedoff.

7. Ifnoflameisdetectedonasingle-trymodule,thegasvalve

isclosed,andthemodulewilllockoutuntilitisreset.Reset

isaccomplishedbyremovingpowerfromthemoduleforat

leastfive(5)seconds(thermostatcyclerequired.)

8. Ifnoflameisdetectedonathree-trialmodule,thegas

valveisclosed,andapurgeperiodbegins.Afterthepurge,

themoduleactstopowertheigniterforasecondwarm-

upperiod,andasecondtrialforignitionperiod.Ifflameis

stillnotestablished,athirdandfinalpurge,warm-up,and

trialcyclebegins.Afterthreetrials,themodulewilllockout

untilreset.Resetisaccomplishedbyremovingpowerfrom

themoduleforatleastfive(5)seconds(thermostatcycle

required.)

9. Onathree-trialmodule,ifflameisestablishedandlost

onthefirstorsecondtrial,thegasvalveisturnedoff,a

purge,warm-up,andtrialforignitionwilloccuronathree-

trialmodule,onlythreetrialsforignitionareallowedper

thermostatcycle.

Maintenance

Forbestperformance,thefollowingmaintenanceproceduresshould

beperformedbeforeeachheatingseason:

1. Besuregasandelectricalsupplytoheaterareoffbefore

performinganyserviceormaintenance.

2. Checkconditionofblowerscrollandmotor.Dirtanddust

maybeblownoutwithcompressedair,oravacuumcleaner

maybeused.Whenusingcompressedairdonotexceed30

psiinordertonotdamagefragilehotsurfaceigniter.

3. Checkconditionofburner.Carefullyremoveanydustor

debrisfrominsidetheburnerboxorburnercup.

4. Inspecttheigniter.Replaceigniterifthereisexcessivecarbon

residue,erosion,breakageorotherdefects.

5. Checktheinsideofthefiringtubewithaflashlight.Ifcarbon

orscalearepresent,scrapeoutthedepositswithawire

brushorrod,ormetalplateattachedtoawoodenpole.

6. Checktoseethattheburnerobservationwindowisclean

andfreeofcracksorholes.Cleanorreplaceasnecessary.

7. Checkthefluepipeforsootordirt.Aftercleaningas

necessary,re-attachthefluepipetotheheater.

8. Outsidesurfacesofheatermaybecleanedbywipingwitha

dampcloth.

20

Enerco | Heatstar ERXL Series Heater Operating Instructions and Owner’s Manual

Burner Does Not 1.Checkgroundwirecontinuity.

Stay Lit: 2.Checkburnerinternalwiringforreversed

leads.

3.Checkinsulationontheigniterleads.

4.Replacemoduleifnecessary.

Honeywell Valve LED Status

TheEner-RadiantXLseriesTubeHeaterisequippedwithahoneywell

SmartValve.Thisvalvehasabuilt-indiagnosticprogram,whichwill

assistintroubleshootingintheeventofavalve-relatedproblem.The

LEDor(LightEmittingDiode)islocatedonthetopofthevalveas

shownindiagrambelow.TheLEDstatusindicationsarelistedbelow

tohelpwiththetroubleshooting.

FIGURE 19:

OFF INDICATED

Off Nopowertothecontrol

Bright-Dim Normaloperation.

Thisindicationshowswheneverthesystemis

powered,unlesssomeabnormaleventhasoccurred.

2-Flashes Airflowprovidingswitchremainsclosedlongerthan

30secondsaftercallforheatbegins(airproviding

switchstuckclosed.)

3-Flashes Airflowprovidingswitchremainsopenlongerthan30

secondsaftercombustionairblowerisenergized-or

blowerdoesnotenergize.

4-Flashes Whitejumperwireisloose.

5-Flashes Flamesignalsensedoutofpropersequence.

6-Flashes SystemLockout.

LED

HoneywellSmartValve

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

HeatStar ERXL-175 Le manuel du propriétaire

- Catégorie

- Chauffe-eau

- Taper

- Le manuel du propriétaire

dans d''autres langues

- English: HeatStar ERXL-175 Owner's manual

- español: HeatStar ERXL-175 El manual del propietario

Documents connexes

-

HeatStar ERXL125-N Le manuel du propriétaire

-

HeatStar ERXL125-N Le manuel du propriétaire

-

HeatStar ERXL125-N Le manuel du propriétaire

-

HeatStar ER2STG175-LP Le manuel du propriétaire

-

HeatStar ER2STG175-LP Le manuel du propriétaire

-

HeatStar ERSP175-LP Le manuel du propriétaire

-

HeatStar HS45GSP Le manuel du propriétaire

-

HeatStar HEATSTAR HS9120 Mode d'emploi