Simplicity MANUAL, OPERATOR'S AND INSTALLATION Manuel utilisateur

- Catégorie

- Groupes électrogènes

- Taper

- Manuel utilisateur

Generator for Standby and Non-Emergency Use, Models: 17kW -

26kW

Installation and Operation Manual

Manual de instalación y operación

Manuel d’installation et d’utilisation

This generator is rated in accordance with UL (Underwriters Laboratories) 2200 (stationary engine generator assemblies) and

CSA (Canadian Standards Association) standard C22.2 N. 100-14 (motors and generators).

Este grupo electrógeno está clasificado conforme a la norma UL (Underwriters Laboratories) 2200 (conjuntos de grupos

electrógenos con motores fijos) y a la norma CSA (Canadian Standards Association) C22.2 N. 100-14 (motores y grupos electrógenos).

Ce groupe électrogène est certifié UL (Underwriters Laboratories) 2200 (groupes électrogènes à moteur fixe) et conforme à la

norme CSA (Canadian Standards Association) C22.2 N. 100-14 (moteurs et groupes électrogènes).

© 2023 Briggs & Stratton. All rights reserved. 80126266

Revision A

Not for

Reproduction

Manual Contents:

Important Safety Instructions..............................................2

General Information..............................................................3

Installation............................................................................. 5

Operation............................................................................. 21

Maintenance.........................................................................25

Troubleshooting..................................................................32

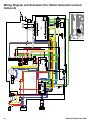

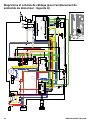

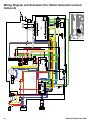

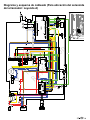

Wiring Diagram and Schematic(For Starter Solenoid

Location: Callout A)............................................................34

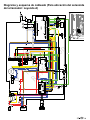

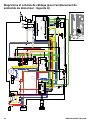

Wiring Diagram and Schematic(For Starter Solenoid

Location: Callout A)............................................................35

Concrete Pad Specifications............................................. 36

Specifications......................................................................37

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that must be read, understood,

and obeyed during installation of generator kits and/or

accessories.

Safety Symbols and Meanings

Symbol Meaning

Safety alert symbol shows a possiblepersonal injury hazard.

Read Manual. Failure to obey warnings, instructions,

installation manual, andOperator’sManual could result in

death or serious injury.

Explosion

Electric Shock

Auto-start

Fire

Chemical Burn

Symbol Meaning

Toxic Fume

Eye Protection

Hot Surface

Rotating Parts

Safety Alert Symbol and Signal Words

The safety alert symbol identifies safety information

about hazards that could result in personal injury. A signal

word (DANGER, WARNING, or CAUTION) is used to

indicate the likelihood and the potential severity of injury. In

addition, a hazard symbol is used to represent the type of

hazard.

DANGER indicates a hazard which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE indicates information considered important but not

hazard-related.

Safety Messages

WARNING

This product can expose you to chemicals including used

engine oil, which is known to the State of California to cause

cancer, and carbon monoxide, which is known to the State of

California to cause birth defects or other reproductive harm.

For more information go towww.P65Warnings.ca.gov.

WARNING

This product contains lead and lead compounds,

known to the state of California to cause birth defects

or other reproductive harm. Wash your hands after

handling this product. Cancer and Reproductive Harm -

www.P65Warnings.ca.gov.

2 BRIGGSandSTRATTON.COM

Not for

Reproduction

NOTICE: Improper treatment of generator could damage it

and shorten its life.

• Use generator only for intended uses. See Product Use

section of this manual.

• If you have questions about the intended use, contact

your authorized dealer.

• Operate the generator only on level surfaces.

• Adequate, unobstructed flow of cooling and ventilating

air is critical for correct generator operation.

• The access panels/doors must be installed whenever

the unit is running.

• DO NOT expose the generator to excessive moisture,

dust, dirt, or corrosive vapor.

• Remain alert at all times while working on this

equipment. Never work on the equipment when you are

physically or mentally fatigued.

• DO NOT insert any objects through the cooling slots.

• DO NOT use the generator or any of its parts as a step.

Stepping on the unit could cause stress and break parts.

This may result in dangerous operating conditions from

leaking exhaust gases, fuel leakage, oil leakage, etc.

• Shut off generator if:

• electrical output is lost.

• equipment sparks, smokes, or emits flames.

• unit vibrates excessively or makes unusual noises.

FCCStatementPart15(ToUser)

Pursuant to part 15.21 of the FCC Rules, you are

cautioned that changesor modificationsto the product

notexpresslyapproved by Briggs & Strattoncouldvoid

yourauthority to operate the product.

This devicecomplies withpart 15 of the FCC Rules.

Operationis subjectto thefollowing two conditions:(1) This

device may notcauseharmfulinterference, and (2) this

device must acceptanyinterference received,including

interferencethatmaycause undesiredoperation.

This equipment has been tested and found

tocomplywith the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits

aredesignedtoprovidereasonableprotection

againstharmfulinterference in a residential installation.

This equipment generates, uses and can radiate radio

frequency energy and, if not installed and usedin accordance

withthe instructions,maycauseharmfulinterference to

radio communications. However, there is no guarantee that

interference will not occur in aparticularinstallation. If this

equipmentdoescauseharmfulinterference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct

the interference by one or more of thefollowing measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV

technician for help.

General Information

For most applications, the Installation and Operation Manual

contains the informationnecessaryto correctly install,

operate, and maintain the generator. Briggs & Stratton has

made every effort tomake surethat the information in this

manual is accurate and current. Briggs & Stratton reserves

the right to change, alter, or otherwise improve the product

and this document at any time without prior notice.

Thank You

Thank you for purchasing this quality-built Briggs & Stratton®

generator. We are pleased that you have placed your

confidence in the Briggs & Stratton brand. When operated

and maintained according to the instructions in this manual,

your generator can provide many years of dependable

service. This manual contains safety information to make

you aware of the hazards and risks associated with standby

generators and how to avoid them.

SAVE THESE INSTRUCTIONS. This manual contains

important instructions that users must obey during installation,

operation, and maintenance of the generator and battery.

Where to Find Us

Youdo nothave to look far to find support and service for

your equipment. There are many authorized service dealers

worldwide thatsupplyquality service. You can also contact

Customer Service by phone at 800-732-2989 between 8:00

AM and 5:00 PM central time or click on "Dealer Locator"

at www.briggsandstratton.com, which will supplya list of

authorized dealers.

For Future Reference

Fill out the information that follows and keep it with your

receipt. Have this information at hand if you need to contact

your installer or authorized dealer regarding service or repair

of the unit.

Date of Purchase: ________________________________

Dealer/Retailer: _________________________________

Dealer's/Retailer'sPhone Number: __________________

GENERATOR:

Model Number: ____________________________

Model Revision: ____________________________

Serial Number: ____________________________

ENGINE:

Model Number: __________________________________

3

Not for

Reproduction

Serial Number: ___________________________________

Equipment Description and Product Use

These generators are EPA certified for optional standby

applications. Non-Emergency generator use is intended

for non-emergency demand response use and optional

standby applications. Optional standby provides an alternate

source of electric power and serves loads such as heating,

refrigeration systems, and communication systems that,

when stopped during a power outage, can cause discomfort

or inconvenience. Non-emergency generators used for

demand response are an energy source for electrical utility or

cooperative providers to rely on during peak demand times or

dispatched during capacity congestion.

NOTICE: Generator models do NOT qualify for either an

emergency standby or legally required standby system as

defined by NFPA 70 (NEC).

• Emergency generator systems are intended to

automatically supply illumination, power, or both, to

designated areas and equipment in the event of failure

of the normal supply. Emergency systems can also

supply power for such functions as ventilation where

essential to maintain life, where current interruption of

the normal supply would produce serious life safety or

health hazards.

• Legally required standby generator systems are

intended to automatically supply power to selected

loads in the event of failure of the normal source (which

can create hazards or prevent rescue or fire-fighting

operations).

Installer Responsibilities

• Read and obey the safety, installation and operation

instructions in this Installation and Operation Manual.

• Install only aNationally Recognized Testing Laboratory

(NRTL) approved transfer switch that is compatible with

the generator.

• Installation must obey all applicable codes, industry

standards, laws, and regulations.

• Allow sufficient room on all sides of the generator for

maintenance and service.

• Speak with the owner about generator placement.

• Speak with the owner aboutcarbon monoxide (CO)and

smoke detectors. It is the owner's responsibility to have

carbon monoxide and smoke detector(s) installed and

maintained indoors according to the manufacturer’s

instructions and recommendations.

• Make sure that ALL of the manuals are given to the

owner after the installation has been completed.

• The unit is to be installed so that the risk of contact by

people is minimized.

Owner Responsibilities

• Read and obey the instructions in this Installation and

Operation Manual.

• Follow a regular maintenance schedule and use the

generator as specified in this manual.

• Carbon monoxide detector(s) MUST be installed and

maintained indoors according to the manufacturer’s

instructions and recommendations. Smoke alarms

cannot detect carbon monoxide gas.

• Smoke detector(s) MUST be installed and maintained

indoors according to the manufacturer’s instructions and

recommendations. Carbon monoxide alarms cannot

detect smoke.

Installation Factors to Consider

The illustrations shown in this manual depict typical

circumstances. They are meant to familiarize you with the

installation options available for the generator.

Always consider installation factors such as federal and local

codes, appearance, noise levels, fuel types, and distances.

As the distance increases from the existing electrical service

and gaseous fuel supply, and the number of bends in the

fuel supply increases, installers must make compensations

for piping and wiring materials. These compensations are

necessary to comply with local codes and overcome drops in

electrical voltage and drops in gaseous fuel pressure.

Delivery Inspection

Avoid damage from dropping, bumping, or collision with the

shipping carton.

Remove the carton and carefullyexaminethe generator for

damage thatcanoccur during shipment.

If an owner sees loss or damageat the time of delivery, the

ownermusttellthe person or persons who made the delivery

to document the loss or damage on the freight bill and affix

a signature under the consignor’s memo of loss or damage.

If the owner notices loss or damage after delivery, separate

the damaged materials and then contact the carrier for claim

procedures. Missing or damaged parts are not warranted.

Shipment Contents

The generator system is supplied with:

• Oil (5W30 Full Synthetic)

• Flexible fuel line

• Fuel pipe coupling

•Quick Operation Manual

•Installation and Operation Manual

• Product and emissions warranty booklet

• Two access keys (generator is shipped withaset of

identical keys fastened to one of the end caps)

• Two 15 amp ATO-type fuses

• Four lifting hole caps

The generator system does not included (An owner will

need to purchase before installation):

• Carbon monoxide detectors

• Smoke detectors

• Starting battery

4 BRIGGSandSTRATTON.COM

Not for

Reproduction

• Connecting wire and conduit

• Fuel supply valves and plumbing

• Crane, lifting straps, chains or cables

• Two 60 in (152.4 cm) lengths of .75 in (1.9 cm) nominal

minimum Schedule 40 steel pipe (NOT conduit)

• Torque screwdriver, 5 to 50 inch-pound (0.6 to5.6N·m)

range

• Multimeter

Installation

WARNING

Generator and utility voltage could cause electrical shock or

burn resulting in death or serious injury.

• Installation must be performed by a licensed

professional.

• Disconnect all sources of electricity before installing or

servicing equipment.

• Ground system before applying power.

WARNING

Hazardous Voltage - Installing low and high voltage wire in

same conduit could cause electric shock or burns, resulting in

death or serious injury.

• Do not run low and high voltage wire in the same

conduit unless the insulation rating on ALL wiring is

rated for 600 V. See NFPA 70 for more information.

Only current licensed electrical professionalsare

qualified to dosystem installations. Installations must

obeyallrelatedcodes, industry standards and regulations.

The equipment warranty is VOID unless the system is

installed by licensed electricalprofessionals.

NOTICEDisconnect all power connections before you install

this equipment. Failure to do so could cause internal damage

to the board during electrical connections.

Incorrect installation can cause damage to the circuit boards

and shorten their life. If you install the circuit boards in live

circuits it will damage the board, which is not included in the

warranty. ALWAYS disconnect ALL sources of power before

you service the generator.

All wiring must be the correct gauge, correctly supported and

protected by conduit. All wiring must be done as specified

by federal, state and local codes, standards and regulations.

Obey the wire type and torque specifications printed on the

terminal blocks, neutral/ground connectors, and installation

instructions. Use the installer supplied 600VAC or greater

copper or aluminum wire of a gauge that complies with the

latest version of the National Electric Code to complete the

connections between utility power, transfer switch, generator,

main distribution panel, and optional remote modules. Apply

the necessary correction factors and wire size calculations.

1. Set the Generator Circuit Breaker to the OFF position.

2. Set the Generator ON/OFF Switch to the OFF position.

3. Remove the 15 Amp fuse from the generator.

4. Disconnect the utility power to the generator and transfer

switch.

Generator Placement

Beforethe generator is installed, speak with the owner and

convey the requirements that follow. They must be satisfied

before the installation is complete.

The owner must be told about twoequally important

safetyconcerns:

• Carbon monoxide poisoning

• Fire

An installer must meet several other general location

guidelines that are contained in this manualbefore the

installation is complete.

WARNING

Engine exhaust contains carbon monoxide, a poisonous gas

that could kill you in minutes. You cannot smell it, see it, or

taste it. Even if you do not smell exhaust fumes, you could

still be exposed to carbon monoxide gas.

• Operate this product ONLY outdoors in an area that will

not accumulate deadly exhaust gas.

• Direct exhaust gas away from any windows, doors,

ventilation intakes, soffit vents, crawl spaces, open

garage doors or other openings that can allow exhaust

gas to enter inside or be drawn into a potentially

occupied building or structure.

• Carbon monoxide detector(s) MUST be installed and

maintained indoors according to the manufacturer’s

instructions/recommendations. Smoke alarms cannot

detect carbon monoxide gas.

• If you start to feel sick, dizzy, weak, or your carbon

monoxide alarm sounds while using this product, get to

fresh air right away. Call emergency services. You may

have carbon monoxide poisoning.

• DO NOT run this product inside homes, garages,

basements, crawlspaces, sheds, or other partially-

enclosed spaces even if using fans or opening doors

and windows for ventilation. Carbon monoxide can

quickly build up in these spaces and can linger for

hours, even after this product has shut off.

5

Not for

Reproduction

1

• (A)Exhaust outlet side of enclosure.

• (B)Air inlet side of enclosure.

• (C) Front of enclosure.

• (D) Back of enclosure.

Generator Location Considerations

The installation location of the generator directly effects:

1. The amount and size of the plumbing required to fuel the

generator.

2. The amount and size of the wiring required to control and

connect the generator.

3. The safety of the installation regarding exhaust gas and

carbon monoxide hazards, fire risks, proximity to other

utilities, and exposure to weather elements.

The Generator Placement section addresses specific location

guidelines. The owner and installer must speak to one

another to determine how the site can affect installation costs

and compliance with local codes and standards.

Federal and International Standards

Generator installation must strictly adhere to ICC, IFGC,

NFPA 37, NFPA 54, NFPA 58, and NFPA 70 standards.

National Fire Protection Association (NFPA) 37: This

standard addresses the installation and use of stationary

combustion engines. Its requirements describe keeping

an enclosed generator a specific distance from a structure

or wall. This standard also requires that when you locate

a generator, you provide adequate space to perform

maintenance and repair tasks and space for the maneuvering

of first responders.

NFPA 37, Section 4.1.4, Engines Located Outdoors: This

requirement specifies that engines and their weatherproof

housings (if provided) installed outdoors must remain at least

5 ft (1.52 m) from openings in walls and at least 5 ft (1.52 m)

from structures with combustible walls. The standard does

not require a minimum separation if either of the following

conditions exist:

1. The structure’s adjacent wall has a fire-resistance rating

of at least one hour.

2. Where a fire test involving consumption of the available

combustibles, within the engine or, if provided, its

weatherproof housing demonstrates that a fire originating

at the engine or its weatherproof housing will not ignite

combustible structures.

Annex A—Explanatory Material

A4.1.4 (2): This requirement means that demonstrating

compliance involves conducting a full-scale fire test or by

followingthe calculation procedures found in Chapter 10 of

NFPA 555.

This requirement concludes that due to the limited space

frequently available for installation of the unit, exception (2) is

beneficial for many residential and commercial installations.

The manufacturer has contracted with an independent testing

laboratory to conduct full-scale fire tests.

The ultimate goal of the fire testing was to evaluate the

absolute worst fire scenario within the generator andto

determine the ignition risk foritems outside the engine

enclosure at specific distances. Note that the enclosure is

constructed of non-combustible materials. Outcomes from

independent lab tests showed that a fire that started within

the generator enclosure would not pose an ignitability risk to

nearby combustibles or structures for at least one hour.

Combining results from these full-scale tests and the

requirements of NFPA 37, Sec 4.1.4, the guidelines for

installation of the generators previously mentioned change

to 18 in (45.7 cm) from the back side of the generator to a

stationary wall or building.For more information see Distance

Requirements section in this manual.

Reduce the Risk of Carbon Monoxide Poisoning

In high concentrations, carbon monoxide (CO) can be fatal

in minutes. However, the effects of lower concentrations can

also be lethal. This gas poses serious dangers to humans

and their animals because no one can smell, see, or taste it.

Symptoms of exposure to CO include:

• Watery, itchy eyes

• Throbbing temples

• Inability to think coherently

6 BRIGGSandSTRATTON.COM

Not for

Reproduction

• Ringing in the ears

• Headache

• Incoherent or slurred speech

• Flushed appearance

• Inattentiveness

• Loss of physical coordination

• Tightness across the chest

• Drowsiness

• Nausea

• Dizziness

• Vomiting

• Fatigue

• Collapse

• Convulsions

If you (or someone nearby) suffers from any of the above

symptoms, immediately seek fresh air and call for emergency

medical help for possible carbon monoxide poisoning. If your

carbon monoxide alarm sounds while using this product,

immediately seek fresh air (even if you experience none of

the previously mentioned symptoms).

Carbon Monoxide (CO) Detectors

NOTICE: Installing functioning CO alarms indoors is the only

way to recognize CO gas. Common smoke alarms do not

detect CO gas and will not alert occupants of its presence.

A CO detector is an electronic device that detects hazardous

levels of CO. When a buildup of CO occurs, the detector will

alert the occupants by sounding an alarm and by flashing a

visual indicator light.

By law many states require a home to have a functioning

carbon monoxide (CO) detector.The installer must speak

with the owner aboutcarbon monoxide (CO) detectors.

Carbon monoxide detector(s) MUST be installed and

maintained indoors according to the manufacturer’s

instructions and recommendations. Smoke alarms cannot

detect carbon monoxide gas.

Contact the local building inspection division for any relevant

requirements regarding the use of CO detectors. See

National Fire Alarm and Signaling Code (NFPA) 72 Code and

Section R315 in the International Residential Code (ICC) for

additional details.

Potential Carbon Monoxide Entry Points

Operation Guidelines:

NOTICE: Operate this product only outdoors and in an area

that will not allow this deadly exhaust gas to collect.

Never operate this product inside homes, garages,

basements, crawl spaces, sheds, under a deck, or other

partially enclosed areas and understand that using fans and

opening doors in these areas may not provide adequate

ventilation. Carbon monoxide can quickly accumulate in these

forbidden spaces and can remain in the air for several hours

after this product has shut off.

Installation Guidelines:

Follow all instructions and illustrations in this manual when

placing an enclosure.

Always point the generator’s engine exhaust away from

occupied areas. Never expose your neighbors’ homes to the

engine exhaust flowing from your standby generator during

the installation process.

Never place the standby generator in any area where leaves

or debris can accumulate.

Generator exhaust can enter through windows, doors, and

other openings of a structure. Understand that exhaust and

CO can seep into a structure through the smallest openings.

7

Not for

Reproduction

Protecting the Structure

Examine the structure to make sure that the sealing and caulking is sufficientenough to prevent air from leaking in or out.

Examine the structure for voids, cracks, or openings surrounding windows, doors, soffits, pipes, and vents, as these areas can

permit exhaust gas and Carbon Monoxide (CO) to enter the structure.

2

The table that follows includes examples of potential entry points for CO gas.

LOCATION ENTRY POINT EXPLANATION

A Windows and doors Openings that are part of a structure’s architecture can permit fresh air and CO into the structure, especially

when open.

B Garage door An open or improperly unsealed garage door can allow CO to flow into a garage.

C Attic vent Generator exhaust can enter through attic vents and the vents for soffits, crawl spaces, and ridges or roofs.

D Basement windows Basement windows or hatches that permit ventilation to or from the structure’s lower level also allow CO gas to

enter the structure.

E Furnace intake or exhaust

vent

Air intakes and furnace exhaust pipes are common entry points for CO gas.

F Wall cracks Any cracks in a structure’s walls, including the foundation and mortar, and any gaps around windows, doors,

and pipes can let CO in.

G Dryer vent Sometimes the exhaust vent for the clothes dryer lets CO gas into the structure.

H Airflow restrictions Areas featuring structural corners and heavy vegetation restrict the airflow and collect exhaust gas.

J Makeup air system Note: Keep all mechanical and gravity outdoor air intake openings for HVAC supply air systems 10 ft (3 m)

horizontally from the generator’s enclosure. Refer to section 401 in the ICC Mechanical Code for details on

requirements.

K Carbon monoxide

detector(s)

Note: Installing functioning CO alarms indoors is the only way to recognize CO gas. Common smoke alarms

do not detect CO gas and will not alert occupants of its presence.

8 BRIGGSandSTRATTON.COM

Not for

Reproduction

Reducing the Risk of Fire

WARNING

Exhaust heat/gases could ignite combustibles causing a fire, resulting in death or serious injury.

• Remove all combustible materials from in and around the generator compartment.

To help prevent fires, the generator must be installed a safe distance from all combustible materials. The unit’s engine,

alternator, and exhaust system components can become very hot during operation. Reduce the likelihood of a fire by keeping

the unit properly ventilated, properly maintained, free of fuel leaks, and away from combustible materials. Also, flammable

debris may collect within or outside the generator enclosure and may possibly ignite, causing a fire.

Distance Requirements

An owner must maintain minimum clearances around the generator enclosure. These clearances exist primarily for fire

prevention, but they also make sure that adequate space for maintenance tasks, such as removing the unit’s front, back,

exhaust outlet side, and air inlet side panels.

3

The table that follows explains the correct distances required for installation.

LOCATION ITEM EXPLANATION

A Front and end clearance Maintain a 3 ft (.91 m) minimum clearance from the front and ends of the generator. Keep shrubs, bushes,

plants, and trees this same minimum distance from the unit and never use vegetation to conceal the unit.

B Back clearance Since fuel and electrical connections occur here, keep 18 in (45.7 cm) minimum clearance per

independent testing laboratory, unless state codes tell you otherwise.

C Windows, vents, and openings Install the generator at least 5 ft (1.52 m) from all windows, doors, vents, window wells, or openings in the

wall. See Protecting the Structure section in this manual.

D Existing wall Keep the generator at least 18 in (45.7 cm) away from existing walls.

E Removable fence Keep removable fences at least 3 ft (.91 m) away from the front of the generator. Removable fences

include visual surrounds, fence panels, and temporary barriers without footings.

F Overhead clearance Maintain a 5 ft (1.52 m) minimum clearance from all structures, overhangs, projections on a wall, or trees.

G Maintenance and servicing

(not shown)

Allow adequate space to perform routine maintenance, such as servicing the engine and replacing the

battery. Never use shrubs, bushes, trees, or plants to conceal the generator.

9

Not for

Reproduction

Other General Location Guidelines

• Place the standby generator in a prepared location that

is flat and has provisions for water drainage.

• Install the standby generator in a location where sump

pump discharge, rain gutter down spouts, roof run-off,

landscape irrigation, or water sprinklers will not flood

the unit or spray the enclosure and enter any air inlet or

outlet openings.

• Install the standby generator where it will not affect or

obstruct any services (including covered, concealed and

underground), such as telephone, electric, fuel (natural

gas / LPG vapor), irrigation, air conditioning, cable,

septic, sewer, well and so forth.

• Install the standby generator where leaves, grass, snow,

etc will not obstruct air inlet and outlet openings. If

prevailing winds will cause blowing or drifting, you may

need to construct a windbreak to protect the unit.

Cold Weather Kits

If the generator operates in temperatures below 30 °F (-1 °C),

it is recommended that a Cold Weather Kit be installed.

Oil Sump Warmer Kit, Part Number 6840, includes:

• Oil sump warmer

• Install brackets

• Hardware

• Harness

Fuel Regulator Warmer Kit, Part Number 6845, includes:

• Regulator warmer

• Harness

Battery Warmer Kit, Part Number 6869, includes:

• Battery warmer

• Harness

These items are available at your local service dealer.

For more information, call 800-732-2989 between 8:00 AM

and 5:00 PM CT.

Lift the Generator

WARNING

Hazardous Voltage - Contact with power lines could cause

electric shock or burns, resulting in death or serious injury.

• If lifting or hoisting equipment is used, DO NOT contact

any power lines.

• DO NOT lift or move generator without assistance.

Correct tools, equipment, and qualified personnel must be

used in all phases of handling and moving the generator. The

approximate weight of the generator is listed in the Generator

Specifications section.

Use the lifting holes (A, Figure 4) in the base of the generator

to lift the generator onto the concrete slab or pad. Lift the

generator in accordance with the Occupational Safety and

Health Administration (OSHA) or local lifting regulations.

4

Anchor the Generator and Wind Ratings

Unless mandated by local or state codes, or required to

achieve wind rating, a concrete pad is not required for

anchoring the generator. For concrete pad mounting and

wind rating details, reference the Anchoring and Wind Rating

Diagram at the end of this manual.

Electrical and Fuel Inlet Locations

The .75 in (19 mm) N.P.T. fuel inlet connector (A) and

electrical inlet locations (B) are shown inFigure 5.

A 1.73 in (44 mm) knock-out hole is provided for the electrical

inlet. Make sure that the installed conduit(s) enter the unit in

zone (C) as shown in the drawing below so that they properly

enter the electrical box and do not interfere with the fully

opened roof.

5

10 BRIGGSandSTRATTON.COM

Not for

Reproduction

Access Panels:Installation and Removal

The generator enclosure has several access panels. The

access panels and the components located behind them are

referenced in the lists and images that follow (Figure 6):

• (A)Roof (controller, air filter, oil dipstick, and circuit

breaker)

• (B)Front Panel (oil drain, oil filter, battery)

• (C)End Cap,Air Inlet Side of Enclosure(control box

wiring cover, fuel regulator, fuel selector, generator data

label)

• (D)End Cap,Exhaust Outlet Side of

Enclosure(alternator fan)

• (E)Back Panel (engine starter, starter relay)

• (F)Control Box Wiring Cover (field wiring, control wiring)

Each generator is shipped with a set of identical keys

fastened to one of the end caps.

6

Open the roof (A, Figure 6):

1. Insert the key into the lock (G) of the front panel (B).

Gently push down on the roof above the lock to assist in

turning the key. Turn the key one-quarter turn clockwise.

2. Lift the roof (A) to the OPEN position.Make sure that the

roof (A) is in the open positionduring any panel removal

or attachment.

Remove the front panel (B):

1. Loosen the two self-retaining fasteners (H) that secure

the front panel (B) to the unit.

2. Lift the front panel (B) to remove it from the unit.

Attach the front panel (B):

1. Put the front panel (B) into the unit and align the tabs on

the frontpanel into the slots on the base.

2. Tighten the two self-retaining fasteners (H) to attach the

front panel (B) to the unit.

Remove theair inlet side end cap (C):

1. Loosen the two self-retaining fasteners (M)that secure

the endcap (C) to the unit.

2. Lift the end cap (C) to remove it from the unit.

Attachtheair inlet sideend cap(C):

1. Put the end cap (C) into the unit and align the tabs on the

end cap into the slots on the base.

2. Tighten the two self-retaining fasteners (M) that secure

the end cap (C) to the unit.

Removeexhaust outlet sideend cap (D):

1. Loosen the two self-retaining fasteners (J)that secure

the endcap (D) to the unit.

2. Lift the end cap (D)to remove it from the unit.

Attach theexhaust outlet sideend cap (D):

1. Put the end cap (D) into the unit and align the tabs on the

end cap into the slots on the base.

2. Tighten the two self-retaining fasteners (J) that secure

the end cap (D) to the unit.

Remove the back panel (E):

1. Using a Phillips head screw driver, loosen two self-

retaining fasteners (K) that secure the back panel (E) to

the unit.

2. Using a standard blade screw driver, gently lift the back

panel (E) lip off of the back rail.

3. Tip the back panel (E) back under the roof (A).

4. Move to the back of the unit and lift the back panel (E)

off.

Attach the back panel (E):

1. Move to the back of unit and place back panel (E) into

the unit, aligning the tabs on the back panel into the slots

on the base.

2. Tip the back panel (E) forward under the roof (A).

3. From the front or side of the unit, align the fasteners (K)

and tighten with a Phillips head screw driver.

Remove the control box wiring cover (F):

1. Remove two fasteners (L) that secure the control box

wiring cover (F) to the control box.

2. Tip the control box wiring cover (F) down to access field

and control wiring.

Attach the control box wiring cover (F):

11

Not for

Reproduction

1. Tip the control box wiring cover (F) up.

2. Attach the control box wiring cover (F) with the two

fasteners (L).

Fuel Installation Plan

WARNING

Propane and Natural Gas are extremely flammable and

explosive, which could cause burns, fire or explosion resulting

in death or serious injury.

• Installation must be performed by a licensed

professional.

• Install the fuel supply system according to NFPA 37 and

other applicable fuel-gas codes.

• Before placing the generator into service, the fuel

system lines must be properly purged and leak tested.

• NO leakage is permitted.

• DO NOT operate engine if smell of fuel is present.

WARNING

Propane and Natural Gas are extremely flammable and

explosive, which could cause burns, fire or explosion resulting

in death or serious injury.

• DO NOT operate the equipment if the fuel shut-off valve

is missing or inoperative.

WARNING

Propane and Natural Gas are extremely flammable and

explosive, which could cause burns, fire or explosion resulting

in death or serious injury.

• LP gas is heavier than air and will settle in low areas.

• Natural gas is lighter than air and will collect in high

areas.

• The slightest spark could ignite these fuels and cause

an explosion.

• DO NOT allow any open flame, spark, heat, or lit

cigarette.

NOTICE: DO NOT install the supplied flexible fuel line

underground or in contact with the ground.

Keep the entire flexible fuel line visible for periodic inspection.

Do not conceal it or run it within any wall, floor, or partition.

Never let the line contact these structures.

NOTICE: DO NOT bend the supplied flexible fuel line.

The following information addresses the planning phase

of installations for technicians specializing in gaseous fuel

systems. Always obey the local applicable fuel-gas codes

affecting the installation site. Consult your local fuel supplier

or fire marshal with any questions or problems.

TO THE INSTALLER: Consult with the generator owner(s)

and address any technical considerations affecting their

installation plans before applying these guidelines.

The general rules that follow apply to piping on gaseous fuel

systems:

• The piping material must follow federal and local codes,

with rigid mounting and protection against vibration.

• Protect piping from physical damage, especially where

it passes through flower and shrub beds and other

cultivated areas where damage can occur.

• Install the provided flexible fuel line(B, Figure

7)between the generator fuel inlet port (A) and the rigid

piping to prevent excessive stress on the piping material

due to thermal expansion and contraction.

• Provide a union (C) or flanged connection downstream

to allow for future removal.

• Install a manometer test port (D) for vapor fuels.

Use the port to install a manometer and check if the

engine receives the proper fuel pressure adequate for

operation. See the service center for a digital or analog

manometer designed for vapor fuels only (part number

19495). After completing the initial test runs, remove the

manometer and plug the port.

• For vapor fuels only: Protect piping from freezing in

areas that are prone to the formation of hydrates or ice.

When terminating hard piping, use a sediment trap (E)

where condensate liquid cannot likely freeze.

• Install a minimum of one accessible, approved manual

shut-off valve (F) in the fuel supply line within 6 ft (1.8

m) of the generator.

• Install a manual shut-off valve in the interior of the

building.

• Increase strength and flexibility of the piping supports

and connections in areas prone to earthquakes,

tornados, flood hazards, and unstable ground.

• Make sure that the size of the piping is adequate

enough to maintain the required supply pressures and

volume flow under varying generator load conditions,

with all gas appliances connected to the fuel system

turned on and operating.

• Use a pipe sealant or joint compound approved for use

with natural gas/liquefied petroleum on all threaded

fittings to reduce the possibility of leakage.

NOTICE: Keep thread sealant out of the gas piping to

prevent damage to component parts.

• Purge and leak-test piping according to applicable

codes and standards.

12 BRIGGSandSTRATTON.COM

Not for

Reproduction

7

• (A)Generator Fuel Inlet

• (B)Flexible Fuel Line

• (C)Union Fitting

• (D)Manometer Test Port

• (E)Sediment Trap

• (F)Manual Shut-off Valve

Fuel Consumption

Estimated fuel supply requirements at half and full load for

Liquified Petroleum Vapor (Propane) and Natural Gas (NG)

fuels are shown in the table that follows:

Liquified Petroleum Vapor Fuel (Propane)

17kW 18kW 20kW 22kW 26kW

Full

Load

ft3/hr

(m3/hr)

118

(3.4)

124 (3.6) 135

(3.9)

147

(4.3)

171

(4.9)

gal/hr (L/

hr)

3.3

(12.2)

3.5 (12.8) 3.7 (14) 4.1

(15.3)

4.70

(17.7)

BTU/

hr(MJ/

hr)

295,000

(312)

310,000

(327)

338,000

(356)

368,000

(388)

427,000

(450)

1/2 Load ft3/hr

(m3/hr)

74 (2.1) 77 (2.2) 83 (2.4) 87 (2.5) 94 (2.7)

gal/hr (L/

hr)

2.10

(7.7)

2.2 (8.0) 2.3

(8.6)

2.4 (9.0) 2.60

(9.7)

BTU/hr

(MJ/hr)

185,000

(196)

193,000

(204)

208,000

(219)

217,000

(229)

235,000

(248)

Natural Gas (NG)

17kW 18kW 20kW 22kW 26kW

Full

Load

ft3/

hr(m3/

hr)

248

(7.1)

252 (7.2) 260

(7.4)

281

(8.0)

323

(9.2)

BTU/

hr(MJ/

hr)

248,000

(262)

252,000

(267)

260,000

(275)

281,000

(297)

323,000

(341)

1/2 Load ft3/

hr(m3/

hr)

170

(4.9)

176 (5.1) 187

(5.3)

194

(5.5)

206

(5.9)

BTU/hr

(MJ/hr)

170,000

(180)

176,000

(186)

187,000

(198)

194,000

(205)

206,000

(218)

Physical

Properties

Natural Gas Propane (LP

Vapor)

Normal Atmospheric

State

Gas Gas

Boiling Point°F (°C) -259 (-167) -44 (-42)

Heating Value

BTU/gal (MJ/L)

liquid(Net LVH*)

63,310 (17.65) 83,340 (23.23)

BTU/gal (MJ/L)

liquid(gross**)

N/A 91,547 (25.52)

BTU/ft3 (MJ/m3) gas* 1,000 (37.26) 2,500 (93.15)

Density - ft3/gal (m3/L) 57.75 (0.43) 36.39 (0.27)

Weight -lb/gal (kg/L) 2.65 (0.32) 4.24 (0.51)

*LHV (Low Heat Value) is the more realistic rating.

**Gross heat value does not consider heat lost in the form of

water during combustion

Fuel Type

Consider the type of fuel that your generator uses, as it

affects the entire installation process. The system was factory

tested and adjusted using natural gas, but it can be converted

to use liquefied petroleum vapor. For correct engine function,

consider factors that affect each of these fuels, such as the

location and the duration of possible utility interruptions.

When choosing fuel type, obey these guidelines that follow:

• Use a clean, dry fuel that is free of moisture or

any particulate material. Using fuels outside the

recommended values can cause performance problems.

• In engines set up to run on propane (liquefied

petroleum), You must use commercial-grade HD-5

propane.

Natural gas or LP engines are certified to operate on natural

or liquid propane gas. The emissions control system for this

engine is EM (Engine Modifications).

Fuel Pressure

Bothliquefied petroleum (LP) and natural gas (NG) fuel

supply pressure at the generator’s fuel inlet port must be a

minimum value at full load with all gas appliances turned on

and in operation.

Natural Gas must be 3.5 to 7 in (89 to 178 mm) Water

Column (WC).

Liquefied Petroleum must be 11 to 14 in(279 to 356

mm)WC.

Make sure that all gas line shut-off valves are OPEN and

that adequate fuel pressure is available whenever automatic

operation is needed.

Power Loss

Engine power will decrease 3.5% for each 1,000 feet (300

meters) above sea level and 1% for each 10°F (5.6 °C) above

77 °F (25 °C).

13

Not for

Reproduction

Fuel Conversion

The engine of your generator system is factory calibrated and

set to operate on natural gas (NG). It may also be operated

on liquefied petroleum (LP) vapor.

NOTICE: Units are set to NG at the factory.

To convert to either fuel, do the steps that follow:

1. Unlock and open the roof as described in the Access

Panels section of this manual.

2. Push the controller OFF button.

3. Remove the 15 amp fuse from the fuse holder (see fuse

location in the Features and Controls section).

4. Remove utility power to generator to de-energize the

battery charger.

5. Disconnect the negative (-) cable at the battery.

6. Remove theair inlet sideend cap.

7. Find the fuel selector valve (A, Figure 8) on top of the

fuel regulator (B).

8

8. Set Fuel Selector:

a. For LP, rotate the lever (C, Figure 9)on the fuel

selector valve until LP is aligned with “OUT” on the

fuel regulator.

9

b. For NG, rotate the lever clockwise 90° so the handle

position of the lever will be up and down and the

“NG” letters (D, Figure 10) will be on the left.

10

14 BRIGGSandSTRATTON.COM

Not for

Reproduction

9. Find the fuel selector switch (E, Figure 11).

11

10. Select either LP or NG.

11. Connect the negative (-) cable at the battery.

12. Install the air inlet sideend cap.

13. Install 15 amp fuse(see fuse location in the Features and

Controls section).

14. Push and hold the CONFIG button to access the

configuration menu.

15. Push SELECT to edit the items in the configuration

menu.

16. To set up the generator’s controller for LP fuel, enter the

configuration menu by using the dealer password, which

is available on the Power Portal.

17. Navigate to “select profile” and push “select” on the

correct profile for the generator. For example, choose

“20KW_LP” for operating a 20kW unit running on LPfuel.

NOTICE: Selecting a profile that is not intended for the

generator can cause the generator to run erratically and could

result in damage.

18. To save the new fuel setting, push and hold the CONFIG

button until “Saving Settings…” displays.

19. For additional information on the operation of the

generator controller please refer to the "Operation

Instructions GC1030 Series GENSET Controller" manual

associated with your generator.

20. Restore utility power to generator.

21. Push the control board AUTO button.

22. Close and lock the roofas described in the Access

Panels: Installation and Removal section of this manual.

15

Not for

Reproduction

Electrical Field Connections

WARNING

Generator and utility voltage could cause electrical shock or burn resulting in death or serious injury.

• Installation must be performed by a licensed professional.

• Disconnect all sources of electricity before installing or servicing equipment.

• Ground system before applying power.

WARNING

Hazardous Voltage - Installing low and high voltage wire in same conduit could cause electric shock or burns, resulting in

death or serious injury.

• Do not run low and high voltage wire in the same conduit unless the insulation rating on ALL wiring is rated for 600 V.

See NFPA 70 for more information.

Low Voltage connections are made via a field connections terminal block (E, Figure 12) in main electrical area. Compare this

illustration with your generator to familiarize yourself with the location of these connections.

12

Legend for System Connector Location(Figure 12):

• (A)Utility and Field Connections Terminal Block — Connects utility 240 VAC from the fuse block in ATS to the controller.

Connect only one wire per terminal. Reference the table that follows for field connections.

• (B)Transfer Switch Connection — Controls the transfer switch contactor.

• (C)Two-wire Start — Helps provide optional remote start contact.

• (D)E-Stop — Use with the optional external E-Stop.

• (E)Power Connection (L1 and L2) — Offers power connection to the transfer switch.

• (F)Ground Connection — Connects to the transfer switch ground wire.

16 BRIGGSandSTRATTON.COM

Not for

Reproduction

• (G)Neutral Connection — Connects to the transfer switch neutral wire.

• (H)Communications Terminal Block — Reference the table that follows:

Pin Number Description Wire Type Connect To Notes

1 +12V # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

Transfer Switch Basic

Controller J7-8 12 VDC

2 GND # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

Transfer Switch Basic

Controller J7-7 GND

3 Xfer # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

Transfer Switch Basic

Controller J7-4 T/R

Transfer Switch Transfer

Signal (only works with Basic

Transfer Switch Controller)

4 2-WIRE START # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

5 2-WIRE START # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

Refer to the Transfer Switch

manual to verify if this function

is available

Contact Close for GENSET

Start. (Only for Transfer

Switch that provides this

option).

Mains monitoring must be

disabled in the controller

6 E-STOP # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

E-Stop Switch

7 E-STOP # 18

AWG[1mm2]conductors, 600

V minimum, 90° C Cu wire

E-Stop Switch

Contact Open to Shutdown

GENSET

8 Not Used - - -

9 VIN+

(+12V)

# 18

AWG[1mm2]conductors, 600

V minimum, 90° C Cu wire

Refer to the Amplify Gateway

manual

10 (D+) # 18 AWG[1mm2]

conductors, 600 V minimum,

90° C Cu wire

11 (D-) #18

AWG[1mm2]conductors,

600V minimum, 90° C Cu

wire

12 GND # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

Comm to WIFI module

Twisted pair #1: +12 V and

GND

Twisted pair #2: (D+) and (D-)

13 +12V # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

14 (A) # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

15 (B) # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

16 GND # 18 AWG

[1mm2]conductors, 600 V

minimum, 90° C Cu wire

Refer to the InfoHub™

Premium manual

Comm to Cellular Module

Twisted pair #1: +12 V and

GND

Twisted pair #2: (A) and (B)

25 UTILITY # 14 AWG [2.5mm2]600 V

minimum, 90° C Cu wire

Transfer Switch Utility

26 UTILITY # 14 AWG [2.5mm2]600 V

minimum, 90° C Cu wire

Transfer Switch Utility

Delivers power to the

generator’s battery charger,

controller, optional battery

warmer, optional oil warmer,

and optional fuel regulator

warmer. Also, when voltage

on these leads is lost in AUTO

Mode, generator will start if

Mains Monitoring is enabled

(default setting)

• For power output connection (L1, L2, Neutral (N), and Ground), refer to the National Electric Code (NEC) and local

codes.

• For communication wires use 600 V wire and # 18 AWG (1 mm2) twisted-pair conductors that do not exceed a length of

500 ft (150 m).

17

Not for

Reproduction

• When connecting to the terminal block, fasten only one wire to each connector screw.

• Torque terminal block screws to 4.4 in-lb [0.5 Newton meter (N·m)].

Connection Specifications: 17kW through 22kW

Connection Temperature Rating Recommended Wire Size

(AWG)

Torque Specifications

Circuit Breaker N/A N/A N/A

Field Connection Terminal 167°F(75°C) 2 to 14 CU

2 to 8 AL

2 to 3 AWG:50 in-lbs(5.64 Nm)

4 to 6 AWG: 45 in-lbs(5.08 Nm)

8 AWG:40 in-lbs(4.52 Nm)

10 to 14 AWG: 35 in-lbs(3.95 Nm)

Connection Specifications: 26kW

Connection Temperature Rating Recommended Wire Size

(AWG)

Torque Specifications

Circuit Breaker N/A N/A N/A

L1, L2, and N Terminal(copper or

aluminum)

140 °F/ 167 °F(60 °C/ 75 °C) 2/0 to 14 CU/AL 2/0 to 6 AWG: 120 in-lbs (13.56 Nm)

8 to 14 AWG: 40 in-lbs(4.52 Nm)

Ground Lug (copper or aluminum) 194 °F(90°C) 2 to 14 CU

2 to 8 AL

50 in-lbs(5.64 Nm)

AC System Connections

The generator uses a single-phase, three-wire AC connection

system(Figure 13). The stator assembly consists of a pair

of stationary windings with two leads appearing from each

winding. The junction of leads 22 and 33 forms the neutral

lead.

NOTICE: Neutral is not bonded to ground at generator.

NOTICE: The generator must be used with an UL listed

transfer switch that is compatible with the generator.

Only use the generator with a listed transfer switch that is

compatible with the generator.

13

Ground the Generator

Unless mandated by local code, additional chassis grounding

to earth at the generator is not required. Any grounding at

the generator must use paint-piercing lock washers (or their

equivalent). Any listed terminals must be installed per the

18 BRIGGSandSTRATTON.COM

Not for

Reproduction

terminal supplier’s instructions. All grounding and terminal

installations must comply with national electrical codes and

local requirements.

Engine Oil

NOTICE: Any attempt to crank or start the engine before it

has been correctly filled with the recommended oil will result

in equipment failure and service codes.

• Refer to Maintenance in the Operation section of this

manual for oil fill information.

• Damage to equipment resulting from failure to obey this

instruction will void the engine and generator warranty.

This engine ships from the factory pre-run and filled with

full synthetic oil (API SJ/CF 5W-30). This allows for system

operation in a wide range of temperature and climate

conditions. Before starting the engine, check the oil level as

described in the Maintenance section of this manual.

The use of full synthetic oil does not alter the required oil

change intervals described in the Operation section of this

manual.

Battery

WARNING

Storage batteries give off explosive hydrogen gas during

recharging. Slightest spark could ignite hydrogen and cause

explosion, resulting in death or serious injury.

• DO NOT dispose of battery in a fire. Recycle battery.

• DO NOT allow any open flame, spark, heat, or lit

cigarette during and for several minutes after charging a

battery.

• Discharge static electricity from body before touching

batteries by first touching a grounded metal surface.

WARNING

Battery electrolyte fluid contains acid and is extremely

caustic. Contact with battery contents could cause severe

chemical burns.

• DO NOT open or mutilate the battery.

• Wear protective goggles, rubber apron, rubber boots

and rubber gloves.

• Immediately wash electrolyte from skin with water.

• If electrolyte contacts eyes, immediately flush with water

and seek medical attention.

• Spilled electrolyte is to be washed down with an acid

neutralizing agent.

• A common practice is to use a solution of one pound

(500 grams) bicarbonate of soda to one gallon (4 liters)

of water. The bicarbonate of soda solution is to be

added until the evidence of reaction (foaming) has

ceased. The resulting liquid is to be flushed with water

and the area dried.

The installer must supply and install a rechargeable 12 V

starting battery. The starting battery MUST conform to the

specifications shown in the chart that follows.

Battery Specifications

Specifications Standard Cold Start (Less

than 30 °F / -1 °C)

Volts 12 VDC 12 VDC

Amps (Minimum) 540 CCA (Cold

Cranking Amps)

800 CCA(Cold

Cranking Amps)

Construction Wet Lead Acid Wet Lead Acid

Terminal Type Top Post Type Battery Top Post Type Battery

Dimensions (Maximum) BCI Size 26 or BCI Size

51

BCI Size 24

WARNING

With the battery connected, the generator could crank and

start without warning resulting in death or serious injury.

• Do not connect the negative (-) cable at the battery until

the installation is complete.

Install the battery as described in Servicing the Battery in

the Maintenance section of this manual. Make sure that

the NEGATIVE cable is connected last and that the red

POSITIVE terminal insulator is secure.

System Controller

The generator's controller, located inside the generator

housing, is shown in the image that follows (Figure 14).Brief

descriptions of the controls used during installation are:

• (A)Menu/Programming Navigation Buttons

• (B)Stop/Config Button

• (C)Start/Select Button

• (D)Auto/Manual Button

• (E)Alarm

• (F)Digital Display — Displays generator mode, menu

options, and alarms

NOTICE: Detailed descriptions of the controls are located

in the Description of Control Keys section insidethe online

"Operation Instructions GC1030 Series GENSET Controller"

manual associated with your generator.

19

Not for

Reproduction

14

Initial Start-Up (No Load)

WARNING

Exhaust heat/gases could ignite combustibles causing a fire,

resulting in death or serious injury.

• Remove all combustible materials from in and around

the generator compartment.

The unit has been set up for natural gas (NG) operation at the

factory.Fuel conversion must be completed prior to doing the

steps that follow.See the Fuel Conversion section.

Before operating the standby generator or putting it into

service, inspect the entire installation carefully. Then begin

testing the system without electrical loads connected, as

follows:

NOTICE: When the generator starts for thefirst time, it

purges air from the gaseous fuel lines. This process can

cause the engine to run roughly for a few minutes.

1. Remove the two screws(A, Figure 15)retaining the

control box wiring cover. Remove the cover.

2. Connect an accurate multimeter to the line side of the

generator’s main circuit breaker.

3. Set the generator’s main circuit breaker to the ON

(closed) position.

4. Install a 15 amp fuse in the fuse holder below the

controller(see fuse location in the Features and Controls

section).

5. Push the start/select button on the controller. The engine

starts in Low Idle Mode (LIM).

6. Push the button again to bring the engine to full speed.

7. Listen for unusual noises, vibrations, or other indications

of abnormal operation. Check for oil leaks while the

engine runs.

8. Let the engine warm up for approximately five minutes to

allow the internal temperatures to stabilize.

9. Examine the generator output at the load side of the

circuit breaker. The voltage should be 225 to 250 V and

the frequency should be 59 to 61 Hz.

10. Examine the generator output between one generator

connection lug and a neutral lug, then between the

other generator connection lug and a neutral lug. In both

cases, the voltage reading should be 112 to 125 V.

11. Push the STOP/CONFIG button on the controller. The

engine enters cool-down mode for approximately five

minutes. Push the button again to stop the engine.

12. Install the control box cover.

15

20 BRIGGSandSTRATTON.COM

Not for

Reproduction

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

Simplicity MANUAL, OPERATOR'S AND INSTALLATION Manuel utilisateur

- Catégorie

- Groupes électrogènes

- Taper

- Manuel utilisateur

dans d''autres langues

Documents connexes

-

Simplicity 080084 Manuel utilisateur

-

Simplicity 076071-00 Guide d'installation

-

Simplicity 076030-0 Guide d'installation

-

Simplicity 076072-00 Guide d'installation

-

Simplicity 076070-00 Guide d'installation

-

Simplicity 076830-00 Manuel utilisateur

-

Simplicity 076150-01 Guide d'installation

-

Simplicity MANUAL, OPERATOR'S AND INSTALLATION Manuel utilisateur