Apollo 51000-300 Manuel utilisateur

- Catégorie

- Détecteur de fumée

- Taper

- Manuel utilisateur

Ce manuel convient également à

APD0671 A160301

© 2016 Apollo Fire

Copyright © 2016 l 1

51000-300

WIRELESS SMOKE ALARM INTERCONNECT BASE

GENERAL INFORMATION

The Wireless Smoke Alarm Interconnect Base part number 51000-300 is a 120V AC

powered sensor. It monitors the interconnect line on interconnected hardwired smoke

alarm systems and sends out a transmission when any of the smoke alarm units on the

same circuit enter an alarm state. The device has LEDs to visually indicate the status of the

interconnect base. A single CR2032 ba ery provides backup power in the event that AC

power is lost on the alarm system circuit. The Wireless Smoke Alarm Interconnect Base

communicates with a compa ble control panel and can send alarm, low ba ery, AC power

loss, and supervisory messages to the system's receiver.

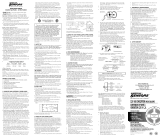

Contents of Carton:

• 1 Wireless Smoke Alarm Interconnect Base

• 2 2" long 10-32 Screws

• 1 CR 2032 3 Volt Coin Ba ery

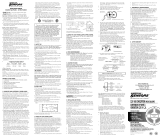

Figure 1. 51000-300 Kit

IMPORTANT: This device must be tested and maintained regularly. This device is intended

for use with compa ble smoke alarms, but will not detect the presence of smoke, heat, or

re directly.

✓ Note: Each of the smoke alarms part of interconnected smoke alarms must be:

• Present in every required loca on per NFPA 72,11.5.1

• Con rmed as less than ten years from date of installa on (or manufacture). Please

check label on the device or original smoke detector device manual.

• Hardwired to a single, common 120V AC circuit designated for interconnected smoke

alarms.

• Pass the manufacturer's stated tes ng regimen to con rm proper interconnect

opera on.

• Have fresh back-up ba eries.

• On the list of compa ble models (any model not listed may work but has not been

compa bility tested).

• This device shall not be installed in loca ons where the normal ambient temperature

is below 40F(4.4C) or exceeds 100F (37.8C), unless the alarm has been determined

capable of being used at installa on points with higher or lower ambient temperatures.

• Please see sec on at the end regarding informa on on the proper installa on of smoke

alarms that are intended to work with the Wireless Smoke Alarm Interconnect Base.

This device is not intended to work with smoke alarms paired with smoke alarm guards,

unless the combina on has been evaluated and found suitable for this purpose.

Compatible Smoke Alarm Models

• BRK Brands Model 7010B: AC Powered Photoelectric Smoke Alarm with Ba ery

Backup

• Firex Kidde Model i4618: Hardwire Ioniza on Smoke Detector with Ba ery Backup

• First Alert BRK Model 9120B: Hardwired Smoke Alarm with Ba ery Backup

• Kidde Model i12040: 120V AC Wire-in Smoke Alarm with Ba ery Backup

• USI Electric Model 5304: Hardwired Ioniza on Smoke and Fire Alarm with Ba ery

Backup

CAUTION: Before a emp ng installa on, locate the primary electrical circuit that

powers the interconnected hardwired smoke alarm system and shut o or disconnect

power to this circuit. An electrical shock hazard is present if this electrical circuit is not

temporarily disabled during installa on.

AVERTISSEMENT: Avant de commencer l’installa on, trouver le circuit électrique

principal qui alimente le système câblé de détec on de fumée interconnecté

et l’éteindre ou couper l’alimenta on de ce circuit. Un risque d’électrocu on

est présent si ce circuit électrique n’est pas temporairement coupé pendant

l’installa on.

WARNING: Remember to turn on or reconnect power to the primary electrical circuit

that powers the interconnected hardwired smoke alarm system. The re warning system

may be disabled if electrical power is not restored to the system.

ATTENTION : Ne pas oublier d’établir ou de rétablir le courant du circuit électrique

principal qui alimente le système câblé de détec on de fumée interconnecté. Le

système d’alerte incendie serait inopérant si le courant électrique alimentant le

système n’était pas rétabli.

Install Wireless Interconnect Base

Select a smoke alarm that will be used to provide power and communicate to the

wireless interconnect base. Any smoke alarm that is within range of a compa ble

wireless receiver can be selected if the smoke alarm is part of an interconnected

hardwired system.

Remove the exis ng smoke alarm from the exis ng moun ng bracket. This is

usually done by twis ng the alarm counter clockwise or clockwise from where it

is mounted.

Figure 2. Remove Exis ng Smoke Alarm from Smoke Alarm Moun ng Base

Figure 3. Unplug Pigtail of Exis ng Smoke Alarm

Unplug the exis ng smoke alarm from the smoke alarm pigtail. Loosen the two screws

used to hold the exis ng moun ng bracket and remove it from the wall or ceiling.

Figure 4. Remove Exis ng Smoke Alarm Moun ng Bracket from Wall or Ceiling

Figure 5. Install Wireless Smoke Alarm Interconnect Base between Wall and

Moun ng Bracket

Place the interconnect base where the exis ng moun ng bracket was located. Make

sure the wire/wiretaps are inserted through the center opening of the smoke alarm

moun ng bracket.

Place the exis ng smoke alarm moun ng bracket on top of interconnect base. Align the

interconnect base and the smoke alarm moun ng bracket and replace the two screws

used to hold the bracket in place. Tighten all screws down.

✓ NOTE: It is suggested that the smoke alarm sensor LEDs be oriented towards the

bo om or in a manner that allows the LEDs on the unit to be visible.

Figure 6. Wiretaps/Wires, & Pigtail through Center

PRINTER’S INSTRUCTIONS:

INSTR,INSTL,APOLLO WIRELESS SMKE ALARM INTERCONNECT BASE - P/N: 10011636 X1- INK: BLACK - MATERIAL: 20 LB. MEAD BOND - SIZE: 8.500” X 11.000” - TOL. +/- .125”- SCALE: 1-1 - FOLDING: FOLD 1X TO FINAL SIZE: 8.500" X 5.500"- FINISH WITH LOGO

SHOWING

+

CR2032

3V

WIRELESS SMOKE ALARM

INTERCONNECT BASE

WIRETAPS

CR2032

COIN BATTERY

10-32 X 2”

SCREWS

SMOKE

EXISTING

SMOKE

ALARM

MOUNTING

BASE

EXISTING

SMOKE

ALARM

ROTAT E

COUNTER

CLOCKWISE

TO REMOVE

EXISTING SMOKE

ALARM

EXISTING SMOKE ALARM

MOUNTING BRACKET

UNPLUG

SMOKE ALARM

FROM EXISTING

POWER PIGTAIL

REMOVE EXISTING SMOKE

ALARM MOUNTING

BRACKET FROM WALL OR

CEILING

EXISTING

SMOKE

ALARM

POWER

PIGTAIL

ACCESS HOLE

IN WALL OR

CEILING

REMOVE

EXISTING

SCREWS

WIRELESS SMOKE

ALARM INTERCONNECT

BASE

EXISTING SMOKE ALARM

MOUNTING BRACKET

EXISTING

POWER

PIGTAIL

WALL ACCESS HOLE

WIRETAPS (3)

(NOT CONNECTED)

WIRELESS SMOKE

ALARM INTERCONNECT

BASE

EXISTING

SMOKE

ALARM

MOUNTING

BRACKET

EXISTING

POWER

PIGTAIL

WIRETAPS (3)

(NOT CONNECTED)

MOUNT BRACKET

WITH LED’S AT BOTTOM

Apollo

WIRELESS SMOKE ALARM INTERCONNECT BASE

MODEL 51000-300

APD0671 A160301

© 2016 Apollo Fire

2 Copyright © 2016

Figure 7. Crimping Wiretaps onto Wires

Figure 8. Wiretap Connec ons

Wiring the Connections

Before connec ng the wires from the interconnect base, iden fy the (+) line (hot)

120VAC wire and the neutral wire. Usually the (+) line (hot) 120VAC wire will be black

and the neutral wire white. Use a voltmeter or voltage sensor to verify that the proper

wires are selected. You may need to reconnect power to the electrical circuit powering

the interconnected hardwired smoke detectors in order to do this (Figure 8).

WARNING: Remember to disconnect or shut o electrical power to the interconnected

hardwired smoke detector if it was powered on in the previous step to iden fy the

120VAC wires.

Use an electrician’s linesman plier or equivalent tool (See Figure 8) and using the installed

wiretaps on the device, crimp the wiretap with the black wire onto the 120VAC line

(hot) wire.

ATTENTION : Ne pas oublier de déconnecter ou couper le courant électrique pour le

détecteur de fumée câblé s’il avait été alimenté auparavant pour iden er les ls 120 AC.

U liser une pince d’électricien ou un ou l équivalent (voir image 8) et en u lisant les

connecteurs installés sur l’appareil, ser r le connecteur avec le l noir sur la ligne 120VAC

(posi f).

✓ NOTE: Wiretaps must be used on a sec on of stranded wire. This is typically located

between the connector to the smoke detector and the wire nut.

The wiretap with the yellow wire should be a ached to the wire lead connected to the

interconnect wire of the smoke detector. This wire is typically yellow or orange.

Once all (3) three wiretaps have been installed (Figure 8), rea ach the electrical wire

pigtail to the back of the smoke detector unit and mount the smoke alarm on the

moun ng base (Refer to Figure 3).

Installing the Back-Up Battery

Figure 9. Installing Back-up Ba ery

WARNING: Ensure that the interconnect base has been wired correctly. Damage to

the interconnect base may occur if the 120 VAC line (hot) wire neutral wire are reversed.

The unit may fail to func on properly if incorrectly wired.

Turn on or reconnect power to the primary electrical circuit that powers the

interconnected hardwired smoke alarm system. The device should now power on.

Use a at bladed tool, slide out the ba ery tray that holds the backup ba ery. Insert

a CR2032A ba ery (included) into the ba ery slot. Slide the ba ery tray back into the

device (Figure 9).

ATTENTION : S’assurer que le détecteur de fumée a été branché correctement. Le capteur

du détecteur de fumée pourrait être endommagé si le l de la ligne 120AC (posi f) et

le l neutre sont inversés. L’appareil pourrait ne pas fonc onner correctement s’il était

mal branché. Etablir ou rétablir le courant du circuit électrique principal qui alimente

le système câblé de détec on de fumée. L’appareil devrait à présent s’allumer. U lisant

un ou l à lame plate, coulisser le roir de la pile de sécurité. Insérer une pile CR2032A

(incluse) dans l’emplacement. Coulisser à nouveau le roir pour le refermer (image 9).

✓ NOTE: Orient the (+) ba ery terminal up so that it is visible when facing the unit.

Programming the Wireless Smoke Alarm Interconnect Base

Follow the instruc ons on how to program a sensor into a compa ble control panel. See

the control panel’s Installa on & Programming Guide for more informa on on how to

learn a sensor into the control panel.

The device should learn in as a sensor device. Use a small paper clip or other sharp

object and carefully insert into the learn/test bu on hole. This will send out an alarm

transmission ID so the the sensor can be learned into a compa ble control panel or can

be used to test that the transmi er is working properly.

Replacing the Battery

If the compa ble control panel shows that this sensor has a low ba ery, the backup

ba ery may need to be replaced.

Use a at headed screw driver or other tool to slide the ba ery tray out of the device.

Remove the ba ery from the tray and replace with a new CR2032A ba ery. Slide the

ba ery tray back into the unit, making sure that the tray is fully inserted into the unit.

✓ NOTE: Use Panasonic CR2032A ba eries or equivalent. Use of another ba ery may

damage or nega vely a ect the opera on of the device.

End-of-Life

The Wireless Smoke Alarm Interconnect Base does not have an End-of-Life (EOL), however

the smoke alarm(s) that this device monitors may have an EOL condi on. Follow the

owner's manual for the smoke alarm regarding instruc ons on proper smoke alarm EOL

condi ons.

LED Status

Status LEDs Radio Signaling

PowerOn Sequential green, orange, red fl ashes N/A

Normal Green LED fl ash every 48s N/A

Alarm Red fl ash every 1s Alarm

Loss of AC Power

Fault

Orange fl ash every 20s Tamper

Low Battery Fault Orange fl ash every 4s Low Battery

Learn Button Sequential green, orange, red fl ashes Alarm

Testing the Smoke Alarm System

Figure 10. Loca on of LEDs and Learn/Test Bu on Hole

The device should be tested in accordance with NFPA 72 guidelines. The following

instruc ons are intended to provide a general guideline on how to test the smoke alarm

system, wireless smoke alarm interconnect base and communica ons to an alarm panel.

Follow the smoke alarm instruc on manual on tes ng the smoke alarm and any

interconnected units. There usually is a test bu on on the smoke alarm that can be

pressed to ini ate a test mode. This should cause the sounder to alarm and also any

smoke alarms that are interconnected to also alarm.

The interconnect base should send out a transmission to a compa ble alarm panel.

If this transmission is not received, rst check if the Smoke alarm is properly programmed

into a compa ble alarm panel. Please follow the alarm panel instruc ons on learning in

a sensor.

Also, check that the interconnect wire on the smoke alarm is properly connected to the

Wireless Smoke Alarm Interconnect Base. The LEDs on the interconnect base should

ash red indica ng that it has received the alarm signal from the smoke alarm .

Testing the Wireless Smoke Alarm Interconnect Base Radio Trans-

mission Only

The Wireless Interconnect Base incorporates a small test bu on. This test bu on can be

ac vated by inser ng a straightened paper clip or sharp object into the Learn/Test hole.

The Smoke Detector Sensor will then send an alarm signal transmission to a compa ble

alarm panel. This can be used to test that the Wireless Smoke Alarm Interconnect Base

will send a proper transmission to an alarm panel. This DOES NOT test if the wiring

between the smoke alarm and the interconnect base is correct.

Troubleshooting Installation Chart

When tes ng the Wireless Smoke Alarm Interconnect Base sensor, check for these

common issues.

Condition

Smoke Alarm

Result Resolution

Wireless Smoke Alarm

Interconnect Base LED

Alarm Panel

Smoke detector is in

alarm mode

LED on interconnect base

do not work properly

Alarm panel does not

receive alarm signals

Check to make sure

interconnect wire from

the smoke alarm is

properly connected to the

interconnect base

Smoke detector is in

alarm mode

LED on interconnect base

sensor works properly

Alarm panel does not

receive alarm signals

Check to make sure

the interconnect base

is properly learned or

programmed into a

compatible alarm panel

EXISTING

POWER

PIGTAIL

WIRETAPS (3)

CRIMPED

TO PRIMARY

CIRCUIT WIRES

WIRING CODE:

• BLACK TO BLACK (120 VAC)

• WHITE TO WHITE (NEUTRAL)

• YELLOW TO YELLOW OR

ORANGE (INTERCONNECT)

PRIMARY POWER

WIRING

WHT/WHT (NEUTRAL)

BLK/BLK (120VAC)

YEL/YEL OR

YEL/ORANGE

+

CR2032

3V

MOVE TO

FRESH AIR

SMOKE

+

CR2032

3V

STEP 1

PULL OUT

BATTERY TRAY

WITH FLATHEAD

SCREWDRIVER

STEP 2

INSERT

BATTERY + POLARITY

FACING UP

WIRELESS SMOKE ALARM

INTERCONNECT BASE

SMOKE ALARM

LEDS ON WIRELESS SMOKE

ALARM INTERCONNECT BASE

LEARN/TEST BUTTON

HOLE

1. PLACE WIRE

INTO

WIRETAP.

2. HINGE WIRETAP

UP AND OVER

WIRE STRAND

3. CRIMP

WIRETAP WITH

PLIERS

WIRING CODE:

•BLACK TO BLACK (120 VAC)

•WHITE TO WHITE (NEUTRAL)

•YELLOW TO YELLOW OR

ORANGE (INTERCONNECT)

APD0671 A160301

© 2016 Apollo Fire

Copyright © 2016 l 3

Specifi cations

Input Power 120VAC 50/60Hz 12W

Backup Power 3-Volt CR2032 Battery or Equivalent

Backup Battery Life >8 years

Operating Temperature 32°F to 122°F (0°C to 50°C)

Operating Humidity 5–95% RH non-condensing

Compatibility ADT Lynx and ADT Vista

Wireless Signal Range 350ft (110m)

Supervisory Interval 70 minutes

Certifi cation FCC/IC and ETL

FCC Notice

This device complies with Part 15 of the FCC’s Rules. Opera on is subject to the following two condi ons:

1 This device may not cause harmful interference, and 2 This device must accept any interference received,

including interference that may cause undesired opera on. This equipment has been tested and found to

comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protec on against harmful interference in a residen al installa on.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruc ons, may cause harmful interference to radio communica ons. However, there is

no guarantee that interference will not occur in a par cular installa on. If this equipment does cause harmful

interference to radio or television recep on, which can be determined by turning the equipment o and on,

the user is encouraged to try to correct the interference by one or more of the following measures:

✓ Reorient or relocate the receiving antenna.

✓ Increase the separation between the equipment and receiver.

✓ Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

✓ Consult the dealer or an experienced radio/TV technician for help. To satisfy FCC/IC RF exposure safety

requirements, a separation distance of 20 cm or more should be maintained between this device and

person’s body (excluding extremities: hands, wrists, feet, and ankles).

NOTE: Any changes or modi ca ons not expressly approved by the party responsible for compliance could

void the user’s authority to operate this equipment.

Industry Canada (IC) Compliance

This device complies with Industry Canada license-exempt RSS standard(s). Opera on is subject to the

following two condi ons: (1) this device may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired opera on of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de

licence. L’exploita on est autorisée aux deux condi ons suivantes:

1 l’appareil ne doit pas produire de brouillage, et 2 l’u lisateur de l’appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est suscep ble d’en comprome re le fonc onnement.

This Class B digital apparatus complies with Canadian ICES-003. Cet appareil numérique de la classe B est

conforme à la norme NMB-003 du Canada.

Apollo

25 Corporate Drive

Auburn Hills, MI 48326 USA

TEL: +1-248-332-3900

FAX: +1-248-332-8807

www.apollo- re.com

10011636 X1

APD0671 A160301

© 2016 Apollo Fire

25 Corporate Drive

Auburn Hills, Michigan 48326

+1 (248) 332-3900 FAX: +1 (248) 332-8807

www.apollo-re.com • SalesUSA@apollo-re.com

-

1

1

-

2

2

-

3

3

-

4

4

Apollo 51000-300 Manuel utilisateur

- Catégorie

- Détecteur de fumée

- Taper

- Manuel utilisateur

- Ce manuel convient également à

dans d''autres langues

- English: Apollo 51000-300 User manual

Documents connexes

Autres documents

-

Perixx PERIMICE-819 Manuel utilisateur

-

Perixx PERIMICE-813 Manuel utilisateur

-

Perixx PERIBOARD-813 Manuel utilisateur

-

DMP Electronics 1166 Guide d'installation

DMP Electronics 1166 Guide d'installation

-

Qbic Luminen 10 Touch Panel PC Mode d'emploi

Qbic Luminen 10 Touch Panel PC Mode d'emploi

-

Kidde SM120X Manuel utilisateur

-

American Sensor ASD200 Le manuel du propriétaire

American Sensor ASD200 Le manuel du propriétaire

-

Tiiwee X1 XL Manuel utilisateur

Tiiwee X1 XL Manuel utilisateur

-

BRK RM4 Manuel utilisateur

-

American Sensor ESA5011 Manuel utilisateur

American Sensor ESA5011 Manuel utilisateur