OPERATOR’S MANUAL & SAFETY INSTRUCTIONS

3M™ File Belt Sander

PN 33573 330 mm (13 in.) 17,000 RPM

PN 33575 457 mm (18 in.) 17,000 RPM

For more information visit our website

3MCollision.com

2017-02-21, Version 2

Translation of Original Instructions

1Translation of Original Instructions

English

TABLE OF CONTENTS

TABLE OF CONTENTS .........................................................1

IMPORTANT SAFETY INFORMATION .........................................3

SUMMARY OF DEVICE LABELS CONTAINING SAFETY INFORMATION ..........3

EXPLANATION OF SIGNAL WORD CONSEQUENCES ...........................4

GENERAL POWER TOOL SAFETY PRECAUTIONS: .............................. 4

!

WARNING ..............................................................5

!

CAUTION ...............................................................6

NOTICE .....................................................................6

INTENDED USE ..............................................................6

PRODUCT CONFIGURATION/SPECIFICATIONS ...............................6

EXPLODED SANDER (PARTS) VIEW ............................................ 7

PARTS LIST .................................................................. 7

MAINTENANCE/LUBRICATING and OPERATING INSTRUCTIONS ...............8

TO INSTALL/REMOVE THE ABRASIVE BELT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TO INSTALL/REMOVE THE CONTACT ARMS ..................................11

TO INSTALL/CHANGE THE CONTACT WHEEL ................................ 12

REPLACEMENT PARTS ...................................................... 13

DECLARATION OFCONFORMITY ........................................... 14

3M LIMITED ONE YEARWARRANTY ......................................... 15

3Translation of Original Instructions

IMPORTANT SAFETY INFORMATION

Please read, understand, and follow all safety information contained in these instructions prior to the use of this device. RETAIN THESE

INSTRUCTIONS FOR FUTURE REFERENCE.

Exposure to DUST generated from workpiece

and/or abrasive materials can result in lung

damage and/or other physical injury.

Use dust capture or local exhaust as stated in

the SDS. Wear government-approved

respiratory protection and eye and skin

protection.

Failure to follow this warning can result in

serious lung damage and/or physical injury.

Read the Safety Data Sheets (SDS)

before using any materials.

Contact the suppliers of the workpiece

materials and abrasive materials for

copies of the SDS if one is not

readily available.

SDS

WARNING

Health Hazard by Dust – California Proposition 65 Statement

!

WARNING! Various dust created by power sanding, sawing, grinding, drilling and other construction activities contains chemicals

known [to the State of California] to cause cancer, birth defects or other reproductive harm. Some examples of these chemicalsare:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically treated lumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To reduce your exposure to

thesechemicals:

• Work in a well-ventilated area, and

• Work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

• Wash hands after handling

SUMMARY OF DEVICE LABELS CONTAINING SAFETY INFORMATION

Markings Description

!

WARNING: READ AND UNDERSTAND INSTRUCTION MANUAL

BEFORE OPERATINGTOOL.

!

WARNING: ALWAYS WEAR APPROVED EYE PROTECTION.

!

WARNING: ALWAYS WEAR APPROVED HEARING

PROTECTION

Direction of rotation

WARNING: HAND/WRIST/ARM INJURY CAN OCCUR WITH

PROLONGED EXPOSURE TO VIBRATION

17,000 RPM / 4100 SFPM Maximum rotational speed

90 PSIG / 6.2 BAR MAX Maximum air pressure

4 Translation of Original Instructions

EXPLANATION OF SIGNAL WORD CONSEQUENCES

!

WARNING:

Indicates a potentially hazardous situation, which, if not avoided, could result in

death or serious injury and/or property damage.

!

CAUTION:

Indicates a potentially hazardous situation, which, if not avoided, may result in minor

or moderate injury and/or property damage.

NOTICE:

Indicates a potentially hazardous situation, which, if not avoided, may result in

property damage.

GENERAL POWER TOOL SAFETY PRECAUTIONS:

For multiple hazards, read and understand the safety instructions before installing, operating, repairing, maintaining or changing

accessories on, or working near the power tool. Failure to do so can result in serious bodily injury.

WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Dust can be highly combustible. Keep work area clean.

c) Keep bystanders away while operating a power tool. Distractions can cause you to lose control.

PERSONAL SAFETY

• As compressed air is used as the power source, it must be remembered that compressed air can be dangerous when used

incorrectly. The user should take time to read and understand these operating instructions fully.

• Immediately release the start trigger in the event of any disruption of pressure. Do not attempt to restart until the disruption has

been corrected.

• Do not use the power tool if it has been damaged.

• The tool RPM should be checked on a regular basis to ensure proper operating speed.

• Never operate the tool with loose, broken or missing parts.

• Do not carry the tool by the air hose. Always be careful to prevent the tool from being started when carrying the tool with the

air supply connected.

• This tool is not protected against hazards inherent in grinding and cutting operations, which require a guard, and no such

grinding and cutting products should ever be attached.

• Do not use damaged abrasives or wrong type of accessories.

• Take care to avoid entanglement with the moving parts of the tool with clothing, ties, hair, cleaning rags or loose hanging

objects. If entangled, stop air supply immediately to avoid contact with moving tool parts.

• Always use personal protective equipment. Always wear eye protection. Protective equipment such as gloves, dust mask, non-

skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

• Do not overreach. Keep proper footing, balance and grip at all times. This enables better control of the power tool in

unexpected situations.

• Always ensure the material being worked is firmly affixed to avoid movement.

• Do not allow persons to use this power tool if unfamiliar with these instructions or operation of the tool.

• Always disconnect this tool from the air supply when attaching/adjusting/replacing abrasives and accessories or when starting

any maintenance/cleaning tasks.

• Whenever performing maintenance procedures, use care to avoid exposure to any hazardous substances deposited on the tool

as a result of work processes.

• If the tool appears to malfunction, remove from use immediately and arrange for service and repair.

5Translation of Original Instructions

!

WARNING

To reduce the risks associated with impact from abrasive product or tool breakup, sharp edges, hazardous pressure, rupture,

vibration and noise:

• Read, understand and follow the safety information contained in these instructions prior to the use of this tool. Retain these

instructions for future reference.

• Only personnel who are properly trained should be allowed to service this tool.

• Practice safety requirements. Work alert, have proper attire, and do not operate tool under the influence of alcohol or drugs.

• Operators and other personnel must always wear protection for eyes, ears and respiratory protection when in the work area or

while operating this product. Follow your employer’s safety policy for Personal Protective Equipment (PPE) and/or ANSI Z87.1 or

local/national standards for eyewear and other personal protective equipment requirements.

• Proper eye protection must be worn at all times.

• Wear leather apron or other protective apparel, taking into consideration the type of work being done.

• Never exceed marked maximum input pressure (90 psi / 0.62Mpa / 6.2 Bars). Exceeding maximum marked pressure rating will

result in device operating at an unintended speed and therefore enhances the possibility of serious injury.

• Tool shall not be operated in the presence of bystanders.

• If you notice any abnormal noise or vibration when operating the product, immediately discontinue its use and inspect for worn

or damaged components. Correct or replace the suspect component. If abnormal noise or vibration still exists, return the tool to

3M for repair or replacement. Refer to warranty instructions.

• Never operate this tool without all safety measures in place and in proper working order.

• Never use a damaged tool until it has been repaired.

• Never over-ride or disable the safety features of the start-stop control such that it is in the on position.

• If the tool is jammed, shut off the tool and ease it free.

• Make sure the tool is disconnected from its air source before servicing, inspecting, maintaining, cleaning, and before changing

abrasive product.

• Prior to use, or if dropped or jammed, inspect mounting hardware, drive pulley and abrasive product for possible chips, cracks or

other damage and ensure the abrasive product is correctly secured.

• Only use accessories supplied or recommended by 3M.

• Use only with mounting hardware recommended by 3M; check with 3M for mounting hardware requirements.

• Never allow this tool to be used by children or untrained people.

• Do not leave an unattended tool connected to an air source.

To reduce the risks associated with skin abrasion, burns, cuts, or entrapment:

• Keep hands, hair, and clothing away from the cutting part of the tool.

• Wear suitable protective gloves while operating tool.

• Do not touch the rotating parts during operation for any reason.

• Do not force tool or use excessive force when using tool.

To reduce the risk of all hazards associated with vibration:

• If any physical hand/wrist discomfort is experienced, work should be stopped promptly to seek medical attention. Hand, wrist

and arm injury may result from repetitive work, motion and overexposure to vibration.

To reduce the risks associated with loud noise:

• Always wear hearing protection while operating this tool. Follow your employer’s safety policy or local/national standards for

personal protective equipment requirements.

To reduce the risks associated with fire or explosion:

• Do not operate the tool in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. The abrasives are

able to create sparks when working material, resulting in the ignition of the flammable dust or fumes.

• Refer to SDS of material being worked as to potential for creating fire or explosion hazard.

To reduce the risks associated with hazardous dust inhalation or eye/skin exposure:

• Use appropriate respiratory and skin protection, or local exhaust as stated in the SDS of the material being worked on.

• Exposure to dust generated in the workplace and/or abrasive materials can result in lung damage and/or other physical injury.

• Use dust capture or local exhaust as stated on the SDS. Wear government approved respiratory protection and eye and

skinprotection.

• Failure to follow this warning can result in serious lung damage and/or physical injury.

To reduce the risk of foot injury from dropped tools:

• Wear safety shoes with a reinforced toe to help protect your feet from injury caused by a dropped tool. Safety footwear comes

in a variety of styles and is widely available. Choose footwear that offers traction for your work site.

To reduce the risks associated with hazardous voltage:

• Do not allow this tool to come into contact with electrical power sources as the tool is not insulated against electrical shock.

6 Translation of Original Instructions

!

CAUTION

To reduce the risk associated with whipping or hazardous pressure-rupture:

• Ensure supply hose is oil resistant and is properly rated for required work pressure.

• Do not use tools with loose or damaged air hoses or fittings.

• Be aware that incorrectly installed hoses and fittings might unexpectedly come loose at any time and create a whipping/

impacthazard.

To reduce the risk associated with fly off of abrasive product or parts:

• Use care in attaching abrasive product and mounting hardware; follow the instructions to ensure that they are securely attached

to the tool before use or free-spinning.

• Never point this product in the direction of yourself or another person, or start tool unintentionally.

• Never over-tighten accessory fasteners.

NOTICE

To maximize the life of the system:

• Do not operate tool without a properly attached 3M™ abrasive.

• Reference Maintenance/Lubricating and Operating Instructions section for proper lubrication procedures.

INTENDED USE

The 3M™ File Belt Sander is intended for use in industrial locations, and used only by skilled, trained professionals in accordance with

the instructions in this manual. The 3M™ File Belt Sander is designed to effectively remove spot welds with less manual effort and

force than spot weld drills. The tool can also be used to remove gaskets and sealants. Only accessories specifically recommended by

3M should be used with this tool. Use in any other manner or with other accessories could lead to unsafe operating conditions.

• Do not operate tool in water or in an excessively wet application.

• Do not use abrasive products that have a Max RPM less than the Max RPM rating marked on the tool.

• Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a 3M service facility for a

free replacement.

At the end of its useful life, recycle or dispose of tool according to federal, state, and local regulations.

PRODUCT CONFIGURATION/SPECIFICATIONS

Model

No.

Belt Size

In. (mm)

Motor

Speed

(RPM)

Belt

Speed

SFPM

(SMPM)

Product

Net Wt

lb (kg)

Height

In.

(mm)

Length

In.

(mm)

Width

In.

(mm)

Motor

hp

(W)

Noise

Level

dBA

Pressure

(Power)

Vibration

Level

m/s

2

Uncertainty

Km/s

2

33573

1/2 × 13

(13×300)

17,000

4100

(1250)

1.91

(0.87)

2.87

(73)

12.50

(320)

3.80

(96)

.65

(485)

87.0

(98.0)

1.71 0.66

33575

1/2 × 18

(13×457)

17,000

4100

(1250)

2.03

(0.92)

2.87

(73)

15.15

(385)

3.80

(96)

.65

(485)

87.5

(98.5)

1.92 0.68

* Declared noise level; measurements carried out in accordance with EN ISO 15744. It is recommended to wear ear protection while

using this tool.

** Declared vibration level in accordance with standard EN ISO 28927.

IMPORTANT NOTE: The noise and vibration values stated are from laboratory testing in conformity with stated codes and standards

and are not sufficient risk evaluation for all exposure scenarios. Values measured in a particular work place may be higher than the

declared values. Exposure to high noise levels can cause permanent, disabling hearing loss and other problems, such as tinnitus

(ringing, buzzing, whistling or humming in the ears). Therefore, risk assessment and the implementation of appropriate controls

for these hazards are essential. The actual exposure values and amount of risk or harm experienced to an individual is unique to

each situation and depends upon the surrounding environment, the way in which the individual works, the particular material being

worked, work station design, as well as upon the exposure time and the physical condition of the user. 3M cannot be held responsible

for the consequences of using declared values instead of actual exposure values for any individual risk assessment.

7Translation of Original Instructions

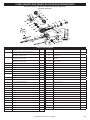

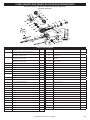

EXPLODED SANDER PARTS VIEW

PN 33573 (13 in.) AND PN 33575 (18 IN.)

File Belt Sander

PARTS LIST

ITEM DESCRIPTION QTY ITEM DESCRIPTION QTY

1

18 in. Contact Arm Assembly- 10 mm Wheel 1 24 Parallel Key 1

18 in. Contact Arm Assembly- 13 mm Wheel 1 25 Rotor Blade 5

1-1

13 in. Contact Arm Assembly- 10 mm Wheel 1 26 Cylinder 1

13 in. Contact Arm Assembly- 13 mm Wheel 1 27 Rear End Plate 1

2 Stopper Pin 1 28 Ball Bearing (608ZZ) 1

3 Guard Bushing 1 29 O-Ring 1

4 Tension Spring 1 30 Cap 1

5 Guard Body 1 31 Safety Lever Assembly 1

6 Head Cap Screw (M5×15) 1 32 Spring Pin (Ø 3×20) 1

7

Shoe For 18 in. 1 33 Valve Body 1

Shoe For 13 in. 1 34 O-Ring 1

8 Hex. Socket Headless Set Screw 1 35 O-Ring 1

9 Dust Cover 1 36 O-Ring 1

10 Spring Pin (Ø 2.5×10) 1 37 Valve Stem 1

11 Stopper 1 38 O-Ring 1

12 Stopper Spring 1 39 Valve Spring 1

13 Hex. Nut (M6) 1 40 Air Regulator 1

14 Washer (M6) 1 41 O-Ring 2

15 Drive Pulley 1 42 External Stop Ring 1

16 Button Head Screw 1 43 Ring 1

17 Knurled Head Screw 1 44 Muffler 1

18 Belt Cover 1 45 Exhaust Diffuser 1

19 Housing 1 46 Inlet Bushing 1

20 Ball Bearing (6000ZZ) 1 47 Hex. Wrench - 1.5 mm 1

21 Front End Plate 1 48 Hex. Wrench - 40 mm 1

22 Spacer 1 49 Set Screw 1

23 Rotor 1

8 Translation of Original Instructions

MAINTENANCE/LUBRICATING AND OPERATING INSTRUCTIONS

PRIOR TO THE OPERATION

The tool is intended to be operated as a hand held tool. It is always recommended that while using the tool, operators stand on a solid

floor, in a secure position with a firm grip and footing. Be aware the sander can develop a torque reaction. Reference “GENERAL POWER

TOOL SAFETY PRECAUTIONS” section.

Use a clean lubricated air supply that will give a measured air pressure at the tool of 6.2 bar (90 psig) when the tool is running with the

trigger fully depressed. It is recommended to use an approved 9.52 mm (3/8 in) x 8 m (25 ft) maximum length airline.

Do not connect the tool to the airline system without incorporating an easily accessible air shut off valve. It is strongly recommended

that an air filter, regulator and lubricator (FRL) be used as shown in Figure A as this will supply clean, lubricated air at the correct

pressure to the tool. In any case appropriate air pressure regulators shall be used at all times while operating this tool where the supply

pressure exceeds the marked maximum of the tool. Details of such equipment can be obtained from your tool distributor. Adjust airline

lubricator equipment such that two drops of 3M™ Air Tool Lubricant PN 20451 (or equivalent 10 centistoke oil) per minute are provided

through the hose to the air inlet of the tool. If excessive oil is noted in the exhaust air, reduce the drip rate of the airline lubricator

equipment accordingly. If such equipment is not used, the tool should be manually lubricated.

To manually lubricate the tool, disconnect the airline and put two to three drops of 3M™ Air Lubricant PN 20451 (or equivalent 10

centistoke oil) into the air inlet of the tool. Reconnect tool to the air supply and run tool slowly for a few seconds to allow air to circulate

the oil. If the tool is used frequently, lubricate it on a daily basis or lubricate it if the tool starts to slow or lose power. It is recommended

that the air pressure at the tool be 6.2 bar (90 psig) while the tool is running so the maximum RPM is not exceeded. The tool can run at

lower pressures but should never be run higher than 6.2 bar (90 psig). If run at lower pressure the performance of the tool is reduced.

Recommended Airline Size –

Minimum

Recommended Maximum

Hose Length

Air Pressure

9.52 mm (3/8 in) 8 meters (25 feet) Maximum Working Pressure 6.2 Bar 90 psig

Recommended Minimum N/A N/A

Air Compressor

and Tank

Air

Flow

Closed Loop Pipe

System Sloped in the

direction of air flow

Drain

Leg

Ball Valve

Ball

Valve

Filter

Ball

Valve

To Tool

Station

Drain

Valve

Lubricator

Regulator

To Coupler

at or

near Tool

Air Hose

Air

Dryer

9Translation of Original Instructions

GENERAL SET UP AND USE:

• Read all instructions before using this tool. All operators must be fully trained in its use and aware of all safety rules. All service

and repair must be carried out by trained personnel.

• The tool RPM should be checked on a regular basis to ensure proper operating speed.

• Make sure the tool is disconnected from the air supply and then attach 3M abrasive belt to the sander. Always wear required

safety equipment when using this tool.

• When sanding always start the tool just prior to contacting the work piece. Stop air flow to the tool as it is removed from the

work piece.

• Always remove the air supply to the sander before fitting, adjusting or removing the abrasive.

• Use only 3M approved parts.

• Prior to installing any File Belt Sander accessory, always check that its marked maximum operating speed is equal to or higher

than the rated speed of this tool.

SETTING & TESTING TOOL SPEED:

1. Ensure the Trigger is not depressed

2. Connect the compressed airline

3. Press the Trigger slowly and increase force until tool is at full speed

4. Use a Rotary Tachometer to check the speed

5. Check speed regularly

10 Translation of Original Instructions

TO INSTALL/REMOVE THE ABRASIVE BELT

1. Disconnect the tool from the air line.

2. Hold the tool with the contact arm pointing downward. Push the contact arm against a hard surface to gain some slack until the

safety latch (A) clicks into the locking position.

3. Unfasten the set screw (B). (See Fig. 1)

B

A

(Fig. 1)

4. Rotate the belt cover (C) and replace the belt.(See Fig. 2)

(Fig. 2)

C

5. Press the safety latch (A) until the contact arm springs back to its original extended position. (See Fig. 3).

6. Rotate the belt cover into the closed position and tighten the set screw (B).

B

C

A

(Fig. 3)

11Translation of Original Instructions

TO INSTALL/REMOVE THE CONTACT ARMS

1. Disconnect the tool from the air line.

2. Hold the tool with the contact arm facing downward. Push the contact arm against a hard surface until the safety latch (A) clicks

into the locking position.

3. Release the set screw (B).(See Fig. 1)

4. Rotate the belt cover (C) and remove the belt.(See Fig. 2)

(Fig. 1)

B

A

(Fig. 2)

C

5. Press the safety latch (A) to release the contact arm to its original position.

6. Place the tool in horizontal position with the cap facing upward (See Fig. 3). Use a pin punch (D) to tap out the pin (E). Remove and

replace the contact arm (F).

7. Place the tool with the cap facing downward. (See Fig. 4). Use a pin punch (D) to install the pin (E).

D

F

E

(Fig. 3)

D

(Fig. 4)

8. Repeat Step 2.

9. Install the belt.

10. Repeat Step 5.

11. Flip back the belt cover and tighten the set screw (B). (See Fig. 5)

B

C

A

(Fig. 5)

12 Translation of Original Instructions

TO INSTALL/CHANGE THE CONTACT WHEEL

1. Disconnect the tool from the air line.

2. Hold the tool with the contact arm pointing downward. Push the contact arm against a hard surface to gain some slack until the

safety latch (A) clicks into the locking position. Unfasten the set screw (B).(See Fig. 1)

3. Rotate the belt cover (C) and remove the belt.(See Fig. 2)

(Fig. 1)

B

A

(Fig. 2)

C

4. Press the safety latch (A) until the contact arm springs back to its original extended position.

5. Unfasten the screw (D) with a screw driver. Remove and replace the wheel (E). Apply one drop of removable threadlocker on the

threads of the screw and then tighten the screw. (See Fig. 3)

(Fig. 3)

D

E

6. Repeat Step 2.

7. Install the belt.

8. Repeat Step 5.

9. Rotate the belt cover into the closed position and tighten the set screw (B). (See Fig. 4)

(Fig. 4)

B

A

C

13Translation of Original Instructions

REPLACEMENT PARTS

CONTACT WHEEL REPLACEMENT KIT

KIT DESCRIPTION PART NUMBER CONTENT

10 mm Contact Wheel Kit 33583 1. 10 mm - Wheel Assembly

2. Screw for 10 mm Wheel

13 mm Contact Wheel Kit 33584 1. 13 mm –Wheel Assembly

2. Screw for 13 mm Wheel

CONTACT ARM ASSEMBLY PARTS

DESCRIPTION PART NUMBER

330 mm (13 in) Contact Arm Assembly – 10 mm Wheel 33585

330 mm (13 in) Contact Arm Assembly - 13 mm Wheel 33586

457 mm (18 in) Contact Arm Assembly – 13 mm Wheel 33588

13 in. Contact

Arm Assembly

18 in. Contact

Arm Assembly

14 Translation of Original Instructions

DECLARATION OFCONFORMITY

15Translation of Original Instructions

3M LIMITED ONE YEARWARRANTY

Product Use: Many factors beyond 3M’s control and uniquely within user’s knowledge

and control can affect the use and performance of a 3M product in a particular application.

Given the variety of factors that can affect the use and performance of a 3M product, user

is solely responsible for evaluating the 3M product and determining whether it is fit for a

particular purpose and suitable for user’s method of application.

Warranty, Limited Remedy and Disclaimer: 3M warrants this tool against defects in

workmanship and materials under normal operating conditions for one (1) year from the

date of purchase. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED

WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR

USAGE OF TRADE. If the 3M product does not conform to this warranty, then the sole

and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the

purchase price.

This warranty extends only to the original purchaser and does not cover a defect or

product malfunction resulting from abuse, misuse, neglect, or any use not in conformity

with the printed directions. Any attempt to repair or adjust any electrical or mechanical

functions on this unit will void the warranty. This warranty does not cover part failure due

to normal wear or tool abuse. 3M also identifies: Merchandise that has become damaged

or inoperative because of ordinary wear, misuse, cold, heat, rain, excessive humidity,

freeze damage, use of improper chemicals, negligence, accident, failure to operate

the product in accordance with the instructions provided in the Operator’s Manual(s)

supplied with the product, improper maintenance, the use of accessories or attachments

not recommended by 3M, or unauthorized repair or alterations.

To make a claim under the warranty, you must first contact the 3M service center

at 1-877-MMM-CARS (1-877-666-2277) to receive a return authorization number.

Merchandise must be returned freight prepaid by the purchaser, to the service location

address given by the 3M Customer Service center. Upon validation of the warranty claim,

3M will replace or repair the merchandise, at 3M’s option, and return it to the purchase at

3M’s expense, including parts, labor and return shipping charges. If it is determined that

the claim is not covered by the warranty, the purchaser will be given the option to have

the merchandise repaired outside of the warranty. An estimate of parts and labor will be

provided by 3M and must be approved by the purchaser in advance.

Limitation of Liability: Except where prohibited by law, 3M will not be liable for any

loss or damage arising from the 3M product, whether direct, indirect, special, incidental

or consequential, regardless of the legal theory asserted, including warranty, contract,

negligence or strict liability.

MANUAL DEL OPERADOR E

INSTRUCCIONES DE SEGURIDAD

Lijadora con Banda Limadora de 3M™

PN 33573 330 mm (13 pulgadas) 17,000 RPM

PN 33575 457 mm (18 pulgadas) 17,000 RPM

Para más información, visite nuestro sitio web

3MCollision.com/es

2017-02-21, Version 2

Traducción de las Instrucciones Originales

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

3M File Belt Sanders Manuel utilisateur

- Catégorie

- Outils électroportatifs

- Taper

- Manuel utilisateur

dans d''autres langues

- italiano: 3M File Belt Sanders Manuale utente

- español: 3M File Belt Sanders Manual de usuario

- Deutsch: 3M File Belt Sanders Benutzerhandbuch

- português: 3M File Belt Sanders Manual do usuário

Documents connexes

Autres documents

-

Sioux Tools SPS10P6 Mode d'emploi

-

Ingersoll-Rand CA120RS818 Operation and Maintenance Manual

-

Parkside 275647 Translation Of The Original Instructions

-

Sioux Tools SAS10A122-20 Original Instructions Manual

-

GYS PNEUMATIC BELT SANDER (10x330mm) Le manuel du propriétaire

-

Andis 65925 Use & Care Instructions

-

Andis 65925 Mode d'emploi