Haier 1U12AP2VHA Manuel utilisateur

- Catégorie

- Climatiseurs split-system

- Taper

- Manuel utilisateur

Ce manuel convient également à

Ductless Split Heat Pump

Service Manual

Design may vary by model number.

• Please read this manual before using the heat pump.

• Keep this user manual for future reference.

PAGE 1

Safety Precautions/Introduction .................................................................................................3

Outdoor Unit Controls and Components ..................................................................................... 7

Indoor Unit Controls and Components ......................................................................................15

Sequence Of Operation ............................................................................................................. 21

Error Codes and Problem Solving ..............................................................................................29

Reference Information ..............................................................................................................43

Table of Contents

Indoor

AW09ES2VHB

AW12ES2VHB

AW15ES2VHB

AW18ES2VHB

AW24ES2VHB

Outdoor

1U09AP2VHA

1U12AP2VHA

1U15AP2VHA

1U18AP2VHA

1U24AP2VHA

[This page intentionally left blank.]

INTRODUCTION

PAGE 3

ENGLISH

Introduction

Safety Precautions ............................................................................................................................................................. 4

Warning and Cautions ......................................................................................................................................................................4

Introduction to System ......................................................................................................................................................5

Specicationsforproperoperationshouldbefollowed ................................................................................................................ 5

FundamentalTheoryOfHowSystemWorks..................................................................................................................................5

Table of Contents

INTRODUCTION

PAGE 4

ENGLISH

• Read these Safety Precautions carefully to ensure correct installation.

• This manual classies the precautions by WARNING and CAUTION.

• Follow all precautions below. They are all important for ensuring safety and preventing property/equipment damage.

!

WARNING: Failure to follow any of WARNING is likely to result in grave consequences such as death or serious injury.

!

CAUTION: Failure to follow any of CAUTION may, in some cases, result in grave consequences.

• The following safety symbols are used throughout this manual:

Observe this instruction

Establish an earth connection

Never attempt

• After completing installation, test the unit to check for installation errors. Give the user adequate instructions concerning the

use and cleaning of the unit according to the Operation Manual.

!

WARNING

• Installation should be performed by the dealer or another professional.

Improper installation may cause water leakage, electrical shock, or re.

• Install the heat pump according to the instructions given in this manual.

Incomplete installation may cause water leakage, electrical shock, or re.

• Use only the supplied or specied installation parts.

Use of other parts may cause the unit to come lose, water leakage, electrical shock, or re.

• Install the heat pump on a solid base that can support the unit’s weight.

An inadequate base or incomplete installation may cause injury in the event the unit falls o the base.

• Electrical work should be carried out in accordance with the installation manual and national/local electrical wiring codes and

rules of practice.

Insucient capacity or incomplete electrical work may cause electrical shock or re.

• Use a dedicated power circuit. Never use a power supply shared by another appliance.

• For wiring, use a cable long enough to cover the entire distance with no splices.

Do not use an extension cord. Do not put other loads on the power supply, use a dedicated power circuit.

(Failure to do so may cause abnormal heat, electric shock or re.)

• Use only the specied wire types for electrical connections between the indoor and outdoor units.

Firmly clamp the interconnecting wires so they receive no external stresses. Incomplete connections or clamping may cause terminal over-

heating or re.

• After completing interconnecting and supply wiring connections, shape the cables so that they do not put undue force on

the electrical covers or panels.

Install covers over the wires. Incomplete cover installation may cause terminal overheating, electrical shock, or re.

• If any refrigerant has leaked out during the installation work, ventilate the room.

(The refrigerant produces a toxic gas if exposed to ame.)

• After all installation is complete, check for and repair any system refrigerant leaks.

(The refrigerant produces a toxic gas if exposed to ames.)

•When installing or relocating the system, keep the refrigerant circuit free from substances other than the specied

refrigerant (R410A), such as air.

(The presence of air or other foreign substance in the refrigerant circuit causes an abnormal pressure rise or rupture, resulting in injury.)

• During pump-down, stop the compressor before removing the refrigerant piping.

If the compressor is still running, and the stop valve is open during pump-down, air will be sucked into the system while the compressor is

running. This will cause abnormal pressure and noncondensables added to the system.

• Be sure to establish a ground. Do not ground the unit to a utility pipe, arrester, or telephone earth.

An complete earth may cause electrical shock, or re. A high surge current from lightning or other sources may

cause damage to the heat pumpheat pump.

!

CAUTION

• Do not install the heat pump in a place where there is danger of exposure to ammable gas.

If the gas builds up around the unit, it may catch re.

• Install drain piping according to the instructions of this manual.

Inadequate piping may cause ooding.

•Tighten the are nut according to the specied torque using a torque wrench.

If the are nut is overtightened, the are nut may eventually crack and cause refrigerant leakage.

• Provide adequate measures to prevent the outdoor unit from being used as a shelter by rodents.

Rodents making contact with electrical parts can cause malfunctions, smoke or re. Please instruct the customer to keep the area around

the unit clean.

Safety Precautions

INTRODUCTION

PAGE 5

ENGLISH

Introduction to System

Single Zone Ductless Split System Heat Pumps feature a wall

mounted indoor fan/evaporator unit that receives refrigerant

from an inverter driven variable speed outdoor condensing

unit. The system operation is controlled with a remote

control.

The outdoor unit features a variable speed rotary

compressor, EEV metering device and DC fan motor. These

systems use R410A refrigerant and PVE oil. The outdoor units

are 208/230 volt rated systems. They come factory charged

for up to 25 ft. of interconnecting piping.

The indoor units are wall mounted type. They feature a DC

blower motor and a DC louver motor. The unit has a room

temperature sensor and an evaporator tube temperature

sensor. The wall unit is powered by voltage from the outdoor

unit.

Specications for proper operation should be followed

• The systems are designed to operate in room temperature

ranges of 60°F to 86°F in cooling mode and 60°F to 86°F in

heat mode.

• PVE oil is non reactive to water and will not go into

Hydrolysis. There is no need to add a refrigeration drier

when servicing or installing this system.

• The indoor wall mounted unit receives operating voltage

and communication data signals on #14 AWG wire that

connects between the indoor and outdoor units. There

should not be any splices in the eld wiring that goes

between terminals 1, 2, 3 and 4. A splice in these wires may

cause the system to lose communication between the

indoor and outdoor units. The system will then display an

error code E7.

• The systems come with enough factory charge for up to

25 feet of connecting refrigeration tubing. The tubing

connects using are type ttings at both the indoor and

outdoor units. Tubing must be sized per the specications.

Both lines must be insulated. The only method of checking

charge or adjusting charge is by weight method explained in

this manual (no exceptions).

• The condensate system is a gravity type. A eld installed

condensate pump may be added to the system. Always

follow the manufacturer’s installation instructions when

installing a condensate pump.

• Proper clearances at both indoor and outdoor units must be

maintained. Improper clearances cause system conditions

that include high refrigerant pressure, low refrigerant

pressure and indoor coil freezing problems.

Fundamental Theory of How the System Works

The indoor unit will sense room temperature at the point

where the wall unit is installed. The indoor fan will run

continuously when placed in heating or cooling mode

operation and will not cycle on and o with the outdoor

unit. If it did, room temperature could not be sensed or

Introduction

maintained.

The inverter compressor system in the outdoor unit will vary

the refrigerant ow and indoor air volume levels to match

the cooling requirement inside the conditioned space. If an

abnormal condition is detected by the system’s sensors, the

system has the ability to take reactive measures.

The amount of refrigerant ow and associated capacity

generated by the system will be determined by how fast the

system’s variable speed rotary compressor is pumping. The

compressor operating speed requirement is determined by

the dierence between the conditioned space temperature

versus the set point established by the homeowner’s remote

control.

If a large amount of capacity is needed, the compressor will

operate at a high frequency speed. As the need for capacity

reduces and the temperature of the room nears set point,

the compressor will slow down. When set point has been

reached, the compressor will shut o but the indoor fan

will continue to operate. Once a dierence in temperature

is sensed between remote control set point temperature

and room temperature, the compressor will restart at a new

calculated speed.

If a system sensor determines there is a need to adjust

the frequency signal to prevent a system malfunction,

the compressor frequency may be over ridden and a new

frequency established. It should be noted that the frequency

signal level that is sent to the compressor cannot be

determined by a servicing technician.

In this manual, system components, operation, sensor

functions and diagnostic procedures will be explained in

greater detail.

INTRODUCTION

PAGE 6

ENGLISH

[Thispageintentionallyleftblank.]

OUTDOOR UNIT CONTROLS & COMPONENTS

PAGE 7

ENGLISH

Outdoor Unit Controls & Components

Table of Contents

Outdoor Unit Introduction .................................................................................................................................................8

Outdoor Component Identication ....................................................................................................................................8

Outdoor Main Control Board ..............................................................................................................................................9

Terminal Block .................................................................................................................................................................. 10

Reactor ............................................................................................................................................................................ 10

Compressor .....................................................................................................................................................................10

Outdoor Fan Motor ........................................................................................................................................................... 10

Discharge Temperature Sensor ........................................................................................................................................ 11

Defrost Temperature Sensor ............................................................................................................................................ 11

Outdoor Ambient Temperature Sensor ............................................................................................................................ 11

Suction Line Temperature Sensor ..................................................................................................................................... 11

4-Way Valve .....................................................................................................................................................................12

Electronic Expansion Valve ............................................................................................................................................... 12

Accumulator .................................................................................................................................................................... 12

Filters ............................................................................................................................................................................... 12

Electrical Base Pan Heater ................................................................................................................................................ 12

DIP Switch ........................................................................................................................................................................ 13

OUTDOOR UNIT CONTROLS & COMPONENTS

PAGE 8

ENGLISH

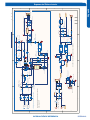

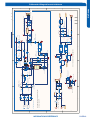

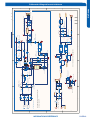

Outdoor Unit Introduction

The outdoor condensing unit models are heat pump systems. The outdoor unit has two circuit boards, a Module board that

drives the compressor and a Main Control Board that manages system functions and inverter calculations. Temperature

sensors monitor key temperatures throughout the system to manage operational decisions.

Outdoor Component Identication

4-Way Valve

Accumulator

Compressor

Defrost Temperature Sensor

Discharge Temperature Sensor

Electronic Expansion Valve

Refrigerant Filters

Outdoor Ambient Temperature Sensor

Outdoor Fan Motor

Power Factor Reactor

Suction Line Temperature Sensor

Terminal Block

Main Control Board

(board cover not shown)

Module Control Board

Fan Blade

Base Pan Heater

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

8

4

6

11

12

13

14

1

3

16

2

7

5

9

10

15

OUTDOOR UNIT CONTROLS & COMPONENTS

PAGE 9

ENGLISH

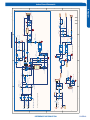

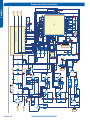

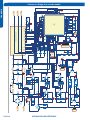

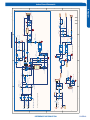

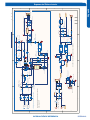

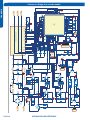

Outdoor Control Board

PCB (1) (Outdoor Control PCB)

PCB (2) (Module PCB for 09-12K )

PCB (3) (Module PCB for 18-24K )

2

CN3 - Connector for ground

10

CN36 - Connector for communicate

between indoor and outdoor unit

6

CN11 - Connector for four way valve coil

4

CN9, CN8 - Connector for

CN2,CN1 on the module board

12

CN50 - Connector for DRED-control

09-12

18-24

8

CN24 - Communication connector for

control board and the module board

CN1, CN2 - Connector for power N and L

CN17, CN47 - Connector for

thermistors

7

CN23 - Connector for DC POWER

15V and 5V to the module board

3

CN15 - Connector for

electric expansion valves

11

CN28, CN25 - Connector to

P and N of the module board

9

CN22 - Connector for fan motor

5

FUSE 1: (25A, 250VAC); FUSE 2:(1A, 250VAC)

13

LED 1 - Constant ON is normal operation, ashing

indicates alarm.

14

RV1, RV2, RV3 Varistor

15

CN10 - Connector for the DC power 5V and 15V

form the control PCB

18

Base Pan Heater Connection

16

BM2-1, BM2-2 - Defrost DIP Switches

17

CN10 - Connector for the DC power 5V

and 15V form the control PCB

23

23

CN11 - Connector for communicate between the

control board and the module board

19

CN11 - Connector for communicate between the

control board and the module board

24

P (CN1), N (CN5) - Connector for capacitance board

20

P (CN8), N (CN9) - Connector for capacitance board

25

25

LI (CN7), LO (CN6) - Connector for reactor

21

21

LI (CN3), LO (CN4) - Connector for reactor

26

CN2, CN3, CN4 - Connector for the U, V, W

wire of the compressor

22

CN5, CN6, CN7 - Connector for the U, V, W

wire of the compressor

27

27

1

2

3

16

17

5

4

6

8

9

10

12

13

11

7

18

19

20

22

24

26

1

OUTDOOR UNIT CONTROLS & COMPONENTS

PAGE 10

ENGLISH

Terminal Block

Power Factor Reactor

The Reactor is an inductive lter that will aid in correction of

electrical power factor inuence of inverter capacitance. It is

unlikely to ever have an electrical failure of this component.

The Reactor is electrically connected to the Module Board on

terminal connections CN-7 and CN-8.

The outdoor unit is powered by 208/230 Volt Single Phase

electricity connected at the Outdoor Unit Terminal Block.

Terminals 1 and 2 on the outdoor unit terminal connect

this voltage to the system. The number 3 terminal is a

communication terminal that connects wiring between the

indoor and outdoor units. An earth ground source terminal

connects the outdoor unit to the line voltage power source.

Condensate safety switches should break wire 1.

The indoor unit is also powered by the same electrical supply

as the outdoor unit. #14 AWG wire is connected to the wiring

terminal block at the outdoor unit and is run to the indoor unit

wire terminal block.

When installing the eld supplied wiring, make certain the

wire gauge is correct. There should not be any electrical

wiring splices between the indoor unit and outdoor unit

wire. Wire #3 is used to carry communication data between

the indoor and outdoor units. A wiring splice where wires

are twisted in a wire nut may cause deformation of the

communication of the data signal. If communication is lost

between the indoor and outdoor units, an ERROR CODE E7

will occur.

Compressor

Outdoor Fan Motor

The outdoor fan motor is a variable speed motor. The

required motor speed is calculated by the Main Control

Board. The motor is electrically connected to the Main

Control Board via PLUG CN-21.

In COOL MODE operation, the motor will slow down as

outdoor air temperature falls. In HEAT MODE operation, the

motor will increase speed as the outdoor air temperature

falls.

The compressor is a three phase DC inverter driven Rotary

type. The compressor is capable of variable speed operation.

The compressor operating frequency will be determined by

the temperature dierence between set point and room or

outdoor air temperature. (Cool Mode versus Heat Mode)

The compressor is electrically connected to the Module

Board on terminal connections CN-2, CN-3 and CN-4.

The compressor has an internal temperature overload that

will open if the compressor becomes too hot. Additional

protection of the compressor will be provided by the

Compressor Discharge Temperature Sensor and Suction

Line Temperature Sensor.

OUTDOOR UNIT CONTROLS & COMPONENTS

PAGE 11

ENGLISH

Discharge Temperature Sensor

Defrost Temperature Sensor

The Defrost Temperature Sensor is a negative coecient

thermistor that will change resistance in response to outdoor

coil temperature changes. The Main Control Board monitors

the temperature of the outdoor coil to determine when the

system is needing to perform a defrost cycle. The sensor also

monitors outdoor coil temperature during defrost cycles to

determine termination conditions.

This sensor connects to the Main Control Board at PLUG

CN-19.

The Discharge Temperature Sensor is a Negative Coecient

thermistor that senses the temperature of the compressor

hot gas. The Main Control Board monitors the temperature of

the compressor hot gas and will make inverter speed changes

in response to input from this device.

This sensor connects to the Main Control Board at PLUG

CN-17.

Outdoor Ambient Temperature Sensor

Suction Line Temperature Sensor

The Suction Line Temperature Sensor is a negative

coecient thermistor that senses the temperature of

the suction line. The Main Control Board monitors the

temperature of the suction line to determine EEV orice size

in an attempt to maintain proper operating superheat.

This sensor connects to the Main Control Board at PLUG

CN-18.

The Outdoor Ambient Temperature Sensor is a negative

coecient thermistor that will change resistance in response

to outdoor air temperature changes. The Main Control Board

monitors the temperature of the outdoor air to determine

outdoor fan speed requirements and inverter speed. The

sensor also plays a role in calculation of required defrost

conditions.

This sensor connects to the Main Control Board at PLUG

CN-20.

OUTDOOR UNIT CONTROLS & COMPONENTS

PAGE 12

ENGLISH

4-Way Valve

Electronic Expansion Valve

The metering device is an electronic expansion valve type

EEV. The valve consists of an electrical operator and a valve

body with internal variable size orice. When operating,

the Main Control Board will send pulses of voltage to the

electrical operator. The operator will then magnetically move

the position of the metering orice pin to vary its size.

The metering device position is determined by input from

a Suction Line Temperature Sensor located in the outdoor

unit. The EEV will change the internal orice size to maintain a

superheat level of around 10°F.

The 4-Way Valve redirects the ow of refrigerant in the piping

circuit to allow the system to swap the functions of the indoor

and outdoor coils. When de-energized in COOL MODE, the

valve will direct the refrigerant hot gas to the outdoor coil.

When energized in HEAT MODE, the valve will direct the hot

gas to the indoor coil.

The valve ow direction capability is controlled by an

electrical solenoid. When energized by 240 Volts, line voltage,

the solenoid will magnetically move an internal slide within

the 4-Way Valve to change the direction of refrigerant ow.

The 4-Way Valve is electrically connected to the Main Control

Board at PLUG CN-10.

Accumulator

The Accumulator is located in the suction line circuit at the

entrance to the compressor. The accumulator helps prevent

liquid refrigerant from entering the compressor during run

operation.

Refrigerant Filters

Electrical Base Pan Heater

The system has debris catching lters that protect internal

system components from contaminants in the refrigerant.

The lter is a permanent part that is not typically replaced.

During COOL MODE operation, the valve meters low

pressure refrigerant to the indoor coil. During HEAT MODE

operation, the valve meters low pressure refrigerant to the

outdoor coil.

The system has an electrical base pan heater for defrosting.

OUTDOOR UNIT CONTROLS & COMPONENTS

PAGE 13

ENGLISH

DIP Switch

DIP Switch Settings

The outdoor unit PCB board DIP switches are used to control

defrost cycle settings. The DIP switches are factory set for

Demand Defrost (BM2-1 ON, BM2-2 ON). The DIP switch

settings may be adjusted as follow:

BM2-1 BM2-2 Description - (Defrost is generally every 45 minutes)

OFF OFF Demand defrost for cold climate (default)

ON OFF

Time defrost at lower frequency

(10 Hz lower than the regular defrost)

OFF ON

Time defrost at higher frequency

(10 Hz higher than the regular defrost)

ON ON Demand defrost for moderate climate

INDOOR UNIT CONTROLS & COMPONENTS

PAGE 14

ENGLISH

[Thispageintentionallyleftblank.]

INDOOR UNIT CONTROLS & COMPONENTS

PAGE 15

ENGLISH

Indoor Unit Controls & Components

Table of Contents

Indoor Unit Introduction .................................................................................................................................................. 16

Indoor Component Identication ..................................................................................................................................... 16

Indoor Control Board ........................................................................................................................................................17

Terminal Block .................................................................................................................................................................. 18

Display .............................................................................................................................................................................18

Ambient Temperature Sensor .......................................................................................................................................... 18

Coil Temperature Sensor .................................................................................................................................................. 18

Louver Motor ................................................................................................................................................................... 19

Fan Motor ......................................................................................................................................................................... 19

Emergency Button ........................................................................................................................................................... 19

DIP Switch and DIP Switch Settings .................................................................................................................................. 20

INDOOR UNIT CONTROLS & COMPONENTS

PAGE 16

ENGLISH

Indoor Component Identication

Indoor Unit Introduction

The indoor unit is mounted high on the wall to provide air conditioning coverage of a conditioned space. Field installed/supplied

condensate pump accessories can be added to these systems.

Features of the system include: Variable speed blower operation that speeds up and slows down with changes in demand,

Moving louvers to direct air, Indoor air temperature sensing, Evaporator coil temperature sensing, Consumer operation display,

Evaporator coil with metering device located in outdoor unit, and an Emergency Operation Switch.

Indoor Ambient Temperature Sensor

Display

Fan Motor

Louver Motor

1

2

3

4

Main Control Board

Piping Temperature Sensor

Terminal Block

5

6

7

5

7

6

4

1

3

2

INDOOR UNIT CONTROLS & COMPONENTS

PAGE 17

ENGLISH

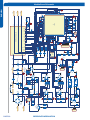

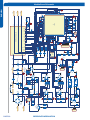

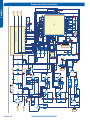

Indoor Control Board

2

2

CN27 - Connector for ground

4

4

CN6 - Connector for thermistors

9

9

CN2 - Connector for wiring-control

6

6

CN7 - Connector for display

11

11

CN34 - Connector for Wi-Fi-control

RV1 - Varistor

13

13

SW2 – 1-Select remote code A or B,

2-Select room card enable or disable

3,4-Select eeprom code 23, 26, 33 and 35

CN21, CN52 - Connector for power N and L

1

CN11 - Connector for left-right stepper motor

8

8

CN9 - Connector for fan motor

5

5

SW1 - Connector for Emergency

operation ON / OFF switch

12

15

15

CN23 - Connector for communication

between indoor and outdoor unit

3

3

CN51 - Connector for room card

10

10

CN5 - Connector for up-down stepper motor

7

7

14

14

FUSE1 - Fuse 3.15A/250VAC

12

INDOOR UNIT CONTROLS & COMPONENTS

PAGE 18

ENGLISH

Terminal Block

Display

The indoor unit terminal block receives electrical power from

the outdoor unit. There are 4 connections for electrical wires.

Terminals 1 and 2 are connected to terminals 1 and 2 of the

outdoor unit. This wiring supplies power to the indoor unit.

Terminal 3 is a communication wire. The indoor unit sends

indoor air temperature, coil temperature and temperature

setpoint information to the outdoor unit on this wire. If a

splice or break in this wire is present, the indoor unit will not

be able to communicate with the outdoor unit. The ERROR

CODE will be code E7.

The indoor display has an infrared communication circuit that

receives operating commands from the remote control. This

display will indicate operating modes, error codes, indoor air

temperature, timer status and power status.

Ambient Temperature Sensor

The Room Ambient Temperature Sensor is a negative

coecient thermistor that will decrease in resistance with

increases in room air temperature. The sensor is located on a

clip mounted to the surface of the indoor coil.

The sensor connects to the control board at Plug CN-6.

Coil Temperature Sensor

The Coil Temperature Sensor is a negative coecient

thermistor that will decrease in resistance with increases in

coil temperature. The sensor is located in a socket soldered

to the surface of the indoor coil.

This sensor will monitor the temperature of the indoor coil

in both cooling and heating modes of operation. Should

abnormally cold or hot coil temperature be detected by this

sensor, the system will take functional corrective steps to

correct the condition or report an ERROR CODE.

The sensor connects to the control board at Plug CN-6.

INDOOR UNIT CONTROLS & COMPONENTS

PAGE 19

ENGLISH

Stepper Motor Louver

Fan Motor

Emergency Button

The Indoor Fan Motor is a variable speed motor. The

motor will vary speed with the speed of the compressor

inverter. The speed can also be set at the remote control

or automatically adjusted using the AUTO fan mode. When

in AUTO fan mode, the speed of the fan is calculated using

the indoor set temperature and the indoor room ambient

temperature. (Outdoor air temperature in heat mode.)

The Fan Motor is connected to the indoor control board via

PLUG CN-9.

If the remote control is non-functional, the Emergency

Button can be accessed by swinging open the front of the wall

unit. The button is located on the right side.

Pushing this button will activate AUTO MODE operation.

AUTO MODE activated with this button will maintain 75°F.

The system will stay in this mode until commands are

received by the indoor unit communication circuit via the

remote control.

The STEPPER MOTOR moves the louver up or down, and

right or left depending upon selections made at the remote

control.

The motor is connected to the indoor control board at PLUG

CN-11.

INDOOR UNIT CONTROLS & COMPONENTS

PAGE 20

ENGLISH

DIP Switch Settings

The PCB for the indoor unit of the Advanced series of single

zone mini-splits has a set of DIP switches that must be set

when replacing the PCB.

The replacement PCB is shipped with all switches set to the

OFF position.

Switch settings:

SW2-1 Selects remote code A or B. Normally set to the o

position for code A operation.

If two indoor units are used in the same area and the user

wishes to control them separately, switch SW2-1 of the

second unit is set to the ON position for code B operation.

The wireless remote for the second unit is also set to code B.

SW2-2 Selects room card enable or disable.

Normally set to the OFF position. Set to the ON position

when used in conjunction with a room card interface utilized

in hotel rooms.

SW-3 & SW-4 Selects eeprom code 23, 26, 33 and 35. Set to

identify the tonnage of the unit.

Settings:

9K (23) SW-3 OFF SW-4 OFF

12K (26) SW-3 OFF SW-4 ON

15K (33) SW-3 ON SW-4 OFF

18K (33) SW-3 ON SW-4 OFF

24K (35) SW-3 ON SW-4 ON

DIP Switch

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

Haier 1U12AP2VHA Manuel utilisateur

- Catégorie

- Climatiseurs split-system

- Taper

- Manuel utilisateur

- Ce manuel convient également à

dans d''autres langues

- English: Haier 1U12AP2VHA User manual

- español: Haier 1U12AP2VHA Manual de usuario

Documents connexes

Autres documents

-

Fujitsu AOTG45LBLA6 Guide d'installation

-

Hitachi RAC-D18EX3 Manuel utilisateur

-

Hitachi RAC-50FX8 Manuel utilisateur

-

Hitachi RAF-35NX2 Manuel utilisateur

-

Hitachi RAD40QH4 Manuel utilisateur

-

Olimpia Splendid Sherpa AQUADUE S2 Manuale d'installazione

Olimpia Splendid Sherpa AQUADUE S2 Manuale d'installazione

-

Hitachi RAC-18SX8 Manuel utilisateur

-

Hitachi RAC-18SX8 Manuel utilisateur

-

Fujitsu AUGA36FRTA Guide d'installation

-

Fujitsu UTY-XWZXZJ Guide d'installation