Amerec AI Boiler, "AI12 Through AI48" Mode d'emploi

- Catégorie

- Chauffe-eau

- Taper

- Mode d'emploi

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 1 of 29

COMMERCIAL STEAM GENERATOR

WITH COOLFLUSH™ AUTO DRAIN OPTION

AND INTEGRAL LOW WATER CUT-OFF

BOILERS FOR LARGE STEAM ROOMS

INSTALLATION INSTRUCTIONS

MODELS AI 12, AI 18 AI 24, AI 30, AI 36, AI 42 & AI 48

208 and 240V 1 & 3 phase, and 480V 3 phase

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 2 of 29

INDEX

SECTION PAGE

WARNINGS 3-6

GENERAL INFORMATION 7

WATER QUALITY REQUIREMENTS 7

BOILER RATINGS 8

INSPECTION INFORMATION 9

DIMENSIONS 10

INSTALLATION 11

GENERATOR 11

PLUMBING 11

WATER LINE 11

STEAM LINE 12

SAFETY VALVE 13

DRAIN 13

ELECTRICAL SERVICE 12

ROOM CONTROLS 14

TEMPERATURE SENSOR 14

THERMOSTAT 15

ROOM SWITCH (I60 or other) 15

and Bath Time Settings

REFRESH SWITCH 16

WIRING DIAGRAM – CONTROL CIRCUITS 17

WIRING DIAGRAM – POWER AND CONTACTOR 18

STARTING THE GENERATOR 19

OPERATING INSTRUCTIONS 20

BOILER START 20

STEAM ROOM OPERATION 20

THE THERMOSTAT 21

THE I60 SWITCH 21

THE REFRESH™ SWITCH 21

LIGHTS AND SWITCHES 21

ROUTINE MAINTENANCE 22

WATER LEVEL CONTROL 22

LOW WATER CUT-OFF (LWCO) 22

BLOWDOWN - CoolFlush™ AUTO DRAIN OPTION 23

BLOWDOWN - MANUAL DRAIN 24

APPENDIX 1: RUN CLOCK AND AUTOBLOWDOWN TIMERS 25

APPENDIX 2: RUN AND AUTOBLOWDOWN DIGITAL CLOCKS 27

APPENDIX 3: PRESSURE CONTROL ASSEMBLY 29

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 3 of 29

WARNING

SAVE THIS MANUAL

A MANUFACTURER’S REPORT: CONTROLS AND SAFETY DEVICES is supplied with each generator.

You may be required to present this form to a state, provincial or other inspection agency.

Secure this document in a safe location.

Thank you for purchasing your new AMEREC steam generator.

If we can be of any assistance do not hesitate to call our Technical Support at 1-800-363-0251.

FOR THE SAFETY OF YOU AND YOUR FAMILY OR CUSTOMERS, PLEASE READ THE FOLLOWING

WARNINGS AND ALL INSTRUCTIONS BEFORE USING YOUR STEAMBATH.

POST "STEAMBATH INSTRUCTIONS" LABEL OUTSIDE STEAMBATH FOR SAFETY WARNINGS.

FOR THE SAFETY OF YOU AND YOUR FAMILY OR CUSTOMERS, PLEASE READ THE

FOLLOWING WARNINGS AND ALL INSTRUCTIONS BEFORE USING YOUR STEAMBATH.

POST "STEAMBATH INSTRUCTIONS" LABEL OUTSIDE STEAMBATH FOR SAFETY WARNINGS.

Electric Shock Hazard - High voltage exists within this equipment. Disconnect all electrical power

before servicing the generator. All installation and service to this equipment should be performed by

qualified licensed personnel in accordance with local and national codes. There are no user

serviceable parts in this equipment.

Electrical grounding is required on all AMEREC steambath generators. The generator is designed for hookup

with copper wire only, 75°C or better.

Wire the controls exactly as described. Do not connect any additional wiring or power supplies to the controls or

their terminals in the generator.

Service only by authorized personnel!

All plumbing must be installed by a licensed plumber in accordance with all applicable local and national codes.

Install indoors only. Protect from freezing. Generator must be level side to side and end to end.

The pressure relief valve and generator drain must be installed in such a fashion that the risk of scalding is

reduced to a minimum. Draining these outlets into the steam room may present a scald hazard and may damage

materials used to construct the room.

Danger To reduce the risk of explosions, do not interconnect steam lines!!

Caution The steam outlet carries hot vapor! A separate steam line is required for each steam outlet.

Do not connect a valve or shut-off in the steam line! Avoid traps and valleys in the steam line where

water could collect and cause a steam blockage. The hot steam line must be insulated against user contact.

Do not install the steam head near a bench or where steam may spray or where condensation will drip on the

user as this will present a scald hazard.

Be certain that steambath enclosures are properly sealed to avoid water damage from escaping steam. It is

recommended that 100% silicone caulk be used to seal all pipes and fittings. Steam must be prevented from

escaping into the wall cavity. Centering the steam pipe is critical in rooms made of plastic, acrylic, resin,

fiberglass or similar materials. Allowing the steam pipe to touch materials not rated 240°F (115°C) or higher will

result in damage to these materials.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 4 of 29

AVERTISSMENT

Merci pour l'achat de votre nouveau AMEREC AK générateur de vapeur.

Si nous pouvons vous être utiles n'hésitez pas à appeler notre assistance technique au 1-800-363-0251.

POUR LE SËCURITË DE VOTRE FAMILLE ER VOUS OU CLIENTS, VEUILLEZ

LIRE LES AVERTISSEMENTS SUIVANTS ET TOUTES LES INSTRUCTIONS AVANT

D'UTILISER VOTRE BAIN DE VAPEUR.

POST "BAIN DE VAPEUR" LABEL HORS D UN BAIN DE d'INSTRUCTIONS

POUR DES AVERTISSEMENTS EN MATIÈRE DE SÉCURITÉ.

ENREISTREZ CE MANUEL

POUR LA SËCURITË DE VOTRE FAMILLE ET VOUS OU VOS CLIENTS, VEUILLEZ LIRE

APRèS AVERTISSEMENTS ET TOUTES LES INSTRUCTIONS AVANT D'UTILISER VOTRE BAIN DE

VAPEUR. POST "BAIN DE VAPEUR" LABEL HORS D' UN BAIN DE VAPEUR D'INSTRUCTIONS POUR DES

AVERTISSEMENTS EN MATIÈRE DE SËCURITË.

Risque de choc électrique - Haute tension existe au sein de ce matériel. Débranchez toute source d'alimentation

avant de procéder à l'entretien du générateur. Toutes les instructions d'installation et service à cet équipement doit

être effectuée par du personnel autorisé qualifié conformément aux codes locaux et nationaux. Il n'y a pas de

pièce réparable par l'utilisateur à cet équipement.

Mise à la terre électrique est requis sur tous les générateurs bain de vapeur AMEREC. Le générateur est conçu pour

connecter un fil de cuivre uniquement, 75 °C ou mieux.

Câbler le contrôle très exactement comme indiqué. Ne connectez aucun câblage supplémentaire ou blocs d'alimentation pour

les commandes ou leurs terminaux dans le générateur.

Service uniquement par le personnel autorisé!

Toute la tuyauterie doit être installé par un plombier sous licence conformément à tous les codes locaux et nationaux

applicables.

Installer à l'intérieur uniquement. Protéger du gel. Générateur doit être mise à niveau latérale et l'extrémité à l'autre.

La valve de limitation de pression et purge du générateur doit être installé de telle façon que le risque de brûlure est réduit à

un minimum. Vidange de ces prises dans la salle de vapeur peut présenter un risque de brûlure et peut endommager les

matériaux utilisés pour construire la salle.

Danger Pour réduire les risques d'explosion, ne pas connecter les conduites de vapeur t!!

Attention La sortie vapeur transporte vapeur chaude ! Une conduite de vapeur distincte est requise pour

chaque sortie vapeur. Ne connectez pas une valve ou l'arrêter dans la conduite de vapeur! Éviter les pièges et

les vallées dans la conduite de vapeur où l'eau pourrait recueillir et provoquer un blocage de vapeur. La vapeur chaude ligne

doit être isolée par rapport au contact de l'utilisateur.

Ne pas installer la tête de vapeur près d'un banc ou où la vapeur peut pulvériser ou où la condensation s'égoutter sur

l'utilisateur comme cela présentera un risque de brûlure.

Etre certain que le bain de vapeur boîtiers sont étanches afin d'éviter les dégâts d'eau de s'échapper la vapeur. Il est

recommandé que 100% mastic au silicone utilisée pour obturer tous les raccords et tuyaux. La vapeur doit être empêché de

s'échapper dans la cavité du mur. Centrage du tube à vapeur est critique dans les chambres faites de plastique, de

l'acrylique, résine, la fibre de verre ou des matériaux similaires. Permettant le tube à vapeur pour toucher les matériaux non

coté 115°C ou plus aura pour effet d'endommager ces matériaux.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 5 of 29

POST "WARNING LABEL OUTSIDE STEAMBATH FOR SAFETY WARNINGS. REQUIRED POSTING ON

DOOR OF STEAM ROOM OR ADJACENT TO DOOR FOR ALL COMMERCIAL INSTALLATIONS.

Étiquette d'avertissement "Extérieur poste baiin de vapeur pour les avertissements relatifs à la sécurité

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 6 of 29

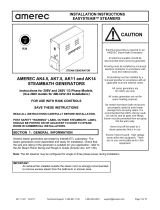

IMPORTANT USER SAFETY INSTRUCTIONS

1. READ AND FOLLOW ALL INSTRUCTIONS.—SAVE THESE INSTRUCTIONS!

2. The steam bath is not intended for use by anyone (including children) with reduced physical, sensory or mental capabilities or who lack

experience or knowledge, unless they have supervision or training on the use of the steam bath by a person responsible for their safety.

3. WARNING - To reduce the risk of injury, do not permit children to use this product unless they are closely supervised at all times.

Ensure they do not play in the steam bath.

4. WARNING - To reduce the risk of injury:

a. The wet surfaces of steam enclosures may be slippery. Use care when entering or leaving.

b. The steam head is hot. Do not touch the steam head and avoid the steam near the steam head.

c. Prolonged use of the steam system can raise excessively the internal human body temperature and impair the body’s ability to

regulate its internal temperature (hyperthermia). Limit your use of steam to 10 to 15 minutes until you are certain of your body’s

reaction.

d. Excessive temperatures have a high potential for causing fetal damage during the early months of pregnancy. Pregnant or possibly

pregnant women should consult a physician regarding correct exposure.

e. Obese persons and persons with a history of heart disease, low or high blood pressure, circulatory system problems, or diabetes

should consult a physician before using a steam bath.

f. Persons using medication should consult a physician before using a steam bath since some medication may induce drowsiness

while other medications may affect heart rate, blood pressure and circulation.

5. WARNING - Hyperthermia occurs when the internal temperature of the body reaches a level several degrees above the normal body

temperature of 98.6°F (37°C). The symptoms of hyperthermia include an increase in the internal temperature of the body, dizziness,

lethargy, drowsiness and fainting. The effects of hyperthermia include:

a. Failure to perceive heat:

b. Failure to recognize the need to exit the steam bath:

c. Unawareness of impending risk:

d. Fetal damage in pregnant women:

e. Physical inability to exit the steam bath: and

f. Unconsciousness.

6. WARNING - The use of alcohol, drugs or medication can greatly increase the risk of hyperthermia

1. Lire et suivre toutes les instructions. -- Conservez ces instructions !

2. Le bain de vapeur n'est pas destiné à être utilisé par toute personne (y compris les enfants) avec toutes leurs capacités physiques,

sensorielles ou mentales ou qui manquent d'expérience ou de connaissances, à moins qu'ils aient la supervision ou de la formation sur

l'utilisation du bain de vapeur par une personne responsable de leur sécurité.

3. Avertissement : Pour réduire les risques de blessures, ne pas permettre aux enfants d'utiliser ce produit, sauf s'ils sont étroitement

surveillés en tout temps. S'assurer qu'ils ne jouent pas dans le bain de vapeur.

4. Avertissement : pour limiter les risques de blessure :

a. Les surfaces mouillées de boîtiers de vapeur peut être glissant. Soyez prudent lorsque vous entrant ou sortant.

b. La tête de vapeur est chaud. Ne pas toucher la tête de vapeur et éviter la vapeur près de la tête de vapeur.

c. Une utilisation prolongée de la chaudière à vapeur peut augmenter excessivement la température du corps humain et d interne

nuisent à la capacité du corps de régler sa température interne (hyperthermie). Limitez votre consommation de vapeur pour 10 à

15 minutes jusqu'à ce que vous soyez certain de la réaction de votre corps.

d. Des températures excessives ont un haut potentiel de causer de dommages foetaux pendant les premiers mois de la grossesse.

Enceinte ou peut-être les femmes enceintes devraient consulter un médecin au sujet de l'exposition correcte.

e. Les personnes obèses et les personnes ayant des antécédents de maladie du coeur, tension artérielle basse ou élevée, des

problèmes du système circulatoire ou de diabète devraient consulter un médecin avant d'utiliser un bain de vapeur.

f. Les personnes qui utilisent ces médicaments devraient consulter un médecin avant d'utiliser un bain à vapeur depuis quelques

médicaments peut induire une somnolence tandis que d'autres médicaments peuvent affecter la fréquence cardiaque, la tension

artérielle et de la circulation.

5. Avertissement - L'hyperthermie survient lorsque la température interne du corps atteint un niveau à plusieurs degrés au-dessus de la

normale de la température corporelle de 37 °C. Les symptômes de l'hyperthermie comprennent une augmentation de la température

interne du corps, sensation vertigineuse, léthargie, somnolence et d'évanouissement. Les effets de l'hyperthermie comprennent :

a. L'incapacité de percevoir la chaleur

b. L'incapacité à reconnaître la nécessité de quitter le bain de vapeur :

c. La méconnaissance de l'imminence d'un risque :

d. Dommages au foetus chez les femmes enceintes :

e. Incapacité physique pour quitter le bain de vapeur : et

f. L'inconscience.

Avertissement - La consommation d'alcool, de drogues ou de médicaments peut augmenter considérablement le risque d'une hyperthermie

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 7 of 29

GENERAL INFORMATION: The AI Commercial Steam Generator is a low

pressure heating boiler, UL/CUL Listed, built to NEC requirements and with an ASME “H”

stamped certified and National Board registered pressure vessel.

The generator has all steel construction with powder coated finish on visible surfaces and stainless steel

mounting feet to minimize the risk of corrosion. The mounting feet hold the generator one inch above the floor to

allow cleaning the floor below it and to further prevent corrosion. This also allows the generator to sit directly on a

combustible surface without additional protection. The feet extend beyond the sides of the generator chassis and

have clearance holes to allow securing the generator in place using ¼” bolts.

AI Commercial Steam Generators are factory assembled and tested and ready to install. All generators are

plumbed for a ½” potable water feed inlet, a ¾” drain discharge and a ¾” pressure relief valve discharge.

Generators are available for connection to 208VAC or 240VAC single or three phase, or 480VAC in three phase

only. All models require the appropriate full power electrical service plus ground. Models in 208V and 240V also

require a 14 gauge minimum Neutral for the control circuit; 480V models require a separate 120VAC+N service

for the control circuit. Use 75° minimum copper wire for all service connections. A ¾”-1”-1½”-2” combination

knockout is provided in the generator’s electrical box for the main service conduit and an additional ½”-¾”

knockout is provided for the 480V models’ 120V control service.

The generator’s control circuit is protected by a 250VAC 3A non-time-delay fuse installed in the front panel of the

generator’s electrical box. No other fusing is installed in the steam generator.

Room controls (

ON/OFF, thermostat, temperature sensing and steam Refresh™) are connected during generator

installation using factory supplied wire or cables. Room controls operate on a low voltage Class 2 circuit. An

access hole and ½” trade size knockouts, are provided for room control wiring. The thermostat must be mounted

outside the steam room, the temperature sensor must be mounted inside the steam room, the optional Refresh™

switch mounts inside the steam room, and the optional

I60 Bath On/Off switch must mount outside the steam

room. Temperature sensors require factory supplied cables for connection to the generator, all other controls

require 3 conductors, 18 to 24 AWG copper, 75° 300V minimum (50 foot long cables are provided, longer cable

may be available: contact Technical support for assistance).

Standard equipment:

Manual operation (generator mounted RUN switch and manual ball valve drain) and single steam room (one

steam valve, one temperature sensor, one thermostat with integral steam bath

ON/OFF switch and bath-on

indicator light, two steam heads).

Switches allowing manual heat and water control during routine service, lights indicating heat and valve

operating status and self-check fault codes.

A built in automatically resetting Low Water Cut Off and a built in manual reset LWCO.

Optional equipment:

Second steam room (second steam valve, thermostat and temperature sensor) factory installed only!

RUN CLOCK (7-day or 24 hour programmable time clock or 7-day programmable digital clock for generator

ON/OFF scheduling).

CoolFlush™ Auto Drain consisting of a ¾ inch electronically operated ball valve and a time clock. (7-day or

24 hour programmable time clock or 7-day programmable digital clock for generator are available).

I60 Steam bath on/off switch: commercial (mounts to single gang switch box in a dry location only). Bath

time is switch selectable for automatic bath time out of 15, 30 or 60 minutes using a switch on the boiler’s

circuit board.

Steam bath

ON/OFF switch: residential (membrane switch, may be mounted in steam room, operates the

same as the

I60).).

Steam Refresh™ (membrane switch for mounting inside steam room, status indicator light).

Water Quality Requirements:

The nature of a steambath generator requires testing of the feedwater to avoid potential high concentrations of

impurities which can cause a deposit or scale to form on the internal surfaces. This deposit or scale can interfere

with the equipment’s proper operation and even cause premature generator failure. Concentration of impurities is

generally controlled by treating the feedwater and/or “blowing down” the generator when it is not heating. The

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 8 of 29

“blow down” process involves removing a portion of the tank water with high solid concentration and replacing it

with makeup water.

To reduce corrosion and element damage risks, always flush new feedwater lines thoroughly to eliminate flux

residue and avoid sodium based water softeners. The ASX-200 filter system available from Amerec provides

very good protection in most installations and should be connected to a cold water supply. Feedwater

temperature must be no hotter than 100°F if the ASX-200 is installed! Contact Technical support for more

information.

To insure proper operation, the water supply should be tested prior to operating the equipment. There are

several treatment processes which can be used if you have a problem with hard water. A local reliable water

treatment company can recommend the appropriate treatment if required. The recommended feedwater quality is

listed below.

Feedwater Quality

Hardness, ppm 10 – 30 (.5 – 1.75 gpg)

T-Alkalinity, ppm 150 – 700 (8.75 – 40.8 gpg)

Silica, ppm 15 – 25 (.875 – 1.45 gpg)

PH (strength of alkalinity) 10.5 – 11.5

IMPORTANT! Regular maintenance will help your steamer work properly for a long time. Check for leaks, loose

or damaged wires, signs of corrosion and calcium build up in the tank and on the level probe.

This is particularly important in areas with high calcium levels and other water quality problems. Calcium buildup

can cause poor steamer performance and damage the heating elements!

AMEREC AI BOILER RATINGS

CATALOG#

UL MODEL#

WATTS

VOLTS

PHASE

AMPS

MAX ROOM

SIZE (CU FT)

STEAM

LB-HR

DIMENSIONS

(INCHES)

L W H

AI 12

12-208

12-208

12-240

12-480

12,000

208

208

240

480

1

3

1

3

59

34

51

15

550 36 20 x 22 x 24 ½

AI 18

18-208

18-208

18-240

18-480

18,000

208

208

240

480

1

3

1

3

88

51

76

22

900 54 20 x 22 x 24 ½

AI 24

24-208

24-208

24-240

24-480

24,000

208

208

240

480

1

3

1

3

116

68

101

29

1200 73 20 x 22 x 24 ½

AI 30

30-208

30-240

30-480

30,000

208

240

480

3

3

3

85

73

36

1500 91 20 x 28 x 24 ½

AI 36

36-208

36-240

36-480

36,000

208

240

480

3

3

3

101

88

43

1800 109 20 x 28 x 24 ½

AI 42

42-208

42-240

42-480

42,000

208

240

480

3

3

3

118

102

51

2100 127 20 x 28 x 24 ½

AI 48

48-240

48-480

48,000

240

480

3

3

117

58

2400 145 20 x 28 x 24 ½

Notes:

All models: no internal heating circuit fuses are needed, panel mounted 3A fuse provided for 120V control circuit

208V and 240V models supply 120V to control circuit internally, 480V models require a separate 120V service.

o For 208V and 240V models, run power wires + Ground and a 14AWG Neutral for controls.

o For 480VAC units, run 3 power wires + Ground and run a 120V +N service for the 3A control circuit.

Use only copper wire, rated 75°C or better. Install all wiring per local codes.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 9 of 29

INSPECTION INFORMATION

Pressure vessel: ASME “H” stamped

National Board Registered

MAWP 15 psig

LWCO, Auto and Manual Reset

UL Listed for US and Canada to UL834

All boilers ship with an H2 report and a CSD-1 form

Replacement forms can be obtained by contacting Technical Support

Please have the Serial No.

and Year Built ready when

calling Support for assistance.

Remove this cover to view

Vessel, ASME and

National Board information

Boiler ID Plate

Model and Specifications

LWCO Control switches

and status indicator

1 86

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 10 of 29

ASME - NB

PLATE BEHIND

THIS COVER

CHE CK

VALVE

PRESSURE SWITCHE S

ACCESS FROM FAR SIDE

PRESSURE RELIEF

ALL MODELS ALL MODELS

AI12, AI18, AI24 AI30, AI36, AI42, AI48

22 in

5

4

3

STEAMBATH

OFF

BATH

10

ON

1

OPTIONAL RUN

& DRA IN CLOCK S

ELECTRICAL SHOCK HA ZARD

FOR ASS ISTANC E C ALL

DISC O NNE CT POW ER SU PPLY

BE FOR E R EM O V IN G TH IS CO V E R

NO U SER SERV ICEAB LE PA RTS WI THIN

1-800-331-0349

SERVICEONLYBY AUTHOR IZED PERSONNEL

DRAINCLOCK

DESCAL ANT

ACCESS

24 ¹/2 i

n

23 in

20 in

FILL

2 ¹/4 in

DRAIN

5 ¹/2 in

FOR ASS IST ANCE CALL

DISCONNECTPOWERSUPPLY

BEFOR E R EM OVING THI SC OVE R

NOUSERSERVICEABLE PA RTS WITHIN

1-800-331-0349

SERV ICE O NLY BY A UTHOR IZE D PERSONN EL

ELECTR ICAL SH OCK HAZARD

0

30

2010

5

14

3

/

4

in

V

A

L

V

E

N

O

R

M

A

L

STEAM

VAL VE

OPEN

PHASE

SERIALNo.

MAX. CAPACITY

AMEREC,INC.,WOODINVILLE, WA

CE R TIFIEDANDMANUFACTUREDBY:

MAX. WOR KING PR ESS URE: STEA M, 100 psi

lb.s PERHO UR

NA TI O NALBOAR DNUMBERL OCATEDONSH ELL

VAC

UL

AMPS

YEARBUILT

MA X. kW

C

L

O

C

K

MANUAL

OPEN

BLOWDOWN/FLUS HBOIL ER DAILY

Blo wdo w n/f l us h bo il er at lea s t on ce a da y fo r c omme rci a l/ha r d - u se i ns ta l lat ion s and

in a r ea s of ha rd wate r. Fa ilu r e to p rope rly ma i nta in bo ile r ca n c aus e equ ipment

fa i lu re and ma y v o id wa rr ant y . R efe r to O pe rat ing Ma i ntene nc e In s t r uctions.

C A U T I O N : I mpr o per l y openi n g dr ai n may r el e ase da nge r o u sly

hot water orsteam. Referto Op er at i ng Mai n ten enc e Inst r uc t i o n s.

!

DRAIN

VAL VE

OPEN

ELECTR ONICD RAI N ( O P TIONAL)

N

O

R

M

A

L

FEEDWAT ER

N

O

R

M

A

L

STOP

FILL

HEAT

O

F

F

WAT ER

VAL VE

OPEN

BOILER

HEATING

ELECTR ICAL SHOCK HAZ ARD

SERVICEONLY BYAUTHOR IZED PE RSONNEL

1- 80 0-3 3 1-0349

NOUSERSERVICEAB LE PARTS WITHIN

BEFOR EREMOVINGTHIS COVER

DISCONNECTPOWERSUPP LY

FOR AS S I S T A NC E CA L L

R

O

O

M

2

R

O

O

M

1

IF LI G HT S A RE

BLIN KING RE FER

TO OP ER ATING

INST RU CT IO NS

MANUAL

RUN

ROOM1LOCKOUT

ROOM2LOCKOUT

C

L

O

S

E

BOILEROPERATION

(O P T IO N A L )

CLOCK RUN

STEAM

VAL VE

OPEN

BOILER ON

ROOMSTATUS

CON TR O LS

3A 250 VA C

LEVEL PROBE

ACCE SS

HAMM ER

ARRES TOR

STEAM

20

30

0

5

10

15

25

28 in

20

3

/

4

in

LEVEL PROBE

ACCE SS

25

15

16 ¹/2 in

20 in

OPTIONAL BOILE R

MOUN TED

THERMO STAT

17 ¹/2 in

RUNCL O CK

18 ¹/2 in

ELEC TRICAL

POWER ENTRY

GAGE

GLASS

29

ROOM TEMPERATURE

6

8

7

RESET

STATUS

TES T

LWC O

V

A

L

V

E

N

O

R

M

A

L

ST EAM

VALV E

OPEN

PHASE

SERIALN o.

MA X. C APACIT Y

AMERE C, I NC., W OODINV ILLE, WA

CE R TIFIEDANDMAN UFACTUREDBY:

MAX. WORKING PRESSURE: STEAM, 100 psi

lb.s PE R HOUR

NATIONALBOARDNUMBERL OCATEDONSHELL

VAC

UL

AMPS

YEARBUILT

MA X. kW

MAN UA L

OPEN

BLOWDOWN/FLUSH BOIL ER DAILY

Blo wdo w n/fl u sh bo iler at l ea s t on c e a da y fo r c omme rci a l/ha r d -u s e ins tallat ion s and

i n a rea s of ha rd wate r . F a ilu r e to p r ope rly ma inta i n bo ile r c a n c au s e equ i pment

fa il u re and ma y vo id wa rr ant y. R efe r to Ope rat ing Ma i ntene n c e In s tr uctions.

DRAIN

VALV E

OPEN

N

O

R

M

A

L

N

O

R

M

A

L

STOP

FILL

O

F

F

WA TER

VALV E

OPEN

BOILER

HEATING

R

O

O

M

2

R

O

O

M

1

IF LIGHTS ARE

BLIN KING RE FER

TOOPERATING

MAN UA L

RUN

C

L

O

S

E

(O PT I O NA L )

CLO CK RUN

ST EAM

VALV E

OPEN

BOILER ON

ROOMSTATUS

CONTROLS

3A 250 VA C

RESET

STATUS

TES T

LWC O

CA U TI O N : Imp r ope r l y op eni ng dr a i n ma y r e l ea s e dan ger o u sl y

hot water orsteam. Ref er to Opera t in g Mai nt enen ce I ns tr uc t i o n s.

!

C

L

O

C

K

ELEC TRO NICDRAI N (O P TION A L)

Shown with optional boiler mounted thermostat. All dimensions in inches.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 11 of 29

INSTALLATION

GENERATOR

AI

Steam Generators must be installed by a licensed plumber and electrician to local and national codes.

AI Steam Generators are intended for indoor use only.

Install upright and level side to side and front to back.

Not for space heating purposes.

Protect from freezing.

The steam generator is designed to sit directly on a hard level surface.

The mounting location must be suitable to safely support your boiler.

Models

AI12-AI24 may weigh more than 165lb and models AI30-

AI

48 may weigh more than 220lb. The generator must be mounted

upright and level and prevented from moving. Ensure that the generator is mounted high enough above the drain

receptacle to allow proper drain flow. The weight of the generator is generally sufficient to prevent movement.

Use ¼” bolts through the holes provided in the generator’s feet to secure it in place on the floor if necessary.

The generator’s back end (nearest the water gauge) may be installed 1” or further from a wall or combustible

surface. Use the lift handle to set the minimum clearance by placing the generator so the handle just touches the

adjacent surface. Keep combustibles at least 1” away from left side, 8” from right side plumbing and 6” from top

of switches and steam valve. Do not store solvents, paints or other flammables near the generator.

All electrical access is from the left side

and front end (as viewed at right). Up

to 480VAC may be exposed during

servicing. Leave space for service

access: at least 18” to front and left

side, 6” above the pressure switches

and valves.

Install per code: your local codes may

require even greater clearances.

Left Front

Leave sufficient space between the

right (plumbing) side and adjacent

surfaces to allow servicing the

plumbing when needed. Provide at

least 8” clearance from the piping for

access.

CAUTION: Exposed plumbing may be

over 200°F during normal operation

and can present a severe burn

hazard. Be sure to protect people from

accidental contact!

PLUMBING All valves are factory equipped with a short pipe nipple in their outlet. When attaching plumbing, hold

these nipples while tightening. Do not tighten plumbing by using a wrench on the brass valve bodies as

this can damage the valve! Brass or copper lines are recommended for all plumbing.

1. INSTALL WATER LINE

Run a ½” potable water feed line between the nearest cold water line and the WATER INLET fitting on the

generator. Cold feedwater is required for proper operation of the CoolFlush™ Auto Drain system. Special water

treatment may be required in your area – see Water Quality section on pages 7 and 8 for further details. Install a

shut-off valve near the generator. When tightening the water fittings, always use two wrenches so there will be no

strain on the water inlet valve. The water shut off valve must remain open during generator operation! We

recommend feedwater pressure between 20 and 50 psi. A water hammer prevention device is installed on your

boiler. Excessive water hammer can damage a water valve, preventing it from shutting off the water supply to the

generator!

Flush water supply line thoroughly before final hookup. Debris such as flux residue can prevent the inlet valve

from fully closing and may cause corrosion damage to the water valve or heating elements. A grit filter is factory

installed at the water inlet to trap large debris such as sand. Shut the water supply off and remove and clean the

filter periodically as dictated by local water conditions.

A check valve is installed in the boiler’s feedwater line. An additional customer supplied back-flow prevention

device may be required in your area. Check local codes. To prevent water level sensing errors, backflow

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 12 of 29

prevention is necessary in installations where the steam generator’s water supply is shared with another

generator or other nearby high usage connection.

2. INSTALL STEAM LINE

AI generators come equipped with ¾”NPT steam outlets. Do not place a shutoff device in the steam line! Locate

steam heads so bathers do not come into contact with a steam head and so steam may not exhaust directly on

any part of a bather’s body. Steam and steam heads are very hot and can cause severe burns!

Run a ¾” copper steam line from the generator to the steam room. The steam line should enter the steam room

18" above the floor.

IMPORTANT: The steam line should be pitched away from the generator so any condensate will drain from the

steam line. For best results, the generator should be installed as close to the steam room as possible, with its

steam outlet valve higher than the steam heads in the steam room and the steam line run straight to the steam

heads with a pitch of at least ¼” per foot to drain into the room. Do not allow sags, dips or other low sections in

the steam line: these may block the steam flow or cause spitting of very hot water into the steam room.

As with any steam bath steam generator, spitting, reduced steam and other problems can occur if too many

elbows or tees are placed in the steam line, if the line is too long, if the line has large rises or if there are low area

or traps in the line. The effects depend on the number and size of these practices in a particular installation.

To reduce noise or improve the distribution of steam in larger rooms, additional steam heads may be installed.

Two steam heads are supplied with each generator. Space steam heads at 6” intervals, minimum. The steam

heads should be located to ensure they do not discharge steam or drip condensate where the user may come in

contact with the hot moisture – contact may cause injuries from scalding to severe burns!

At the steam room: drill/prepare a 1

5

/

8

" hole at each steam head location for steam line entry 15 to 18” above the

floor. Terminate the steam line from the generator with a tee at the steam room then plumb each side of the tee

to a steam head location and through the wall. Center the

3

/

4

” copper steam pipe in the 1

5

/

8

" hole. Terminate the

steam line with a

3

/

4

” NPT male adapter. Stub the line out into the room

3

/

8

” from the finished surface. Secure the

steam lines to structural members.

Install steam heads so vent opening is pointed

towards the floor. Use Teflon thread tape to help aim

the steam head correctly if necessary. Protect the

steam head finish from damage while handling and

tightening. Seal the wall around the steam pipes and

all fixtures in the steam room with 100% silicone caulk

to avoid moisture damage within the walls.

IMPORTANT If the steam line is in an area where the

temperature will be below 40°F or if the line is more

than 20 feet long, best results can be obtained by insulating the steam pipe. Any insulation must be suitable for

temperatures of at least 250°F.

Seal rear

Of insulator

With silicone

12” min.

18”

12” min. 12” min.

6” min.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 13 of 29

3. INSTALL SAFETY VALVE LINE All AI generators are equipped with a factory installed 15 psi pressure relief

safety valve. This must be plumbed to a ¾” indirect waste line. Do not install a shut off device in this line. Do not

reduce this line. Do not form a trap in this line! Discharge from the safety valve may be at over 240°F. Do not

plumb this line into the steam room! Plumb this waste line per local plumbing codes.

4. INSTALL DRAIN All

AI generators are equipped with a factory installed manual ball valve to allow draining the

tank. An optional electronic drain may be installed after the manual valve. Plumb the drain to a ¾” indirect waste

line. If the drain is opened while the generator is under pressure, discharge from the drain may be at over 240°F.

Always plumb the drain with piping suitable for 240°F minimum. Do not plumb this line into the steam room!

Plumb this waste line per local plumbing codes. When equipped with an Autodrain system and with the pressure

control properly set to 4 to 5psi, drain water will be at or below 140°F during the CoolFlush™ Auto Drain cycle.

Local codes may require a (customer supplied) expansion tank or blowdown cooling tank if draining water in

excess of 140°F or 5 psi.

ELECTRICAL

Refer to the ID plate on the generator’s switch panel to determine voltage and current requirements. Electrical

service for all models requires two (single phase) or three (3 phase) hot leads plus a suitable ground connection.

Models operating on 208V or 240V also require a 14 AWG Neutral for the generator controls circuit. Models

operating on 480V require a separate 120V (14AWG) service for the controls circuit. Route the copper supply

wire with appropriate strain relief through the hole marked POWER ENTRIES. A multiple knockout is provided at

this point for electrical service using up to 2” conduit. A second knockout, ½” to ¾”, is provided for the 120V

controls circuit, if needed.

L1

L2

L3

3-Phase Power - 208/240

V

NEUTRAL

NEUTRAL

L1

L2

L3

1-Phase Power - 208/240

V

L1

L2

L3

3-Phase Power - 480

V

NEUTRAL

120V

Connect the control circuit’s Neutral (208/240V models) or 120V+N (480V models) to the outside terminal of the

small terminal block provided in the generator’s electrical enclosure. Connect the power service to the

generator’s large terminal block and the ground to the generator’s ground lug, located near the front edge of the

electrical enclosure (a copper wire clamping lug with green screw). Ensure all wires are tightly clamped at their

respective terminals.

CAUTION: Loose wire connections can cause heat damage to wires, terminal blocks and other

components and may void the warranty.

NOTE: A GFCI device is not required by UL. A GFCI may be installed if required by local codes or the owner. A

GFI device will tend to nuisance trip due to heater element aging.

C

240VAC 240VAC

N

120VAC 120VAC

240VAC

CAUTION when connecting to 3-phase: Your 3 phase 208/240VAC

may be supplied with one side center tapped and connected to Neutral

in order to provide 120VAC circuits. Check your voltage before

connecting to the boiler and make sure to use one of the lines

referenced to N (L1 or L2 at left) so the boiler’s L1 connection will have

a 120V supply for the control circuit. Connecting to the 240V High leg

(L3 at left) will supply too high a voltage and cause the boiler’s 3A fuse

to blow and it could damage parts and valves in the control circuit!

Also remember, 480V 3 phase requires bringing in a separate 120V

line for the control circuit!

L1

L2

L3

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 14 of 29

ROOM CONTROLS

Each steam valve outlet is to be used for a single steam room. Each room requires one temperature sensor

mounted in the room and one thermostat control mounted outside the room. The thermostat mounts to a

standard single switch/outlet electrical box. The thermostat may be mounted directly on the generator’s electrical

enclosure using a common ½” conduit z-bracket between the box and a knockout provided in the generator’s

electrical enclosure. To reduce the risk of electrical interference between circuits, do not run the low voltage

control cables inside the same conduit as high voltage circuits. Avoid running control cables closely alongside

high voltage wiring in cable troughs and raceways.

05

Two independent control circuits are available for two steam outlets to supply two separate steam rooms. If only

one valve is installed on the steam generator, it will be controlled by the ROOM 1 circuit with controls connected

to the terminal blocks alongside the upper left edge of the printed circuit board (PCA) located in the generator’s

electrical enclosure. When the (optional) second outlet is provided, the second room’s controls connect along the

lower left side of the circuit board in the same manner as the ROOM 1’s circuit’s described here..

1. TEMPERATURE SENSOR INSTALLATION The temperature sensor must be mounted in the steam room. Cut

a

7

/

8

” diameter hole in the steam room wall to mount the sensor. It is recommended that the sensor be mounted

6" down from the ceiling, but not directly over the steam dispersion head and not more than 7 feet above the

floor. Do not cover or enclose the sensor: if the airflow across the sensor is blocked or reduced, the room may

overheat or suffer large temperature variations.

String the sensor cable from the sensor location through

1

/

2

" holes

in the wall studs or ceiling joists to the generator location. Leave

12" of slack at the sensor location. Route the generator end of the

sensor cable through the generator hole marked CONTROL

WIRING ENTRY using the strain relief provided.

Note: Do not staple through or otherwise damage the cable. Use a

factory supplied sensor cable only.

In the steam room: Plug the temperature sensor into the sensor cable. The cable and the sensor connectors are

designed to lock together when properly aligned. Run a bead of 100% silicone caulk around the underside of the

sensor head then carefully feed the cable and sensor through the hole and attach the sensor in place.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 15 of 29

INSTALL ONLY IN A DRY LOCATION

FOR SERVICE CALL: 1-800-363-0251

Saunatec Inc.

P.O. Box 2258

Woodinville, WA 98072

BLACK WIRE

RED WIRE

WHITE WIRE

5

6

ROOM TEMPERATURE

7

8

9

10

4

3

OFF

2

1

BATH

STEAMBATH

ON

CABLE TO

TEMPERATURE SENSOR

At the generator: Connect the sensor cable’s end plug into its socket on the generator’s control circuit board. The

socket is directly above the room’s T’STAT terminal block. Orient the cable end to match its socket and insert it

until the end locks in place. Make sure the thermostat and temperature sensor cables are connected at the same

side of the circuit board: either along the left edge (ROOM 1) or the right (ROOM2). When only one steam outlet

valve is available, always connect to ROOM 1.

2. THERMOSTAT INSTALLATION The low voltage thermostat control can be mounted up to 50 feet from the

generator and must be located outside the steam room. A 50 foot cable is provided. String the 50’ cable from the

control location through ½” holes in the wall studs or ceiling joists to the generator and the switch box installed at

the desired control mounting location. An

IT1 is always required for each room.

At the control: Connect the control cable to the thermostat control using wire nuts (provided). Match the provided

cable’s red and black wires to the thermostat’s red and black wires, respectively. Match the cable’s third wire

(white or green) to the thermostat’s white wire.

At the generator: Route the generator end of the control

cable through the generator hole marked CONTROL

WIRING ENTRIES using the strain relief provided. Strip the

control cable wire ends ½” and place the bare copper into

the ROOM 1 (or ROOM 2) T’STAT terminal block, putting

the black wire in the bottom hole (“3”), red in the center (“2”)

and white (or green) in the top (“1”). Use a small screwdriver

to carefully press the terminal block’s orange tabs down to

insert or remove the wire ends. When only one steam outlet

valve is installed, always connect to ROOM 1.

The thermostat has an integral switch to start and stop the heating of the steam room: see operating instructions.

If an (optional)

I60 switch or other switch is to be used, it will connect to the ROOM SWITCH terminal block as

described in the following section. When using the thermostat as the Bath on/off switch, all positions of the boiler

circuit board’s switch must be set down (the switch is located near the upper the center of the PCA).

3. ROOM SWITCH INSTALLATION The (optional)

I60 switch is a momentary switch (closed only while

pressed) intended for installations with occasional use. When an I60 switch or equivalent is connected, the circuit

board’s switch must be correctly set as shown below. The steam bath will start when the switch is pressed and

stop when the switch is pressed again or stop automatically at the bath time selected using the switch.

The

I60 may be mounted up to 50 feet from the generator and must be located outside the steam room. A 50

foot cable is provided. String the 50’ cable from the control location through

1

/

2

" holes in the wall studs or ceiling

joists to the generator and the switch box installed at the desired control mounting location.

If the optional second steam room is installed, both rooms must use the same type of on/off switch,

either the thermostat or the

I60!

OPTIONAL To use a timer control on/off switch as a Room Switch (supplied by user), be sure it is capable of

switching a 3VDC circuit. Connect the switch contacts to positions 1 and 2 of the Room Switch terminal block

and set the circuit board’s switch to position 1 up (room switch control, no time out). This will not work with a

momentary switch.

Thermostat

On/Off

RoomSwitch

No Bath Timer

15 Minutes

Bath Time

30 Minutes

Bath Time

60 Minutes

Bath Time

ON

ON

1234 1234 1234 1234

ON

ON

1234

ON

When using the I60

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 16 of 29

Saunatec Inc.

INSTALL ONLY IN A DRY LOCATION

FOR SERVICE CALL: 1-800-363-0251

P.O. Box 2258

Woodinville, WA 98072

STEAMBATH

ON/OFF

BATH

ON

RED WIRE

WHITE WIRE

BLACK WIRE

CABLE TO THERMOSTAT

CABLE TO TEMPERATURE SENSOR

1

3

2

CABLE TO TEMPERATURE SENSOR

CABLE TO THERMOSTAT

BLACK WIRE

WHITE WIRE

RED WIRE

At the I60: Connect the control cable to the switch using wire nuts (provided). Match the provided cable’s red

and black wires to the switch’s red and black wires, respectively. Match the cable’s third wire (white or green) to

the switch’s white wire.

At the generator: Route the generator end of the switch cable

through the generator hole marked CONTROL WIRING ENTRY

using the strain relief provided. Strip the control cable wire ends ½”

and place the bare copper into the ROOM 1 (or ROOM 2) ROOM

SWITCH terminal block, putting the black wire in the bottom hole

(“3”), red in the center (“2”) and white (or green) in the top (“1”). Use

a small screwdriver to carefully press the terminal block’s orange

tabs down to insert or remove the wire ends. When only one steam

outlet valve is installed, always connect to ROOM 1.

4. REFRESH SWITCH INSTALLATION The (optional) Refresh™ switch uses a low voltage control to provide a

short burst of steam into the steam room when the switch is pressed. The switch may be mounted up to 50 feet

from the generator and must be located inside the steam room. A 50 foot cable is provided. String the 50' cable

from the control location through ½” holes in the wall studs or ceiling joists to the generator and the desired

control mounting location in the steam room.

At the control: Connect the control cable to the switch terminal block on the Refresh™

switch. Connect the switch cable to the switch and note which wire is connected to which

terminal block position. An instruction plate is provided and should be attached to the wall

alongside the Refresh™ switch in the steam room to help bathers understand the

Refresh™ operation. The instruction plate is adhesive backed for easy mounting to a clean

dry surface.

At the generator: route the generator end of the switch cable through

the generator hole marked CONTROL WIRING ENTRIES using the

strain relief provided. Strip the switch cable wire ends ½” and place

the bare copper into the ROOM 1 (or ROOM 2) REFRESH SWITCH

terminal block, matching the colors to the terminal block positions

identically to the switch’s connections. When finished, the switch’s

block position 1 should be connected to the PCA’s position 1, 2 to 2

and 3 to 3. Use a small screwdriver to carefully press the terminal

block’s orange tabs down while inserting or removing the wire ends.

When only one steam outlet valve is installed, always connect to

ROOM 1.

Note: In areas with high humidity or a high chlorine or chemical environment, such as around pool treatment

equipment, we recommend adding some dielectric grease to low voltage wire connections to reduce the risk of

corrosion.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 17 of 29

WIRING: Control Circuit, All Models

ALL WIRING MUST BE INSTALLED BY A LICENSED ELECTRICAL CONTRACTOR IN ACCORDANCE

WITH ALL APPLICABLE LOCAL AND NATIONAL CODES.

ELECTRIC SHOCK HAZARD – HIGH VOLTAGE EXISTS WITHIN THIS EQUIPMENT. THERE ARE NO USER

SERVICEABLE PARTS IN THIS EQUIPMENT.

ELECTRICAL GROUND REQUIRED ON ALL STEAMERS.

DISCONNECT ALL ELECTRICAL SUPPLIES WHEN SERVICING THIS EQUIPMENT; 480V GENERATORS HAVE TWO

SEPARATE SUPPLIES.

BOILER ON

LIGHT

GND

N

MANU AL

RUN

BOILER

OPERATION

RUN CLOCK

(OPTION)

M

CLOCK

RUN

M

AUTODRAIN CLOCK

(OPTION)

MANUAL OP EN

120V

CONTROL

CIRCUIT

FUSE

3AMP

NON TIME

DELAY

NEUT

LINE

GND

DRAIN

CLOCK

ROOM 2 CONTROLS ANDSTEAM VALVE

ARE OPTIONALAND MAY NOT BE INSTALLED

STEAM VALVE

OPEN LIGHT

3241-051

PRINTED

CIRCUIT BOARD

ROOM

STATUS

LEDS

ROOM1 LOCKOUT

ROOM2 LOCKOUT

NORM AL

ROOM-1

RELAY

ROOM-2

RELAY

HEAT

RELAY

FEEDWATER

RELAY

STOP FILL

OFF

HEAT

STM

STEAM VALVE

OPEN LIGHT

STM

CLOSE VALVE

NORM AL

WATER VALVE

OPEN LIGHT

CLOSE VALVE

NORMAL

ROOM 2

STEAM

OUTLET

SOLENOID

ROOM 1

STEAM

OUTLET

SOLENOID

FEEDWATER

SOLENOID

BOILER

HEATING LIGHT

NORM AL

OFF

H0

2

PRESSURE

SWITCH 2

PRESSURE

SWITCH 1

LWCO

RELAY

TEST

RESET

LWCO STATUS LED

RM1

RD1

RM2

RD2

LWCO TEST

LWCO RESET

LWCO LED

ON

STEAM B AT H

ON

STEAM B AT H

LEVE L PR O BES

WATER ON

WATER OFF

HEAT OKAY

ON/OFF

ON/OF F

BATH

29

ON/OFF

10

7

ROOM TEMPERATURE

9

8

4

56

1

ON

OFF

BATH

2

3

STE A MBAT H

7

ROOM TEMPERATURE

8

ON/OF F

4

56

3

BATH

10 1

ONBATH

OFF

STE A MBAT H

L

(OPTIONAL)

ROOM SWITCH

T'STAT

TEMP SENSOR

AUTO-LW CO

MANUAL

LWC O

HEAT

RM1

RM2

WATER

R

D

H

M

L

DRAIN

RELAY

DRAIN

STEAM VALVE

OPEN LIGHT

ELECTRONIC

DRAIN VALVE

(OPTION)

(OPTIONAL)

REFRESH

SWITCH

M

(OPTIONAL)

FRAG PUMP

T'STAT

TEMP SENSOR

(OPTIONAL)

ROOM SWITCH

(OPTIONAL)

REFRESH

SWITCH

(OPTIONAL)

FRAG PUMP

ROOM1

ROOM2

OPEN ON RISE

120VN

TO CONTACTORS

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 18 of 29

WIRING: Contactor and Power wiring, All Models

ALL WIRING MUST BE INSTALLED BY A LICENSED ELECTRICAL CONTRACTOR IN ACCORDANCE

WITH ALL APPLICABLE LOCAL AND NATIONAL CODES.

ELECTRICAL GROUND REQUIRED ON ALL STEAMERS.

ELECTRIC SHOCK HAZARD – HIGH VOLTAGE EXISTS WITHIN THIS EQUIPMENT.

THERE ARE NO USER SERVICEABLE PARTS IN THIS EQUIPMENT.

DISCONNECT ALL ELECTRICAL SUPPLIES WHEN SERVICING THIS EQUIPMENT;

480V GENERATORS HAVE TWO SEPARATE SUPPLIES.

1PHZ 3PHZ

480VAC 3 PHZ

208/240VAC 3 PHZ

ELEMENT

ASSEMBLY

1 2

3

HEAT CONTACTORS

1 2

3

ELEMENT

ASSEMBLY

GND

N

120V

L2

L1

HEAT CONTACTORS

ELEMENT

ASSEMBLY

1 2

3

GND

N

120V

L2

L3

L1

HEAT CONTACTORS

ELEMENT

ASSEMBLY

1 2

3

GND

N

120V

N

120V

GND

L2

L3

L1

HEAT CONTACTORS

ELEMENT

ASSEMBLY

1 2

3

L2

L1

L3

ELEMENT

ASSEMBLY

1 2

3

HEAT CONTACTORS

1 2

3

ELEMENT

ASSEMBLY

GND

N

120V

L2

L1

L3

12kW, 18kW, 24kW

30kW, 36kW, 42kW, 48kW

12kW, 18kW, 24kW

3PHZ

12kW, 18kW, 24kW 12kW, 18kW, 24kW

208-240V 30kW, 36kW, 42kW

and 240V 48kW

Note: A jumper is factory installed between field wiring

terminal blocks to pick off 120VAC for the control circuit.

The jumper is not installed for 480V models. Separate

120V+N service required for 480V models.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 19 of 29

STARTING THE GENERATOR FOR THE FIRST TIME

Before applying power to the generator for the first time: On the electrical box’s front panel set all rocker switches to

the left, their normal operating position. If installed, set the optional Run Clock so the generator is off (no orange

showing in area above pointer) and make sure the water supply is connected to the generator and turned on.

Open the valves on the glass water gauge all the way (counterclockwise).

Open the pressure gauge valve (handle horizontal). or

If the CoolFlush™ Auto Drain option is not installed, close the manual

drain (handle up).

If the optional electronic CoolFlush™ Auto Drain is installed, open

the manual drain ball valve as shown (handle pointing towards

electronic valve). Set the Drain Clock to an off position (no orange

showing in area above pointer).

Set the room thermostat(s) to the

OFF position.

Turn on the electrical service to the boiler. All lights and valves should be off at this point.

Set the

BOILER OPERATION switch to the right (red showing) or set the optional run clock to a “RUN” position.

The BOILER ON light, both room STEAM VALVE OPEN lights and the WATER VALVE OPEN light should turn on

and the boiler will start filling with water. The water will become visible in the water gauge a short time later.

The LWCO LED should be yellow or amber then change to green once the mid water level is reached. When the

maximum water level is reached, the feedwater valve and its light will turn off and the steam valve lights will turn

off, the

BOILER HEATING light will turn on and the heating element contactors will close. The boiler will continue

heating until it reaches its operating pressure of approx. 4 to 5 psi then the BOILER HEATING light and the

contactors will turn off. During normal operation, the water level should always be visible in the lower half of the

gauge glass. If it drops to less than 1 inch of water, the manual reset LWCO may alarm and shut the boiler down

until serviced.

Check for steam and water leaks. Repair any leaks before continuing.

NOTE: When the boiler is started with an empty tank, the room steam valves will open to release the air pressure

created during water fill. Once the tank has filled, the valves will operate normally, opening only when steam

needs to be released to a room to increase its temperature. Also, whenever a steam valve opens to release

steam to a room, the boiler heating is disabled for a few seconds. This is designed to increase the elements’

working life.

Turn the thermostat(s) on to begin heating the steam room(s). If an (optional)

I60 room switch is installed, set the

thermostat to the desired temperature and press the

I60 switch to start the steam bath and begin heating the

room. The status LEDs on the thermostat(s), switches and boiler will light and remain on continuously when the

steam bath is on and operating normally.

4211-1631 05/29/19 Technical Support: 1-800-363-0251 [email protected] 20 of 29

OPERATING INSTRUCTIONS The AI model steam generators are based on two operating systems. The first is

the generator itself, maintaining water levels and boiling the water to create steam for use in a steam bath. The

second is the steam room control circuit, maintaining a comfortable steam bath by releasing steam from the

generator only when needed to raise the temperature in the steam room. The generator’s control circuit board is

used for both systems so the generator must be running before starting a steam bath. And the generator may run

continuously without affecting the steam room temperature when the bath is off. In this way the generator can be

left running so it is ready to provide steam immediately when the thermostat (or optional

I60 room switch) is used

to start a steam bath.

BOILER START (RUN) The generator operation may be started in one of two ways.

1. MANUAL RUN To start the generator manually, place the BOILER OPERATION switch (located on the

generator’s switch panel) to its MANUAL RUN position. The switch will show a red color at its left side to

indicate that it has been turned on and the BOILER ON light will turn on to show the generator is running. If an

optional Run Clock is installed, this manual switch will start the generator regardless of the clock setting and

the generator will continue to run until the switch is returned to the CLOCK RUN position.

2. CLOCK RUN To start the generator using the optional Run Clock, leave the

BOILER OPERATION switch in its

CLOCK RUN position. Program the Run Clock to the desired on (RUN) and off periods. If the clock is switching

properly, when an on period is reached the BOILER ON light will turn on and the generator will fill and heat as

necessary. Check the Run Clock later in the day to ensure it is maintaining time correctly. See clock

attachments for further details.

Normal RUN operation controls water fill and heating using three water levels. The lowest level serves as a low

water cut-off safety level: if the water level drops too far the heating elements are turned off to prevent damage.

When the water level is at the mid level, there is enough water in the tank to allow heating it safely. When the

water level reaches top level (just above mid-glass) the water level has reached its maximum depth and the

water valve will close until the level drops to the mid level again. If the water takes too long to fill, the mid level

may turn off heating using its automatic resetting LWCO. If the level continues to drop during normal operation,

the boiler will go into a LWCO error and shut down completely about 10 seconds after the low level becomes dry.

Also see page 22 for more LWCO information.

Water heating is controlled by the operating pressure switch. While there is enough water in the tank to allow

heating, the elements will be energized if the pressure in the tank is below the switch setting (about 4 psi) and

the water will be heated until enough steam pressure is generated to build up pressure in the tank to about 7 psi.

At this point the elements are turned off until the pressure drops again.

If the steam bath is not turned on, no steam will be released to the room and the generator will need to heat the

water only to make up for temperature loss from the generator itself. During a steam bath, particularly during

initial heating, the generator may need to heat continuously to compensate for the steam being released to the

steam room. The generator might not build up any pressure during this period.

When the generator is started with an empty tank, the steam outlet valve(s) will open to release air pressure

created by adding water. If not released, this air pressure could be sensed by the pressure switch, preventing

heating. When the water reaches its maximum depth, the heat will turn on, the water valve will close and, if the

steam bath is not turned on, the steam room valve(s) will close.

STEAM ROOM OPERATION (BATH) The steam room begins heating when the thermostat or

room switch is used to “turn on” the steam bath. While the steam bath is on, steam is released to

the room as needed to bring the temperature up to the thermostat setting. When the generator

supplies two rooms, the room operations are identical but independent. Only the use of one

room will be described here.

The thermostat sets the room temperature using a 1 to 10 scale, with 1 being the coolest at

about 90°F and 10 the hottest at about 124°F. These are the steam room temperatures sensed

by the temperature sensor near the ceiling. For bather safety and to prevent damage to the

steam room, never attempt to force these temperatures higher!

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

Amerec AI Boiler, "AI12 Through AI48" Mode d'emploi

- Catégorie

- Chauffe-eau

- Taper

- Mode d'emploi

dans d''autres langues

Documents connexes

-

Amerec AX Generator, "AX4.5", "AX6", "AX7.5", "AX9", "AX11" & "AX14" Mode d'emploi

Amerec AX Generator, "AX4.5", "AX6", "AX7.5", "AX9", "AX11" & "AX14" Mode d'emploi

-

Amerec AK Generator, "AK4.5", "AK6", "AK7.5", "AK9", "AK11" & "AK14" Mode d'emploi

Amerec AK Generator, "AK4.5", "AK6", "AK7.5", "AK9", "AK11" & "AK14" Mode d'emploi

-

Amerec EasySteam Generator "AK4.5", "AK7.5", "AK11" & "AK14" Mode d'emploi

Amerec EasySteam Generator "AK4.5", "AK7.5", "AK11" & "AK14" Mode d'emploi

-

Amerec EasySteam Generator-Canada Only "AK4.5", "AK7.5", "AK11" & "AK14" Mode d'emploi

Amerec EasySteam Generator-Canada Only "AK4.5", "AK7.5", "AK11" & "AK14" Mode d'emploi

Autres documents

-

MrSteam AirTempo™ Installation & Operation Manual

-

MrSteam xButler Package Installation & Operation Manual

-

MrSteam Basic Butler Installation & Operation Manual

-

TPI CV Series Installation and Operation Instructions

TPI CV Series Installation and Operation Instructions

-

Kohler 5535-NA Guide d'installation

-

Kohler K-5526-NA Guide d'installation

-

Mr. Steam iSteam3 Guide d'installation

-

Mr. Steam MS Chroma Guide d'installation

-

MAAX 101125-000-001-005 Guide d'installation

-

Intermatic ET90000 Series Installation And Programming Manual