1

PV500-56 03/19

INSTALLATION & MAINTENANCE MANUAL

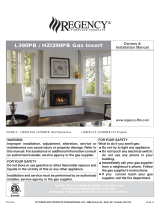

MODEL SU-3 GAS BURNER

Inputs 199,000 thru 399,000 Btu/h

(Inputs 58.32 kW thru 116.94 kW)

This burner is for use with Natural Gas or Propane Gas (LP), as specified on the name plate

Installation and service must be performed by a qualified service installer, service agency or the gas supplier.

IMPORTANT: THIS MANUAL CONTAINS INFORMATION REQUIRED FOR INSTALLATION, OPERATION AND

MAINTENANCE OF THIS EQUIPMENT. READ AND FOLLOW THE INFORMATION IN THIS MANUAL AND ALL OTHER

PROVIDED INSTRUCTIONS, LABELS AND MARKINGS BEFORE INSTALLING, OPERATING OR SERVICING THIS UNIT.

WARNING: If the information and instructions in this manual, the appliance installation and maintenance manual

and product markings are not followed exactly, a fire or explosion may result, causing property damage,

personal injury or death.

TO THE INSTALLER: After installation, these instructions must be given to the equipment user or left near the appliance.

SPECIAL INSTRUCTIONS TO THE OWNER: Retain this manual for future reference. These instructions contain important

information that will help you in maintaining and operating this appliance.

PVI INDUSTRIES, LLC - Fort Worth, Texas 76111 - Web www.pvi.com - Phone 1-800-433-5654

2

PV500-56 03/19

TABLE OF CONTENTS

1. Safety Considerations

2. Codes

3. Electrical Specifications

4. Combustion and Ventilation Air

4.1 Equipment Located in Confined Spaces

4.2 Maximum Allowed Remote Combustion Air Inlet Length

4.3 Vertical or Horizontal Remote Air Duct Termination

4.4 Remote Air Consideration for Combined Remote Air Ducting

5. Venting

6. Gas Supply and Piping

6.1 Gas Train and Controls Certification

6.2 Gas Control Trains

6.3 Inlet Pressure

6.4 Manifold Pressure

6.5 Gas Service and Pipe Capacity

6.6 Gas Piping to Burner

6.7 Appliance Isolation During Gas Supply Piping Pressure

7. Sequence of Operation

8. Burner Operation

9. Electrode & Flame Sensor Positioning

10. Burner Setup and Adjustment

10.1 Commissioning Checklist

10.2 Adjusting Burner Using Combustion Analyzer

10.3 Adjusting Burner Head

10.4 Burner Operation Record

11. Maintenance Instructions

12. Troubleshooting

13. Materials List

3

PV500-56 03/19

1. SAFETY CONSIDERATIONS

WARNING: Installation, adjustment and maintenance of this burner must be performed in accordance

with this manual and with local codes by a qualified service agency. Improper installation, adjustment,

alteration, service or maintenance can result in property damage, personal injury or death.

WARNING: Deadly levels of CARBON MONOXIDE can occur if the burner is not properly operating. Verify

proper carbon monoxide levels during first operation and commissioning and following any burner, gas

supply, heater or venting change or adjustment. Additionally, have combustion checked annually by a

qualified service agency. Failure to verify proper carbon monoxide levels can result in property damage,

personal injury or death.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or

property damage. Refer to this manual for assistance, or consult a qualified installer.

WARNING: The burner supplied with this water heater must be adjusted and operated on the gas, at the

firing rate and pressures shown on the appliance and burner decals. Firing this burner above the allowed

firing rate will void the warranty, and may result in improper operation, a fire or explosion, causing

property damage, personal injury or death.

WARNING: If the information in these instructions is not followed exactly, a fire or explosion may result,

causing property damage, personal injury or death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electric switch; do not use any phone in your building.

Immediately call your gas supplier from a location away from your building and the smell of gas. Follow the gas

supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Seasonal or annual combustion check-out by a qualified service agency is recommended to enable continued safe and

efficient operation.

POUR VOTRE SECURITE

• Ne pas entreposer ni utiliser d’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appareil

ou de tout autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir des téléphones dans le bâtiment où vous vous trouvez.

• Appeler immédiatement votre fournisseur de gaz depuis un voisin. Suivez les instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de gaz, appelez le service des incendies.

L’installation et l´installation et l’entretien doivent être assurés par un installateur ou un service d’entretien qualifie ou par le

fournisseur de gaz.

AVERTISSEMENT: Assurez-vous de bien suivre les instructions données dans cette notice pour réduire au minimum

le risque d’incendie ou d’explosion ou pour éviter tout dommage matériel, toute blessure ou la mort.

4

PV500-56 03/19

2. CODES

The water heater and burner must be installed in accordance with those installation regulations in force in the

local area where the installation is to be made. Authorities having jurisdiction must be consulted before

installation is made. In the absence of such requirements, the installation shall be in accordance with the

instructions in this manual, the water heater Installation and Maintenance manual, appliance markings and

supplemental instructions and in compliance with the Standard for Installation of Domestic Gas Conversion

Burners and the latest edition of the National Fuel Gas Code, ANSI Z223.1. Where required by the Canadian

authority having jurisdiction, the equipment must be installed in accordance with the latest edition of the

Installation Code for Gas Burner Appliances and Equipment CAN/CSA B149.1 and/or B149.2 and applicable

Provincial Regulations.

3. ELECTRICAL SPECIFICATIONS

Electric Wiring

See appliance rating decal for electrical service requirements. The appliance must be electrically supplied

and grounded in accordance with the requirements of the authority having jurisdiction or in the absence of

such requirements, with the latest edition of the National Electrical Code ANSI/NFPA No. 70. In Canada, the

electrical service must conform to local electrical codes and/or CSA C22.1, Canadian Electrical Code, Part 1.

Connect multi-pin connector at end of flexible conduit from the water heater to the multi-pin plug on the

burner control box.

To avoid serious damage, DO NOT energize the unit until the system and appliance is full of water.

The burner is grounded through the electrical connection to the water heater. Be certain the water heater

has been properly grounded.

Refer to the burner control wiring diagram located inside the burner control cabinet for further information.

Blower Motor - 120 Volt/ 60 Hz/1 Phase, 1/6 HP PSC motor.

4. COMBUSTION AND VENTILATION AIR

Provisions for adequate combustion and ventilation air to the mechanical room must be in accordance with

Section 5.3 “Air for Combustion and Ventilation” of the latest edition of the National Fuel Gas Code, ANSI

Z223.1 and/or CAN/CSA B149, Installation Codes or applicable provisions of the local building codes.

4.1 Equipment Located in Confined Spaces

Equipment located in confined spaces requires two openings installed within 12” (30.5 cm) from the top and

bottom of the room to assure adequate combustion air and proper ventilation. The total input of all gas utilization

equipment installed in the room must be used to determine the required minimum air volume needed for

combustion, ventilation and dilution of flue gasses.

All Air From Outdoors:

Each opening requires a minimum free area of 1 square inch (6.45 cm

2

)

per 4000 Btu/hr (1.17 kW) input if

directly communicating with the outdoors or communicating to the outdoors through vertical ducts.

Each opening requires a minimum free area of 1 square inch (6.45 cm

2

)

per 2000 Btu/hr (0.59 kW) input if

communicating with the outdoors through horizontal ducts.

All Air From Inside The Building:

Each opening requires a minimum free area of 1 square inch

(6.45 cm

2

)

per 1000 Btu/hr (0.29 kW) input, but

not less than 100 square inches (0.06 m

2)

.

Combination Of Air From The Indoors And From The Outdoors:

Refer to National Fuel Gas Code, ANSI Z223.1 and/or CAN/CSA B149, Installation Codes or applicable

provisions of the local building codes.

SU-3 Electrical Specifications

Primary Electric Input

Secondary Electric Input

Total Watts

Total Amps

120 Volt, 60 Hz, 1 Ph

24 Volts

150 Max

3 or less

5

PV500-56 03/19

WARNING: Adequate clean combustion air must be provided to the appliance. Under no circumstances

should the appliance ever be under a negative pressure. Particular care should be taken when exhaust

fans, compressors, air handling units, etc. may rob air from the appliance. The combustion air supply

must be completely free of any chemical or fumes, which may be corrosive to the appliance. Some

common chemical fumes to avoid are fluorocarbons and other halogenated compounds, most

commonly present as refrigerants or solvents, such as Freon, trichloroethylene, perchlorethylene,

chlorine, etc. These chemicals, when in contact with the equipment or when burned, form acids which

quickly attack the tubes, flue collector, stack and other appliance and auxiliary equipment. The result

of inadequate clean combustion air or negative pressure can be premature unwarranted product failure

or unsafe operation producing carbon monoxide that could escape into the building. Exposure to

carbon monoxide can lead to injury or death.

4.2 Maximum Allowed Remote Combustion Air Inlet Length (Equivalent Length)

Burners are suitable for use with an optional outside combustion air intake system that may be routed either

horizontally or vertically using a field obtained 3” by 4” (7.62 cm by 10.16 cm) increaser and 4 inch (10.16 cm)

sealed plastic or metal pipe, extending up to 100 equivalent feet (30.48 equivalent meters). Larger pipe may

be used to extend the equivalent length, if the pressure drop is not increased. A UL, ETL, ULC or CSA listed

vent cap must be applied to the terminus of the air intake system. The terminus may be either horizontal (from

sidewall) or vertical above roof.

The Listed air intake vent termination cap MUST be attached to the remote combustion air vent termination to

adequately protect the combustion air inlet from wind and weather. A UL Listed air intake termination cap is

available from PVI Industries and may have shipped with the water heater and burner as a purchased option.

4.3 Vertical or Horizontal Remote Air Duct Termination

Air inlet and exhaust vents should terminate in the same wind pressure area whenever possible.

Air inlet must be located no less than 3 feet (0.91m) below the exhaust terminal if they are within 10 feet

(3.05 m) of each other.

If terminating through the roof, the air inlet must terminate at least 12 inches (0.3 m) above roof level and

at least 12 inches (0.3 m) above snow levels.

If terminating through a sidewall, the air inlet must terminate at least 12 inches (0.3 m) above grade and/or

at least 12 inches (0.3 m) above normal snow levels.

6

PV500-56 03/19

4.4 Remote Air Consideration for Combined Remote Air Ducting

When remote air ducting is used, each water heater burner MUST have separate combustion air intake piping.

5. VENTING

For appliances connecting to gas vents or chimneys, vent installation and vent size must be in accordance

with Part 7, "Venting of Equipment," of the latest edition of the National Fuel Gas Code, ANSI Z223.1, using

the “FAN” rating or, in Canada, Section 7, “Venting Systems and Air Supply for Appliances” of the latest edition

of the CAN/CSA B149 Installation Codes, or applicable provisions of the local building codes.

Suitable for use with Category I (non-positive vent static pressure, with a gas vent gas temperature that

avoids excessive condensate production in the vent) Type B gas vent systems with 1” (2.54 cm) minimum

clearance or Type L vent systems.

Vent should not be sized based only upon vent connection diameter at the burner.

Locate units as close as possible to chimney or gas vent. For conventionally vented installations, the

connection from the vent to the stack or vent termination outside the building must be made with listed Type

“B” double wall (or equivalent) vent connectors and must be direct as possible with no reduction in diameter.

Support horizontal portions of the venting system to prevent sagging. Horizontal runs must slope upwards

not less than 1/4 inch per foot (21 mm/m) from the appliance to the vent terminal. Follow manufacturer’s

instructions.

Do not connect vent connectors serving this Category I, natural/negative draft vented, appliance to any

portion of a mechanical draft system operating under positive pressure.

Vent pressure must be between -.02" to -.06" W.C. (- 0.005 kPa to - 0.015 kPa) (Negative Pressure).

A barometric damper (draft control) is supplied for use on conventional vented installations. A properly

installed and adjusted barometric damper helps stabilize draft and regulate high updraft. Conventional

vented multiple unit installations with combined venting require barometric dampers to regulate draft at

each unit. Adjust the barometric damper to 0.04 inches water column (0.01 kPa) updraft. Follow the

barometric damper manufacturer’s installation instructions.

A listed vent terminal suitable for Category I products must be installed to adequately protect the gas vent

from wind and weather.

The vent terminal must extend at least 3 ft (.09 m) above the highest point where it passes through the roof

of a building and at least 2 ft (.06 m) higher than any portion of a building within a horizontal distance of 10

ft. (3.0 m).

The vent cap must terminate at least 3 feet (0.91 m) above any forced air inlet within 10 feet (3.05 m); 4

feet (1.22 m) below, 4 feet (1.22 m) horizontally from or 1 foot (0.3 m) above any door, window or gravity

air inlet to the building; 1 foot (0.3 m) above grade, 1 foot (0.3 m) above normal snow levels and shall

terminate at least 7 feet (2.13 m) above grade when located adjacent to public walkways or gathering areas.

The vent terminal must not be installed closer than 3 feet (0.91 m) from an inside corner of an L-shaped

structure.

6. GAS SUPPLY AND PIPING

Verify that the type of gas specified on rating plate is supplied to the unit. This unit is orificed for operation up

to 2000 feet (610 m) altitude. Appliance Btu/h (kW) output derates 4% per 1000 feet (305 m) elevation above

sea level. Consult Factory for installations above 2000 feet ((610 m) elevation.

6.1 Gas Train and Controls Certification - NOTE: The gas train and controls assembly provided on this unit

have been tested under the applicable American National Standard to comply with safety and performance

criteria such as proper ignition, combustion and safety shutdown operation.

6.2 Gas Control Trains - All models include gas control trains with the following components: main manual shutoff

valve, two safety shutoff valves and pressure regulator. These components may be separate or two or more

may be combined in a common housing.

7

PV500-56 03/19

CAUTION: Do not adjust or remove any screws or bolts on gas train control components which are sealed

with a red or blue colored compound. Doing so will void all approvals and warranties.

6.3 Inlet Pressure - Measure at the inlet pressure at the inlet pressure tap located on the upstream side (side

away from burner) on the top of the combination gas valve. The inlet pressure must remain within the minimum

and maximum values while the unit is at rest and while the unit is operating at maximum firing rate.

6.4 Manifold Pressure - Measure the manifold pressure at the manifold pressure tap located on top of the silver

elbow attached to the burner head. The rated manifold pressure appears on the burner data label located on

side of the burner control panel and is duplicated on the decal located near the front of the water heater.

6.5 Gas Service and Pipe Capacity - Before connecting the burner to the gas supply, insure that the gas pipes

and service meter are large enough to permit the additional load of the gas burner. (See Pipe Capacity Table)

Pipe Capacity for Natural Gas Table*(x 1,000 Btu/h’s)

Pipe Length**

Nominal diameter of pipe in inches

1”

1 ¼”

1 ½”

2”

15’

345

750

30’

241

535

850

45’

199

435

700

60’

173

380

610

75’

155

345

545

90’

141

310

490

105’

131

285

450

920

120’

120

270

380

850

150’

109

242

300

780

180’

100

225

225

720

* Using 0.6 Specific Gravity Gas and a Pressure Drop of 0.3” of Water Column

Multiplier for Propane: 1.57

** Each 90

0

elbow counts as 3’ for the purpose of these calculations

Pipe Capacity Example:

There is 75 feet of 1¼” pipe from the meter to the burner and there are 5 elbows.

(5 elbows X 3’) + 75’ pipe = 15’ + 75’ = 90’ of effective pipe length.

The maximum Btu/h that can be fired is 310,000 Btu/h. (See Pipe Capacity Table)

6.6 Gas Piping to Burner

All Piping Must Conform To Local Codes. Use black steel pipe and malleable iron fittings (do not use cast

iron parts) with a suitable pipe dope which is resistant to liquefied petroleum gases.

Safe operation of unit requires adequate gas supply with the required static and dynamic (flow) pressures.

Actual piping selection depends on many variables that must be carefully considered by the gas piping

system designer.

Do not select gas pipe sizes based only on the supplied tables. These tables are for use by the gas piping

system designer as a reference in checking pipe size selections.

The required gas pipe size may be larger than pipe connection size to the burner.

It is advisable to run a separate gas line from the meter to the gas burner to avoid pressure drops.

Installation of a union is suggested for ease of service.

Install a manual main gas shutoff valve, as specified by Code, approximately 6 feet (1.8 m) away from unit.

A sediment trap (drip leg) MUST be provided in the inlet of the gas connection to the unit.

6.7 Appliance Isolation During Gas Supply Piping Pressure

WARNING: The gas valve must not be subjected to more than ½” psig (3.45 kPa). Subjecting the gas

valve to pressure above ½” psig (3.45 kPa) can damage the valve and can cause gas leaks or loss of

gas control, which can result in property damage, personal injury or death.

INLET PRESSURE

NAT. GAS

LP

Maximum Static Pressure (Inches-Water Column)

10.5" (2.62 kPa)

13" (3.24 kPa)

Minimum Flow Pressure (Inches-Water Column)

4.5" (1.21 kPa)

8" (1.99 kPa)

8

PV500-56 03/19

The burner must be isolated during gas leak tests. The burner and its combination gas valve must be

disconnected from the gas supply piping system during any pressure testing of that system at test pressures

in excess of ½” psig (3.45 kPa). The appliance must be isolated from the gas supply piping by closing its

individual manual shut off valve using the gas control knob on top of burner combination valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than ½” psig (3.45 kPa).

Gas Burner Piping

(Piping upstream of burner combination gas valve supplied by others)

7. SEQUENCE OF OPERATION – Fenwal #35-66

Limits close.

Blower motor starts as the 24 Volt transformer powers the airflow switch.

When the airflow switch is proven, the 35-66 control initiates a pre-purge of approximately 15 seconds.

At the end of the pre-purge, the spark is energized for 4 seconds. At the same time, the 24 Volt transformer

powers the gas valve, allowing the fuel to flow. (The combination gas valve contains two separate automatic

safety shutoff valves, a pressure regulator and a manual shutoff valve)

Within 4 seconds, the flame should be established and proved. The spark will shut off and the control will

hold power to the gas valve until the limits open and the burner stops firing.

If the flame is not established, the blower motor continuously runs.

To restart, power should be interrupted for five minutes. Then turn on the power to start this sequence again.

WARNING: Should overheat occur, shut off the manual gas shut off valve to control the appliance. Do

not shut off the control switch to the pump or blower, which provides burner cooling and post purge.

Failure to follow this warning may result in a fire or explosion, causing property damage, personal injury

or death.

En cas de surchauffe : (1) fermez la commande manuelle de gaz à l'appareil, (2) ne pas fermer la commande

de la pompe ou de la soufflerie.

THIS IS NOT PART OF

THE SU-3 BURNER

SU-3 GAS BURNER

9

PV500-56 03/19

1” (2.54 cm)

8. BURNER OPERATION

Before placing the burner in service, a qualified installer, service agency or the gas supplier must perform

installation and service. All piping must conform with local codes.

Do not try to light the burner by hand.

Lighting Instructions

1. Set the thermostat to the lowest temperature.

2. The control knob on the gas valve should be in the “OFF” position for at least five minutes.

3. Rotate the control knob counter-clockwise to the “ON” position and set the thermostat to the desired

temperature settings. The burner will energize on call for heat.

Reset, If Flame Lockout Occurs

1. Turn the thermostat off or turn the main power off.

2. Wait five minutes.

3. Return thermostat to the desired setting or turn the main power on.

To Shut the Burner Off

1. Set the thermostat to the lowest temperature.

2. Turn off all electrical power to the appliance if service is to be performed.

3. Rotate the control knob on the gas valve to the “OFF” position.

9. ELECTRODE AND FLAME SENSOR POSITIONING

Two electrodes act as a sparker and a flame rod. Flame rectification by this flame rod monitors the continued

presence of the burner flame.

ELECTRODE AND FLAME SENSOR POSITIONING

Number and positioning of holes in pressure plate (head) may vary.

5/8” (1.59 cm)

Projection of ceramic past retention plate = 3/16” (0.48 cm)

1/8” Spark Gap

(1.59 cm)

10

PV500-56 03/19

10. BURNER SETUP AND ADJUSTMENT

WARNING: The burner supplied with this water heater has been factory adjusted to operate on the type

gas, gas pressure, manifold pressure and firing rate identified on the burner data decal and must be

verified after installation and adjusted as required to obtain those values. Firing this burner above the

burner decal specified firing rate will void the warranty, and may result in improper operation, a fire or

explosion, or dangerous carbon monoxide, causing property damage, personal injury or death.

See the burner and water heater data decals for the proper firing rate, gas pressure requirements and other

important information.

Top View of Gas Valve Adjusting the Firing Rate

SU3 Gas Manifold

Manifold Pressure Tap

Air Adjustment

Head Adjustment

Top View of Gas Valve

11

PV500-56 03/19

10.1 Commissioning Checklist

1. Be sure the water heater tank is filled with water before commissioning the burner.

2. Check the combustion air, venting and gas supply complies with the Section 4, “Combustion and Ventilation

Air”, Section 5, “Venting”, and Section 6 “Gas Supply and Piping”.

3. Check burner wiring.

Check that 120VAC is coming into the burner.

Check that the burner is properly grounded using a ground wire.

Check the polarity to the burner is correct. (To check polarity: Set a multimeter to VAC. Touch L1 to

one of the probe tips and ground to the other. If a voltage between 110 and 125 is shown then it has

the correct polarity; if any other reading is shown, then check the L2 wire. If the L2 wire shows a voltage

between 110 and 125 is shown then the polarity to the burner is reversed.)

4. Check that the orifice is installed. All SU-3 burners, except natural gas burners with inputs above 199,000

btuh (58.32 kW), have an orifice installed in the burner’s gas pipe union. If the required orifice is missing,

contact PVI for a proper size replacement.

5. Install monometers at the inlet pressure tap and manifold pressure tap on the burner.

Check the gas pressure at the gas valve inlet pressure tap (line pressure). This pressure must be within

the minimum and maximum gas pressures printed on the burner data decal, both when the burner is

firing and when it is not firing. If the pressure drops and then surges back up, double check the piping,

because it means the gas supply is probably undersized.

Record the static incoming gas pressure. When the burner lights off, record the running incoming gas

pressure; the incoming gas pressure must never be above or below the minimum and maximum

pressures shown on the burner information decal, whether the burner is firing or not.

Check the manifold pressure at the manifold pressure tap located on top of the silver elbow attached

to the burner head. Note: When checking manifold pressure, do not subtract burner housing

pressure during valve-on delay (pre-purge).

10.2 Adjusting Burner Using Combustion Analyzer

While the burner is firing and with a combustion analyzer sampling flue products in the vent near the burner,

adjust the gas pressure regulator as required to match the manifold pressure shown on the burner data

decal. If adjustments need to be made, remove the cap screw and adjust the pressure regulator. Screwing

the regulator clockwise will increase the manifold pressure and counter-clockwise will decrease the

manifold pressure. Note that a slight turn of the adjustment screw can result in a very large change

in manifold pressure.

Adjust the air shutter as necessary to obtain a CO2 reading between 8% and 9.5% for Natural gas and

9.5% to 10.5% for LP gas (O2 between 4.5% and 7.0%). Carbon monoxide levels should be below 200

ppm (less than 100 ppm is preferred). If air shutter adjustment is needed, rotate the air adjustment screw

clockwise to open the air shutter or counter-clockwise to close the air shutter. Changing the air shutter

setting will require the manifold pressure to be readjusted to match the pressure shown on the burner

information decal.

Continue to adjust the burner’s gas regulator and air shutter until the manifold pressure matches the value

shown on the burner data decal and CO2 (or O2) and Carbon Monoxide is within the range specified above.

10.3 Adjusting Burner Head

Do not change the factory setting of the burner head, except as directed in Section 12, Troubleshooting.

If directed to change the burner head position number, with the burner firing and with a combustion analyzer

inserted in the flue and a manometer attached to the manifold pressure tap, use an allen wrench to rotate

the head adjustment screw clockwise to increase the burner head position number or rotate counter-

clockwise to decrease the burner head position number. Changing the burner head position will require the

manifold pressure to be readjusted to match the pressure shown on the burner data decal. Then follow the

instructions contained in section 10.2, Adjusting Burner Using Combustion Analyzer.

12

PV500-56 03/19

10.4 Burner Operation Record

Note: if any adjustments are made, it is important to recheck the manifold pressure and combustion

analysis. Check the following readings in the vent above the flue collector and below the barometric

damper.

BURNER OPERATION: Record the Readings at Steady State

Incoming Static Gas Pressure = “W.C. (kPa) (see burner data decal for range)

Incoming Flow Gas Pressure = “W.C. (kPa) (see burner data decal for range)

Manifold Gas Pressure = “W.C. (kPa) (see burner data decal for specified pressure)

CO2 % = (8% to 9.5% for Natural gas) (target 8.5%)

(9.5% to 10.5% for LP gas) (target 10.0%)

O2 % = (7.0% to 4.5%)

Carbon Monoxide (CO) in PPM = (should not exceed 200PPM) (target <100PPM)

NOx in PPM (If necessary)

Stack Temperature – Gross

0

F (300

0

F minimum, 500

0

F maximum)(149

0

C to 260

0

C)

Room Temperature

0

F (

0

C)

Draft (should be - 0.02 “W.C. to - 0.06 “W.C.)(- 0.005 kPa to - 0.015 kPa) (target - 0.04”

W.C.) (- 0.01 kPa)

High Gas Pressure Switch Setting (if equipped)

Low Gas Pressure Switch Setting (if equipped)

Head Setting Number

Air Shutter Setting Number

Running Motor Amps and Volts

Stored Water Temperature

0

F (

0

C)

Vent Diameter

13

PV500-56 03/19

11. MAINTENANCE INSTRUCTIONS

At least once a year, a qualified service agency needs to be contracted for other than routine maintenance,

including such things as checking the burner head and checking combustion.

WARNING: Turn off all electrical service to the appliance when accessing the limit or other controls

located inside the appliance or burner control cabinet. This cabinet contains High Voltage wiring and

terminals. Close and fasten the control cabinet cover before restoring electrical service to the

appliance. If the electrical service is not turned off and these terminals are touched, a dangerous shock

causing personal injury or death could occur.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation. Verify proper operation after servicing.

ATTENTION: Au moment de l'entretien des commandes, étiquetez tous les fils avant de les débrancher. Des

erreurs de câblage peuvent entraîner un fonctionnement inadéquat et dangereux. S'assurer que l'appareil

fonctionne adéquatement une fois l'entretien terminé.

1. Keep the area around the conversion burner clear and free from combustible materials, gasoline, and other

flammable vapors and liquids.

2. The blower motor is the only moving part. It does not require lubrication, since the ball bearings have been

permanently lubricated.

3. The user should do periodic visual checks of the burner and the flame.

4. Check for obstruction of combustion air and ventilating air flow.

5. Periodically inspect and checkout the burner ignition, control system, and fuel valve operation (for tight

close-off).

6. Examine the venting system at least once each year for proper connections, alignment and corrosion.

7. The blower inlet will collect dust from the air during operation. Disconnect the power to the heater and clean

the blower wheel when necessary.

8. Inspect all parts and make replacements when necessary.

9. Check wiring for loose connections and burned wires.

14

PV500-56 03/19

12. TROUBLESHOOTING

Condition

Solutions

1. Burner motor runs and:

No flame after pre-purge

Check 24V feed to airflow switch & after airflow switch to control. Fix or

replace the airflow switch. If there is no secondary power, then replace

the 24V transformer.

No flame, faulty ignition transformer or spark

separately

Check ignition transformer output from Fenwal control and check for

cracked electrode or gap. Fix or replace.

Burner locks out after 4 seconds

First, check ionization electrode, ionization cable (for cracks) and boot.

Fix as needed.

Polarity reversed

Check power feed for reversed polarity following instructions in the

Commissioning Checklist, Section 10.1.

Bad earth grounding

Fix the ground wire.

Gas supply pressure is too low

Check the gas supply regulator and adjust to proper pressure, check that

gas piping is adequately sized following the instructions in Section 6, Gas

Supply and Piping.

2. Pulsation – * Follow the instructions in Section 10, Burner Setup and Adjustment and using a combustion analyzer,

readjust combustion air as required to obtain proper combustion.

Gas pressure is too high.

Use manometer and readjust the inlet pressure. *

Manifold pressure too high

Use manometer and readjust regulator for correct manifold pressure.*

Burner is dirty

Clean burner.

Venting is inadequate

Adjust barometric damper, clear flue and cap of foreign materials or

correct vent system following the instructions in Section 5, Venting, to

provide draft within the specified range.

Misadjusted burner head

First correct by steps above, if still pulsating, adjust to a lower head

position number. Manifold pressure must be readjusted to match that

shown on the burner information decal and combustion must be

rechecked following the instructions in Section 10, Burner Setup and

Adjustment.

3. Burner locks out

Ionization current is too low

Check current. Minimum 0.8 micro amps. Check position of ionization

electrode and the condition of the cable.

4. The CO content is too high

Excess air is too low or possibly too high

Adjust air shutter.

The gas holes in pressure plate are clogged

Clean them.

The fresh air intakes are too small

Increase the size of combustion air openings to those specified in Section

4, Combustion and Ventilation Air.

Negative pressure in mechanical room

Remove source of negative pressure and/or increase size of combustion

air openings.

Gas supply is too high or too low

Check the gas supply regulator adjust to proper pressure, check that gas

piping is adequately sized following the instructions in Section 10, Burner

Setup and Adjustment.

Burner settings or adjustment incorrect

Follow the instructions in Section 10, Burner Setup and Adjustment and

using a combustion analyzer.

5. Condensation in the heat exchanger

Firing Rate is too low

Check burner combustion. If combustion is in range, increase firing rate

so the gross stack temperature is at least 350

o

F (177

o

C) by adjusting to

a higher head position number. Manifold pressure must be readjusted to

match that shown on the burner information decal and combustion must

be rechecked following the instructions in Section 10, Burner Setup and

Adjustment. If allowed by code and vent manufacturer, insulate the vent.

15

PV500-56 03/19

13. MATERIALS LIST

ITEM

Part #

PART

ITEM

Part #

PART

1

118916

Blast Tube

14

119167

Ionization Cable

2

101329

Flange Gasket

15

101630

Ignition Transformer

3

101306

Adjustable Flange

15A

5734 & (2)

5315

Ignition Cable for 2260-TWO

4

118941

Front piece - Housing

16

118936

Cover Plate - Air Regulation

5

119183

Rear piece - Housing

16A

118937

Cover Plate - Nozzle Line

6

110195

Fan Wheel -133 mm (199, 270,

300)

17

118938

Scale - Nozzle Line

6A

119166

Fan Wheel -146 mm (399 only)

17A

118939

Scale -Air Regulation

7

106419

1/6 HP PSC Blower motor

18

107552

24 Volt Transformer

8

119181

Shielding Plate Housing

19

102785

Safety Control

8A

119165

Plate for Cone (399 only. Not

shown)

20

118929

Plastic Cover Plate

9

101315

&101041

Outside Air Boot (optional)

21

118918

Screw (Long Special)

9A

118930

Silencer

22

110995

Airflow Switch

10

118917

Air Regulation Plate

23

119186 Assy

Ignition Electrode

11

118921

Air Damper

24

Flame Rod

12

118922

Air Regulation Adjustment screw

25

Retention head

13

118935

Adjustment Screw – Nozzle Line

26

5928

Union

27

102415

Gas Valve

-

Gas Orifice (varies by model , gas

& input) Located in union (not

shown)

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16