Wacker Neuson GH3500E Manuel utilisateur

- Catégorie

- Groupes électrogènes

- Taper

- Manuel utilisateur

OPERATOR'S MANUAL / PARTS BOOK

Generator

GH3500

0075066 007

0500

0075066

DANGER

CARBON MONOXIDE

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide (CO). This is a poison you cannot see or

smell. If you can smell the generator exhaust, you are breathing CO. But even if you cannot

smell the exhaust, you could be breathing CO.

• NEVER use a generator inside homes, garages, crawlspaces, or other partly enclosed

areas. Deadly levels of carbon monoxide can build up in these areas. Using a fan or

opening windows and doors does NOT supply enough fresh air.

• ONLY use a generator outside and far away from windows, doors, and vents. These

openings can pull in generator exhaust.

Even when you use a generator correctly, CO may leak into the home. ALWAYS use a

battery-powered or battery-backup CO alarm in the home.

If you start to feel sick, dizzy, or weak after the generator has been running, move to fresh

air RIGHT AWAY. See a doctor. You could have carbon monoxide poison.

GH3500

i

This manual provides information and procedures to safely operate and maintain this WACKER model. For your

own safety and protection from injury, carefully read, understand and observe the safety instructions described

in this manual. THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION

AT THE TIME OF PUBLICATION. WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY PORTION

OF THIS INFORMATION WITHOUT NOTICE.

This manual is divided into the sections listed below:

Item Number:

0005785

Operation

Generator Parts

Engine Parts

1

2

3

Keep this manual or a copy of it with the machine. If you lose this manual or need an

additional copy, please contact WACKER Corporation. This machine is built with user

safety in mind, however, it can present hazards if improperly operated and serviced.

Follow operating instructions carefully! If you have questions about operating or

servicing this equipment, please contact WACKER Corporation.

Engine exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm.

!

WARNING

1040SD71

GH3500

ii

MENOMONEE FALLS, WI USA 53051

Model

Serial Number

kW max

V

Item No.

kg

A

lbs

Rev.

P.F.

hz

MADE IN

JAPAN

86345

Ø

Serial Number

My machineís numbers are:

RevisionItem Number

Model number

GH3500GH3500

GH3500GH3500

GH3500

00057850005785

00057850005785

0005785 101101

101101

101

50101015010101

50101015010101

5010101

Nameplate

A nameplate listing the Model Number, Item Number, Revision, and Serial Number is attached to each unit. Please

record the information found on this plate so it will be available should the nameplate become lost or damaged. When

ordering parts or requesting service information, you will always be asked to specify the model, item number,

revision number, and serial number of the unit.

PATENT PENDING

111545

This machine may be covered by one or more of the following patents:

111891

OF THESE U.S. PATENTS:

4643611; 4555238; 5564375; 5586630; 4419048

WACKER MACHINES PROTECTED BY ONE OR MORE

1038SD78

GH3500

Operating Information

1

1-1

Table of Contents

1.1 Safety Information ..................................................................................... 1-2

1.2 Operating Safety........................................................................................ 1-3

1.3 Operator Safety while using Internal Combustion Engines ........................ 1-4

1.4 Service Safety ........................................................................................... 1-4

1.5 Technical Data ........................................................................................... 1-5

1.6 Label Locations.......................................................................................... 1-6

1.7 Safety & Operating Labels ......................................................................... 1-7

1.8 Determining Power Requirements ............................................................. 1-8

1.9 Outdoor Installation.................................................................................... 1-8

1.10 Indoor Installation ...................................................................................... 1-8

1.11 Grounding the Generator ........................................................................... 1-9

1.12 Use of Extension Cords ............................................................................. 1-9

1.13 Control Panel ........................................................................................... 1-10

1.14 Circuit Breaker Protection ........................................................................ 1-10

1.15 Before Starting......................................................................................... 1-10

1.16 Recommended Fuel ................................................................................ 1-11

1.17 To Start.................................................................................................... 1-11

1.18 To Stop .................................................................................................... 1-11

1.19 Periodic Maintenance Schedule .............................................................. 1-12

1.20 Spark Plug ............................................................................................... 1-12

1.21 Engine Oil ................................................................................................ 1-13

1.22 Air Cleaner ............................................................................................... 1-13

1.23 Throttle Adjustment ................................................................................. 1-14

1.24 Adjusting Idle Speed ................................................................................ 1-14

1.25 Cleaning Fuel Strainer ............................................................................. 1-14

1.26 Storage .................................................................................................... 1-15

1.27 Transporting ............................................................................................ 1-15

1.28 Troubleshooting ....................................................................................... 1-15

1.29 Wiring SchematicñSerial Numbers 578501001 through 578501101........ 1-16

1.30 Wiring SchematicñSerial Numbers 578501102 and Higher ..................... 1-17

1-2

1 OPERATION GH3500

Notice: California Assembly Bill 1642, Section 4442, requires that all internal combus-

tion engines be equipped with spark arresters if used on any forest-covered, brush-

covered, or grass-covered, unimproved land. The arrester must be maintained in

effective working order by the operator. Other states may have similar laws. Federal laws

apply on federal lands.

1.1 Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be followed to reduce the

possibility of personal injury, damage to the equipment, or improper service.

CAUTION: Used without the safety alert symbol,

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

Note: Contains additional information

important to a procedure.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

!

WARNING

!

CAUTION

!

!

DANGER

1-3

GH3500 OPERATION 1

1.2 Operating Safety

Familiarity and proper training are required for the safe operation of electrical equipment! Equipment operated

improperly or by untrained personnel can be dangerous! Read the operating instructions and familiarize yourself

with the location and proper use of all instruments and controls. Inexperienced operators should receive

instruction from someone familiar with the equipment before being allowed to operate the generator.

NEVER operate generator when open containers

of fuel, paint, or other flammable liquids are near.

NEVER operate generator, or tools attached to

the generator, with wet hands.

NEVER use worn electrical cords. Severe electri-

cal shock and equipment damage may result.

NEVER place flammable material or liquids near

generator.

NEVER operate generator indoors unless ex-

haust fumes can be adequately ventilated.

NEVER run electrical cords under the generator,

or over vibrating or hot parts.

NEVER enclose or cover generator when in use or

when hot.

NEVER overload generator. The total amperage

of the tools and equipment attached to the genera-

tor must not exceed the load rating of the genera-

tor.

NEVER allow untrained personnel to operate or

service the generator. Know how to operate and

stop generator before starting it.

NEVER operate generator in snow, rain, or standing

water.

ALWAYS keep generator at least three feet (one

meter) away from structures, buildings and other

equipment during use.

ALWAYS keep generator out of reach of children

and pets.

ALWAYS keep the area immediately surrounding

the generator clean, neat and free of debris.

ALWAYS position and operate generator on a

firm, level surface.

ALWAYS remove all tools, cords, and other loose

items from generator before starting it.

ALWAYS make certain generator is well-grounded

and securely fastened to a good earthen ground.

ALWAYS transport generator in an upright position.

BACKFEED FROM THE GENERATOR INTO THE PUBLIC POWER DISTRIBUTION SYSTEM CAN

CAUSE SERIOUS INJURY OR DEATH TO UTILITY WORKERS!

Improper connection of generator to a building's electrical system can allow electrical current from the generator

to backfeed into utility lines. This may result in electrocution of utility workers, fire, or explosion. Connections

to a building's electrical system must be made by a qualified electrician and comply with all applicable laws and

electrical codes.

If connected to a building's electrical system the generator must meet the power, voltage, and frequency

requirements of the equipment in the building. Differences in power, voltage, and frequency requirements may

exist and improper connection may lead to equipment damage, fire, and personal injury or death.

WARNING

!

!

DANGER

1-4

1 OPERATION GH3500

1.3 Operator Safety while using Internal Combustion Engines

Internal combustion engines present special hazards during operation and fueling ! Failure to follow the safety

guidelines described below could result in severe injury or death.

1.4 Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly

over a long period of time, periodic maintenance and occasional repairs are necessary. If the generator is

experiencing problems or is being serviced, attach a "DO NOT START" sign to the control panel to notify other people

of its condition.

NEVER allow water to accumulate around the base

of the generator set. If water is present, move the

generator and allow it to dry before servicing.

NEVER service generator if clothing or skin is wet.

NEVER use gasoline or other low flash point solvents

to clean air cleaner elements.

NEVER allow untrained personnel to service this

equipment. Only trained electrical tech-nicians should

be allowed to service the electrical components of

this equipment.

NEVER modify the equipment without express writ-

ten approval from WACKER Corporation.

ALWAYS replace all guards and safety devices

immediately after servicing.

ALWAYS turn engine off before servicing genera-

tor. If engine has electric start, disconnect negative

terminal on battery.

ALWAYS replace all missing and hard-to-read de-

cals. Decals provide important operating instruc-

tions and warn of dangers and hazards.

ALWAYS let engine cool before transporting or

servicing.

ALWAYS remain aware of moving parts and keep

hands, feet, and loose clothing away from moving

parts on generator and engine.

DO NOT run engine indoors or in an area with

poor ventilation unless exhaust hoses are used.

DO NOT fill or drain fuel tank near an open flame,

while smoking, or while engine is running.

DO NOT fill fuel tank in an enclosed area with

poor ventilation.

DO NOT touch or lean against hot exhaust pipes.

DO NOT operate with the fuel tank cap loose or

missing.

DO NOT add fuel to a hot or running engine.

DO NOT start engine if fuel has spilled or an odor

of fuel is present. Move generator away from the

spill and wipe generator dry before starting.

!

DANGER

WARNING

!

1-5

GH3500 OPERATION 1

1.5 Technical Data

rotareneG

tuptuO

WkxaM

WksuounitnoC

5.3

9.2

epyT metsyssselhsurb,egatlovlauD

elbaliavasegatloV

esahp/stlov

¯3/042

CD/011

ycneuqerF

zH

081

rotcaFrewoP

¯3CAV042

CDV011

0.1

elcatpeceRtloV042CA

selcatpeceRtloV011CD

pma/ytq

pma/ytq

5/2

62/2

)yrd(thgieW

)gk(.sbl

)66(641

enignE

ekaMenignE niboR

ledoMenignE 00912W082YE

rewoPdetaR

Wk

5.3

gulPkrapS

epyt

68LnoipmahC

paGedortcelE

hcni

720.0-420.0

yrettaB

ruoh-pma/tlov/epyt

02/21/A-L81N-05

daollluf-deepSgnitarepO

mpr

0063

daolon-deepSgnitarepO

mpr

0083

deepSeldI

mpr

0072

renaelCriA

epyt

tnemelelauD

noitacirbuLenignE

edarglio

ssalcecivres

03EAS)C∞05otC∞5(F∞021otF∞04

02EAS)C∞5otC∞01-(F∞04otF∞51

03W01EAS)C∞01-(F∞51woleB

FS

yticapaCliOenignE

)lm(.zO

)058(82

leuF

epyt

enilosagdedaelnuralugeR

yticapaCknaTleuF

retil

5.91

emiTgninnuR

.srh

0.6

noitpmusnoC

.rh/retil

42.3

)dloc(ecnaraelCevlaV

mm

51.0:telnI

02.0:teltuO

1-6

1 OPERATION GH3500

1.6 Label Locations

CAUTION

PRECAUTION

PRECAUCION

VORSICHT

1038SD78

ADVERTENCIA

AVERTISSEMENT

DANGER

GEFAHR

PELIGRO

DANGER

STOP

DANGER

DANGER

GEFAHR

PELIGRO

DANGER

DANGER

GEFAHR

PELIGRO

CAUTION

PRECAUTION

PRECAUCION

VORSICHT

1-7

GH3500 OPERATION 1

1.7 Safety & Operating Labels

This WACKER machine uses international pictorial labels where needed. These labels are described below:

Pictorial Meaning

Warning! Hot surface.

111024

CAUTION

PRECAUTION

PRECAUCION

VORSICHT

Caution! Read and understand the supplied

operator's manual before operating this machine.

Failure to do so increases the risk of injury to

yourself or others.

117045

ADVERTENCIA

AVERTISSEMENT

117039

DANGER

DANGER

GEFAHR

PELIGRO

Danger! Engines emit carbon monoxide; operate only

in well ventilated area. Read the operator's manual.

Danger! No sparks, flames or burning objects near

machine. Shut off engine before refueling.

DANGER

GEFAHR

PELIGRO

DANGER

STOP

DANGER

DANGER

GEFAHR

PELIGRO

Danger! Electrical shock hazard! Read the operatorís

manual.

114474

114473

CAUTION

PRECAUTION

PRECAUCION

VORSICHT

111623

Caution! Lifting point

1-8

1 OPERATION GH3500

1.8 Determining Power

Requirements

This generator is designed to operate single-phase,

60 Hz appliances running at 120 VAC. Check the name-

plate or label provided on tools and appliances to make

sure their power requirements match the power output of

the generator.

Some appliances and tools require a surge of current

when starting. This means that the amount of power

needed to initially start the equipment is larger than the

power required to keep it running. The generator must be

capable of supplying this ìsurgeî current. Other types of

appliances require more power than is actually stated on

their nameplate.

The chart below is offered only as a general guideline to

help you in determining power requirements for different

types of equipment. Check with your nearest WACKER

Dealer, or contact the manufacturer or dealer of the tool

or appliance, with questions regarding its power require-

ments.

1.9 Outdoor Installation

Place the generator in an area where it will not be

exposed to rain, snow or direct sunlight. Make sure it is

positioned on firm, level ground so it will not slide or shift.

Position engine exhaust away from areas where people

may be present.

If operating the generator inside a tunnel or deep trench,

make sure there is adequate ventilation. Precautions

similar to those required when operating indoors may be

necessary.

The surrounding area must be free from water and

moisture. All components must be protected from exces-

sive moisture.

1.10 Indoor Installation

If the generator must be installed indoors, adequate

ventilation or exhaust hoses must be provided. When

venting exhaust fumes, make sure the exhaust piping is

large enough to prevent excessive back pressure to the

engine. Back pressure reduces engine efficiency and

may cause the engine to overheat.

- Incandescent lights, and appliances such as irons

and hot plates, which use a resistive-type heating

element, require the same wattage to start and run

as is stated on their nameplates.

- Fluorescent and mercury lamps require 1.2 ñ 2

times their stated wattage to start.

- Electrical motors and many types of electrical tools

often require a large starting current. The amount of

starting current depends on the type of motor and

its use.

- Most electrical tools require 1.2 ñ 3 times their

stated wattage for running.

- Loads such as submersible pumps and air com-

pressors require a very large force to start. They

need as much as 3 ñ 5 times the wattage stated on

the nameplate in order to start.

If the wattage is not given for a particular tool or

appliance, it can be calculated by multiplying its

voltage and amperage requirements:

VOLTS X AMPS = WATTS

CAUTION: If a tool or appliance does not reach full

speed within a few seconds when switched on, turn it off

immediately to avoid damage.

Exhaust fumes contain carbon monoxide and are

extremely poisonous!

!

DANGER

1-9

GH3500 OPERATION 1

1.11 Grounding the Generator

The generator should be grounded to a good ground

source in compliance with National Electric Code stan-

dards and local regulations.

Use #8 wire and secure one end to the ground terminal

(a) provided on the generator frame and the other end to

a suitable ground source.

1.12 Use of Extension Cords

When a long extension cord is used to connect an appliance or tool to the generator, a voltage loss occursóthe longer

the cord, the greater the voltage loss. This results in less voltage being supplied to the appliance or tool and increases

the amount of current draw or reduces performance. A heavier cord with a larger wire size will reduce the voltage loss.

Use the chart below as a guide for selecting proper cable size.

Use only extension cords rated for outdoor use and equipped with a third-wire ground.

Current Load in Watts Maximum Cable Length in Ft.

Amps 120V 240V #10 #12 #14 #16

2.5 300 600 1000 ft. 600 ft. 375 ft. 250 ft.

5 600 1200 500 ft. 300 ft. 200 ft. 125 ft.

7.5 900 1800 350 ft. 200 ft. 125ft. 100 ft.

10 1200 2400 250 ft. 150 ft. 100 ft. ñ

15 1800 3600 150 ft. 100 ft. 65 ft. ñ

20 2400 4800 125 ft. 75 ft. 50 ft. ñ

1001SD02

Keep electrical cords in good condition. DO NOT use worn,

bare, or frayed cords which can cause electrical shock.

a

CAUTION: Operating equipment at low voltage can cause it to overheat.

WARNING

!

1-10

1 OPERATION GH3500

1.15 Before Starting

1. Inspect generator for any signs of damage which may

affect operation or pose a safety hazard. Tighten any

loose nuts or bolts.

2. Check engine oil and fill to recommended level.

Note: The engine is equipped with an oil alert system. If

the oil level in the engine drops too low the engine will not

start.

3. Fill fuel tank with fresh, regular, unleaded grade

gasoline. DO NOT use an oil/gas mixture. The use

of gasohol or any fuel containing more than 10%

ethanol is not recommended. Consult engine owner's

manual for complete fuel specifications.

5A

V

OUTPUT VOLTAGE

5A

TOTAL 26A

AC240V 180Hz 3Ø

DC110V

AC240V 180Hz 3Ø

AUTO IDLER SW

ON

OFF

POWER

30A

f

1

d

2

d

1

c

a

1

f

2

ba

2

Control Panel

a

1

30A circuit breaker

a

2

110V DC receptacle

b voltmeter

c power ON pilot lamp

d

1

, f

1

5A circuit breaker

d

2

, f

2

240V AC, 180 Hz, 3ÿ receptacle

e auto idle switch

1038SD54

1.13 Control Panel

The control panel supplies power for high-cycle 3ÿ,

240V, 180 Hz equipment, as well as convenience outlets

at 110V DC. To power equipment, check for correct

voltage on the voltmeter, plug in the equipment to the

correct receptacle type, then turn the appropriate circuit

breaker to ON.

The auto idle switch enables the slow down unit, which

automatically reduces engine speed and fuel consump-

tion during periods of no-load operation.

CAUTION: DO NOT exceed the total wattage or amper-

age rating of the generator.

1.14 Circuit Breaker Protection

The generator is protected by two 5 Amp circuit breakers

(d

1

, f

1

) and a 30 Amp circuit breaker (a

1

) located on the

control panel.

The circuit breakers protect the generator from severe

overloads or short circuits. If a circuit breaker opens,

stop the engine immediately and determine the cause

before restarting. Check the appliances and tools at-

tached to the generator for defects and make sure their

power requirements do not exceed the power rating of

the generator or the current limit of the receptacles.

e

1-11

GH3500 OPERATION 1

1.18 To Stop

1. Reduce engine RPM to idle by moving throttle com-

pletely to the left (j

1

).

2. Turn the ON/OFF switch to the ìOî (OFF) position

(g

2

). The engine will stop.

1.17 To Start

1. Turn the ON / OFF switch to the ìIî (ON) position (g

1

).

2. If engine is cold, move choke lever to closed position

(h

1

). If engine is hot, set choke to open position (h

2

).

3. Open throttle by moving it to the right (j

2

).

4. Pull starter rope (k).

Note: If the engine oil level is low, the engine will not

run. If engine does not run, check oil level and add oil

as needed.

5. Open choke as engine warms (h

2

).

6. Open throttle fully (j

3

) to operate machine.

g

1

1038SD89

h

2

1020SD44

h

1

1020SD45

1006SD79

1038SD88

g

2

j

1

k

j

2

j

3

OFF

ON

O

I

OFF

ON

O

I

1.16 Recommended Fuel

The engine requires regular, unleaded gasoline. Use

only fresh, clean fuel. Fuel containing water or dirt will

damage fuel system. Consult engine ownerís manual for

complete fuel specifications.

1-12

1 OPERATION GH3500

Check fuel level.

Check engine oil level.

Inspect air filter. Replace as needed.

Check and tighten external hardware.

Inspect shockmounts for damage.

Check and adjust drive belt.

Change engine oil.

Clean sediment cup.

Check and clean spark plug

Clean air cleaner.

Check and adjust valve clearance.

Daily After Every Every Every

before first two weeks month 6 months

starting 20 or or or

hours 50 hrs. 100 hrs. 500 hrs.

1.19 Periodic Maintenance Schedule

The chart below lists basic plate and engine maintenance. Refer to engine manufacturerís Operation Manual for

additional information on engine maintenance. A copy of the engine Operatorís Manual was supplied with the machine

when it was shipped.

1.20 Spark Plug

Clean or replace spark plug as needed to ensure proper

operation. Refer to the engine Ownerís Manual.

Recommended Plug: Champion L86

1. Remove spark plug and inspect it.

2. Replace plug if the insulator is cracked or chipped.

Clean spark plug electrodes with a wire brush.

3. Set gap to 0.024ñ0.027" (0.6ñ0.7 mm).

4. Tighten spark plug securely.

CAUTION: A loose spark plug can become very hot

and may cause engine damage.

The muffler becomes very hot during operation and

remains hot for a while after stopping the engine. Do

not touch the muffler while it is hot.

0.028ñ0.031 in.

(0.7ñ0.8 mm)

1006SD37

WARNING

!

1-13

GH3500 OPERATION 1

b

c

a

1020SD48

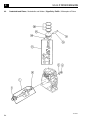

1.21 Engine Oil

Drain oil while engine is still warm.

1. Remove drain plug (a) to drain oil. Dispose of used oil

in an appropriate manner. Contact local recycling

center.

2. Install drain plug.

3. Fill engine crankcase with 20 ounces of SAE10W30

motor oil through filler port (b). Check oil level with oil

gauge (c). Do not thread gauge into filler port when

checking level. Replace gauge before running en-

gine.

Note: In the interests of environmental protection, place

a plastic sheet and a container under the machine to

collect any liquid which drains off. Dispose of this liquid

in accordance with environmental protection legislation.

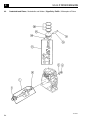

1.22 Air Cleaner

The engine is equipped with a dual element air cleaner.

Service the air cleaner frequently to prevent carburetor

malfunction.

CAUTION: NEVER run engine without air cleaner. Se-

vere engine damage will occur.

To service:

1. Remove air cleaner cover (d). Remove both ele-

ments and inspect them for holes or tears. Replace

damaged elements.

2. Wash foam element (e) in solution of mild detergent

and warm water. Rinse thoroughly in clean water.

Allow element to dry thoroughly.

Soak element in clean engine oil and squeeze out

excess oil.

3. Tap paper element (f) lightly to remove excess dirt.

Replace paper element if it appears heavily soiled.

d

e

f

1006SD80

NEVER use gasoline or other types of low flash

point solvents for cleaning the air cleaner. A fire or

explosion could result.

WARNING

!

1-14

1 OPERATION GH3500

1.24 Adjusting Idle Speed

Adjust idle when engine is warm.

To adjust engine idle speed:

1. Start engine and allow it to warm up for a minute.

2. With throttle in lowest (slowest) position, adjust idle

speed screw (g) to obtain correct idle speed -1600

RPM.

g

1012SD50

1.25 Cleaning Fuel Strainer

Turn fuel valve off. Remove strainer cup (j), seal (h) and

strainer (i). Wash them thoroughly in a nonflammable

solvent. Dry them and install. Turn fuel valve on and

check for leaks.

j

h

i

1006SD76

1.23 Throttle Adjustment

1. Place machine on a rubber test mat to prevent it from

moving.

2. Start engine and allow it to warm up to operating

temperature.

3. Move throttle control to high speed position

(e).

4. Adjust throttle stop screw (f) to set operating speed.

CAUTION: Running plate at a speed higher than that

listed in ìTechnical Dataî can damage both the plate and

the engine.

f

1006SD74

e

1-15

GH3500 OPERATION 1

1.28 Troubleshooting

If engine doesn't start, check that:

1. Engine switch is on ìStartî.

2. Fuel valves under fuel tank and on engine are open.

3. Fuel tank has fuel.

4. Choke lever is in correct position. Choke should be

closed when starting a cold engine.

5. All loads are disconnected from generator.

6. Spark plug is in good condition.

7. Spark plug cap is tight.

8. Engine oil level is adequate.

1.26 Storage

Before storing generator for a long period of time:

1. Close the fuel valve and remove and empty sediment

cup under carburetor.

2. Disconnect the fuel line from the carburetor. Place

open end of fuel line into a suitable container and open

fuel valve to drain fuel from tank.

3. Loosen the drain screw on the carburetor and drain

any remaining fuel from carburetor.

4. Change the engine oil.

5. Remove the spark plug and pour approximately one

tablespoon (1 ounce) of clean engine oil into the

cylinder. Crank the engine a few turns to distribute the

oil to the inside of the cylinder walls.

6. Pull the starter rope slowly until resistance is felt and

leave handle in this position. This ensures that the

intake and exhaust valves are closed.

7. Store generator in a clean, dry area.

Gasoline is extremely flammable. Drain fuel tank in

a well-ventilated area. DO NOT drain tank in an area

with flames or sparks.

1.27 Transporting

To avoid burns or fire hazards, let engine cool before

transporting generator or storing indoors.

Turn the fuel valves under the tank and on engine to

the off position and keep the engine level to prevent

fuel from spilling.

If engine starts but there is no power at receptacles,

check that:

1. Circuit breaker is closed.

2. Connector from generator to control panel is tight.

WARNING

!

WARNING

!

1-16

1 OPERATION GH3500

Br

L

L

Ex

+

_

~

~

ROTOR

GENERATOR

SDU

3

2

1

ENGINE

SD

OIL

Sensor

CONTROL BOX

CON1

CON2

CON3

STATOR COIL

5P

TERMINAL

NFB1

NFB2

NFB3

SW

Re6

2P CONNECTOR (white)

2P CONNECTOR (blue)

Re5 Re4

Re1 Re2

Re3

FRAME

PL

V

~

~

LC

U

V

W

P

N

J1

K1

J

K

L

L

2B

2B

2WOr

2WOr2WOr

2Or

2Y

2Br

0.75Gr

.075L

0.75Vi

0.75Y

0.5Y

0.5L

0.75Br

0.75Or

2L

2L

2L

2L

0.75Or

0.75Br

0.75R

0.75Y

0.75R

0.75L

1.25R

1.25W

1.25L

1.25R

1.25W

1.25L

1.25R

1.25W

1.25L

2R

2W

2WR

2WR

2WL

2WL

2G 2G

3.5R

3.5R

3.5L3.5L

1.25G

1.25G

1.25L

1.25L

2G

0.75R

0.5B

0.5B

0.75W

0.5W

0.5W

Or

Or

Br

.075WY

1.29 Wiring SchematicñSerial Numbers 578501001 through 578501101

1040SD96

lobmySemaNkrameR

1eRedoiDnociliS04BV51S

2eRedoiDnociliS04BV51S

3eRedoiDnociliS04BV51S

4eRedoiDnociliS04BV52S

5eRedoiDnociliS04BV52S

6eRedoiDnociliS04BV51S

V

reteMegatloVV003-005-RRT

LPpmaLtoliPV022CA212NB

1BFNrekaerBesuFoNA5P2V064CA23-Y

lobmySemaNkrameR

2BFNrekaerBesuFoN23-YB A5P2V064CA

3BFNrekaerBesuFoNP2V521CD25-MK03A

1NOCelcatpeceRA02V052R02-51LAMEN

2NOCelcatpeceRA02V052R02-51LAMEN

3NOCelcatpeceRA02V521R02-5AMEN

WShctiwSP1400-SD

UDS

tinUnwoDwolS50-CT

DSdioneloSV21CD2101S

CLlioCpmaL)enignehtiw(10-66107-432

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

Wacker Neuson GH3500E Manuel utilisateur

- Catégorie

- Groupes électrogènes

- Taper

- Manuel utilisateur

dans d''autres langues

- English: Wacker Neuson GH3500E User manual

Documents connexes

-

Wacker Neuson GPS6600A Manuel utilisateur

-

Wacker Neuson GPS9700 Manuel utilisateur

-

Wacker Neuson GPS6600 Manuel utilisateur

-

Wacker Neuson GP3800 Manuel utilisateur

-

Wacker Neuson GPS6600A Manuel utilisateur

-

Wacker Neuson GPS9700 Manuel utilisateur

-

Wacker Neuson GP5600 Manuel utilisateur

-

Wacker Neuson GPS6600 Manuel utilisateur