04/15 2015 JM HEAT STAR, Inc., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

WARNING:

· Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

· An LP cylinder not connected for use shall not be stored in the vicinity of this or any other

appliance.

· WHAT TO DO IF YOU SMELL GAS

• Do not try to light appliance.

• Extinguish any open flame.

• Shut off gas to appliance.

· Service must be performed by a qualified service agency.

This is an un-vented gas-fired portable heater. It uses air (oxygen) from the area in which it is used.

Adequate combustion and ventilation must be provided. Refer to pages 4 & 5.

FORCED AIR DUAL-FUEL NOMAD

HEATER

If the information in this manual is not followed exactly, a fire or explosion

may result, causing property damage, personal injury or loss of life.

HS115TC

HS190TC

HS250TC

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place instructions in a safe place

for future reference. Do not allow anyone who has not read these instructions to assemble, light, adjust

or operate the heater.

Model #

LANGUAGES INCLUDED

•ENGLISH

•FRENCH

•SPANISH

2

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

CONTENTS

WARNINGS ..........................................................................2

SPECIFICATIONS ...................................................................3

OPERATING PRECAUTIONS ..................................................4

SAFETY PRECAUTIONS .........................................................4

ODOR FADE WARNING ........................................................5

ASSEMBLY AND PREPARATION FOR OPERATION ..................6

HOSE AND REGULATOR INFORMATION ...............................6

FUEL AND RATE SELECTION .................................................7

OPERATION .........................................................................7

USING THE ACCESSORIES ...................................................8

SHUT DOWN AND STORAGE ...............................................9

MAINTENANCE ....................................................................9

PROPANE TANK SIZE SELECTION ........................................10

TROUBLESHOOTING .......................................................... 11

WIRING DIAGRAM ............................................................. 12

PARTS LISTS AND EXPLODED VIEWS .................................. 13

WARRANTY INFORMATION ...............................................20

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING

MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE

AWAY FROM THE HEATER AS RECOMMENDED BY THE

INSTRUCTIONS. NEVER USE THE HEATER IN SPACES

WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR UN-

KNOWN CHEMICALS.

WARNING:

NOT FOR HOME OR RECREATIONAL VEHICLE USE

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF FIRE,

EXPLOSION, BURN, ASPHYXIATION, CARBON MONOX-

IDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW

THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTIONS MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

THE STATE OF CALIFORNIA REQUIRES THE FOLLOWING WARNINGS:

WARNING: Combustion by-products produced when using this product contain carbon monoxide, a chemical

known to the State of California to cause cancer and birth defects (or other reproductive harm).

WARNING: This product contains chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm.

This NOMAD Forced Air Duel-fuel construction

heater was Assembled in the U.S.A. by:

Enerco Group Inc. 4560 West 160th Street

Cleveland, Ohio 44135

For Questions and Inquiries Contact us at:

CALL: 866-447-2194

FAX: 800-321-0552

VISIT: HEATSTARBYENERCO.COM.

Office hours are:

Monday - Friday 8:00am - 5:00pm

Operating Instructions and OwnerÊs Manual

3

Forced-Air Dual-Fuel NOMAD Construction Heater

MODEL# (Stock#) HS115TC (F109100) HS190TC (F109110) HS250TC (F109120)

PROPANE BTU/kW INPUT

HIGH LP (kW) 110,833 BTU/HR (32kW) 190,200 BTU/HR (56kW) 248,625 BTU/HR (73kW)

LOW LP (kW) 80,612 BTU/HR (24kW) 127,100 BTU/HR (37kW) 181,119 BTU/HR (53kW)

HIGH NG (kW) 107,586 BTU/HR (32kW) 183,600 BTU/HR (54kW) 248,625 BTU/HR (73kW)

LOW NG(kW) 77,124 BTU/HR (23kW) 128,700 BTU/HR (38kW) 172,252 BTU/HR (50kW)

OPERATINGS GAS PRESSURES (W.C./kPa)

MAX IN-LP TANK PRESSURE TANK PRESSURE TANK PRESSURE

MAX IN-NG (Kpa) 14" W.C. (3.49 Kpa) 14" W.C. (3.49 Kpa) 14" W.C. (3.49 Kpa)

MIN IN-LP (Kpa) 15 PSI (103.4 Kpa) 15 PSI (103.4 Kpa) 15 PSI (103.4Kpa)

MIN IN-NG (Kpa) 7" W.C. (1.74 Kpa) 7" W.C. (1.74 Kpa) 7" W.C. (1.74 Kpa)

MANIFOLD PRESSURE 4" W.C. (.99 Kpa) 4" W.C. (.99 Kpa) 4" W.C. (.99 Kpa)

FUEL CONSUMPTION PER HOUR

LP-HIGH LBS (Kg) 5.326 LBS/HR (2.41 Kg) 8.8 LBS/HR (3.99Kg) 12.042 LBS/HR (5.46 Kg)

LP-LOW LBS (Kg) 3.937 LBS/HR (1.78 Kg) 6.253 LBS/HR (2.83 Kg) 8.568 LB/HR (3.88 Kg)

NG-HIGH MCF .110 MCF .185 MCF .240 MCF

NG-LOW MCF .08 MCF .130 MCF .175 MCF

ELECTRICAL SPECIFICATIONS

ELEC. SUPPLY

(VOLTS/Hz/PHASE) 115V-60HZ- 1Ø 115V-60HZ-1Ø 115V-60HZ-1Ø

CONTINUOUS AMPS 3.5 AMPS 5.5 AMPS 8 AMPS

MOTOR H.P. 1/3HP 1/2HP 3/4HP

MOTOR WATTS 220 W 500 W 800 W

MOTOR R.P.M. 1100 1100 1035

HEATER DIMENSIONS/WEIGHTS

HEATER WEIGHT 91 LBS (40.3KG) 159 LBS (72 KG) 165 LBS (75 KG)

HEATER DIMENSIONS

(LxWxH)

30" x 23.75" x 15" 35.75" x 34.75" x 20.25" 35.75" x 34.75" x 20.25"

CARTON WEIGHT

(LBS/K.G.)

102 LBS (46.3KG) 176 LBS (79.8 KG) 182 LBS (83 KG)

CARTON DIMENSIONS

(LxWxH)

34.5" x 25.75" x 20" 39" x 36.75" x 24.25" 39" x 36.75" x 24.25"

SPECIFICATIONS

TOP SIDES BACK OUTLET

HS115TC 1' 1' 1' 6'

HS190TC 1' 1' 1' 6'

HS250TC 1' 1' 1' 6'

CLEARANCE TO COMBUSTIBLES

4

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

OPERATING PRECAUTIONS

This is a propane or natural gas, direct-fired, forced air

heater. It's intended use is primarily temporary heating of

buildings under construction, alteration or repair.

Propane is heavier than air. If the fuel leaks from a

connection or fitting, it sinks to the floor, collecting there

with the surrounding air, forming a potentially explosive

mixture. Obviously, fuel leaks should be avoided, so set up

the fuel supply with utmost care. Read the Odor Fade and

Propane warnings included in this manual for additional

information about detecting gas leaks. Leak check new

connections or re-connections with a soap and water

solution and follow all connection instructions herein. Also,

ask your propane dealer or natural gas supply company for

advice on the heater application and supply installation and

ask him to check it if there are any questions.

This heater was designed and certified for use as a

construction heater in accordance with ANSI Standard

Z83.7/CSA 2.14. Check with your local fire safety authority

if you have any questions about your applications. Other

standards govern the use of fuel gases and heat producing

products in specific applications. Your local authority can

advise you about these.

Direct-Fired means that all of the combustion products enter

the heated space. Even though this heater operates very

close to 100 percent combustion efficiency, it still produces

small amounts of carbon monoxide. Carbon monoxide

(called CO) is toxic. We can tolerate small amounts but not a

lot. CO can build up in a heated space and failure to provide

adequate ventilation could result in death. The symptoms of

inadequate ventilation are:

• headache

• dizziness

• burning eyes and nose

• nausea

• dry mouth or sore throat

So, be sure to follow advice about ventilation in these

operating instructions.

Forced Air means that a blower or fan pushes the air

through the heater. Proper combustion depends upon this

air flow; therefore, the heater must not be revised, modified

or operated with parts removed or missing. Likewise, safety

systems must not be circumvented or modified in order to

operate the heater.

When the heater is to be operated in the presence of other

people the user is responsible for properly acquainting those

present with the safety precautions and instructions, and of

the hazards involved.

SAFETY PRECAUTIONS

1. Check the heater thoroughly for damage. DO NOT

operate a damaged heater.

2. DO NOT modify the heater or operate a heater which has

been modified from its original condition.

3. Use only fuel types for which the heater has been

certified.

4. If using propane use only VAPOR WITHDRAWAL type

propane supply. If there is any question about vapor

withdrawal, ask your propane dealer.

5. Mount the propane cylinders vertically (shutoff valve

up). Secure them from falling or being knocked over and

protect them from damage.

6. Locate propane containers at least (USA) 7 ft. (2.13m),

(Canada) 10 ft. (3m) from the heater and do not direct

exhaust toward containers.

7. IMPORTANT Use only the hose and regulator assembly

provided with the heater. Inspect hose assembly before

each use of the heater. If there is excessive abrasion or

wear, or hose is cut, replace with hose assembly listed on

parts list in this manual before using heater.

8. For indoor or outdoor use where adequate ventilation has

been provided. Minimum openings of 1/2 sq. ft. (.046

m²) near the floor and 1/2 sq. ft. (.046 m²) near the

ceiling (also see "Operating Precautions").

9. If at any time gas odor is detected, IMMEDIATELY

DISCONTINUE operation until the source of gas has been

located and corrected. Read enclosed Odor fade and

Propane information for additional information about

detecting propane or natural gas leaks.

10. While this heater is designed to withstand a reasonable

about of harsh weather. It is best to install the heater such

that it is not directly exposed to water spray, rain and/or

dripping water.

11. Maintain minimum clearance from normal combustible

material like paper, canvas, plastic tarpaulins or similar

coverings and secure them to prevent flapping or

movement due to wind action.

12. Due to the high surface and exhaust temperatures, adults

and children must observe clearances to avoid burns or

clothing ignition.

13. Operate only on a stable, level surface.

14. For use with only approved duct lengths and materials.

15. Use only the electrical power specified. The electrical

connection and grounding must comply with National

Electrical Code - ANSI/NFPA 70 (USA) and CSA C22.1

Canadian Electrical Code, Part 1 (Canada).

16. Use only a properly grounded 3-prong receptacle or

extension cord (6 ft (1.83m) in length minimum).

17. Do not move, handle or service while hot or burning.

18. Use only in accordance with local codes or, in the absence

of local codes, with the Standard for the Storage and

Handling of Liquefied Petroleum Gases ANSI/NFPA 58 and

CSA B149.1, Natural Gas and Propane Installation Code.

Operating Instructions and OwnerÊs Manual

5

Forced-Air Dual-Fuel NOMAD Construction Heater

FUEL GAS ODOR

LP gas and natural gas have man-made odorants

added specifically for detection of fuel gas leaks.

If a gas leak occurs you should be able to smell

the fuel gas. Since these fuels are heavier than air

you should smell for the gas odor low to the floor.

ANY GAS ODOR IS YOUR SIGNAL TO GO INTO

IMMEDIATE ACTION!

• Do not take any action that could ignite the fuel gas.

Do not operate any electrical switches. Do not pull

any power supply or extension cords. Do not light

matches or any other source of flame. Do not use your

telephone.

• Get everyone out of the building and away from the

area immediately.

• Close all propane (LP) gas tank or cylinder fuel supply

valves, or the main fuel supply valve located at the

meter if you use natural gas.

• Propane (LP) gas is heavier than air and may settle in

low areas. When you have reason to suspect a propane

leak, keep out of all low areas.

• Use your neighborÊs phone and call your fuel gas

supplier and your fire department. Do not re-enter the

building or area.

• Stay out of the building and away from the area until

declared safe by the firefighters and your fuel gas

supplier.

• FINALLY, let the fuel gas service person and the

firefighters check for escaped gas. Have them air out

the building and area before you return. Properly

trained service people must repair any leaks, check for

further leakages, and then relight the appliance for

you.

ODOR FADING - NO ODOR DETECTED

• Some people cannot smell well. Some people cannot

smell the odor of the man-made chemical added to

propane (LP) or natural gas. You must determine if you

can smell the odorant in these fuel gases.

• Learn to recognize the odor of propane (LP) gas

and natural gas. Local propane (LP) gas dealers will

be more than happy to give you a scratch and sniff

pamphlet. Use it to become familiar with the fuel gas

odor.

• Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor. Odors present in

animal confinement buildings can mask fuel gas odor.

• The odorant in propane (LP) gas and natural gas

is colorless and the intensity of its odor can fade

under some circumstances.

• If there is an underground leak, the movement of gas

through the soil can filter the odorant.

• Propane (LP) gas odor may differ in intensity at

different levels. Since Propane (LP) gas is heavier than

air, there may be more odor at lower levels.

• Always be sensitive to the slightest gas odor. If

you continue to detect any gas odor, no matter how

small, treat it as a serious leak. Immediately go into

action as discussed previously.

ATTENTION- CRITICAL POINTS TO REMEMBER

• Propane (LP) gas has a distinctive odor. Learn to

recognize these odors. (Reference Fuel Gas Odor and

Odor Fading sections above.

• Even If you are not properly trained in the service and

repair of the heater, ALWAYS be consciously aware of

the odors of propane (LP) gas and natural gas.

• If you have not been properly trained in repair and

service of propane (LP) gas then do not attempt to

light heater, perform service or repairs, or make any

adjustments to the heater on the propane (LP) gas fuel

system.

• A periodic sniff test around the heater or at the

heaterÊs joints; i.e. hose, connections, etc., is a good

safety practice under any conditions. If you smell even

a small amount of gas, CONTACT YOUR FUEL GAS

SUPPLIER IMMEDIATELY. DO NOT WAIT!

UNPACKING (Tools needed: Box cutter)

Remove heater and all components from cardboard

container. Thoroughly inspect all packing material for

pieces that are not garbage. Next check the unit for

possible shipping damage. If any is found immediately

notify the factory.

ODOR FADE WARNING

WARNING- ASPHYXIATION HAZARD

Do not use this heater for heating human living quarters.

• Do not use in unventilated areas.

• The flow of combustion and ventilation air must not be obstructed.

• Proper ventilation air must be provided to support the combustion air requirements of the heater being used.

• Refer to the specification section of the heaterÊs manual, heater data-plate, or contact the Factory to determine

combustion air ventilation requirements of the heater.

• Lack of proper ventilation air will lead to improper combustion.

• Improper combustion can lead to carbon monoxide poisoning leading to serious injury or death. Symptom of carbon

monoxide poisoning can include headaches dizziness and difficulty in breathing.

6

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

Assembly

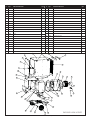

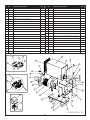

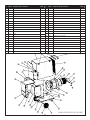

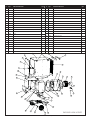

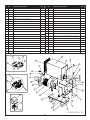

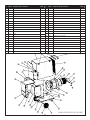

INSTALLING THE WHEELS & FOOT (Tools needed: Pliers)

Most units will be completely assembled. However if for

any reason you do need to assemble these components

follow the these instructions. Using the cardboard that

your heater was shipped in turn your heater on to one

of it sides or its top so that the bottom of the heater is

accessible. First, take the axel and insert it into one of the

wheels supplied. Then on the outside of the wheel place

the large washer over the axle. You can then insert one

of the cotter pins into the hole in the end of the axle and

bend over one or both of the tails of the pin so that it

cannot be removed. Then on the inside of that wheel run

one of the spacers over the other end of the axel so that

it is pressed against the back of the wheel. Then slide the

axle into the holes along the bottom edge of the heater.

Then install the other spacer followed by the other wheel

and washer. You can then insert and bend the other

cotter pin. Finally you can press the rubber hub caps over

the end of the axle. It is designed to press over the washer

to hold the cap in place once you are sure you have the

wheels and axle installed on your heater in the order

shown in figure 1.

INSTALLING THE HANDLE

Most units will be completely assembled. However if for

any reason you do need to assemble these components

follow the these instructions. First locate the metal "U"

shaped handle that was packed with your heater. (Does

not apply to model # HS115TC, If this is your model

move to hose and regulator setup). Next locate the two

handle bolts included in your hardware package. Then,

while looking at the outlet side of the heater open the

access panel opposite the control panel side by removing

the screws that hold it in place around its perimeter. Just

above the top edge of the door opening you should see

two holes close to the top edge of the heater. Align the threaded

holes in the handle up to the holes in the cover of the heater.

Then thread the two supplied bolts through the case into the

handle from inside of the case. Using a socket wrench tighten

down the bolts. Be sure not to over tighten.

Hose and Regulator setup

SETUP FOR PROPANE

First locate the hose and regulator assembly included with

your heater. Inspect the hose for cracks, breaks and any

signs of damage. If any damage is found, contact the factory

for a replacement. The regulator end is equipped with a

standard POL connection designed to fit most vertical vapor

draw propane tanks. Note: This is a reverse "left hand"

thread. Next attach the P.O.L. to an appropriately sized tank

for your application. This is a flared fitting and this type of

connection does not require any additional sealant or thread

tape. Check all connections with a mixture of soap and

water for leaks. Mix water and a small amount of dish soap

in a spray bottle and apply the solution on all connections, looking

for small bubbles to appear. If you see bubbles that is an indication

of a leak. Tighten your connection until the bubble are eliminated.

For proper tank sizing, refer to the sizing chart in the trouble

shooting section of this manual. (page 10)

SETUP FOR NATURAL GAS.

You must first determine if a regulator will be

required. When using NG a regulator will only be

required when the source of the gas has an output

pressure greater than 14" w.c. (3.48 Kpa).

First locate the hose and regulator assembly included with

your heater. Inspect the hose for any cracks breaks or signs

of damage. If any damage is found, contact the factory

for a replacement. The regulator end is equipped with

a standard POL connection designed to fit most vertical

vapor draw propane tanks. If you are using your unit with

Natural Gas and you have determined the regulator will

be needed, first the "P.O.L. fitting will have to be removed

and replaced with a connector/connectors that will allow

for connection to your Natural Gas supply. To remove the

P.O.L. fitting, secure the regulator body in a vice being

careful not to damage it. Then

using a socket wrench remove

he P.O.L. stem and nut from the

regulator. Then replace the POL

with the appropriate pieces to

make your connection. Be sure

to use an appropriate sealant

or thread tape when required.

Check all connections with a

mixture of soap and water for

leaks. Mix water and a small

amount of dish soap in a spray

bottle and apply the solution on

all connections, looking for small

bubbles to appear. If you see bubbles that is an indication

of a leak. Tighten your connection until the bubble are

eliminated.

1

2

3

5

2

3

4

4

# DESCRIPTION QTY

1 WHEELS 2

2 COTTER PINS 2

3 RETAINER WASHERS 2

4 WHEEL SPACERS 2

5 AXLE 1

FIGURE 1

POL

Remove for NG installation

Operating Instructions and OwnerÊs Manual

7

Forced-Air Dual-Fuel NOMAD Construction Heater

power switch). The male plug end of the heater will

go inside the female receptacle on the thermostat plug

end. Next plug in your properly grounded three pronged

extension cord into the other side of the thermostat

plug. You can now switch on your heater and return to

where you have your thermostat located and set the

temperature at which you would like your heater to cycle

on and off at. Once the temperature in the space to be

heated drops below the point at which your thermostat

is set, the green indicator light above the switch will

illuminate and the heat sequence will begin. The unit

will continue to run until the setting of the thermostat

is satisfied. If your heater shuts down for any reason

other than the operator turns it off or the thermostat

is satisfied, refer to the troubleshooting portion of this

manual on page 11.

RATE AND FUEL SELECTION

FUEL SELECTION

When setting up your Nomad heater you will need to

know which fuel you will be using and move the Rate/

Fuel selector switch to the correct settings before use. For

LP you will use the Red settings and rate. For NG you will

use the Blue settings and rates Refer to figure 5.

RATE SELECTION

Your Nomad heater is equipped with multi-rate and dual

fuel technology. During setup of your area to be heated

you have the option to use the heater on either the high

or low setting. In order to bring the heat in your space

up to your desired temperature as quickly as possible set

the heater on its high setting (refer to figure 5). Once

you have your space heated to the desired temperature,

you can then turn your setting to the low position to

maintain your desired temperature resulting in dramatic

cost savings from the lower fuel consumption during the

entire heating project.

OPERATION (NO THERMOSTAT)

Plug in your unit using an appropriately sized properly

grounded three pronged extension cord. Attach the small

length of power cord on the heater to your extension

cord. Once power is supplied to the heater you should

see the green indicator light above the switch light up.

Before you turn on your heater you will want to ensure

that you make your fuel and rate selection. Refer to the

"Rate and fuel selection" section for more information.

You can now flip your power switch to the ON position.

After a few seconds your heater will light and you should

feel hot air begin to emit from the outlet of the heater.

With this setup the heater will run continuously until

the operator flips the switch to the off position. If you

would like your heater to cycle on and off based on

the temperature of the space, you will need to use the

supplied remote thermostat.

OPERATION (WITH THERMOSTAT)

To operate your Nomad heater with a thermostat you will

need to place the thermostat in the environment to be

heated and turn the dial to the lowest temperature. Take

the "Piggy-Back" style plug end that was factory installed

on the thermostat and attach it to the small length of

power cord attached to the heater (located near the

FIGURE 5

INCLUDED THERMOSTAT

Cord to heater Extension cored to power

source

Cord to the

Thermostat

THERMOSTAT HOOKUP

PIGGY BACK PLUG

8

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

heated is needed or required. To use this setup you will

need the end diffuser and the 10' specially designed duct-

ing. To assemble attach one end of the 10' length of duct

to the duct adapter and the other to the end Diffuser.

Then place the end diffuser in the space to be heated.

USING NOMAD HEATER ACCESSORIES

The Nomad line of forced air heaters is designed to be

used as a stand alone gas fired heating appliance. It is

also designed and certified to be used with a collection

of useful accessories. For information on any additional

accessories that may be available for your model refer to

the list of accessories in this booklet or visit www.heat-

starbyenerco.com.

USING NOMAD HEATERS WITH DUCT & DIFFUSERS

When using this heater to heat a party tent or construc-

tion environment from out side of the space you will

need to employ the help of a few different diffuser at-

tachments.

Direct Diffuser & Duct Adapter

A direct diffuser allows the

user to duct the heat being

produced by the Nomad

heater into a space need-

ing heat without having the

heater in that space. To do

this you will need a duct

adapter. The duct adapter at-

taches to special connection

points on the heater that

match up to the connec-

tors on the adapter. Align

the tabs on the adapter to the holes on the heater and

turn clock wise to lock them in place. Next you will need

the flexible duct transition piece. The duct transition is a

short piece of special silicone lined ducting that attaches

the adapter to the End diffuser. With the duct adapter

attached to the heater, place the transition duct piece

over the outside of the adapter ring and tighten down the

strap. The other end of the Duct is then attached to the

diffuser see figure 6. The diffuser is an accessory designed

to help direct the air being discharged from the heater.

The air comes out of the diffuser and spreads out in

multiple directions to better fill the space and heat more

evenly. The channel on top of the diffuser is designed to

hold the tent material from falling in front of the diffuser.

The heater can be used without the diffuser but it is rec-

ommended for more effective and efficient use.

Long Duct & Diffuser

Nomad heaters are also designed to be used with 10'

of flexible duct for when distance from the area to be

DUCT ADAPTER

FIGURE 6

DIFFUSER

12" X 10' SILICONE LINED

FLEXIBLE HEATING DUCT

F109108

12" X 30" TRANSITION DUCT F109107 12" DUCT ADAPTER F109106

16" DUCT ADAPTER F10911616" X 30" TRANSITION DUCT F109117

16" X 10' SILICONE LINED

FLEXIBLE HEATING DUCT

F109118

12" UNIVERSAL DIFFUSER

F109105

16" UNIVERSAL DIFFUSER

F109115

FITS HS115TC

FITS HS115TC

FITS HS190TC & HS250TC

FITS HS115TC

FITS HS190TC & HS250TC

FITS HS190TC & HS250TC

Operating Instructions and OwnerÊs Manual

9

Forced-Air Dual-Fuel NOMAD Construction Heater

SHUTDOWN , STORAGE & MAINTENANCE

When your Nomad heater is no longer needed there are

a few steps you should take to ensure it is ready and in

working condition the next time you need it.

SHUTDOWN

While the heater is running, turn off the gas supply to

the heater and allow the fuel left in the system and in

the hose and regulator to burn off. This should only take

a few seconds. Then at the heater, flip the switch to the

middle or OFF position. You should allow your heater to

completely cool before placing your heater in storage or

before you per-

form any service

or maintenance.

Once the unit

has cooled verify

that the gas has

been shut off.

Then disconnect

the hose and

regulator from

the fuel source.

Next disconnect

the hose from

the inlet fitting

on the heater

and neatly wrap

up your hose

assembly. You

can then place

your hose into storage until it is needed again. On the

HS190TC and HS250TC Nomad units you can use the

optional top mounted storage box to store your heater

hose and regulator along with any other accessories or

tools needed for setup and tear down. Next unplug the

unit and wrap up the thermostat and return it to storage.

Your heater can now be stored.

STORAGE & MAINTENANCE

Before and after extended storage or if the heater was

used in dusty conditions you should thoroughly clean the

heater. With the heater unplugged, use soap, water and

a soft cloth to clean off any loose dust or dirt. While your

Nomad heater is certified to be used outdoor and can

withstand wet weather, water should not be used. This

can cause water to be forced into components where it

should not be. To clean off the inside, you will need a

standard flat head screwdriver to open the access panel.

To clean do not use water, use compressed air to blow

dust and debris from the insides. Once the unit is again

clean shut the door and secure the latch with the screw-

driver used to open it. You can now store your heater

until it is needed again. Be sure to make note of the stor-

age "do's and Don't" listed on this page. At least once a

year or the heater has been used in a dusty environment,

it is recommended that the blower wheel be thoroughly

cleaned. Start by removing the access panel cover on

the blower side of the heater. There are 8 screws on the

HS115 and 14 Screws on the larger HS190 and HS250

(4 and 7 on each side respectively) holding the panel in

place.

Once you have access to the blower motor mounting

plate remove the motor and wheel then use compressed

air to blow off the wheel. If a more aggressive clean-

ing method is required to get the wheel clean you can

remove the wheel from the motor by loosening the set

screw. Water solvents and cleaners can then be utilized to

complete the cleaning. Re install the blower in the reverse

it was removed.

DO NOT....

• Do not store the unit outside.

• Do not lose the components shipped with your

heater.

• Do not store your heater in an area prone to rodents.

They can damage internal wiring and the nesting

material is a fire hazard. Always open and inspect

your heater for signs of insect and rodents before

use especially after long bouts of storage.

SERVICE & REPAIR

A hazardous condition may result if a heater is used that

has been modified or is not functioning properly.

When the heater is working properly:

STORAGE UNIT AVAILABLE FOR THE HS190TC

& HS250TC

1

2

3

4

5

6

7

8

9

8 SCREWS

4 ON EACH SIDE

8

SCREWS

4

ON

E

AC

H

SI

DE

1

1

2

2

3

3

4

4

10

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

PROPANE TANK SIZE SELECTION

Below are a few quick points of reference for when you

need to select propane cylinders for your applications.

There are two major points to consider. What is the

temperature outside? & What are the BTU requirements

of the heater I will be using. While 20lb, 40lb and 100lb

tanks are the most common tank sizes, there are various

other options available. Contact you propane supplier for

details.

LBS OF LP IN THE CYLINDER

MAXIMUM CONTINUOUS BTU OUTPUT PER HOUR

@ VARIOUS TEMPERATURES

0°F (-18°C) 20°F(-7°C) 40°F (4°C)

200 (2 x 100's) 226,000 334,000 428,000

100 113,000 167,000 214,000

80 (2 x 40's) 94,000 137,000 180,000

40 55,000 79,000 105,000

20 36,000 51,000 69,000

PROPANE TANK SELECTION @ 20°F (-7°C)

HIGH SETTING LOW SETTING

HS115TC 110,833 BTU/HR 80,612 BTU/HR

2 X 40LB TANKS 1 X 40LB TANK

HS190TC 190,200 BTU/HR 127,100 BTU/HR

2 X 100LB TANKS 2 X 40LB TANKS

HS250TC 248,625 BTU/HR 181,119 BTU/HR

2 X 100LB TANKS 2 X 100LB TANKS

EXAMPLE TANK SELECTION

20LBS 40LBS 100LBS

18”

29”

48”

12.5”

12.5”

14.5”

• The flame is contained within the heater.

• The flame is essentially blue with perhaps some yel-

low tipping.

• There is no strong disagreeable odor, eye burning or

other physical discomfort.

• There is no smoke or soot internal or external to the

heater.

• There are no unplanned or unexplained shut downs

of the heater.

• The parts lists and wiring diagram show the heater

as it was constructed. Do not use a heater which is

different from that shown. In this regard, use only

the hose, regulator and cylinder connection fitting

(called a POL fitting) supplied with the heater.

For this heater, the regulator must be set as shown in

„SPECIFICATIONS‰. If there is any uncertainty about the

regulator setting, have it checked. A heater which is not

working right must be repaired, but only by a trained,

experienced service person. The heater is equipped with

a 1 year Limited Warranty, for full warranty information

please read page 20. Please include a brief statement

indicating date, place of purchase, the nature of the

problem and proof of purchase for warranty inquiries.

Out-of-warrranty products can be repaired with a charge

for parts and labor. Contact customer service for a list of

certified repair centers near you.

Operating Instructions and OwnerÊs Manual

11

Forced-Air Dual-Fuel NOMAD Construction Heater

Symptom Troubleshooting

Blower does not come on 1. Make sure the switch is either in the on or fan only posi-

tion

2. Verify the extension cord being used is not too long

3. Check power source is 110v

4. Verify the setting on the thermostat is higher than the

temperature in the space to be heated

Blower runs but the burner does not ignite 1. Make sure the switch is in the on position not in the fan

only position

2. Verify that the fuel connected to the unit is turned on and

flowing. It may take a few cycles to get all the air out of

the lines.

3. Make sure the rate and fuel switch are in the desired posi-

tion for the fuel you are using and the setting (high or

low) that you desire.

Unit producing little heat or no heat. 1. Make sure the switch is in the on position not the fan only

position

2. Make sure the rate and fuel switch are in the desired posi-

tion for the fuel you are using and the setting (high or

low) that you desire.

3. Verify that the fuel pressure being supplied to the heater is

adequate. Refer to the specification table in this manual for

required pressures.

4. Make sure the factory supplied hose and regulator are be-

ing used.

Heater will not shut down 1. Verify the switch is in the off position not on or fan only.

2. Check current setting on the thermostat. Is it set to a tem-

perature higher than the space being heated?

3. Heater will only cycle on and off when optional thermostat

is installed.

Unit will not turn on with thermostat installed 1. Verify that the thermostat is installed correctly. Heater will

only cycle on and off when the optional thermostat is

installed.

2. Verify the setting on the thermostat is higher than the

temperature in the space to be heated

3. Check that the power switch is in the "on" position. The

thermostat will only cycle on and off if the power switch is

in the on position

Unit will not turn off with thermostat installed. 1. Verify the setting of the thermostat is lower than the tem-

perature in the space being heated.

2. Verify that the thermostat is installed correctly, the unit

may just be on the on position.

3. Heater may be undersized or for the space being heated.

Red HLS fault light is on 1. Verify that the path of heat is not obstructed.

2. Check for blockage in the duct and at the end diffuser

3. Check the fuel and rate selections are accurate. If the

wrong fuel is selected the unit will over heat.

FOR FURTHER ASSISTANCE

If after you have reviewed the trouble shooting in this

manual and you still require assistance please use any of

the following methods to contact our technical service

department. We will do our absolute best to resolve any

issues or problems that arise. Most problems can be solved in

just a few minutes.

HOURS ARE: Monday- Friday 8:00am until 5:00pm

CALL: 866-447-2194

FAX: 800-321-0552

VISIT: HEATSTARBYENERCO.COM

INQUIRIES IN CANADA ONLY

PLEASE CALL: 877-477-3353

VISIT IPSPOWER.COM

12

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

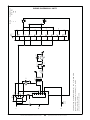

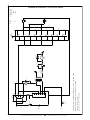

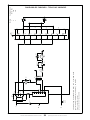

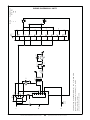

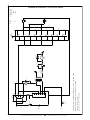

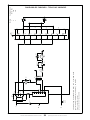

SW1

L

1

2

2A

1B

1A

2B

ign

n/c

n/c

6

5

4

3

2

1

G

VP

N

L

N

led 2

chassis

ground

G

T1

24vac

sail

switch

SW4

hls

led 4

led 5

Gas

Valve

GV1

M

M1

led 1

SW2

3

2

1

1

5

9

3

1

13

15

11

7

2

14

16

12

8

4

10

2

6

SV1

S

SV2

S

Position

1

2

3

Valve(s) Open

SV1 & SV2

SV2

SV1

Chassis wiring is stranded 18 AWG / 105 C / @ 600 Volts

Igniter wiring is16 AWG / 25KVDC / 10 KVAC

(replace with same ratings)

(all quick connects fully insulated)

SW3

WIRING DIAGRAM-ALL UNITS

Operating Instructions and OwnerÊs Manual

13

Forced-Air Dual-Fuel NOMAD Construction Heater

1

23

511

4

9

10

8

6

11

7

12

13

14

15

16

17

19

18

20

22

21

23

24

25

26

27

29

28

41

42

39

40

30

31

32

34

35

33

38

36

37

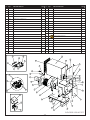

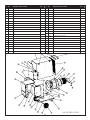

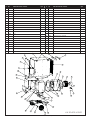

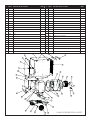

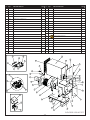

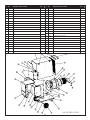

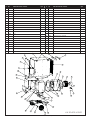

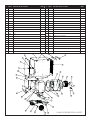

# P/N PART DESCRIPTION QTY

1 60801 HEATER FOOT 2

2 60800 HEATER BASE 1

3 60802 SOLENOID SUPPORT 1

4 60818 COMBUSTION CHAMBER -RIGHT 1

5 60820 COMBUSTION CHAMBER -BACK 1

6 60817 COMBUSTION CHAMBER -LEFT 1

7 60819 COMBUSTION CHAMBER -TOP 1

8 60822 COMBUSTION CHAMBER -UPPER FLANGE 1

9 60821 COMBUSTION CHAMBER -LOWER FLANGE 1

10 60823 LOWER BURNER COVER 1

11 60824 COMBUSTION CHAMBER -HEAT SHIELD 2

12 60813 INSIDE BLOWER PANEL 1

13 60815 BLOWER TUBE 1

14 60816 115 BLOWER WHEEL 1

15 60812 OUTSIDE BLOWER PANEL 1

16 60814 MOTOR MOUNTING PLATE 1

17 60843 115 MOTOR - 1/3HP 1

18 60830 SAIL SWITCH 1

19 60938 SAIL SWITCH BRACKET 1

20 60958 HIGH LIMIT SWITCH 1

21 60833 HEATER COVER 1

# P/N PART DESCRIPTION QTY

22 60835 MOTOR DOOR 1

23 60834 CONTROLS DOOR 1

24 60837 DOOR HINGE 1

25 60839 D-RING LATCH/LOCK 1

26 60847 24V RED LED LAMP - FAULT INDICATOR 1

27 60846 24V GREEN LED LAMP - GAS VALVE ON INDICATOR 1

28 60845 120V LED LAMP - GREEN 2

29 60841 MAIN POWER ROCKER SWITCH 1

30 60883 SELECTOR SWITCH BRACKET 1

31 60842 SELECTOR SWITCH 1

32 27808 FLAME CONTROL BOARD 1

33 60810 115 BURNER 1

34 60827 115 IGNITER BURNER PLATE-FRONT 1

35 60139 IGNITER/FLAME SENSE ASSY. 1

36 60831 115 BURNER CLAMP 1

37 60832 115 BURNER CLAMP BASE 1

38 60826 115 IGNITER BURNER PLATE-BACK 1

39 00600 GAS TRAIN ASSY. 1

40 60129 GAS VALVE 1

41 60848 SOLENOID VALVE 2

42 60809 ORIFICE HOLDER 1

EXPLODED VIEW HS115TC

14

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

NOTES:

Operating Instructions and OwnerÊs Manual

15

Forced-Air Dual-Fuel NOMAD Construction Heater

17

29

16

38

36

35

32

34

33

31

11

10

28

27

13

14

12

19

22

24

23

25

26

18

30

21 20

2

67

8

19

3

45

15

37

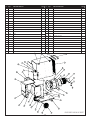

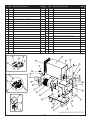

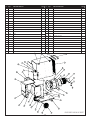

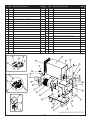

# P/N PART DESCRIPTION QTY

1 60973 190 COVER 1

2 60904 ELECTRICAL DOOR 1

3 60905 MOTOR DOOR 1

4 60906 FIXED PIECE HANDLE MOUNT 1

5 60908 HANDLE 1

6 60916 DOOR HANDLE 1

7 60913 DOOR HANDLE SPACER 1

8 60917 DOOR LATCH 1

9 60915 HOIST RINGS 4

10 60884 BASE 1

11 60901 BASE FOOT 1

12 60802 SOLENOID SUPPORT 1

13 40940 WHEEL 2

14 60902 AXEL 1

15 28787 WHEEL HARDWARE KIT 1

16 60851 SAIL SWITCH 1

17 60938 SAIL SWITCH BRACKET 1

18 60922 COMBUSTION CHAMBER-TOP 1

19 60891 COMBUSTION CHAMBER-LEFT 1

20 60890 COMBUSTION CHAMBER-RIGHT 1

21 60923 COMBUSTION CHAMBER-RIGHT HEAT SHIELD 1

# P/N PART DESCRIPTION QTY

22 90924 COMBUSTION CHAMBER-LEFT HEAT SHIELD 1

23 60892 COMBUSTION CHAMBER-TOP FLANGE 1

24 60893 COMBUSTION CHAMBER-BOTTOM FLANGE 1

25 60925 BURNER STAND-OFF 1

26 60885 COMBUSTION CHAMBER-LOWER HEAT SHIELD 1

27 60974 BLOWER SHELF 1

28 60975 BLOWER SHELF SUPPORT 1

29 60962 HIGH LIMIT SWITCH 1

30 60894 COMBUSTION CHAMBER SUPPORT 2

31 60977 HOUSING RIGHT SIDE 1

32 60978 BLOWER TUBE 1

33 60981 HOUSING DEFLECTOR ATTACHMENT 1

34 60980 HOUSING INLET ADAPTER 1

35 60976 HOUSING LEFT SIDE 1

36 60979 MOTOR MOUNT 1

37 60998 190 BLOWER WHEEL 1

38 60971 1/2HP MOTOR 190 1

EXPLODED VIEW HS190TC

16

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

NOTES:

Operating Instructions and OwnerÊs Manual

17

Forced-Air Dual-Fuel NOMAD Construction Heater

194

5

3

7

6

2

8

21

20

18

26

23

24

19

2227

28

12 14

13 11

10

31

34

32

35

16

17

29

37

36

33

30

15

38

EXPLODED VIEW HS250TC

# P/N PART DESCRIPTION QTY

1 60903 250 COVER 1

2 60904 ELECTRICAL DOOR 1

3 60905 MOTOR DOOR 1

4 60906 FIXED PIECE HANDLE MOUNT 1

5 60908 HANDLE 1

6 60916 DOOR HANDLE 1

7 60913 DOOR HANDLE SPACER 1

8 60917 DOOR LATCH 1

9 60915 HOIST RINGS 4

10 60900 BASE 1

11 60901 BASE FOOT 1

12 60802 SOLENOID SUPPORT 1

13 40940 WHEEL 2

14 60902 AXEL 1

15 28787 WHEEL HARDWARE KIT 1

16 60851 SAIL SWITCH 1

17 60938 SAIL SWITCH BRACKET 1

18 60922 COMBUSTION CHAMBER-TOP 1

19 60919 COMBUSTION CHAMBER-LEFT 1

20 60918 COMBUSTION CHAMBER-RIGHT 1

21 60923 COMBUSTION CHAMBER-RIGHT HEAT SHIELD 1

# P/N PART DESCRIPTION QTY

22 60924 COMBUSTION CHAMBER-LEFT HEAT SHIELD 1

23 60920 COMBUSTION CHAMBER-TOP FLANGE 1

24 60921 COMBUSTION CHAMBER-BOTTOM FLANGE 1

25 60925 BURNER STAND-OFF 1

26 60885 COMBUSTION CHAMBER-LOWER HEAT SHIELD 1

27 60930 BLOWER SHELF 1

28 60931 BLOWER SHELF SUPPORT 1

29 HIGH LIMIT SWITCH 1

30 60894 COMBUSTION CHAMBER SUPPORT 2

31 60933 HOUSING RIGHT SIDE 1

32 60934 BLOWER TUBE 1

33 60937 HOUSING DEFLECTOR ATTACHMENT 1

34 60936 HOUSING INLET ADAPTER 1

35 60932 HOUSING LEFT SIDE 1

36 60935 MOTOR MOUNT 1

37 60940 250 BLOWER WHEEL 1

38 60960 3/4 HP MOTOR 190 1

18

Forced-Air Dual-Fuel NOMAD Construction Heater Operating Instructions and OwnerÊs Manual

NOTES:

Operating Instructions and OwnerÊs Manual

19

Forced-Air Dual-Fuel NOMAD Construction Heater

# P/N PART DESCRIPTION QTY

1 60129 HONEYWELL GAS VALVE 1

2 60848 SOLENOID VALVE 2

3 70597 3/8" FPT X 3/8" MPT - STREET ELBOW 1

4 60804 3/8" PIPE CLOSE NIPPLE 1

5 60948 ORIFICE HOLDER 1

6 60949 GAS VALVE BRACKET 1

7 60805 3/8" X 3 PIPE NIPPLE 1

8 60955 1/2" FPT X 3/8" MPT - STREET ELBOW 1

9 60954 1/2" PIPE CLOSE NIPPLE 1

10 60956 1/2" X 10" PIPE NIPPLE 1

# P/N PART DESCRIPTION QTY

11 02724 1/2" X 4" PIPE NIPPLE 1

12 60957 1/2" X 1/2" ELBOW 1

13 02744 1/2" MALE FLARE 1

14-A 60881 250 BYPASS ORIFICE 1 1

15-A 60882 250 BYPASS ORIFICE 2 1

16-A 60880 250 MAIN ORIFICE 1

14-B 60878 190 BYPASS ORIFICE 1 1

15-B 60879 190 BYPASS ORIFICE 2 1

16-B 60887 190 BYPASS ORIFICE 2 1

16

57

3

14

2

415 2

8

9

6

1

10

12

11

13

WARNING:

USE ONLY MANUFACTURERÊS REPLACEMENT PARTS. USE OF ANY

OTHER PARTS COULD CAUSE INJURY OR DEATH. REPLACEMENT

PARTS ARE ONLY AVAILABLE DIRECT FROM THE FACTORY AND

MUST BE INSTALLED BY A QUALIFIED SERVICE AGENCY.

FOR SERVICE OR PARTS INQUIRIES

PLEASE CALL: 866-447-2194 OR 216-916-3000

VISIT: WWWHEATSTARBYENERCO.COM

INQUIRIES IN CANADA ONLY

PLEASE CALL: 877-477-3353

VISIT IPSPOWER.COM

COROPORATE ADDRESS

HEATSTAR BY ENERCO

4560 WEST 160TH STREET

CLEVELAND, OHIO 44135

OUR OFFICE HOURS ARE 8:00 AM -5:00 PM EST MONDAY-FRIDAY

WHEN CONTACTING US:

PLEASE HAVE YOUR SERIAL NUMBER AND MODEL NUMBER HANDY.

THESE CAN BOTH BE LOCATED ON THE RATING LABEL LOCATED ON

THE INSIDE OF THE ACCESS PANEL.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Gas Train for HS190TC & HS250TC

WARNING:

USE ONLY MANUFACTURERÊS REPLACEMENT PARTS. USE OF ANY OTHER PARTS

COULD CAUSE INJURY OR DEATH. REPLACEMENT PARTS ARE ONLY AVAILABLE DIRECT

FROM THE FACTORY AND MUST BE INSTALLED BY A QUALIFIED SERVICE AGENCY.

PARTS ORDERING INFORMATION:

PURCHASING: Accessories may be purchased at any HEAT STAR local dealer or direct

from the factory

FOR INFORMATION REGARDING SERVICE

Please call Toll-Free 866-447-2194 • HEATSTARBYENERCO.COM

Our office hours are 8:00 AM – 5:00 PM, EST, Monday through Friday.

Please include the model number, date of purchase, and description of problem in all

communication.

LIMITED WARRANTY

The company warrants this product to be free from imperfections in material or

workmanship, under normal and proper use in accordance with instructions of

The Company, for a period of one year from the date of delivery to the buyer. The

Company, at its option, will repair or replace products returned by the buyer to the

factory, transportation prepaid within said one year period and found by the Company

to have imperfections in material or workmanship.

If a part is damaged or missing, call our Technical Support Department at 866-447-2194.

Address any Warranty Claims to the Service Department, HEAT STAR Group, Inc.,

4560 W. 160th St., Cleveland, Ohio 44135. Include your name, address and telephone

number and include details concerning the claim. Also, supply us with the purchase

date and the name and address of the dealer from whom you purchased our product.

The foregoing is the full extent of the responsibility of the Company. There are no

other warranties, express or implied. Specifically there is no warranty of fitness for a

particular purpose and there is no warranty of merchantability. In no event shall the

Company be liable for delay caused by imperfections, for consequential damages, or

for any charges of the expense of any nature incurred without its written consent. The

cost of repair or replacement shall be the exclusive remedy for any breach of warranty.

There is no warranty against infringement of the like and no implied warranty arising

from course of dealing or usage of trade. This warranty will not apply to any product

which has been repaired or altered outside of the factory in any respect which in our

judgment affects its condition or operation.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you. This Warranty gives

you specific legal rights, and you may have other rights which vary from state to state.

HEAT STAR Group, Inc. reserves the right to make changes at any time, without notice or

obligation, in colors, specifications, accessories, materials and models.

HEAT STAR, INC., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

ANSI Z83.7b-2009/CSA 2.14b-2009

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions. Place instructions in a safe

place for future reference. Do not allow anyone who has not read these instructions to assemble,

light, adjust or operate the heater.

Model #

PRODUCT REGISTRATION: Thank you for your purchase.

Please log in to HEATSTARBYENERCO.COM to register your product.

HS115TC

HS190TC

HS250TC

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

HeatStar HS115TC Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

dans d''autres langues

- English: HeatStar HS115TC Owner's manual

- español: HeatStar HS115TC El manual del propietario

Documents connexes

Autres documents

-

Mr. Heater MH400FAVT Operating Instructions And Owner's Manual

-

Mr. Heater 2 x MH-F270700 Manuel utilisateur

-

DeWalt DXH125FAVHC Mode d'emploi

-

DeWalt DXH125FAVHC Guide d'installation

-

Mr. Heater MH85FAV Mode d'emploi

-

Power Fist 8677486 Le manuel du propriétaire

-

Mr. Heater TS125FAV Manuel utilisateur

-

Mr. Heater MH540T Mode d'emploi

-

Honeywell SV2 Series Valve Programming Tool HMITOOL-000 Mode d'emploi

-

WilTec 60317 Manuel utilisateur