Page 3

Mini-Therm JV

problems. As soon as any fouling is observed, the

cause of the fouling should be corrected.

The heat exchanger can be checked using a

ashlight by locating a mirror under the burners.

An alternate method is to remove the venting and

top panel as necessary to inspect from above.

Also, check the vent system for defects at this

time.

If cleaning is required:

a. Shut off all power to the boiler.

b. Expose the heat exchanger by removing the

draft hood (when equipped), and venting, top

assembly, ue collector, and heat exchanger

bafes.

c. Remove the burners by lifting them off the

orices and pulling them out of the boiler.

For JVH models, pull out the burner tray after

removing the attaching screws.

d. Use a hand-operated spray bottle lled with

water and a wire brush to clean any soot and

loose scale from the underside of the heat

exchanger. Do not use compressed air, high

pressure water or a garden hose.

e. Clean any fallen debris from the bottom of the

unit.

f. Check to make sure that the burner ports

and pilot assembly are free of debris before

returning the burners to their original

positions.

g. Reassemble the boiler in reverse order, making

sure to replace the heat exchanger bafes.

9. The gas and electric controls installed on the

boiler are engineered for both dependable

operation and long life, but the safety of this

equipment completely depends on their proper

functioning. For this reason, it is strongly

recommended that the basic items be checked by

a competent service technician every year and

replaced when necessary.

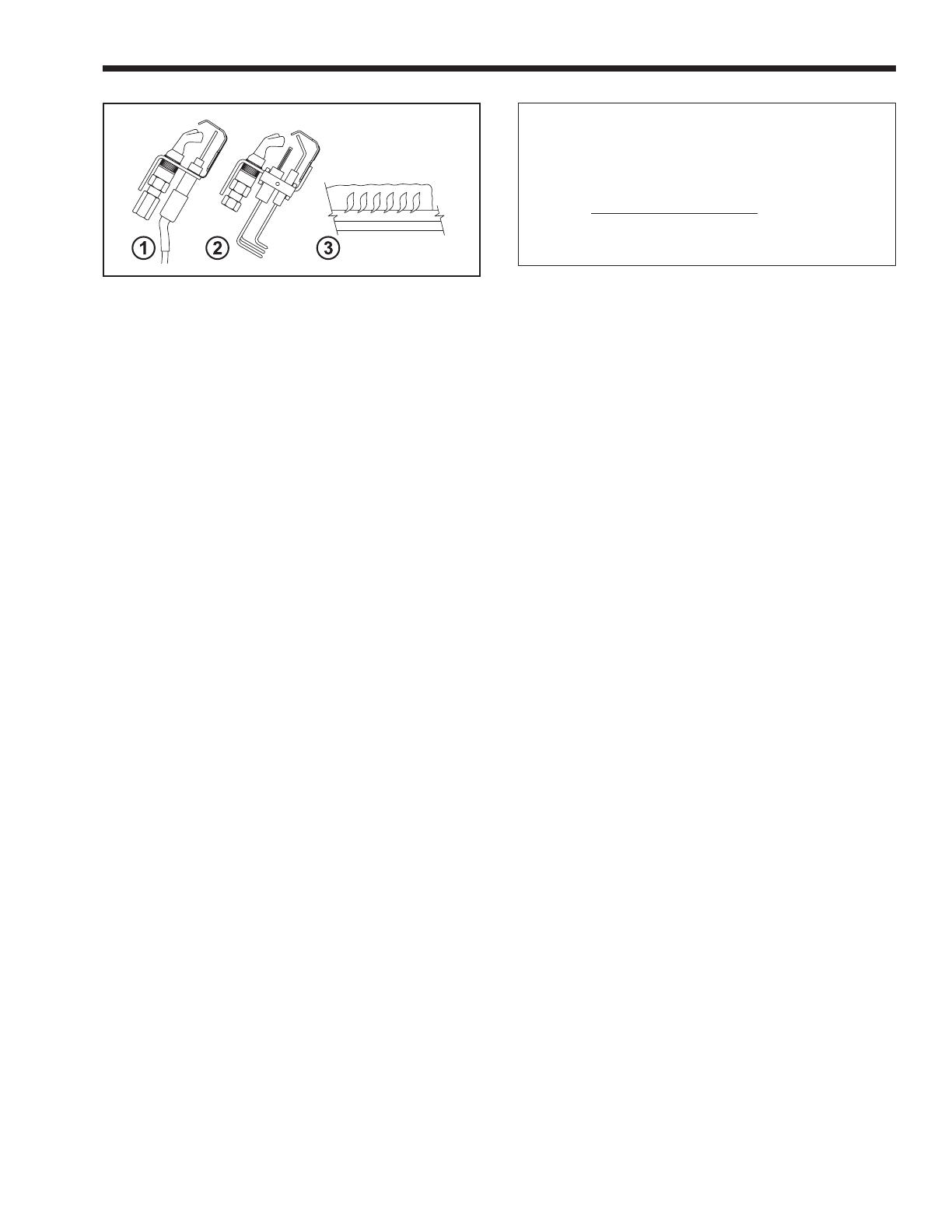

Figure 4 - Pilot Arrangements

1) JVS pilot

2) JVH pilot

3) Main burner ame pattern

The basic controls are:

a. Water temperature controls

b. Pilot safety system

c. Automatic electric gas valve(s)

d. Inducer/blower assembly (JVH )

e. Fan proving pressure switch (JVH )

f. Flue or vent damper

10. The blocked vent safety switch (JVS model only)

is used to shut the boiler down in the case of

insufcient draft due to venting system problems.

Before resetting the blocked vent safety switch

see the Appendix in Section 8D of the Installation

and Operating Instructions (Document number

1254) to ensure that all possible causes have

been investigated and corrected. If the problem

continues and the boiler cannot be restored to

normal operation call a qualied service agency.

11. The ame rollout safety switch provides

additional safety, and will shut down the

boiler should the ame from the main burners

rollout (ashback) towards the main gas valve.

Before resetting the ame rollout switch, see

Section 8D of the Installation and Operating

Instructions, (Document H2355800- for the JVS

model) to ensure that all possible causes have

been investigated and corrected. If the problem

continues and the boiler cannot be restored to

normal operation call a qualied service agency.

Never attempt to bypass the ame roll-out safety

switch for the purpose of operating the boiler.

Do not use this boiler if any part has been under

water. Immediately call a qualied service

technician to inspect the boiler and to replace any

part of the control system and any gas control

which has been under water.

12. Check all heat exchanger water connections,

ange or header gaskets for water tight integrity

24 hours after commissioning. If there are any

signs of water leakage, re-torque fasteners or re-

seat threaded connections as necessary

NOTE: The warranty does not cover any damage

caused by lack of required maintenance or improper

operating practices.

NOTE: After installation and rst start-up, check

the heat exchanger for fouling after the following

periods of operation:

24 hours 30 days

7 days 90 days+

Then once every six months thereafter.