Storage water heater

Acumulador de agua caliente

Préparateur ECS

SU54/5, SU80/5, SU100/5

6 720 805 397-00.1ITL

[en] Installation and maintenance instructions 2

[es] Instrucciones de instalación y de mantenimiento 20

[fr] Notice d'installation et d'entretien 35

6 720 808 532 (2013/08) (US/CA/MX)

WARNING:

These installation instructions are intended solely for

use by a licensed heating contractor or service techni-

cian. Read all instructions before installing. Perform

steps exactly in the order given. Failure to follow these

instructions can result in severe injury, death or proper-

ty damage.

PELIGRO:

Este manual de instalación únicamente lo pueden utili-

zar instaladores de calefacción o técnicos especializa-

dos. Antes de la instalación, lea todas las indicaciones.

Realice todas las acciones exactamente en el orden indi-

cado. En caso de incumplimiento, existe riesgo de lesio-

nes graves e incluso de muerte o daños materiales

considerables.

AVERTISSEMENT :

Cette notice d’installation doit être utilisée uniquement

par des installateurs chauffagistes ou des techniciens de

maintenance qualifiés. Lisez attentivement toutes les

consignes avant l’installation. Exécutez les actions préci-

sément dans l’ordre indiqué. En cas de non-respect,

vous risquez de subir de sérieuses blessures pouvant

conduire à la mort ou d’entraîner de lourds dommages

matériels.

Table of Contents

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)2

Table of Contents

1 Safety Considerations and Symbol Descriptions . . . . . . . . . . 2

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Instructions for the owner and operator . . . . . . . . . . . . . 4

2 Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Pressure drop curve of heating coil . . . . . . . . . . . . . . . . . 5

2.6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7 Physical and connection dimensions . . . . . . . . . . . . . . . 7

3 Standards, regulations and directives . . . . . . . . . . . . . . . . . . . 8

4 Moving the tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Boiler installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1.1 Requirements for installation location . . . . . . . . . . . . . . 8

5.1.2 Wall clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.3 Positioning the tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2.1 Connecting the tank on the water side . . . . . . . . . . . . . 10

5.2.2 Installing a T&P safety valve (on-site) . . . . . . . . . . . . . . 11

5.3 Install a tank water temperature sensor (accessory)

or aquastat (accessory). . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.1 Commissioning the DHW tank . . . . . . . . . . . . . . . . . . . . 13

7 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.1 Shutting down the DHW tank . . . . . . . . . . . . . . . . . . . . . 13

7.2 Shutting down the heating system

when there is a risk of frost . . . . . . . . . . . . . . . . . . . . . . 13

8 Environmental Protection / Disposal . . . . . . . . . . . . . . . . . . . 13

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.1 Preparing the DHW tank for cleaning . . . . . . . . . . . . . . 13

9.2 Descaling/cleaning the DHW tank . . . . . . . . . . . . . . . . . 14

9.3 Checking the magnesium anode . . . . . . . . . . . . . . . . . . 15

9.3.1 Checking the upper magnesium anode

(SU80/5, SU100/5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.3.2 Checking the upper magnesium anode (SU54/5) . . . . 15

9.3.3 Checking the magnesium anode at the side

(SU80/5, SU100/5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.4 Re-commissioning after performing maintenance . . . . 16

10 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1 Safety Considerations and Symbol

Descriptions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this document:

• DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

• WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

• CAUTION indicates a hazardous situation which, if not avoided, could

result in minor to moderate injury.

• NOTICE is used to address practices not related to personal injury.

Important information

Additional symbols

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

This symbol indicates important information where

there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

1

Safety Considerations and Symbol Descriptions

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 3

1.2 Safety considerations

Read all instructions before installing. Perform the steps in the indicated

sequence. Have the DHW tank inspected by a trained service technician

at least once every year. Failure to comply with these instructions can

result in severe, possibly fatal, personal injury as well as damage to

property and equipment.

Installation and maintenance

▶ Risk of fire from soldering and brazing!

Take appropriate protective measures when soldering and brazing as

the insulation is flammable, for example, cover the insulation.

▶ Ensure that only a licensed contractor installs or services the DHW

tank.

▶ Use installation material with adequate temperature stability.

Forbidden:

Connection of the potentiostat for an impressed current anode to the

magnesium anode installed in a storage tank is absolutely forbidden!

This would destroy the tank! The warranty would be voided.

Installation and commissioning

▶ In the Commonwealth of Massachusetts, the DHW tank must be

installed by a licensed plumber.

▶ The electrical power must be connected by a licensed electrician.

The wiring diagram must be followed.

▶ Do not install this device in rooms with a high moisture level

(e.g. bathrooms, saunas).

Function

▶ To ensure that the tank functions properly, heed these installation and

maintenance instructions.

▶ Never close the blow-off line of the T&P safety valve. For safety

reasons, water may escape during heating.

Danger from electric shock

▶ Ensure that only an authorized contractor performs electrical work.

▶ Before performing electrical work, disconnect the power and secure

the unit against unintentional reconnection.

▶ Ensure the system has been disconnected from the power supply.

Risk of scalding at the hot water draw-off point

▶ When the DHW tank is in operation, temperatures in excess of 122 °F

(50 °C) can occur. To limit the temperature at the tap, install a

thermostatic DHW mixing valve.

▶ Water heated for washing the laundry, dishes and for other cleaning

purposes can cause scalding and permanent injuries.

▶ Children, elderly, and handicapped persons are more likely to be

permanently injured by hot water. Never leave such individuals in the

tub or shower unattended under any circumstances. Children must

not be allowed to operate hot water faucets themselves or to fill a

bathtub.

▶ If the building has occupants in the above groups who operate hot

water faucets, or state laws / local ordinances stipulate specific water

temperatures, take the following precautions:

– Use the lowest possible temperature setting.

– To prevent scalding, install a tempering device, such as an

automatic mixing valve, at hot water tap or water heater. Select and

install the automatic mixing valve in accordance with the valve

manufacturer's recommendations and instructions.

▶ Water exiting from drain valves can be extremely hot. To avoid

injuries:

– Check that all connections are tight.

– Direct exiting water away from people.

▶ Measures must be taken to protect against excessive temperature and

pressure! Installation of a T&P safety valve is required.

The chart below shows the relationship between water temperature and

time until there is a risk of scalding. It can be used as the basis for

determining the safest water temperature for your application.

To protect against corrosion and ensure compliance with the rules for

electrical safety, observe the following points:

▶ Use metal fittings for drinking water heating systems with plastic

piping.

▶ Use only original accessories from the manufacturer.

▶ When installation of the tank is complete, inspect the ground

conductor (including metal fittings).

Maintenance

Customers are advised to:

▶ Sign a maintenance and inspection contract with an authorized

contractor. Inspect and maintain the DHW tank as necessary on a

yearly basis. Service as needed.

▶ Use only original spare parts.

Flooding

▶ After a flood, do not use the appliance if any part has been

submerged. Damage to appliances that have been submerged can be

quite severe and pose numerous safety risks.

▶ An appliance that was subject to flooding must be replaced.

Temperature Time to severe scalding

120 °F (48 °C) longer than 5 minutes

125 °F (51 °C) 1.5 to 2 minutes

130 °F (54 °C) approx. 30 seconds

135 °F (57 °C) approx. 10 seconds

140 °F (60 °C) less than 5 seconds

145 °F (62 °C) less than 3 seconds

150 °F (65 °C) approx. 1.5 seconds

155 °F (68 °C) approx. 1 second

Table 2 Approximate time-temperature relationship until there is a risk

of scalding

1)

1) Source: Moritz, A.R. and Henriques, F.C., Jr. (1947). Studies of thermal injury. II.

The relative importance of time and surface temperature in the causation of

cutaneous burns, Am J of Pathol, 23, 695-720.

2

Product information

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)4

1.3 Instructions for the owner and operator

▶ Explain the operation and handling of the heating system and DHW

tank, making a particular point of safety-relevant features.

▶ Explain the function and how to check the T&P safety valve.

▶ Hand all enclosed documents over to the owner/operator.

▶ Recommendation for the user: Sign a maintenance and inspection

contract with a licensed contractor.

▶ Highlight the following for the user:

– Water may be discharged from the T&P safety valve during heat-up.

– The blow-off line on the T&P safety valve must always be kept open.

– Check that the T&P safety valve operates properly at least once

yearly.

– The tank must be inspected annually and maintained as required.

2 Product information

2.1 Scope of delivery

•Tanks

• Installation and Service Instructions

•B-KIT

Fig. 1 B-kit

[1] Tee 1" x 1" x ¾ " (2x)

[2] Temperature and pressure relief valve

[3] Blanking cap ¾ "

[4] Drain valve

[5] Bracket for aquastat, screws for aquastat bracket (4x)

[6] Compensating spring for aquastat or tank temperature sensor

[7] Quarter-circle spacer for aquastat or tank temperature sensor

(2x)

2.2 Intended use

The tank is designed for heating and storing drinking water. Please

observe national, regional, and local codes, regulations, guidelines and

standards for potable water.

Install this tank only in sealed unvented hydronic heating systems.

Any other purpose is considered improper use. Any resulting damage is

excluded from the manufacturer's warranty.

WARNING: Risk of scalding at the taps!

There is a risk of scalding at the taps if the tank

temperature is set above 122 °F (50 °C) and during

thermal disinfection.

▶ Advise users that they should draw off only mixed

water. Otherwise, install a thermostatic DHW mixing

valve.

NOTICE: Risk of tank damage from excessively high

pressure.

▶ Never plug the discharge line of the T&P safety valve.

Requirements for drinking water Unit

Water hardness, min. ppm

grain/US gallon

°dH

36

2.1

2

pH value, min. – max. 6.5 – 9.5

Conductivity, min. – max. μS/cm 130 – 1500

Table 3 Requirements for drinking water

6 720 805 397-01.1ITL

1

2

4

3

5

7

6

2

Product information

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 5

2.3 Product information

Fig. 2 Product information

2.4 Data plate

The data plate is located at the top rear of the DHW tank.

2.5 Pressure drop curve of heating coil

Fig. 3 Pressure drop curve

[1] SU100/5

[2] SU80/5

[3] SU54/5

Example:

[A] 10 gpm, 2 ft of head

12

14

13

11

7

1

5

3

6

2

4

1

5

3

6

2

4

7

8

14

9

10 10

11

12

SU 54/5 SU80/5, SU100/5

6 720 805 397-02.1ITL

Item Description

1 DHW outlet

2 Recirculation connection

3 Boiler flow

4 Sensor well for temperature sensor

5 Boiler return

6 Cold water inlet

7 Heat exchanger for heating by boiler, smooth enameled tubing

8 Inspection port for service and cleaning at the front

9 2nd anode in inspection port, with insulation

10 SU54/5: 2x built-in magnesium anodes with electrical

insulation

SU80, SU100/5:built-in magnesium anode without electrical

insulation

11 Tank, enameled steel

12 Jacket, painted sheet metal with rigid polyurethane foam

insulation, 2" (50 mm)

13 Inspection port for service and cleaning

14 PS top cover

Table 4 Product information

2

2

0

4

6

8

46810121416

6 720 805 397-08.1ITL

1

2

3

Pressure drop [ft of head]

ow rate [gpm]

A

2

Product information

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)6

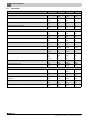

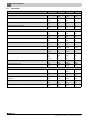

2.6 Technical Data

Unit SU54/5 SU80/5 SU100/5

Tank capacity

Tank capacity (total) gal

(l)

52.8

(200)

79.3

(300)

103

(390)

Maximum flow rate gpm

(l/min)

5.3

(20)

7.9

(30)

10.3

(39)

Maximum DHW temperature °F

(°C)

203

(95)

203

(95)

203

(95)

Maximum operating pressure DHW psi

(bar)

145

(10)

145

(10)

145

(10)

Tank performance at:

Domestic cold water inlet temperature °F

(°C)

50

(10)

50

(10)

50

(10)

Domestic hot water outlet temperature °F

(°C)

140

(60)

140

(60)

140

(60)

DHW temperature rise °F

(°C)

90

(50)

90

(50)

90

(50)

Coil supply water temperature (boiler water) °F

(°C)

176

(80)

176

(80)

176

(80)

Coil flow rate (boiler water) gpm

(l/h)

11.45

(2600)

11.45

(2600)

15.41

(3500)

Coil pressure drop (boiler water) foh

(mbar)

2.68

(80)

3.35

(100)

6.93

(207)

Continuous rating gph

(l/h)

gpm

(l/min)

114

(430)

1.9

(7)

134

(507)

2.2

(8)

209

(791)

3.5

(13)

First hour rating gph

(l/h)

151

(570)

190

(717)

281

(1064)

Maximum heat input to tank btu/hr

(kW)

85304

(25)

100658

(29.5)

156959

(64)

Heat exchanger

Content gal

(l)

1.59

(6)

2.32

(8.8)

3.2

(12.1)

Surface area ft

2

(m

2

)

9.69

(0.9)

13.99

(1.3)

19.38

(1.8)

Standby heat loss (at 149 °F (65 °C) DHW temperature, 68 °F (20 °C) room

temperature)

°F/h

(K/h)

0.55

(0.31)

0.41

(0.23)

0.34

(0.19)

Maximum coil supply water temperature °F

(°C)

230

(110)

230

(110)

230

(110)

Maximum coil operating pressure psi

(bar)

232

(16)

232

(16)

232

(16)

Table 5 Technical Data

2

Product information

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 7

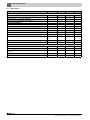

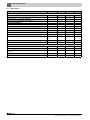

2.7 Physical and connection dimensions

Fig. 4 Physical and connection dimensions

6 720 805 397-03.4TT

F

G

H

I

K

J

E

A

L

M

D

E

F

H

I

J

G

A

C

C

B

D

SU 54/5 SU80/5, SU100/5

1"

1"

1"

1"

¾"

¾"

1"

1"

1"

1"

¾"

¾"

Item Description Unit SU54/5 SU80/5 SU100/5

A Diameter inch

(mm)

21-3/4

(550)

26-3/8

(670)

26-3/8

(670)

B Minimum floor weight carrying capacity Ib

(kg)

628

(284)

893

(405)

1122

(509)

C Clearance off floor inch

(mm)

1/2

(12.5)

3/8 - 3/4

(12.5)

3/8 - 3/4

(12.5)

D Overall height inch

(mm)

60-1/4

(1530)

58-7/8

(1495)

72-1/4

(1835)

E Height, cold water inlet inch

(mm)

3-1/4

(80)

3-1/8

(80)

3-1/8

(80)

F Height, tank return inch

(mm)

10-1/2

(265)

12-1/2

(318)

12-1/2

(318)

G Height, sensor well for temperature sensor inch

(mm)

17-1/8

(433)

31-1/5

(617)

24-3/10

(793)

H Boiler flow height inch

(mm)

21-7/8

(553)

28-1/2

(722)

35-3/8

(898)

I Height, recirculation connection inch

(mm)

27-3/4

(703)

35-1/2

(903)

45

(1148)

J Height, DHW outlet inch

(mm)

56.4

(1399)

53-3/8

(1355)

66-3/4

(1695)

K Minimum room height for anode replacement inch

(mm)

74-1/4

(1880)

72-7/8

(1850)

82-3/4

(2100)

L Weight (empty) lb

(kg)

160.9

(73)

231.5

(105)

282.2

(128)

M Weight (full) lb

(kg)

601.9

(273)

892.9

(405)

1142

(518)

Table 6 Physical and connection dimensions

3

Standards, regulations and directives

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)8

3 Standards, regulations and directives

4 Moving the tank

▶ Position the dolly at the back of the packed DHW tank.

▶ Secure the DHW tank to the means of transportation with a strap.

▶ Transport the DHW tank to the installation location.

▶ Only remove the DHW tank from the packaging at the installation

location.

Fig. 5 Transporting with a dolly

5 Installation

The tank is delivered fully assembled.

▶ Check that the tank is complete and undamaged.

5.1 Boiler installation

5.1.1 Requirements for installation location

▶ Place the DHW tank on a raised platform if there is a risk that water

may collect at the installation site.

▶ The installation site must be a dry and frost-free room.

▶ Observe the minimum height ( Tab. 6, page 7) and minimum wall

clearances inside the installation room ( Fig. 6).

▶ Maintain a distance of 2" (51 mm) from heated pipes and combustible

surfaces.

Observe all national, state, and local code, regulations

and standards applicable to installation and operation of

the tank!

All electrical components must be approved for the USA

and Canada.

WARNING: Risk of injury from carrying heavy loads and

inadequately securing loads for transport!

▶ Use suitable means of transportation, e.g. a dolly with

strap.

▶ Secure the load against falling.

Where possible, do not remove the DHW tank from its

packaging until it has reached the installation location.

This ensures protection during handling.

6 720 800 035-03.1ITL

NOTICE: Risk of damage from inadequate load-bearing

capacity of the supporting substructure or unsuitable

floor surface!

▶ Ensure that the installation area is level and offers

sufficient load-bearing capacity.

NOTICE: Risk of damage from stress cracking and

corrosion!

▶ Position the DHW tank in a dry room free from the risk

of freezing.

▶ Install the tank only in closed-loop, unvented hydronic

heating systems.

▶ Open expansion vessels may NOT be used with this

tank.

NOTICE: If leaks can result in property damage or a drain

pan is required by law:

▶ Install an adequate drain pan.

▶ Follow the installation instructions of the drain pan

manufacturer.

Install an adequate drain pan if required by code, or if a

leak could result in property damage. Follow drain pan

manufacturer's instructions.

5

Installation

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 9

5.1.2 Wall clearances

Fig. 6 Recommended minimum wall clearances

5.1.3 Positioning the tank

▶ Unpack the tank by removing the wrap, wooden boards and foam pad

on the top.

▶ Lay the foam pad on the floor to serve as a mat.

Fig. 7 Unpacking the DHW tank

▶ Carefully place the DHW tank on the cover pad [1].

▶ Cut out the raised sections in the EPS bottom pad [2].

▶ Unscrew the screw-in feet [3].

Fig. 8 Laying the DH tank on its side and exposing the adjustable feet

▶ Position the DHW tank on a level floor with adequate load-bearing

capacity.

Fig. 9 Positioning the tank

▶ Maintain minimum wall clearances.

▶ Using the adjustable feet, align the DHW tank vertically.

6 720 801 769-03.1ITL

6 720 800 035-04.1ITL

6 720 801 769-15.1ITL

1.

2.

3.

6 720 801 769-13.1ITL

5

Installation

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)10

▶ Remove the protective caps from the connections.

Fig. 10 Removing the protective caps

▶ Use Teflon tape or Teflon cord to seal the connections. Do not use

hemp to seal the connections.

5.2 Water connections

5.2.1 Connecting the tank on the water side

System example with all recommended valves and shut-offs

( Fig. 11).

▶ When sizing the heating system expansion vessel, take the volume

of the heating coil in the tank into consideration.

▶ Route the connection cables for the tank temperature sensors at the

back of the tank through the insulation to the heating appliance or

controller.

▶ Install piping runs so that natural circulation is prevented.

If necessary, install check valves.

▶ Install connection cables free of stress.

▶ Attach piping to the tank connections on-site.

▶ Check all connections for leaks.

Fig. 11 Installation (illustrative)

[1] Storage tank

[2] Shut-off valve

[3] P&T safety valve (combined with hot water outlet)

[4] Check valve

[5] Tank primary pump

[6] Recirculation pump (optional)

[7] Air eliminator (in main supply)

[8] Drain valve

[9] Expansion vessel

[AW] DHW outlet

[EK] Cold water inlet

[EL] Tank drain

[EZ] Recirculation inlet

[RS] DHW cylinder return

[VS] DHW cylinder flow

CAUTION: Water damage

▶ Connect the drain to the bottom tank connection prior

to filling the tank.

▶ Seal off all unused tank connections.

DANGER: Risk of fire from soldering and brazing!

▶ Take appropriate safety measures when soldering

and brazing as the thermal insulation is flammable.

For example, cover up the thermal insulation.

▶ Check tank jacket for damage after completing work.

DANGER: Risk of injury from contaminated water!

Work carried out without due care for cleanliness

contaminates the drinking water.

▶ Install in accordance with national standards and

guidelines.

6 720 800 155-22.1ITL

A

B

NOTICE: Risk of corrosion from damage to the enamel

finish!

▶ Attach connections to the DHW tank only "hand-

tight".

6 720 800 138-05.1ITL

AW

5

5

Installation

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 11

5.2.2 Installing a T&P safety valve (on-site)

▶ Install a listed T&P safety valve that is approved for potable water

( ¾ ") in the DHW outlet.

▶ This DHW tank must be installed with a new T&P safety valve.

▶ The T&P valve must be sized no smaller than the rated tank capacity.

▶ Observe the safety valve installation instructions.

▶ T&P discharge pipe:

– The discharge pipe must be at least equal to the outlet cross-

section of the safety valve.

– Route the discharge line from the T&P valve directly to an adequate

drain (maximum length 6 ft (2m) with no more than two 90°-

elbows).

– The discharge line must terminate at an adequate drain in order to

prevent property damage from spillage.

– Check that the T&P safety valve operates properly at least once

annually.

▶ Never plug the blow-off line. During heating, water may be discharged

for operational reasons at any time.

5.3 Install a tank water temperature sensor (accessory)

or aquastat (accessory).

Install a tank temperature sensor or an aquastat on the DHW tank to

measure and monitor the hot water temperature.

Installing the DHW temperature sensor

▶ Take the tank temperature sensor from the scope of delivery of the

control panel (accessories).

▶ Insert the sensor set until it bottoms out inside the sensor well [5].

This automatically pushes back the plastic spiral [3] that holds the

sensor set together.

The compensating spring [4] ensures contact between the sensor well

and sensor surfaces, and a reliable temperature reading.

Fig. 12 Installing the DHW temperature sensor

[1] Quarter-circle spacer

[2] Temperature sensor

[3] Plastic spiral

[4] Compensating spring

[5] Sensor Well

▶ Push sensor retaining clip [1] from the side onto sensor well [2].

▶ Route the sensor lead to the boiler or control panel and ensure the

cable is not strained. This cable must not be in contact with any hot

boiler parts.

▶ In the case a sensor is being used without a compensating spring, the

empty space in the sensor well must be filled with a sufficient amount

of heat-conducting paste.

Fig. 13 Installing the sensor retainer

[1] Sensor retainer

[2] Sensor Well

DANGER: Risk of fatal injury from electric shock.

▶ Isolate the system electrically prior to commencing

work on the system.

Connect the electrical power and set the temperature on

the DHW temperature sensor or the aquastat as shown in

the respective aquastat or control manufacturer's

instructions.

Always ensure that the full length of the sensor surface is

in contact with the sensor well.

6 720 800 155-17.1ITL

5

4

123

5

Installation

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)12

Installing aquastat

▶ Remove cover from the aquastat. To do so, undo the screw on the top.

▶ If necessary, remove any unnecessary attachments. Attach bracket

[3] to aquastat [2] by means of two self-tapping screws [1].

Fig. 14 Attaching the aquastat to the bracket

[1] Self-tapping screws

[2] Aquastat

[3] Bracket

▶ Feed the temperature sensor [4] with the compensating spring [3]

into the sensor well [5].

▶ Attach bracket [6] to DHW tank by means of 4 self-tapping sheet

metal screws [1].

▶ Replace the cover of the aquastat [2].

Fig. 15 Installing aquastat

[1] Self-tapping screws

[2] Aquastat

[3] Compensating spring

[4] Temperature sensor

[5] Sensor Well

[6] Bracket

Installing B-kit components

Fig. 16 Installing B-kit components

[1] Tee 1" x 1" x ¾ " (2x) with P&T safety valve

[2] Cap ¾ " for recirculation connection

[3] Bracket with aquastat

[4] Tee with fill and drain valve

6 720 800 155-03.1ITL

6 720 800 155-04.1ITL

5

4

3

2 1

6

6 720 801 769-04.1ITL

1

2

3

4

6

Commissioning

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 13

6 Commissioning

6.1 Commissioning the DHW tank

Have the installer of the heating system or a qualified contractor

commission the equipment.

▶ Commission the boiler and additional accessories in accordance with

manufacturer's instructions or the appropriate installation and

operating instructions.

▶ To bleed air from the DHW tank, open the highest tap/valve.

▶ To fill the tank, open the shut-off valve for the cold water inlet.

▶ Flush the tank and piping thoroughly prior to commissioning.

▶ Before heating up, verify that the boiler, tank and pipework are filled

with water. Open the air bleeder valve for this purpose.

▶ Check all connections, piping and the inspection port for leaks.

7 Shutdown

7.1 Shutting down the DHW tank

▶ Switch off the temperature controller at the control panel, shut of the

heating system emergency shutoff switch, or disengage the heating

system circuit breaker.

▶ Close the cold water inlet shutoff valve.

▶ Drain the DHW tank via the drain valve by opening the highest faucet.

▶ Close the shut-off valves to and from the boiler.

▶ Depressurize the heat exchanger.

▶ Drain and blow out the heat exchanger.

▶ To prevent corrosion, dry out the inner space and keep the inspection

port covers open.

7.2 Shutting down the heating system when there is a risk

of frost

▶ Shut down the heating system and the DHW tank as shown in

chapter 7.1.

8 Environmental Protection / Disposal

Environmental protection is a fundamental principle of the

Bosch Group.

Quality of products, efficiency and environmental protection are equally

important objectives for us. All legislation pertaining to the environment

is strictly observed.

Packaging

For the packaging, we participate in the country-specific recycling

systems, which guarantee optimal recycling. All packaging materials

used are environmentally-friendly and recyclable.

Old appliances

Old appliances contain materials that should be recycled.

The relevant assemblies are easy to separate, and all plastics are

identified. This allows the various components to be sorted for

appropriate recycling or disposal.

9 Maintenance

▶ Allow the DHW tank to cool down sufficiently before performing any

maintenance.

▶ Remedy all faults immediately.

▶ Use original spare parts only!

▶ The tank must be inspected annually and maintained as required.

▶ Check the T&P safety valve annually.

9.1 Preparing the DHW tank for cleaning

The SU80/5 and SU100/5 tanks are cleaned by means of the cleanout

on the side. The SU54/5 tank is cleaned by means of the cleanout at the

top.

▶ Disconnect electrical power from the heating system.

▶ Drain the DHW tank. To do so, close the shut-off valve for cold water

inlet and the open drain valve. To vent the system, open the air vent

valve or the highest faucet.

▶ Remove the PS top cover (SU54/5) ( Fig. 17, page 14, [1]) or

cleanout cover shroud (SU80/5, SU100/5) ( Fig. 18, page 14,

[1]) from the tank.

▶ Loosen the hex bolts [2] in the cleanout cover [3].

NOTICE: Risk of system damage from excessive

pressure!

Excessive pressure can result in tension cracks in the

enamel coating.

▶ Never plug the discharge line of the T&P safety valve.

Use only drinking water to check the DHW tank for leaks.

On the DHW side, the test pressure must not exceed

145 psi (10 bar) gauge pressure.

CAUTION: Risk of tank damage!.Residual moisture can

result in corrosion.

▶ Thoroughly dry out the inside (e. g. by means of hot

air) and leave the cleanout cover open.

WARNING: Risk of scalding from hot water!

▶ Let the tank cool down sufficiently.

Fully drain the tank – even the lowest section of the tank

and the heating coil.

DANGER: RISK OF SCALDING

Hot water can cause scalding.

▶ Prior to cleaning, allow the DHW tank to cool down

sufficiently.

9

Maintenance

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)14

▶ Remove the cleanout cover [3], magnesium anode [5] and cleanout

cover gasket [4].

Fig. 17 Removing the cleanout cover SU54/5

[1] PS top cover

[2] Hex bolts

[3] Cleanout cover

[4] Cleanout cover gasket

[5] Magnesium anodes

[6] Inspection port

Fig. 18 Removing the cleanout cover SU80/5, SU100/5

[1] Cleanout cover shroud

[2] Hex bolts

[3] Cleanout cover

[4] Magnesium anode

[5] Cleanout cover gasket

[6] Inspection port

9.2 Descaling/cleaning the DHW tank

▶ Check the DHW tank interior for scale deposits (calcium).

Should scale deposits be discovered inside the DHW tank, proceed as

follows:

▶ Hose down the inside of the DHW tank with a “high-pressure” (approx.

58 – 72.5 psi (4 - 5 bar) gauge pressure) cold water jet.

You can increase the cleaning effect by heating up the heat exchanger

in the drained tank before cleaning. The thermal shock effect releases

scale deposits more easily from the coil-type heat exchanger.

▶ Use a wet & dry vacuum cleaner with plastic suction hose to remove

the residues.

Extremely tough scale deposits inside the DHW tank can be removed by

chemical means. We recommend that you have a qualified contractor

carry out the chemical cleaning operation.

Fig. 19 Hose down the inside of the tank as shown in the example

SU80/5, SU100/5

6 720 801 769-07.1ITL

1

2

3

4

5

6

6 720 805 397-09.1ITL

CAUTION: Risk of tank damage due to damaged enamel.

▶ Never use hard objects or tools with sharp edges to

clean the interior of the tank

9

Maintenance

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 15

9.3 Checking the magnesium anode

The purpose of the anode rod is to protect the DHW tank against

corrosion. It is critical that the anode rod be inspection once a year to

determine whether it requires replacing.

Upon inspection, the anode rod surface should appear smooth. If the rod

surface appears pitted, bumpy, rusty, scale has built up on the surface,

or if the rod is less than 5/8" (15 mm) in diameter, then it must be

replaced.

Certain installations may require more frequent replacement of the

anode rod:

• Recirculation applications,

• Poor water quality,

• Galvanic/electrolytic corrosion,

• High flow applications.

In the event of poor water quality it is recommended that a water

treatment professional be consulted for water treatment options.

9.3.1 Checking the upper magnesium anode (SU80/5, SU100/5)

▶ Remove PS top cover if not already removed.

▶ Unscrew the magnesium anodes.

▶ Check the magnesium anodes for decomposition.

▶ Replace the magnesium anode if its diameter has been reduced to

approx. 5/8 " (15 mm).

▶ Screw the magnesium anodes back into the cover.

Fig. 20 Checking the upper magnesium anode SU80/5, SU100/5

[1] Hex bolt

[2] Magnesium anode

9.3.2 Checking the upper magnesium anode (SU54/5)

▶ Remove the cleanout cover ( Fig. 17, page 14), if not yet removed.

▶ Check the magnesium anodes.

▶ Replace the magnesium anode if its diameter has been reduced to

approx. 5/8 " (15 mm).

▶ To release the ground cable eyelet [8], undo nut M8 [9].

▶ Undo nut M8 [7].

▶ Remove cleanout cover [3] from magnesium anode [1].

▶ Install new magnesium anode with the aid of the hardware provided

( Fig. 21).

Fig. 21 Replacing the magnesium anode

[1] Magnesium anode

[2] Gasket

[3] Cleanout cover

[4] Insulating sleeve

[5] U-washer

[6] Serrated washer

[7] M8Nut

[8] Ground wire eyelet

[9] M8Nut

9.3.3 Checking the magnesium anode at the side

(SU80/5, SU100/5)

▶ Empty the tank as described in chapter 9.1, page 13.

▶ Remove the cleanout cover ( Fig. 17, page 14), if not yet removed.

▶ Check the magnesium anodes.

▶ Replace the magnesium anode if its diameter has been reduced to

approx. 1/2 " (15 mm).

▶ To release the ground cable eyelet [8], undo nut M8 [9].

▶ Undo nut M8 [7].

▶ Remove cleanout cover [3] from magnesium anode [1].

▶ Install new magnesium anode with the aid of the hardware provided

( Fig. 21).

If the magnesium anode is not serviced properly, the

warranty is void.

Annual service records must be kept in a safe location

and submitted together with the original purchase

receipt in the event of a warranty claim.

Never bring the magnesium anode surface in contact

with oil or grease.

▶ Keep everything clean.

6 720 800 155-23.1ITL

9

Maintenance

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)16

9.4 Re-commissioning after performing maintenance

▶ Put the cleanout cover [4] back in place (top or side) together with the

new gasket [2].

▶ Thread hex bolts [5] into cleanout cover [4] "hand-tight".

▶ Then use a torque wrench to tighten the hex bolts to 18-22 lbf-ft

(25 - 30 Nm).

▶ Fill the DHW tank and restart the heating system.

▶ Check all connections and the inspection port for leaks.

▶ Replace the cleanout cover shroud.

▶ Reposition the PS top cover on the tank.

Fig. 22 Reassembling the inspection port

[1] Inspection port

[2] Cleanout cover gasket

[3] Magnesium anode

[4] Cleanout cover

[5] Hex bolts

[6] Cleanout cover shroud

CAUTION: Risk of tank damage from a faulty gasket!

▶ To prevent the DHW tank from leaking, install a new

cleanout cover gasket upon completion of cleaning

and maintenance.

6720 800 155-06.1ITL

10

Spare Parts

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 17

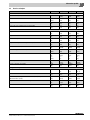

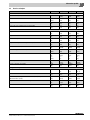

10 Spare Parts

Fig. 23 Spare parts for SU54/5

Item Article description Product No.

1 Cover D550 lid, black 8 718 542 319 0

2 Plug, EPS upper part D370 8 718 541 763 0

4 Self-tapping hex screw M10x25 (8x) 7 747 005 744

6 O-ring 120.02x6.99-N 8 718 572 538 0

9 Spacer, 1/4-circle (1x) 8 718 585 547

10 Compensator spring (5x) 8 718 585 143

13 Self-tapping screw St 4.2x13 (10x) 7 747 027 696

14 Retaining plate for the aquastat 7 747 028 761 0

Logo Buderus 8 718 541 573 0

Table 7

6 720 805 397-18.1ITL

1

2

4

6

9

10

13

14

4

10

Spare Parts

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)18

Fig. 24 Spare parts for SU54/5

Item Article description Product No.

1 Multi-link anode, 3 links 558/528mm M8 63020947

1 Anode D33x400mm (1x) 8 718 571 568 0

2 Anode mounting kit (10x) 5264278

3 Anode grounding cable (insulated) 63037168

4 Self-tapping hex screw M10x25 (8x) 7 747 005 744

5 Cleanout cover DN120 SA5, thermoplastic 8 718 543 791 0

6 O-ring 120.02x6.99-N 8 718 572 538 0

Table 8

6 720 805 397-19.1ITL

2

4

4

3

3

5

6

1

2

1

2

2

4

4

2

1

5

6

3

3

10

Spare Parts

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08) 19

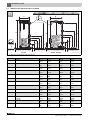

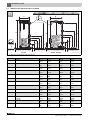

Fig. 25 Spare parts for SU80/5, SU100/5

Item Article description Product No.

1 Cover D670 lid, black 8 718 541 369 0

2 Plug, EPS upper part D672.5 8 718 541 767 0

3 Cleanout gasket D670, black 8 718 542 063 0

5 Self-tapping hex screw M10x25 (8x) 7 747 005 744

6 Cleanout cover DN120 for anode 7 747 004 739

7 O-ring 120.02x6.99-N 8 718 572 538 0

8 Anode D33x400 mm 8 718 571 568 0

9 Anode mounting kit (10x) 5264278

10 Anode G1 1/2x575, without electrical insulation D=33 (80 gal) 8 718 542 779 0

10 Anode G1 1/2x750, without electrical insulation D=33 (100 gal) 8 718 542 778 0

11 Anode grounding cable (insulated) 63037168

13 Self-tapping screw St 4.2x13 (10x) 7 747 027 696

14 Retaining plate for the aquastat 7 747 028 761 0

15 Spacer, 1/4-circle (1x) 8 718 585 547

16 Compensator spring (5x) 8 718 585 143

Logo Buderus 8 718 541 573 0

Table 9

6 720 805 397-20.1ITL

9

11

1

2

10

13

14

9

8

3

5

6

5

7

16

15

15

Índice de contenidos

SU54/5, SU80/5, SU100/5 – 6 720 808 532 (2013/08)20

Índice de contenidos

1 Indicaciones de seguridad y explicación de los símbolos . . 20

1.1 Explicación de los símbolos . . . . . . . . . . . . . . . . . . . . . . 20

1.2 Indicaciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . 21

1.3 Instrucción del usuario . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Datos sobre el producto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.1 Volumen de suministro . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2 Uso adecuado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3 Descripción del producto . . . . . . . . . . . . . . . . . . . . . . . . 23

2.4 Placa de características . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.5 Curva de pérdida de presión intercambiador de calor . 23

2.6 Datos técnicos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7 Dimensiones constructivas y de conexión . . . . . . . . . . 25

3 Normas, prescripciones y directivas . . . . . . . . . . . . . . . . . . . . 26

4 Transporte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Montaje . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1 Instalación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1.1 Requisitos del lugar de emplazamiento . . . . . . . . . . . . 26

5.1.2 Distancia a la pared . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1.3 Colocar el acumulador de agua caliente . . . . . . . . . . . . 27

5.2 Conexión hidráulica . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2.1 Conexión hidráulica del acumulador de agua caliente . 28

5.2.2 Montar la válvula de temperatura y válvula

de seguridad de presión . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3 Montar la sonda de temperatura del acumulador

(accesorio) o el acuastato (accesorio) . . . . . . . . . . . . . 29

6 Puesta en marcha . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Puesta en marcha del acumulador de agua caliente . . . 30

7 Fuera de servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1 Poner el acumulador de agua caliente fuera

de servicio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.2 Desconectar la instalación de calefacción en caso

de riesgo de heladas . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 Protección del medio ambiente/eliminación de residuos . . 31

9 Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.1 Preparar el acumulador de agua caliente

para la limpieza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9.2 Descalcificación/limpieza del acumulador

de agua caliente . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.3 Comprobación del ánodo de magnesio . . . . . . . . . . . . . 33

9.3.1 Comprobar el ánodo de magnesio superior

(SU80/5, SU100/5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.3.2 Comprobar el ánodo de magnesio superior (SU54/5) 33

9.3.3 Comprobar el ánodo de magnesio lateral

(SU80/5, SU100/5) . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.4 Nueva puesta en funcionamiento después del

mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1 Indicaciones de seguridad y explicación de

los símbolos

1.1 Explicación de los símbolos

Advertencias

Las siguientes palabras de señalización están definidas y pueden utili-

zarse en el presente documento:

• AVISO advierte sobre la posibilidad de que se produzcan daños mate-

riales.

• ATENCIÓN advierte sobre la posibilidad de que se produzcan daños

personales de leves a moderados.

• ADVERTENCIA advierte sobre la posibilidad de que se produzcan

daños personales de graves a mortales.

• PELIGRO advierte sobre daños personales de graves a mortales.

Información importante

Otros símbolos

Las advertencias están marcadas en el texto con un

triángulo.

Adicionalmente las palabras de señalización indican el

tipo y la gravedad de las consecuencias que conlleva la

inobservancia de las medidas de seguridad indicadas

para evitar riesgos.

La información importante que no conlleve riesgos per-

sonales o materiales se indicará con el símbolo que se

muestra a continuación.

Símbolo Significado

▶Procedimiento

Referencia cruzada a otro punto del documento

• Enumeración/punto de la lista

– Enumeración/punto de la lista (2.º nivel)

Tab. 1

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

Buderus SU80/5 Fiche technique

- Taper

- Fiche technique

dans d''autres langues

- English: Buderus SU80/5 Datasheet

- español: Buderus SU80/5 Ficha de datos

Documents connexes

Autres documents

-

Atlantic BALLON ANNULAIRE DUOTHERM 200L Le manuel du propriétaire

-

Bradford White BMT2V0200NACK5XC Manuel utilisateur

-

Laars MT2H0300NACK2BXN Guide d'installation

-

Watts CO-190-PR, CO-190-PR-60, CO-1190-PR, CO-1190-PR-60 Guide d'installation

-

Fagor IFF-200_S2 Le manuel du propriétaire

-

MAXA BARREL Le manuel du propriétaire