Solar and High-Performance

DHW Storage Tanks

SM80/5, SM100/5

6 720 647 567-00.1ITL

[en] Installation and Service Instructions - Read carefully prior to installation and maintenance.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

[fr] Notice d’installation et d’entretien - À lire attentivement avant le montage et la maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

[es] Instrucciones de mantenimiento y de instalación -

Léase atentamente antes del montaje o de la realización de trabajos de mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6 720 800 156 (2017/07) US/CA/MX

WARNING:

These installation instructions are intended solely for use by a licensed

heating contractor or service technician. Read all instructions before in-

stalling. Perform steps exactly in the order given. Failure to follow these

instructions can result in severe injury, death or property damage.

NOTICE:

The heat transfer medium must be nontoxic water with Toxicity Class 1

as listed in "Clinical Toxicology of Commercial Products," 5th edition.

The heat transfer medium must be limited to a maximum pressure of

30 PSIG by an approved safety or pressure relief valve.

DANGER :

Cette notice d’installation doit être utilisée uniquement par des installa-

teurs chauffagistes ou des techniciens de maintenance qualifiés. Lisez

attentivement toutes les consignes avant l’installation. Exécutez les ac-

tions précisément dans l’ordre indiqué. En cas de non-respect, vous ris-

quez de subir de sérieuses blessures pouvant conduire à la mort ou

d’entraîner de lourds dommages matériels.

REMARQUE :

Le milieu caloporteur doit être de l’eau non toxique de classe 1 telle que

précisé dans la 5e édition de « Clinical Toxicology of Commercial

Products ». Le liquide caloporteur doit être limité à une pression maximale

de 30 PSIG par une soupape de sécurité ou de surpression homologuée.

PELIGRO :

Este manual de instalación únicamente lo pueden utilizar instaladores de

calefacción o técnicos especializados. Antes de la instalación, lea todas

las indicaciones. Realice todas las acciones exactamente en el orden in-

dicado. En caso de incumplimiento, existe riesgo de lesiones graves e in-

cluso de muerte o daños materiales considerables.

AVISO :

El portador de calor se debe limitar a una presión máxima de 2 bar me-

diante una válvula de seguridad o de sobrepresión.

Contents

SM80/5, SM100/5 – 6 720 800 156 (2017/07)2

Contents

1 Safety Considerations and Symbol Descriptions . . . . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Instructions for the owner and operator . . . . . . . . . . . . . 4

2 Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Pressure drop curve of heating coil . . . . . . . . . . . . . . . . . 6

2.6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.7 Physical and connection dimensions . . . . . . . . . . . . . . . 8

3 Standards, regulations and directives . . . . . . . . . . . . . . . . . . . 9

4 Moving the tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Tank installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1.1 Requirements for installation location . . . . . . . . . . . . . . 9

5.1.2 Wall clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1.3 Positioning the tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Water connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2.1 Connecting the tank on the water side . . . . . . . . . . . . . 12

5.2.2 Installing a T&P safety valve (on-site) . . . . . . . . . . . . . . 12

5.3 Installing the DHW water temperature sensor

(accessory) or Aquastat (accessory) . . . . . . . . . . . . . . 12

5.4 Connecting the KS solar pump station . . . . . . . . . . . . . 14

5.5 Connection as high-performance DHW tank . . . . . . . . . 14

5.5.1 Series connection of the lower and upper heat

exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.5.2 Parallel connection of the lower and upper heat

exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Commissioning the DHW tank . . . . . . . . . . . . . . . . . . . . 15

7 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.1 Shutting down the tank . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.2 Shutting down the heating system when there is a risk

of frost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Environmental protection/disposal . . . . . . . . . . . . . . . . . . . . . 15

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9.1 Preparing the DHW tank for cleaning . . . . . . . . . . . . . . 15

9.2 Descaling/cleaning the tank . . . . . . . . . . . . . . . . . . . . . 16

9.3 Check the magnesium anodes . . . . . . . . . . . . . . . . . . . . 16

9.4 Startup after maintenance . . . . . . . . . . . . . . . . . . . . . . . 17

10 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.1 Spare parts for SM80/5, SM100/5 . . . . . . . . . . . . . . . 18

1

Safety Considerations and Symbol Descriptions

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 3

1 Safety Considerations and Symbol

Descriptions

1.1 Explanation of symbols

Warnings

The following keywords are defined and can be used in this document:

• DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

• WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

• CAUTION indicates a hazardous situation which, if not avoided,

could result in minor to moderate injury.

• NOTICE is used to address practices not related to personal injury.

Important Information

Additional symbols

1.2 Safety instructions

Read all instructions before installing. Perform the steps in the indicated

sequence. Have the DHW tank inspected by a trained service technician

at least once every year. Failure to comply with these instructions can

result in severe, possibly fatal, personal injury as well as damage to

property and equipment.

Installation and servicing

▶ Risk of fire from soldering and brazing!

Take appropriate protective measures when soldering and brazing as

the insulation is flammable, for example, cover the insulation.

▶ Ensure that only a licensed contractor installs or services the DHW

tank.

▶ Use installation material with adequate temperature stability.

Forbidden:

Connection of the potentiostat for an impressed current anode to the

magnesium anode installed in a storage tank is absolutely forbidden!

This would destroy the tank! The warranty would be voided.

Installation and commissioning

▶ The electrical connection must be connected by a electrician.

The wiring diagram must be followed.

▶ Do not install this device in rooms with a high moisture level

(e.g. bathrooms, saunas).

Function

▶ To ensure that the tank functions properly, heed these installation

and maintenance instructions.

▶ Never close the blow-off line of the T&P safety valve. For safety

reasons, water may escape during heating.

Danger from electric shock

▶ Make sure that only certified electricians perform the electrical work.

▶ Before performing electrical work, disconnect the power and secure

the unit against unintentional reconnection.

▶ Ensure the system has been disconnected from the power supply.

Risk of scalding at the hot water draw-off point

▶ When the DHW tank is in operation, temperatures in excess of 122 °F

(50 °C) can occur. To limit the temperature at the tap, install a

thermostatic DHW mixing valve.

▶ Water heated for washing the laundry, dishes and for other cleaning

purposes can cause scalding and permanent injuries.

▶ Children, elderly, and handicapped persons are more likely to be

permanently injured by hot water. Never leave such individuals in the

tub or shower unattended under any circumstances. Children must

not be allowed to operate hot water faucets themselves or to fill a

bathtub.

▶ If the building has occupants in the above groups who operate hot

water faucets, or state laws / local ordinances stipulate specific

water temperatures, take the following precautions:

– Use the lowest possible temperature setting.

– To prevent scalding, install a tempering device, such as an

automatic mixing valve, at hot water tap or water heater. Select

and install the automatic mixing valve in accordance with the

valve manufacturer's recommendations and instructions.

▶ Water exiting from drain valves can be extremely hot. To avoid

injuries:

– Check that all connections are tight.

– Direct exiting water away from people.

▶ Measures must be taken to protect against excessive temperature

and pressure! Installation of a T&P safety valve is required.

The chart below shows the relationship between water temperature and

time until there is a risk of scalding. It can be used as the basis for

determining the safest water temperature for your application.

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

This symbol indicates important information where

there is no risk to people or property. It is separated by

horizontal lines above and below the text.

Symbol Function

▶ Sequence of steps

Cross-reference to another part of the document

• Listing/list entry

– Listing/list entry (2nd level)

Table 1

2

Product Information

SM80/5, SM100/5 – 6 720 800 156 (2017/07)4

To protect against corrosion and ensure compliance with the rules for

electrical safety, observe the following points:

▶ Use metal fittings for drinking water heating systems with plastic

piping.

▶ Use only original accessories from the manufacturer.

▶ When installation of the tank is complete, inspect the ground

conductor (including metal fittings).

Maintenance

Customers are advised to:

▶ Sign a maintenance and inspection contract with an authorized

contractor. Inspect and maintain the DHW tank as necessary on a

yearly basis. Service as needed.

▶ Use only original spare parts.

Flooding

▶ After a flood, do not use the appliance if any part has been

submerged. Damage to appliances that have been submerged can be

quite severe and pose numerous safety risks.

▶ An appliance that was subject to flooding must be replaced.

1.3 Instructions for the owner and operator

▶ Explain the operation and handling of the heating system and DHW

tank, making a particular point of safety-relevant features.

▶ Explain the function and how to check the T&P safety valve.

▶ Hand all enclosed documents over to the owner/operator.

▶ Recommendation for the user: Sign a maintenance and inspection

contract with a licensed contractor.

▶ Highlight the following for the user:

– Water may be discharged from the T&P safety valve during heat-

up.

– The blow-off line on the T&P safety valve must always be kept

open.

– Check that the T&P safety valve operates properly at least once

yearly.

– The tank must be inspected annually and maintained as required.

2 Product Information

2.1 Scope of delivery

• DHW tanks

•Tank components

• Installation and Maintenance Instructions

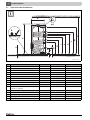

Fig. 1 Tank components

[1] Tee 1" x 1" x 3/4" (2x)

[2] Temperature and pressure relief valve

[3] Recirculation connection cap 3/4"

[4] Drain valve

[5] Bracket for aquastat, screws for aquastat bracket (4x)

[6] Compensating spring for aquastat or cylinder temperature sensor

[7] Quarter-circle spacers for aquastat or tank temperature sensor

(2x)

Temperature Time to severe scalding

120 °F (48 °C) longer than 5 minutes

125 °F (51 °C) 1.5 to 2 minutes

130 °F (54 °C) approx. 30 seconds

135 °F (57 °C) approx. 10 seconds

140 °F (60 °C) less than 5 seconds

145 °F (62 °C) less than 3 seconds

150 °F (65 °C) approx. 1.5 seconds

155 °F (68 °C) approx. 1 second

Table 2 Approximate time-temperature relationship until there is a risk

of scalding

1

1. Source: Moritz, A.R. and Henriques, F.C., Jr. (1947). Studies of thermal injury.

II. The relative importance of time and surface temperature in the causation of

cutaneous burns, Am J of Pathol, 23, 695-720.

WARNING: Risk of scalding at the taps!

There is a risk of scalding at the taps if the tank

temperature is set above 122 °F (50 °C) and during

thermal disinfection.

▶ Advise users that they should draw off only mixed

water. Otherwise, install a thermostatic DHW mixing

valve.

NOTICE: Risk of tank damage from excessively high

pressure.

▶ Never close the temperature and pressure safety

valve blow-off line.

6 720 805 397-01.1ITL

1

2

4

3

5

7

6

2

Product Information

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 5

2.2 Designated use

The DHW tank can be operated in a solar thermal system with a boiler as

a back-up, or for high output only with a boiler. (Operation of the two

heat exchangers in series or parallel.) The tank is designed for heating

and storing drinking water. Please observe national, regional, and local

codes, regulations, guidelines and standards for drinking water. When

operated as part of a solar system, the solar thermal system must be

filled with solar antifreeze to prevent frost damage.

The tank can be used only in closed loop systems and is not suitable for

drain-back solar thermal systems. Any other purpose is considered

improper use. Any resulting damage is excluded from the

manufacturer's warranty.

2.3 Product Information

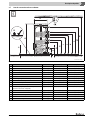

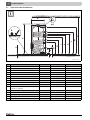

Fig. 2 SM80/5, SM100/5

2.4 Data plate

The data plate is located at the top rear of the DHW tank.

Requirements

for potable water Unit

Water hardness, min. ppm

grain/US gallon

°dH

36

2.1

2

pH value, min. – max. 6.5 – 9.5

Conductivity, min. – max. μS/cm 130 – 1500

Table 3 Requirements for potable water

Item Description

1 DHW outlet

2 Boiler supply

3 Sensor well for temperature sensor, heat source or

aquastat

4 Recirculation connection

5 Boiler return

6 Solar supply

7 Sensor well for temperature sensor, solar

8 Solar return

9 Cold water inlet

10 Bottom heat exchanger for heating by a solar system,

smooth enameled tubing

11 Inspection port for service and cleaning at the front

12 Fitted magnesium anode without electrical insulation

13 Upper heat exchanger for reheating by heating appliance,

smooth enameled tubing

14 Tank, enameled steel

15 Fitted magnesium anode without electrical insulation

16 PS top cover

17 Jacket, painted sheet metal with rigid polyurethane foam

insulation, 2" (50 mm)

Table 4 Product Information

6 720 800 155-01.1ITL

1

10

11

15

16

4

7

8

9

2

3

5

6

14

13

12

17

2

Product Information

SM80/5, SM100/5 – 6 720 800 156 (2017/07)6

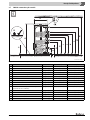

2.5 Pressure drop curve of heating coil

Pressure drop curve of bottom heat exchanger

Fig. 3 Pressure drop curve of bottom heat exchanger

[1] SM80/5

[2] SM100/5

Example:

[A] 8 gpm, 2.2feed of head

Pressure drop curve of top heat exchanger

Fig. 4 Pressure drop curve of top heat exchanger

[1] SM80/5

[2] SM100/5

Example:

[B] 8 gpm, 1.4 feed of head

20.00

feed of head

gpm

15.00

10.00

5.00

0.00

4.00 6.00 8.00 10.00 12.00 14.00 16.00

6 720 800 155-18.2T

1

2

A

18.00

20.00 22.00 24.00

26.00 28.00

feed of head

If the two heat exchangers are piped in series, the

pressure drops are cumulative.

If they are operated in parallel, a separate pump is

recommended for each heat exchanger. Otherwise, flow

setters are needed to regulate the flow through the two

heat exchangers.

Ensure that in any case the pumps meet the load.

6 720 800 155-19.2T

20.00

feed of head

gpm

15.00

10.00

5.00

0.00

4.00 6.00 8.00 10.00 12.00 14.00 16.00

1

2

B

18.00

20.00 22.00 24.00

26.00 28.00

feed of head

2

Product Information

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 7

2.6 Technical Data

SM80/5 SM100/5

Lower heat

exchanger

connected to

boiler

Upper heat

exchanger

connected to

boiler

Both heat

exchangers in

series with the

boiler

Lower heat

exchanger

connected to

boiler

Upper heat

exchanger

connected to

boiler

Both heat

exchangers in

series with the

boiler

Tank capacity

Available capacity (total) gal

(l)

75.4

(285)

96.9

(366)

Maximum flow rate gpm

(l/min)

7.5

(28)

9.7

(37)

Maximum permissible DHW temperature °F

(°C)

203

(95)

203

(95)

Maximum permissible DHW operating pressure psi

(bar)

150

(10.3)

150

(10.3)

Stand-by heat loss (at 149 °F (65 °C) DHW

temperature, 68 °F (20 °C) room temperature)

°F/h

(K/h)

0.6

(0.34)

0.5

(0.28)

Storage tank performance

Cold water inlet temperature °F

(°C)

50

(10)

50

(10)

Domestic hot water outlet temperature °F

(°C)

140

(60)

140

(60)

DHW temperature rise °F

(°C)

90

(50)

90

(50)

Heat exchanger flow temperature °F

(°C)

176

(80)

176

(80)

Heat exchanger flow rate gpm

(l/h)

11.4

(2600)

11.4

(2600)

11.4

(2600)

14

(3180)

14

(3180)

14

(3180)

Heat exchanger pressure drop f o h

(mbar)

2.5

(74)

1.8

(53)

3.2

(95)

5.8

(175)

3.5

(106)

10.2

(305)

Continuous rating gph

(l/h)

gpm

(l/min)

185

(700)

3.1

(12)

135

(510)

2.2

(9)

298

(1128)

5.0

(19)

265

(1005)

4.4

(17)

153

(578)

2.5

(10)

376

(1422)

6.3

(24)

Amount that can be drawn off in the first hour gph

(l/h)

257

(973)

135

(510)

362

(1370)

356

(1348)

153

(578)

462

(1750)

Maximum heat input btu/hr

(kW)

112 398

(33)

78 187

(22.9)

178 797

(52.4)

169 083

(49.5)

87 856

(25.7)

235 434

(69)

Heat exchanger

Content gal

(liter)

2.3

(8.7)

1.6

(6.1)

3.8

(14.4)

3.1

(11.7)

1.9

(7.2)

4.9

(18.5)

Surface area ft

2

(m

2

)

13.99

(1.3)

9.69

(0.9)

23.68

(2.2)

19.38

(1.8)

10.76

(1)

30.14

(2.8)

Maximum heating water temperature °F

(°C)

230

(110)

230

(110)

Max. operating pressure, heat exchanger psi

(bar)

232

(16)

232

(16)

Table 5 Technical Data

2

Product Information

SM80/5, SM100/5 – 6 720 800 156 (2017/07)8

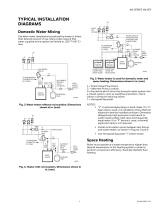

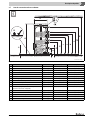

2.7 Physical and connection dimensions

Fig. 5 Physical and connection dimensions

SM80/5 SM100/5

A Diameter inch (mm) 26-3/8 (670) 26-3/8 (670)

B Minimum floor weight carrying capacity lb (kg) 899 (408) 1135 (515)

C Clearance off floor inch (mm) 3/8 - 3/4 (10 - 20) 3/8 - 3/4 (10 - 20)

D Overall height inch (mm) 58-7/8 (1495) 72-1/4 (1835)

E Height, cold water inlet inch (mm) 3-1/8 (80) 3-1/8 (80)

F Height, solar return inch (mm) 12-1/2 (318) 12-1/2 (318)

G Height, sensor well for temperature sensor (solar) inch (mm) 24-21/64 (618) 31-7/32 (793)

H Height, solar supply inch (mm) 28-1/2 (722) 35-3/8 (898)

i Height, tank return inch (mm) 32 (813) 40-5/8 (1033)

J Height, recirculation connection inch (mm) 35-1/2 (903) 45 (1143)

K Height, sensor well for temperature sensor

(heat source or aquastat)

inch (mm) 39-7/8 (1013) 50-5/16 (1278)

V Boiler flow connection height inch (mm) 44 (1118) 54-1/2 (1383)

M Height, hot water outlet inch (mm) 53-3/8 (1355) 66-3/4 (1695)

N Minimum room height for anode replacement inch (mm) 72-7/8 (1850) 82-3/4 (2100)

O Empty weight lb (kg) 260 (118) 298 (135)

P Total weight when filled lb (kg) 899 (408) 1135 (515)

Table 6

C

D

E

F

H

I

J

K

L

M

N

G

B

A

O

P

M1

M2

6 720 800 155-21.2ITL

B

3

Standards, regulations and directives

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 9

3 Standards, regulations and directives

4 Moving the tank

▶ Position the dolly at the back of the packed DHW tank.

▶ Secure the DHW tank to the means of transportation with a strap.

▶ Transport the DHW tank to the installation location.

▶ Only remove the DHW tank from the packaging at the installation

location.

Fig. 6 Transporting with a dolly

5 Installation

The DHW tank is delivered fully assembled.

▶ Check DHW tank for completeness and damage.

5.1 Tank installation

5.1.1 Requirements for installation location

▶ Place the DHW tank on a plinth if there is a risk that water may collect

at the installation site.

▶ The installation site must be a dry and frost-free room.

▶ Observe minimum room height ( Tab. 6, page 8) and minimum

wall clearance in installation room ( Fig. 7, page 10).

▶ Maintain a distance of 2" (51 mm) from heated pipes and

combustible surfaces.

5.1.2 Wall clearances

Observe all local regulations and standards applicable to

installation and operation of the system in your country!

All electrical components must be approved for the USA

and Canada.

WARNING: Risk of injury from carrying heavy loads and

inadequately securing loads for transport.

▶ Use suitable means of transportation, e.g. a dolly

with strap.

▶ Secure the load against falling.

Where possible, do not remove the DHW tank from its

packaging until it has reached the installation location.

This ensures protection during handling.

6 720 647 567-02.1ITL

NOTICE: Risk of damage from inadequate load-bearing

capacity of the supporting substructure or unsuitable

floor surface!

▶ Ensure that the installation area is level and offers

sufficient load-bearing capacity.

NOTICE: Risk of damage from stress cracking and

corrosion!

▶ Position the DHW tank in a dry room free from the

risk of freezing.

▶ Install this DHW tank only in closed-loop, unvented

systems.

▶ Open expansion vessels can NOT be used for this

DHW tank.

NOTICE: If leaks can result in property damage or a drain

pan is required by law:

▶ Install an adequate drain pan.

▶ Follow the installation instructions of the drain pan

manufacturer.

Follow drain pan manufacturer's instructions.

5

Installation

SM80/5, SM100/5 – 6 720 800 156 (2017/07)10

Fig. 7 Recommended minimum wall clearances

5.1.3 Positioning the tank

▶ Unpack the tank by removing the wrap, wooden boards and foam pad

on the top.

▶ Lay the foam pad on the floor to serve as a mat.

Fig. 8 Unpacking the DHW tank

▶ Carefully lay the tank on the foam pad [1].

▶ Cut out the protections in the foam bottom [2].

▶ Unscrewing the adjustable foot[3].

Fig. 9 Lay the DHW cylinder on its side and expose the adjustable foot

6 720 800 155-10.1ITL

15-¾ inch

4 inch

(102 mm)

(400 mm)

(500 mm)

19-¾ inch

6 720 647 567-05.1ITL

6 720 647 567-35.1ITL

1.

2.

3.

5

Installation

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 11

▶ Position the DHW tank on a level floor with adequate load-bearing

capacity.

Fig. 10 Positioning the tank

▶ Maintain minimum wall clearances.

▶ Using the adjustable foot, align the DHW cylinder vertically.

▶ Remove the caps from the connections.

Fig. 11 Remove caps

▶ Use Teflon tape or Teflon cord to seal the connections. Do not use

hemp to seal the connections.

5.2 Water connections

6 720 647 567-07.1ITL

WARNING: Risk of fire from soldering and brazing!

▶ Take appropriate protective measures when

soldering and welding as the insulation is flammable,

for example, cover the insulation.

▶ Check tank jacket for damage after completing work.

DANGER: Risk of injury from contaminated water!

Work carried out without due care for cleanliness

contaminates the drinking water.

▶ Install in accordance with national standards and

guidelines.

NOTICE: Water damage

▶ Connect the drain to the bottom tank connection

prior to filling the tank.

▶ Seal off all unused tank connections.

NOTICE: Risk of corrosion from damage to the enamel

coating!

▶ Attach connections to the DHW tank only "hand-

tight".

6 720 800 155-22.1ITL

A

B

5

Installation

SM80/5, SM100/5 – 6 720 800 156 (2017/07)12

5.2.1 Connecting the tank on the water side

Example of system with all recommended valves ( Fig. 12, page 12).

▶ When selecting the expansion vessel for the hot water side, take the

content of the heat exchanger and DHW tank into consideration.

▶ Route the connection cables for the tank temperature sensors at the

back of the tank through the insulation to the heating appliance or

controller.

▶ Install piping runs so that natural circulation is prevented. If

necessary, install check valves.

▶ Install connection cables free of stress.

▶ Attach piping to the tank connections on-site.

▶ Check all connections for leaks.

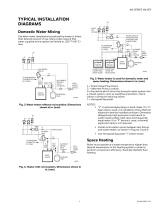

Fig. 12 Installation (illustrative)

[1] Storage tank

[2] Shutoff valve

[3] P&T safety valve (combined with hot water outlet)

[4] Check valve

[5] Tank primary pump

[6] Recirculation pump (optional)

[7] Air eliminator (in main supply)

[8] Drain valve

[9] Expansion vessel

[10] Thermostatic DHW mixing valve

[11] Tank primary pump

[12] Solar pump station

[AW] DHW outlet

[EZ] Recirculation inlet

[VS1] Tank supply (solar)

[RS1] Tank return (solar)

[VS2] Tank supply (boiler)

[RS2] Tank return (boiler)

[EK] Cold water inlet

[EL] Tank drain

5.2.2 Installing a T&P safety valve (on-site)

▶ Install a listed T&P safety valve that is approved for drinking water

( ¾ ")in the DHW outlet.

▶ This DHW tank must be installed with a new T&P safety valve.

▶ The T&P valve must be sized no smaller than the rated tank capacity.

▶ Observe the safety valve installation instructions.

▶ T&P discharge pipe:

– The blow-off line must be at least equal to the outlet cross-section

of the safety valve.

– Route the blow-off line from the T&P valve directly to an adequate

drain (maximum length 6 ft (2 m) with no more than two 90°-

elbows).

– The discharge line must terminate at an adequate drain in order to

prevent property damage from spillage.

– Check that the T&P safety valve operates properly at least once

annually.

▶ Never plug the blow-off line. During heating, water may be

discharged for operational reasons at any time.

Fitting the B-kit

Fig. 13 Connecting the DHW tank components

[1] Tee 1" x 1" x 3/4" (2x) with T&P safety valve

[2] 3/4" cap for recirculation connection

[3] Bracket with Aquastat

[4] Tee with fill and drain valve

5.3 Installing the DHW water temperature sensor

(accessory) or Aquastat (accessory)

6 720 800 155-11.1ITL

1

1

DANGER: Risk of fatal injury from electric shock.

▶ Isolate the system electrically prior to commencing

work on the system.

6 720 800 155-05.1ITL

5

Installation

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 13

Install a tank temperature sensor or an aquastat on the DHW tank to

measure and monitor the hot water temperature.

Installing the DHW temperature sensor

▶ Take the tank temperature sensor from the scope of delivery of the

control panel (accessories).

▶ Insert the sensor set until it bottoms out inside the sensor well [5].

This automatically pushes back the plastic spiral [3] that holds the

sensor set together.

The compensating spring [4] ensures contact between the sensor well

and sensor surfaces, and a reliable temperature reading.

Fig. 14 Installing the DHW temperature sensor

[1] Quarter-circle spacer

[2] Temperature sensor

[3] Plastic spiral

[4] Compensating spring

[5] Sensor Well

▶ Push sensor retaining clip [1] from the side onto sensor well [2].

▶ Route the sensor lead to the boiler or control panel and ensure the

cable is not strained. This piping must not be in contact with any hot

boiler parts.

▶ In the case a sensor is being used without a compensating spring, the

empty space in the sensor well must be filled with a sufficient amount

of heat-conducting paste.

Fig. 15 Installing the sensor retainer

[1] Sensor retainer

[2] Sensor Well

Installing the aquastat

▶ Remove cover from the aquastat. To do so, undo the screw on the

top.

▶ If necessary, remove any unnecessary attachments. Attach bracket

[3] to aquastat [2] by means of two self-tapping screws [1].

Fig. 16 Screw the bracket onto the aquastat

[1] Self-tapping screws

[2] Aquastat

[3] Holder

Connect the electrical power and set the temperature on

the DHW temperature sensor or the aquastat as shown in

the respective aquastat or control manufacturer's

instructions.

Always ensure that the full length of the sensor surface is

in contact with the sensor well.

6 720 800 155-17.1ITL

5

4

123

6 720 800 155-03.1ITL

5

Installation

SM80/5, SM100/5 – 6 720 800 156 (2017/07)14

▶ Feed the temperature sensor [4] with the compensating spring [3]

into the sensor well [5].

▶ Attach bracket [6] to DHW cylinder by means of 4 self-tapping sheet

metal screws [1].

▶ Replace the cover of the aquastat [2].

Fig. 17 Installing the aquastat

[1] Self-tapping screws

[2] Aquastat

[3] Compensating spring

[4] Temperature sensor

[5] Sensor Well

[6] Holder

5.4 Connecting the KS solar pump station

▶ Attach the KS solar pump station [4] to the lower heat exchanger in

the DHW tank at the VS

1

(solar supply) and RS

1

(solar return)

connections.

▶ Attach the reheating device to the upper heat exchanger in the DHW

tank at the VS2 (storage tank supply) and RS2 (storage tank return)

connections.

▶ Use piping and pipe connections made of copper, brass and non-

galvanized steel for the connection between the KS solar pump

station [4] and DHW tank [5].

Fig. 18 Connecting the KS solar pump station (schematic illustration)

[1] Collector supply connection

[2] Collector return connection

[3] Oil-/gas-fired boiler

[4] Solar pump station

[5] DHW tanks

Grounding the piping

▶ Attach one grounding clamp each to the supply and return pipes (at

any position).

▶ Connect the grounding clamps to the building's grounding rod by

means of standard bonding cables AWG9.

Laying pipes with an automatic air vent valve on the roof (available

as accessory)

▶ Pipes to the air vent valve should follow a rising gradient. For every

downwards change of direction, an additional air separator with air

vent valve is required (heat-resistant to 302 °F (150 °C)).

5.5 Connection as high-performance DHW tank

The DHW tank can also be used as a high-performance DHW tank.

In this case, 2 connection configurations are possible.

5.5.1 Series connection of the lower and upper heat exchanger

▶ Attach the upper connection on the lower heat exchanger to the

lower connection on the upper heat exchanger in the DHW tank.

▶ Attach the tank charging pump to the upper connection on the upper

heat exchanger.

▶ Attach the lower connection on the lower heat exchanger to the

return piping on the boiler.

WARNING: Risk of equipment damage from very high

operating temperatures and pressures!

▶ Use pressure- and temperature-resistant piping

materials.

▶ Do not use any galvanized piping, pipe connections

or graphite seals.

▶ Do not use any plastic piping or connections of any

kind.

▶ When using soldered connections in the entire solar

circuit, use high-temperature solder (melting point

455 °F (235 °C)).

To ensure proper operation of the solar thermal system,

air must be bled adequately from the entire system.

For information on bleeding the solar thermal system,

refer to the installation instructions for the KS solar

pump station.

6 720 800 155-04.1ITL

5

4

3

2 1

6

Allow only an authorized contractor to make all the

piping connections.

When the heat exchangers are connected in series, the

pressure loss across the two coils is cumulative.

Pressure drop of connecting pipe must be added. Ensure

that the pump used can handle the resulting pressure

drop.

6

Start-up procedure

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 15

▶ Install the Aquastat or DHW temperature sensor in the sensor well

provided for this purpose ( Fig. 2, page 5, [3]).

5.5.2 Parallel connection of the lower and upper heat exchanger

We recommend that the two heat exchangers in the tank each be

connected to its own primary pump.

6 Start-up procedure

6.1 Commissioning the DHW tank

Have the installer of the heating system or a qualified contractor

commission the equipment.

▶ Commission the boiler and other accessories in accordance with the

manufacturer's instructions in the corresponding installation and

operating manuals.

▶ To bleed air from the DHW tank, open the highest tap/valve.

▶ To fill the DHW tank, open the shut-off valve for the cold water inlet.

▶ Flush the tank and piping thoroughly prior to commissioning.

▶ Before heating up, verify that the boiler, tank and pipework are filled

with water. Open the air bleeder valve for this purpose.

▶ Check all connections, piping and the inspection port for leaks.

7 Shutdown

7.1 Shutting down the tank

▶ Switch off the temperature controller at the control panel, shut of the

heating system emergency shutoff switch, or disengage the heating

system circuit breaker.

▶ Close the cold water inlet shutoff valve.

▶ Drain the DHW tank via the drain valve by opening the highest faucet.

▶ Close the shut-off valves to and from the boiler.

▶ Depressurize the heat exchanger.

▶ Drain and blow out the heat exchanger.

▶ To prevent corrosion, dry out the inner space and keep the

inspection port covers open.

7.2 Shutting down the heating system when there is a

risk of frost

▶ Shut down the heating system and the DHW tank as shown in

Chapter 7.1.

8 Environmental protection/disposal

Environmental protection is one of the fundamental company policies of

the Bosch Group. We regard quality of performance, economy and

environmental protection as equal objectives.

Environmental protection laws and regulations are strictly adhered to.

To protect the environment, we use the best possible technology and

materials taking into account economic points of view.

Packaging

For the packaging, we participate in the country-specific recycling

systems, which guarantee optimal recycling. All packaging materials

used are environmentally-friendly and recyclable.

Old electrical and electronic appliances

Electrical or electronic devices that are no longer

serviceable must be collected separately and sent for

environmentally compatible recycling (in accordance

with the European Waste Electrical and Electronic

Equipment Directive).

To dispose of old electrical or electronic devices, you

should use the return and collection systems put in place

in the country concerned.

9 Maintenance

▶ Allow the DHW tank to cool down sufficiently before performing any

maintenance.

▶ Remedy all faults immediately.

▶ Use original spare parts only!

▶ The tank must be inspected annually and maintained as required.

▶ Check the T&P safety valve annually.

9.1 Preparing the DHW tank for cleaning

▶ Disconnect electrical power from the heating system.

▶ Drain the DHW tank. To do so, close the shut-off valve for cold water

inlet and the open drain valve. To vent the system, open the air vent

valve or the highest faucet.

▶ Remove the cleanout cover [6] shroud over the inspection port [1] in

the DHW tank.

NOTICE: Risk of equipment damage from excess

pressure! Excess pressure can cause stress cracking in

the enamel.

▶ Never close the temperature and pressure safety

valve blow-off line.

Use only drinking water to check the DHW tank for leaks.

On the DHW side, the test pressure must not exceed

150 psi (10.3 bar) gauge pressure.

NOTICE: Risk of tank damage!

Residual moisture can result in corrosion.

▶ Thoroughly dry out the inside (e. g. by means of hot

air) and leave the cleanout cover open.

WARNING: Risk of scalding from hot water!

▶ Let the tank cool down sufficiently.

Drain the DHW tank completely, even the lower chamber

of the tank and the heat exchanger.

WARNING: Risk of scalding!

Hot water can cause scalding.

▶ Prior to cleaning, allow the DHW tank to cool down

sufficiently.

9

Maintenance

SM80/5, SM100/5 – 6 720 800 156 (2017/07)16

▶ Loosen the hex bolts [5] in the cleanout cover [4].

▶ Remove the cleanout cover [4], magnesium anode [3] and cleanout

cover gasket [2].

Fig. 19 Removing the cleanout cover

[1] Inspection port

[2] Handhole cover gasket

[3] Magnesium anode

[4] Handhole cover

[5] Hex bolts

[6] Cleanout cover shroud

9.2 Descaling/cleaning the tank

▶ Check the DHW tank interior for scale deposits (calcium).

Should limescale be discovered inside the DHW tank, proceed as

follows:

▶ Hose down the inside of the DHW tank with a "high pressure"

(approx. 58 – 72.5 psi (4 – 5 bar) gauge pressure) stream of cold

water ( Fig. 20, page 16).

You can increase the cleaning effect by heating up the heat exchangers

in the drained DHW tank before cleaning. The thermal shock effect

releases scale deposits more easily from the coil-type heat exchanger.

▶ Use a wet & dry vacuum cleaner with plastic suction hose to remove

the residues.

Extremely tough limescale inside the DHW tank can be removed by

chemical means. We recommend that you have a qualified contractor

carry out the chemical cleaning operation.

Fig. 20 Hosing down the interior of the DHW tank

9.3 Check the magnesium anodes

The purpose of the magnesium anode is to protect the storage tank

against corrosion.

Every year, check whether the magnesium anode must be replaced. The

surface of the magnesium anode must be free of deposits.

If the rod surface appears pitted, bumpy, rusty, deposits have built up on

the surface, or if the rod is less than 5/8" (15 mm) in diameter, then it

must be replaced.

Certain installations may require more frequent replacement of the

magnesium anode rod:

• Recirculation connection

• Poor water quality

• Galvanic/electrolytic corrosion

• High flow rate

In the event of poor water quality it is recommended that a water

treatment professional be consulted for water treatment options. The

DHW cylinder warranty is void if the magnesium anode is not correctly

maintained.

Checking the top magnesium anode

▶ Remove PS top cover if not already removed.

▶ Unscrew the magnesium anodes.

▶ Check the magnesium anodes for degradation.

▶ Replace the magnesium anode if the diameter has decreased to

approx. 5/8" (15 mm).

NOTICE: Risk of tank damage due to damaged enamel.

▶ Never use hard objects or tools with sharp edges to

clean the interior of the tank.

6720 800 155-02.1ITL

The warranty is void if the magnesium anode is not

correctly maintained. Annual service records must be

kept in a safe location and submitted together with the

original purchase receipt in the event of a warranty

claim.

Never bring the magnesium anode surface into contact

with oil or grease.

▶ Keep everything clean.

9

Maintenance

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 17

▶ Insert the magnesium anodes into the sleeve again.

Fig. 21 Checking the top magnesium anode

[1] Hex bolt

[2] Magnesium anode

Checking the side magnesium anode

▶ Empty the DHW cylinder as described in Chapter 9.1.

▶ Remove cleanout cover ( Fig. 19, page 16), if it is not already

removed.

▶ Check the magnesium anodes.

▶ Replace the magnesium anode if the diameter has decreased to

approx. 5/8" (15 mm).

▶ Unscrew the nut M8 [9] to release the eyelet of the grounding cable

connecting lead[8].

▶ Unscrew the M8 nut [7].

▶ Remove the handhole cover [1] from the magnesium anode [3].

▶ Fit the new magnesium anode together with all small parts supplied

with it.

Fig. 22 Replacing the magnesium anode

Key to Fig. 22:

[1] Magnesium anode

[2] Gasket

[3] Handhole cover

[4] Insulating sleeve

[5] Dished washer

[6] Serrated washer

[7] M8 Nut

[8] Eyelet of the grounding cable connecting lead

[9] M8 Nut

9.4 Startup after maintenance

▶ Put the cleanout cover [4] back in place together with the new gasket

[2].

▶ Thread hex bolts [5] into cleanout cover [4] "hand-tight".

▶ Then use a torque wrench to tighten the hex bolts to 18-22 lbf-ft

(25 – 30 Nm).

▶ Fill the DHW tank and restart the heating system.

▶ Check all connections and the inspection port for leaks.

▶ Replace the cleanout cover shroud.

▶ Reinstall the PS jacket cover ( Fig. 2, page 5) on the DHW tank.

Fig. 23 Reinstall handhole cover

[1] Inspection port

[2] Handhole cover gasket

[3] Magnesium anode

[4] Handhole cover

[5] Hex bolts

[6] Cleanout cover shroud

6 720 800 155-23.1ITL

NOTICE: Risk of tank damage from a faulty gasket!

▶ To prevent the DHW tank from leaking, install a new

cleanout cover gasket upon completion of cleaning

and maintenance.

6720 800 155-02.1ITL

10

Spare Parts

SM80/5, SM100/5 – 6 720 800 156 (2017/07)18

10 Spare Parts

10.1 Spare parts for SM80/5, SM100/5

Fig. 24 DHW tank SM80/5, SM100/5

6 720 800 155-20.1ITL

1

2

10

5

5

5

14

13

6

3

9

8

5

9

11

7

9

Item Description Part number

1 Cover D670 lid, black 8 718 541 369 0

2 Plug, EPS upper part D672.5 8 718 541 767 0

3 Cleanout gasket D670, black 8 718 542 063 0

5 Self-tapping hex screw M10x25 (8x) 7 747 005 744

6 Cleanout cover DN120 for anode 7 747 004 739

7 O-ring 120.02x6.99-N 8 718 572 538 0

8 Anode D33x400 mm 8 718 571 568 0

9 Anode mounting kit (10x) screw-in 5264278

Table 7 Spare parts for SM80/5, SM100/5

10 Anode G1 1/2 x 750,

without electrical insulation D=33

8 718 542 778 0

10 Anode G1 1/2 x 600,

without electrical insulation D=40

8 718 542 704 0

11 Anode grounding cable (insulated) 63037168

13 Self-tapping screw St 4.2x13 (10x) 7 747 027 696

14 Retaining plate for the aquastat 7 747 028 761 0

Logo Buderus 8 718 541 573

Item Description Part number

Table 7 Spare parts for SM80/5, SM100/5

Table des matières

SM80/5, SM100/5 – 6 720 800 156 (2017/07) 19

Table des matières

1 Explication des symboles et mesures de sécurité . . . . . . . . . 20

1.1 Explication des symboles . . . . . . . . . . . . . . . . . . . . . . . 20

1.2 Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.3 Initiation de l’utilisateur . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Description du produit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.1 Fourniture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2 Utilisation conforme à l’usage prévu . . . . . . . . . . . . . . . 22

2.3 Description du produit . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.4 Plaque signalétique . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5 Courbe des pertes de pression échangeur thermique . 23

2.6 Données techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7 Cotes de construction et de raccordement . . . . . . . . . 25

3 Normes, prescriptions et directives . . . . . . . . . . . . . . . . . . . . 26

4 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1 Mise en place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1.1 Exigences requises pour le lieu d’installation . . . . . . . . 26

5.1.2 Distances par rapport aux murs . . . . . . . . . . . . . . . . . . 27

5.1.3 Mise en place du ballon d’eau chaude sanitaire . . . . . . 27

5.2 Raccordements hydrauliques . . . . . . . . . . . . . . . . . . . . 28

5.2.1 Effectuer le raccordement hydraulique du ballon d’eau

chaude sanitaire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2.2 Installer la soupape de sécurité pour la température

et la pression (sur site) . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3 Installation de la sonde de température ECS

(accessoire) ou de l’Aquastat (accessoire) . . . . . . . . . 30

5.4 Raccordement de la station de pompe solaire KS . . . . 31

5.5 Raccordement en tant que ballon ECS grande

puissance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.5.1 Raccordement en série des échangeurs thermiques

inférieur et supérieur . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.5.2 Raccordement en parallèle des échangeurs thermiques

inférieur et supérieur . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 Mise en service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Mise en service du ballon d’eau chaude sanitaire . . . . 32

7 Mise hors service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.1 Mise hors service du ballon d’eau chaude sanitaire . . . 32

7.2 Mise hors service de l’installation de chauffage

en cas de risques de gel . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Protection de l’environnement/

Recyclage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9 Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1 Préparer le ballon d’eau chaude sanitaire pour le

nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9.2 Détartrer/nettoyer le ballon d'eau chaude sanitaire . . 33

9.3 Vérifier les anodes en magnésium . . . . . . . . . . . . . . . . 33

9.4 Mise en service après maintenance . . . . . . . . . . . . . . . 34

10 Pièces de rechange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 Pièces de rechange pour SM80/5, SM100/5 . . . . . . . 36

1

Explication des symboles et mesures de sécurité

SM80/5, SM100/5 – 6 720 800 156 (2017/07)20

1 Explication des symboles et mesures de

sécurité

1.1 Explication des symboles

Avertissements

Les mots de signalement suivants sont définis et peuvent être utilisés

dans le présent document :

• AVIS signale le risque de dégâts matériels.

• PRUDENCE signale le risque d’accidents corporels légers à moyens.

• AVERTISSEMENT signale le risque d’accidents corporels graves à

mortels.

• DANGER signale la survenue d’accidents mortels en cas de non res-

pect.

Informations importantes

Autres symboles

1.2 Consignes de sécurité

Lisez attentivement toutes les consignes avant l’installation. Exécuter

les étapes dans l’ordre indiqué. Faire contrôler le ballon d’eau chaude

sanitaire par un technicien qualifié au moins une fois par an. Le non-res-

pect de ces consignes peut entraîner des accidents graves voire mortels

et/ou des dégâts matériels.

Montage et entretien

▶ Risque d’incendie en raison des travaux de soudure !

L’isolation thermique étant inflammable, prendre des mesures de

sécurité appropriées pour effectuer tous les travaux de soudage, en

recouvrant l’isolation thermique par ex.

▶ S’assurer que les travaux d’installation et de maintenance sont exclu-

sivement réalisés par un professionnel agréé.

▶ Utiliser des matériaux suffisamment résistants aux températures éle-

vées.

Interdiction :

Il est formellement interdit de raccorder le potentiostat d'une anode

externe à l'anode au magnésium montée dans un ballon ! Le ballon serait

endommagé ! Le droit de garantie serait perdu.

Installation et mise en service

▶ Le raccordement électrique doit être réalisé exclusivement par un

électricien. Respecter le schéma de connexion !

▶ Ne pas monter cet appareil dans des pièces humides (par ex. salle de

bain, sauna).

Fonction

▶ Respecter cette notice d’installation et d’entretien afin de garantir un

fonctionnement parfait.

▶ Ne pas obturer la conduite de purge de la soupape de sécurité T&D.

Pendant le chauffage, de l’eau risque de s’écouler pour des raisons

de sécurité.

Risques d’électrocution

▶ S’assurer que seuls des électriciens autorisés réalisent ces travaux

électriques.

▶ Avant de commencer les travaux d’électricité, couper le courant du

câble d’alimentation sur tous les pôles et protéger l’installation

contre tout réenclenchement involontaire.

▶ Vérifier que l’installation est hors tension.

Risques de brûlure aux points de puisage de l’eau chaude sanitaire

▶ Les températures du ballon d’eau chaude sanitaire pendant son fonc-

tionnement peuvent dépasser 122 °F (50 °C). Pour limiter la tempé-

rature de puisage, installer un mélangeur thermostatique.

▶ L’eau chauffée utilisée pour la lessive, la vaisselle et d’autres tâches

de nettoyage peut provoquer des brûlures et des blessures perma-

nentes.

▶ Chez les enfants, les personnes âgées et sénile ou mentalement han-

dicapée, il existe un risque accru de blessure permanente à l’eau

chaude. Ne jamais laisser ces personnes sans surveillance dans la

baignoire ou sous la douche. Ne pas autoriser les jeunes enfants à

actionner eux-mêmes les robinets d’eau chaude ou de remplir une

baignoire.

▶ Si dans un bâtiment les personnes comprises dans les catégories

précédemment citées actionnent des robinets d’eau chaude ou si les

directives locales imposent des températures précises pour les robi-

nets d’eau chaude, prendre les mesures spécifiques suivantes :

– Utiliser le réglage de température le plus bas possible.

– Installer une sécurité anti-brûlure, par ex. une vanne mélangeur

automatique, sur le robinet d’eau chaude ou le chauffe-eau. Choi-

sir et installer la vanne mélangeur automatique en fonction des

recommandations et consignes du fabricant de la vanne.

▶ L’eau s’échappant des vannes de vidange peut être extrêmement

chaude. Pour éviter les blessures :

– Assurer l’étanchéité des raccordements.

– Eloigner les écoulements d’eau de toute personne.

▶ Prendre des mesures de protection contre les températures et pres-

sions trop élevées ! Installer impérativement une soupape de sécu-

rité pour la température et la pression.

Le tableau suivant présente le rapport entre la température de l’eau et le

temps nécessaire à l’apparition de brûlures. Vous pouvez ainsi détermi-

ner les températures d’eau les plus sûres pour votre application.

Les avertissements sont indiqués dans le texte par un

triangle de signalisation.

En outre, les mots de signalement caractérisent le type

et l’importance des conséquences éventuelles si les me-

sures nécessaires pour éviter le danger ne sont pas res-

pectées.

Les informations importantes ne concernant pas de si-

tuations à risques pour l'homme ou le matériel sont si-

gnalées par le symbole ci-contre. Elles sont limitées par

des lignes dans la partie inférieure et supérieure du

texte.

Symbole Fonction

▶Etape à suivre

Renvois à un autre passage dans le document

• Enumération/Enregistrement dans la liste

– Enumération / Entrée de la liste (2e niveau)

Tab. 1

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

Buderus SM80/5 Installation And Service Instructions Manual

- Taper

- Installation And Service Instructions Manual

- Ce manuel convient également à

dans d''autres langues

- English: Buderus SM80/5

- español: Buderus SM80/5

Documents connexes

Autres documents

-

Honeywell Home MX129LF Guide d'installation

Honeywell Home MX129LF Guide d'installation

-

Bradford White BMT2V0200NACK5XC Manuel utilisateur

-

Laars MT2H0300NACK2BXN Guide d'installation

-

Chaffoteaux & Maury BK1S 850 Le manuel du propriétaire

-

ELM LEBLANC MEGALIS NGVA 24-5H V 24 KW Le manuel du propriétaire

ELM LEBLANC MEGALIS NGVA 24-5H V 24 KW Le manuel du propriétaire

-

Atlantic BALLON ANNULAIRE DUOTHERM 200L Le manuel du propriétaire

-

Hunter 43658 Manuel utilisateur

-

ELM LEBLANC ACLEIS NGVM V Le manuel du propriétaire

ELM LEBLANC ACLEIS NGVM V Le manuel du propriétaire

-

Watts CO-190-PR, CO-190-PR-60, CO-1190-PR, CO-1190-PR-60 Guide d'installation

-

Drive AquaSense 3-in-1 Contoured Raised Toilet Seat Le manuel du propriétaire