HRD SERIES

HEATLESS COMPRESSED AIR DRYERS

OPERATOR’S

INSTRUCTION MANUAL

HRD56 – HRD3250

HRD56EM – HRD3250EM

English: 1-1

Español: 2-1

Français: 3-1

Before installation or starting the dryer for the

first time, study this manual carefully to

obtain a clear knowledge of the dryer and of

the duties to be performed while operating

and maintaining the dryer.

RETAIN THIS MANUAL WITH DRYER.

This technical manual contains IMPORTANT

SAFETY DATA and should be kept with the

dryer at all times.

Bulletin 378 (7/00)

HRD and HRD-EM Series (Bulletin 378) 1-1

HRD SERIES

HEATLESS COMPRESSED AIR DRYERS

OPERATOR’S

INSTRUCTION MANUAL

HRD56 – HRD3250

HRD56EM – HRD3250EM

Before installation or starting the dryer for the

first time, study this manual carefully to

obtain a clear knowledge of the dryer and of

the duties to be performed while operating

and maintaining the dryer.

RETAIN THIS MANUAL WITH DRYER.

This technical manual contains IMPORTANT

SAFETY DATA and should be kept with the

dryer at all times.

Bulletin 378 (7/00)

1-2 HRD and HRD-EM Series (Bulletin 378)

Table of Contents

INTRODUCTION.....................................1-3

SAFETY ..........................................1-3

INSTALLATION.....................................1-3

Receiving and Inspection .................................1-3

Handling ..........................................1-3

Ambient Air Temperature .................................1-4

Location and Clearance ..................................1-4

System Arrangement ....................................1-4

Piping and Connections ..................................1-4

Desiccant ..........................................1-5

Mufflers ..........................................1-5

Electrical Connections ...................................1-6

INSTRUMENTATION ..................................1-6

Models HRD56 through HRD3250 ............................1-6

Models HRD56EM through HRD3250EM ........................1-6

Power ON Light ......................................1-6

Vessel Pressure Gauges ..................................1-6

Purge Flow Indicator....................................1-6

Switch-Failure Alarm ...................................1-6

Moisture Indicator .....................................1-6

High-Humidity Alarm (HRD-EM only) ..........................1-6

Compu-Purge (HRD-EM only) ..............................1-7

HOW IT WORKS (HRD SERIES) ...........................1-7

HOW IT WORKS (HRD-EM SERIES) .........................1-8

Compu-Purge Control ...................................1-9

AUTOMATIC DRAIN VALVE (ADV) .........................1-9

START-UP.........................................1-9

Dew Point.........................................1-10

Dew Point Adjustment ..................................1-10

Dew Point Verification ..................................1-11

MAINTENANCE ....................................1-11

Desiccant Dusting.....................................1-11

Shutdown .........................................1-12

Maintenance Schedule ..................................1-12

Daily ...........................................1-12

Weekly ..........................................1-13

Monthly ..........................................1-13

Yearly ...........................................1-13

Returns to Manufacturer .................................1-13

Desiccant Replacement ..................................1-13

Filter Element Replacement ...............................1-14

Servicing The Internal Float Drain Valve (If Equipped) .................1-16

Automatic Drain Valve (ADV) Disassembly and Servicing ...............1-17

High-Humidity Alarm Field Adjustment (HRD-EM only)................1-18

Care of Compu-Purge Sensors ..............................1-19

LCD Display Information ................................1-19

Indicators and Alarms ..................................1-19

FIELD SERVICE GUIDE ...............................1-20

REPLACEMENTPARTS................................A-1

ELECTRICAL SCHEMATICS .............................A-1

INTRODUCTION

HRD Series and HRD-EM (Energy Management) Se

-

ries heatless desiccant compressed air dryers remove

moisture from compressed air to achieve a standard

pressure dew point of –40°F. Refer to Table 5 for rated

capacity and other dryer specifications. The heatless

dryer supplies a continuous flow of dry compressed air

by alternately cycling the airflow through two desic

-

cant beds; one adsorbs moisture from the inlet air

while the other is regenerated by a portion of the dry

air from the active bed.

To ensure continuing good dryer performance and safe

operation, everyone who installs, uses or maintains the

dryer must read and carefully follow the instructions in

this manual. Throughout the manual, the word dryer is

used to refer to HRD and HRD-EM Series heatless air

dryers.

SAFETY

HRD and HRD-EM Series dryers are designed and

built with safety as a prime consideration; industry-

accepted safety factors have been used in the design.

Each dryer is checked at the factory for safety and op-

eration. The desiccant vessels are hydrostatically

tested to 1½ times the maximum pressure in accor-

dance with ASME code requirements. A factory-

installed safety relief valve is standard on each dryer.

WARNING

The following safety rules must be observed to

ensure safe dryer operation. Failure to follow

these rules may void the warranty or result in

dryer damage or personal injury.

1. Never install or try to repair any dryer that has

been damaged in shipment. See the Receiving and

Inspection instructions in this manual for appro

-

priate action.

2. Never operate the dryer at pressures or tempera

-

tures above the maximum conditions shown on

the data plate.

3. Always supply electrical power that complies

with the voltage shown on the data plate.

4. Never dismantle or work on any component of the

dryer or compressed air system under pressure.

Vent internal air pressure to the atmosphere be

-

fore servicing.

5. Never perform electrical service on the dryer un

-

less the main power supply has been discon

-

nected. Parts of the control circuit may remain

energized when the power switch is turned off.

6. Use only genuine replacement parts from the

manufacturer. The manufacturer bears no respon

-

sibility for hazards caused by the use of unauthor

-

ized parts.

Safety instructions in this manual are boldfaced for

emphasis. The signal words DANGER, WARNING

and CAUTION are used to indicate hazard serious

-

ness levels as follows:

DANGER—Immediate hazard which will result in se

-

vere injury or death.

WARNING—Hazard or unsafe practice which could

result in severe injury or death.

CAUTION—Hazard or unsafe practice which could

result in minor injury or in product or property dam

-

age.

The dryer data plate, attached to the electrical control

box, contains critical safety and identification informa

-

tion. If the data plate is missing or defaced, immediate

-

ly contact your local distributor for a replacement.

INSTALLATION

Receiving and Inspection

Immediately upon receipt of the dryer, thoroughly in-

spect for damage that may have occurred during ship-

ping. Since the dryer is shipped F.O.B. New Castle,

Delaware, the carrier is legally responsible for damage

incurred during shipping. Shipping damage is not cov-

ered by the dryer warranty.

If goods are received short or damaged, notify the car

-

rier and insist on a notation of the loss on the face of

the bill of lading. Otherwise no claim can be enforced

against the carrier.

If concealed loss or damage is discovered, notify the

carrier at once and request an inspection. The carrier

will make an inspection and grant a concealed damage

notation. The carrier will not consider any claim for

loss or damage unless an inspection has been made. If

you give the carrier a clear receipt for goods that have

been damaged or lost in transit, you do so at your own

risk and expense.

If there is any damage, file a claim with the carrier,

then call your local distributor for further instructions.

Handling

The dryer is designed to be moved by means of the

shipping skid or the base channels. Handle the dryer

with care and only with equipment capable of lifting

the load.

HRD and HRD-EM Series (Bulletin 378) 1-3

Ambient Air Temperature

Locate the dryer under cover in an area where the am

-

bient air temperature is between 35°F and 120°F.

Location and Clearance

Install the dryer on a level pad. The dryer is provided

with a minimum

5

8

-inch diameter anchor bolt holes.

For dryers 56 through 600 scfm, anchor the dryer to

the floor with four ½-inch diameter bolts with a mini

-

mum 4-inch thread engagement. For dryers 800 scfm

and larger, anchor the dryer to the floor with four ¾-

inch diameter bolts with a minimum 6-inch thread en

-

gagement. Allow 24 inches clearance on all sides of

the dryer for servicing. Provide adequate clearance for

prefilter and afterfilter element replacement. Provide

protection for the dryer if it is installed where heavy

vehicles or similar portable equipment is likely to

cause damage.

System Arrangement

Install the dryer downstream of an aftercooler and sep-

arator so that the dryer inlet air is between 60°F and

120°F and contains no liquid water. Liquid water

and/or inlet air temperatures above 100°F can reduce

drying capacity. Contact your local distributor for in-

formation on proper dryer sizing at elevated inlet air

temperatures.

Oil contaminates the desiccant, reducing drying effi-

ciency and desiccant life. An oil-removing filter is in-

stalled at the dryer inlet to protect the desiccant from

oil contaminants. A particulate filter is installed after

the dryer to remove dirt and other solid particles.

Piping and Connections

All external piping must be supplied by the user unless

otherwise specified. Refer to Table 1 for connection

sizes. Inlet and outlet manual shutoff valves and a vent

valve are recommended so the dryer and filters can be

isolated and depressurized for servicing. Refer to Fig

-

ure 1 for recommended piping layout. The connections

and pipe fittings must be rated for or exceed the maxi

-

mum operating pressure given on the dryer data plate

and must be in accordance with industry-wide codes.

Table 1

CONNECTIONS

Model

Connections

(inches)

Inlet Outlet

HRD56 / HRD56EM ¾ NPT ½ NPT

HRD100 / HRD100EM 1 NPT ¾ NPT

HRD160 / HRD160EM 1¼ NPT 1 NPT

HRD200 / HRD200EM 1½ NPT 1¼ NPT

Model

Connections

(inches)

Inlet Outlet

HRD275 / HRD275EM 2 NPT 1¼ NPT

HRD350 / HRD350EM 2 NPT 1¼ NPT

HRD475 / HRD475EM 2 NPT 1½ NPT

HRD600 / HRD600EM 2½ NPT 2 NPT

HRD800 / HRD800EM 3 NPT 2½ NPT

HRD1000 / HRD1000EM 3 NPT 2½ NPT

HRD1200 / HRD1200EM 3 NPT 3 NPT

HRD1450 / HRD1450EM 3 NPT 3 NPT

HRD1710 / HRD1710EM 4 NPT 3 NPT

HRD2010 / HRD2010EM 4 FLG 4 FLG

HRD2250 / HRD2250EM 4 FLG 4 FLG

HRD2600 / HRD2600EM 4 FLG 4 FLG

HRD3250 / HRD3250EM 6 FLG 4 FLG

Be sure all piping is supported. Do not allow the

weight of any piping to bear on the dryer or filters.

Piping must be the same size as or larger than the

dryer connections. Piping smaller than the dryer con-

nections will cause high pressure drop and reduce dry-

ing capacity.

If the purge exhaust muffler piping must be extended

outside the dryer area, the piping must be sized so that

it will cause no more than 0.25 psig back pressure.

Back pressure reduces the capacity of the dryer.

1-4 HRD and HRD-EM Series (Bulletin 378)

Figure 1

RECOMMENDED PIPING LAYOUT

Consult your local distributor for piping details if re

-

quired.

Dryer bypass piping may be installed to allow uninter

-

rupted airflow during servicing. If the downstream ap

-

plication cannot tolerate unprocessed air for short

periods, install a second dryer in the bypass line.

CAUTION

Do not hydrostatically test the piping with the

dryer in the system. The desiccant will be

damaged if saturated with water.

Desiccant

HRD and HRD-EM Series dryers use activated alu

-

mina as the desiccant in the dryer vessels.

Models 56 through 600 scfm are shipped with acti

-

vated alumina in the dryer vessels. Activated alumina

is shipped loose with all other standard models.

All desiccant shipped loose must be added to the

dryer vessels before the dryer is put into service.

Refer to Table 2 for quantity per vessel.

Table 2

DESICCANT REQUIREMENTS

Dryer Model No

Activated Alumina

(lbs per vessel)

HRD56 / HRD56EM 31

HRD100 / HRD100EM 60

HRD160 / HRD160EM 95

HRD200 / HRD200EM 120

HRD275 / HRD275EM 165

HRD350 / HRD350EM 210

HRD475 / HRD475EM 285

HRD600 / HRD600EM 366

HRD800 / HRD800EM 475

HRD1000 / HRD1000EM 600

HRD1200 / HRD1200EM 725

HRD1450 / HRD1450EM 880

HRD1710 / HRD1710EM 1,025

HRD2010 / HRD2010EM 1,200

HRD2250 / HRD2250EM 1,366

HRD2600 / HRD2600EM 1,567

HRD3250 / HRD3250EM 1,975

To add desiccant:

WARNING

The following procedure provides instructions

for adding the initial desiccant to the vessels. If

replacing desiccant, refer to the instructions

on page 1-13.

1. Verify pressure gauges of both vessels indicate 0

psig. If not, depressurize the vessels according to

the shutdown instructions on page 1-12.

2. Remove the pipe plug from the desiccant fill port

at the top of each vessel. Refer to the dryer label

for the schematic depicting the fill port location.

CAUTION

Pouring desiccant creates a fine dust; safety

goggles, gloves and dust mask should be

worn by personnel installing desiccant. Refer

to the Material Safety Data Sheet (MSDS) on

page 1-23 for more complete information.

Do not tamp the desiccant in vessels. Tamping

damages desiccant and causes dusting.

3. Carefully pour activated alumina into the vessels

through the fill port.

4. Tap the vessels with a rubber mallet to ensure uni-

form distribution of the desiccant.

5. Replace the plugs in the fill port connections.

Mufflers

Purge exhaust mufflers are supplied with every dryer.

If they are not factory installed, they must be screwed

into the purge exhaust connection on the lower mani

-

fold piping before the dryer is operated. Desiccant

dusting may cause a restriction in the purge exhaust

muffler shortly after start-up. Depending on the dryer

model, the muffler cores may be in the control enclo

-

sure or strapped to a vessel leg. For additional infor

-

mation see Desiccant Dusting in the Maintenance

section, page 1-11.

WARNING

Operating dryer without mufflers will cause

noise levels exceeding OSHA standards.

Remove mufflers only for servicing and

maintenance and only after internal pressure

of dryer has been completely vented to

atmosphere.

HRD and HRD-EM Series (Bulletin 378) 1-5

Electrical Connections

The dryer is prewired, ready for use. Connect the dryer

to the power supply specified on the data plate. Con

-

nections, marked L1 and L2, are on a terminal strip in

-

side the electrical box. Make connections through the

plugged hole (identified by a tag) on the bottom right

of the box.

DANGER

Ground the dryer using the connection

supplied inside the electrical box. Refer to the

electrical schematic at the back of this manual

for connection details.

Important Note: Do not switch power to the dryer

on and off via a remote disconnect. To avoid dryer

malfunction, power to the unit must be switched on

and off using the switch on the dryer control panel.

INSTRUMENTATION

The following instrumentation helps in monitoring

dryer operation and performance. Instruments which

are available on either the HRD or HRD-EM (energy

management) are so noted.

Models HRD56 through HRD3250

HRD Series dryers are rated NEMA 1 and include fol-

lowing:

• Power ON light

• Vessel pressure gauges

•

Purge flow indicator

•

Switch-Failure Alarm

•

Moisture Indicator

Models HRD56EM through HRD3250EM

HRD-EM Series dryers are rated NEMA 4 and include

the following:

•

Power ON light

•

Vessel pressure gauges

•

Purge flow indicator

•

Switch-Failure Alarm

•

High-Humidity Indicator

•

Compu-Purge

•

Digital Display

•

Moisture Indicator

•

Audible alarm with auxiliary contacts

Power ON Light

The power ON light on the control panel indicates

when the dryer is turned on and operating.

Vessel Pressure Gauges

A gauge mounted on the gauge bracket indicates

which vessel is onstream and which is regenerating.

The gauge for the onstream vessel indicates operating

pressure; the gauge for the regenerating vessel indi

-

cates 0 psig.

Purge Flow Indicator

A gauge mounted on the gauge bracket of the dryer in

-

dicates purge air pressure as an approximate measure

of purge airflow when used with the calibration graph

shipped with the dryer. To approximate purge airflow,

locate the pressure gauge reading (psig) on the hori

-

zontal axis of the graph. Follow the pressure upward

until it intersects the calibration curve. Follow this

point to the left until it intersects the vertical axis. This

point on the vertical axis is approximately the purge

airflow.

Switch-Failure Alarm

Pressure sensors located on each vessel trigger both

audible and visible alarms if a vessel does not depres-

surize at the completion of its drying cycle. A red

light, labeled SWITCH FAILURE, is located on the

electrical panel. A time-delay relay is included sepa-

rately in the dryer packaging. The relay must be

mounted into the electrical panel before start-up. The

electrical schematic at the back of this manual gives

wiring details.

Moisture Indicator

A color-change moisture indicator is shipped sepa

-

rately in a moisture-proof bag. The moisture indicator

should be installed in a customer-supplied 1¼-inch

NPT threaded port at the dryer outlet. The indicator is

green when dry. The color changes to yellow when the

relative humidity of the dryer outlet air is approxi

-

mately 4%-5%. This indicator is intended only as an

inexpensive means of determining possible dryer mal

-

function.

High-Humidity Alarm (HRD-EM only)

A moisture sensor in the dryer outlet manifold moni

-

tors the relative humidity of the outlet air. The sensor

triggers audible and visible alarms if the relative hu

-

midity of the outlet air exceeds the factory setting. The

audible alarm is located near the control enclosure. A

red light, labeled HIGH HUMIDITY, is located on the

electrical panel. A set-plug adjustment bulb (refer to

Figure 9) is included for use in calibrating the

1-6 HRD and HRD-EM Series (Bulletin 378)

high-humidity alarm. Contacts for remote annunciators

are connected to the terminal strip in the electrical en

-

closure; refer to the electrical schematic for terminal

numbers. Refer to the maintenance section of this

manual for field adjustment instructions.

Compu-Purge (HRD-EM only)

Indicators

HRD-EM Series dryers are equipped with

Compu-Purge

®

control which has an indicating panel

(Figure 2) on the door of the main electrical box.

These indicators help in monitoring dryer operation

and performance. If the dryer malfunctions, first check

this panel to determine the cause of the problem.

Light Function

Power ON

Lights when switch is in “ON” position

and power is supplied to dryer.

Variable Purge

Mode

Lights when drying cycle is controlled

by the microcomputer.

High Inlet Air

Temperature

Lights when inlet air temperature ex

-

ceeds 120°F. Excessive inlet air tem

-

perature significantly decreases

drying capacity and may result in

higher dew point.

Dryer Overload

Lights when inlet dryer load exceeds

dryer ability to maintain dew point.

Low Inlet Air

Pressure

Lights when inlet air pressure is less

than 65 psig. See Maintenance sec-

tion (page 1-11) for additional infor-

mation.

Sensor

Malfunction

Lights when temperature or pressure

sensor sends the microcomputer a

reading which is outside the normal

range of the sensor. See Maintenance

section (page 1-11) for additional in

-

formation.

High Humidity

Lights when the high humidity moni

-

tor senses excessive moisture in the

outlet air. High humidity may result

when dryer is slugged with water.

Failure-to-Switch

Lights if airflow fails to alternate be

-

tween desiccant vessels at desig

-

nated switching time. Failure to switch

causes desiccant saturation, resulting

in higher dew point.

Liquid Crystal Digital (LCD) Display

The LCD display is above the indicating panel on the

main electrical box. It displays “INLET AIR TEM

-

PERATURE” (°F) and “ENERGY SAVINGS” as a

percent of dryer capacity. See Maintenance section,

page 1-11, for complete description of additional read

-

outs.

Audible Alarm

Indicates high-humidity and failure-to-switch alarm

condition.

Remote Contacts

Powered 120 volt, normally open, contacts (1 amp

max.) are furnished to allow hookup of remote audible

or visible system malfunction alarms. Hookup contacts

are identified by a tag on the bottom center of the elec-

trical box.

HOW IT WORKS (HRD SERIES)

HRD Series heatless dryers provide a continuous sup

-

ply of dry compressed air by automatically cycling the

flow of air through two desiccant beds. While one bed

is adsorbing moisture from the inlet air, the other bed

is being reactivated by a portion of the dried air. Cy

-

cling is controlled by a cam timer. Figure 3 shows the

airflow through the dryer with vessel A onstream and

vessel B being reactivated.

Saturated air enters the prefilter which separates oil

mists, liquid oil, water and particulates from the air

-

stream. Separated contaminants are discharged

through the prefilter drain. With purge valve E closed,

filtered air flows through shuttle valve S into the bot

-

tom of vessel A; moisture is removed from the air

-

stream by the desiccant. Dry air exits the top of the

vessel and divides into two streams: process air exits

through the shuttle valve T, passes through the particu

-

late afterfilter and continues to the process.

HRD and HRD-EM Series (Bulletin 378) 1-7

Figure 2

COMPU-PURGE

®

INDICATING PANEL

A portion of the dried air (purge air) is metered

through orifice C and reduced to atmospheric pressure

by orifice D, greatly expanding its volume. The ex

-

panded purge air flows down through vessel B and out

through the purge valve F and muffler, carrying away

moisture adsorbed by the desiccant in the previous cy

-

cle.

The dryer operates this way for approximately four

minutes. Then purge valve F closes, allowing vessel B

to gradually repressurize for approximately one minute

before the cycle changes. The cycle timing sequence

will vary depending on operating pressure. At

switchover, purge valve E opens to depressurize vessel

A. This causes shuttle valves S and T to shift so that

vessel B is onstream and vessel A is being reactivated.

HOW IT WORKS (HRD-EM SERIES)

Figure 4 shows the airflow through the dryer with ves

-

sel A drying and vessel B regenerating.

Saturated air enters the prefilter which separates oil

mists, liquid oil, water and particulates from the

airstream. Separated contaminants are discharged

through the prefilter drain. With exhaust valve C open

and D closed, filtered air enters the inlet shuttle valve

and is directed through vessel A, where moisture is ad

-

sorbed by the desiccant. Dry air exits the vessel, passes

through the outlet shuttle valve and divides into two

streams. The process air passes through the particulate

afterfilter and continues to the process.

A portion of the dried air passes through the purge ori

-

fice at approximately atmospheric pressure and passes

downward through vessel B, where it desorbs moisture

from the desiccant. Wet purge air exhausts to the at

-

mosphere through exhaust valve C and muffler E.

When regeneration is complete, exhaust valve C closes

and vessel B is repressurized to dryer operating pres

-

sure. Vessel B is completely regenerated and

repressurized, ready for the next drying cycle.

1-8 HRD and HRD-EM Series (Bulletin 378)

Figure 3

AIRFLOW SCHEMATIC (HRD Series)

Figure 4

AIR FLOW SCHEMATIC (HRD-EM Series)

At the end of the drying period, exhaust valve D

opens, vessel A depressurizes, inlet and outlet shuttle

valves shift, inlet flow switches to vessel B and the

drying/regenerating cycle is repeated.

Inlet air continues to flow through one vessel for half

of the standard 10-minute cycle.

Compu-Purge Control

Compu-Purge control uses a microcomputer to adjust

the purge airflow rate and drying cycle to automati

-

cally match purge air to the inlet moisture load.

Electronic temperature and pressure sensors continu

-

ously track inlet temperature and inlet and outlet pres

-

sure and transmit these to the microcomputer. The

microcomputer calculates the dryer load and the most

efficient combination of purge flow rate and duration

to regenerate the moisture adsorbed during the drying

period.

Purge flow rate can be varied from 0 to 20% in incre

-

ments of 5% by purge control valves 1 and 2. Purge

duration can also be varied. The optimum combination

of purge control valve openings is automatically se-

lected by the microcomputer to supply only as much

purge air as needed for complete regeneration.

When the amount of purge air required to regenerate

the desiccant is more than 20% of the inlet flow, the

dryer will operate on a shortened cycle until the over-

load condition is corrected. The dryer will operate on a

5-minute cycle when in the Overload Mode.

The microcomputer uses three modes of dryer opera-

tion to match the inlet moisture load:

•

Compu-Purge Mode – When the microcom

-

puter adjusts purge air to match dryer load re

-

quirements, the dryer is operating in the

Compu-Purge mode.

•

Standby Mode – When there is low or no de

-

mand for air, the dryer operates in a standby

mode: the dryer purges until the desiccant is re

-

generated, the vessels repressurize, then the

dryer automatically shuts down; the dryer

purges every 30 minutes to assure dew point

performance.

•

Fixed-Cycle Mode – If all sensors malfunction,

the “Variable Purge Mode” light will turn off

and the dryer will automatically operate in a

fixed cycle mode, using 15% of the design air

-

flow to regenerate the offstream vessel. If only

one sensor malfunctions, the dryer will default

to standard conditions for that sensor and con

-

tinue to operate in the Variable Purge Mode.

See Maintenance section, page 1-11, for addi

-

tional information.

AUTOMATIC DRAIN VALVE (ADV)

Dryers rated 200 scfm and larger are equipped with an

electronic drain valve that automatically discharges

condensate from the prefilter.

The ADV has two LED indicators and a test button to

help verify operation. Pushing the test button causes

the drain port to click open. One LED indicates that

power is supplied to the ADV; the other LED indicates

that the drain port is open. The power indicator turns

off when the drain port opens. If either LED fails to

turn on at the proper time, refer to the maintenance

section of this manual. If the dryer is under warranty,

call your local distributor for authorization before

servicing.

ADV operation is controlled by an electronic timer.

The drain opening can be set from 0.5 to 10 sec. The

drain cycle can be set from 0.5 to 45 min.

To minimize air losses, the timer should be adjusted to

open the port just long enough to discharge accumu-

lated condensate. The timer is properly set if nothing

but air vents at the end of the open period. If air vents

for more than a few seconds, set the timer for a longer

cycle or shorter drain opening. If liquid is still dis-

charging when the port closes, set the timer for a

shorter cycle or longer drain opening.

START-UP

Once your HRD/HRD-EM Series dryer has been in

-

stalled according to instructions, it is ready for start-

up.

To start the dryer:

1. Close customer-supplied shutoff valve at dryer in

-

let.

2. Open customer-supplied bypass valve, if installed.

3. Close customer-supplied letdown and shutoff

valves at dryer outlet.

4. Supply compressed air up to inlet shutoff valve.

5. Slowly open inlet shutoff valve and wait for dryer

to reach operating pressure. Pressure gauges on

both dryer vessels will indicate operating pres

-

sure.

6. Check all piping connections for air leaks. Rem

-

edy leaks before continuing start-up.

7. For HRD Series dryers:

HRD and HRD-EM Series (Bulletin 378) 1-9

•

Turn on the power switch located on the control

enclosure. Depending on the position of the

switching valve and specified operating pres

-

sure, one of the vessels will depressurize, or

both vessels will remain pressurized for up to

90 seconds, then one will depressurize.

•

Operate the dryer for three cycles to verify sat

-

isfactory operation. The dryer cycle is 10 min

-

utes with each vessel onstream for five minutes.

8. For HRD-EM Series dryers:

•

Turn on power switch on electrical box.

•

When power switch is turned on “power on”

light will light. Both vessels will remain at

pressure for up to 60 seconds, then one will

depressurize and the green “Variable Purge”

light will light.

•

The LCD display will show in sequence:

DELTECH ENGINEERING, L.P., COPYRIGHT

1988...1991

INLET TEMP. 99° ENERGY SAVINGS = 80%

NO MALFUNCTIONS EXIST

FIRST CYCLE OF OPERATION

USING DEFAULT VALUES

During the next five minutes, the microcom-

puter will check itself for any malfunctions.

The dryer will operate in a fixed-cycle mode,

using 15% purge, during start-up.

At the end of this period, dryer operation will

be computer-controlled, the “Variable Purge

Mode” light will be on and the microcomputer

will automatically control purge rate to match

the dryer load.

The LCD display will show:

INLET TEMP XX ENERGY SAVINGS = XX%

NO MALFUNCTION EXISTS

If there is low or no demand for compressed

air, the dryer will go into the standby mode.

(See Compu-Purge Control section.)

The LCD display will show:

NO LOAD ON DRYER

IN STANDBY MODE: SAVING PURGE AIR

•

Turn alarm silencer switch on front of electrical

box to “ON.”

9. Slowly open the outlet shutoff valve.

10. Close customer-supplied bypass valve.

Dew Point

The pressure dew point of the outlet air is controlled

by the amount of purge air used for reactivation. Purge

airflow is continuous and is adjustable within a set

range. The dew point can be manually adjusted ±20

degrees (depending on operating conditions) using the

purge adjustment valve. Closing the valve will result

in a higher dew point. Opening the valve will result in

a lower dew point. Dryer installation and start-up must

be completed before the purge valve is adjusted.

For applications requiring dew points outside this

range, contact your local distributor.

Dew Point Adjustment

After your dryer has been installed and the start-up

procedure completed, adjust the dryer for a –40°F dew

point as follows.

1. Determine air pressure (psig) at the dryer inlet.

2. Refer to Table 3. For your model and inlet air

pressure, determine the inlet airflow and average

purge rate (% of inlet air) required to produce a

–40°F dew point.

3. Calculate the required purge flow (scfm):

Purge Flow = Purge Rate x Inlet Flow

4. Refer to the purge flow calibration graph shipped

with the dryer. On the graph, locate the average

purge airflow (calculated in Step 3) and the corre-

sponding purge adjustment valve setting (psig).

5. Manually adjust the purge adjustment valve at the

top of the dryer until the correct setting is indi

-

cated on the gauge. For dryers 55 thru 160 , adjust

the purge as follows:

DANGER

Do not remove the petcock base from the

shuttle valve.

•

Unscrew and remove the petcock wing from the

petcock base on the shuttle valve at the top of

the dryer (see

Figure 5).

•

Insert a

3

16

-inch

allen wrench

through the pet

-

cock base to the

set screw.

•

Adjust the set

screw until the

pressure on the

purge gauge cor

-

1-10 HRD and HRD-EM Series (Bulletin 378)

Figure 5

Cutaway of Shuttle Valve

responds to the desired purge rate as indicated

on the purge flow calibration graph. Turn the set

screw counterclockwise to increase the purge

flow; clockwise to decrease the purge flow.

•

Remove the allen wrench.

•

Replace the petcock wing.

CAUTION

Inlet air temperatures higher than 100°F will

reduce the design dew point of the dryer.

The dryer can now be put into service. No further ad

-

justments are necessary unless there are changes in op

-

erating conditions. Within limits, changes in inlet flow

rate can be compensated for by adjusting the purge ad

-

justment valve (repeat Steps 1 through 5 above).

Dew Point Verification

After the dryer has operated for a minimum of five

days, check the dew point of the outlet air with a pres-

sure dew point instrument. Follow the directions for

the instrument used.

Use only metallic tubing when checking dew point

since plastics, rubber and similar materials absorb

moisture from the ambient air and give false readings.

MAINTENANCE

Desiccant Dusting

The dryer vessels for models 56 through 600 scfm are

shipped filled with desiccant. Some dusting will occur

from movement of the desiccant during shipping. Dust

carried by the purge air eventually plugs the mufflers

preventing complete depressurization of the offstream

vessel and proper airflow switching. When this occurs,

the muffler cores must be replaced. Replace muffler

cores when the pressure gauge on the offstream vessel

indicates a pressure higher than 0 psig. Replacement

interval depends on dryer usage and the quantity of

desiccant dust formed.

HRD and HRD-EM Series (Bulletin 378) 1-11

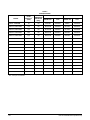

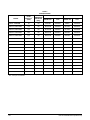

Table 3

INLET AIRFLOW AT VARIOUS INLET AIR PRESSURES

1

Model

Inlet Air Pressure (psig)

30 40 50 60 70 80 90 100 110 125 150

Average Inlet Airflow (scfm)

2

HRD56 / HRD56EM 21 26 31 36 41 45 50 55 60 67 79

HRD100 / HRD100EM 39 48 56 65 74 83 91 100 109 122 144

HRD160 / HRD160EM 62 76 90 104 118 132 146 160 174 195 230

HRD200 / HRD200EM 78 95 113 130 148 165 183 200 217 244 287

HRD275 / HRD275EM 107 131 155 179 203 227 251 275 299 335 395

HRD350 / HRD350EM 136 167 197 228 258 289 319 350 381 426 503

HRD475 / HRD475EM 185 227 268 309 351 392 434 475 516 579 682

HRD600 / HRD600EM 234 286 338 391 443 495 548 600 652 731 862

HRD800 / HRD800EM 312 382 451 521 591 661 730 800 870 974 1149

HRD1000 / HRD1000EM 390 477 564 651 738 826 913 1000 1087 1218 1436

HRD1200 / HRD1200EM 468 572 677 782 886 991 1095 1200 1305 1462 1723

HRD1450 / HRD1450EM 565 691 818 944 1071 1197 1324 1450 1576 1766 2082

HRD1710 / HRD1710EM 666 815 965 1114 1263 1412 1561 1710 1859 2083 2455

HRD2010 / HRD2010EM 783 959 1134 1309 1484 1660 1835 2010 2185 2448 2886

HRD2250 / HRD2250EM 877 1073 1269 1465 1662 1858 2054 2250 2446 2740 3231

HRD2600 / HRD2600EM 1013 1240 1467 1693 1920 2147 2373 2600 2827 3167 3733

HRD3250 / HRD3250EM 1267 1550 1833 2117 2400 2683 2967 3250 3533 3958 4667

Average Purge Rate

(% inlet air)

38.5 31.5 26.6 23.0 20.3 18.2 16.4 15.0 13.8 12.3 10.4

1

Maximum inlet air pressure, 150 psig. Higher pressures available as an option on some models; consult your local distributor

2

Based on 100°F inlet air temperature and –40°F pressure dew point. Maximum recommended inlet temperature, 120°F. For capacity at inlet temperature higher than

100°F, consult your local distributor.

CAUTION

The desiccant beds may fluidize at excessive

airflow rates. Refer to Table 3, page 1-11.

Airflow surges may also cause fluidization.

Surges may occur if the dryer is not started in

accordance with instructions or if the dryer is

located downstream of a receiver.

Conditions that cause fluidization must be

avoided. Fluidization causes excessive

dusting and rapid degradation of the

desiccant, reducing its effective life. Desiccant

dusting causes valves to wear and malfunction

and filters to plug up rapidly.

Shutdown

If the dryer or the air system is shut down desiccant

life can be prolonged by venting the dryer internal

pressure to the atmosphere.

To vent dryer pressure:

1. Turn the power switch OFF.

DANGER

EXPLOSION HAZARD

Dismantling or working on any component of

the compressed air system under pressure

may cause equipment damage and serious

injury. Before dismantling any part of the dryer

or compressed air system, completely vent the

internal air pressure to the atmosphere.

2. Open the customer-supplied bypass valve (if in

-

stalled).

3. Close the customer-supplied shutoff valve down

-

stream of the dryer.

4. Close the customer-supplied shutoff valve up

-

stream of the dryer.

5. Slowly open the customer-supplied depressuriza

-

tion valve to vent the dryer internal air pressure.

6. When the internal air pressure is 0 psig, close the

depressurization valve.

Restart the dryer according to the start-up instructions

on page 1-9.

If electrical maintenance must be performed on the

dryer, electrical power to the dryer must be locked out

and tagged in accordance with OSHA requirements.

DANGER

SHOCK HAZARD

Portions of the electrical control circuit remain

energized when the power switch is turned

OFF. Disconnect the main power supply to the

dryer before performing maintenance on the

electrical system.

Before performing electrical maintenance:

1. Turn the power switch off.

2. Disconnect the main power supply.

Maintenance Schedule

The following periodic checks should be made to

monitor dryer operation. These inspections will help

you schedule servicing to ensure continuing good

dryer performance and safe operation. Maintenance

kits are available from your local distributor (see page

A-1 for a description of each kit.

Action Schedule

Check automatic drain valve Daily

Check system monitor lights Daily

Check filter differential pressure indicators Weekly

Check exhaust mufflers Weekly

Check purge exhaust valves Weekly

Inspect internal float drain on filters (if equip-

ped)

Monthly

Inspect desiccant Yearly

Replace solenoid and butterfly valve dia

-

phragms and seats

Yearly

Replace prefilter and afterfilter elements. Yearly

CAUTION

Contact your local distributor before doing any

work on the solid state controls. Attempting to

service circuit boards or components may

result in equipment damage and will void the

warranty.

Daily

1. For dryers rated 600 to 3,250 scfm, check the fil

-

ter above the dryer inlet.

2. Check automatic drain valve on prefilter (if

equipped) for discharge. If no condensate dis

-

charges from drain valve, follow Shutdown proce

-

dure (page 1-12), then dismantle and clean, repair

or replace drain valve as required.

1-12 HRD and HRD-EM Series (Bulletin 378)

3. Check the switch-failure alarm light on the control

panel. If the light is on, refer to the Field Service

Guide for remedy.

4. Check the color of the moisture indicator in the

dryer outlet. When the dryer is functioning nor

-

mally, the indicator is green. If the indicator is

yellow, refer to the Field Service Guide, page

1-20, for remedy.

For HRD-EM Series only:

5. Check system monitoring lights on bottom half of

indicating light panel. If any light is lit, see expla

-

nations in Indicators section, page 1-7, for diagno

-

sis and Field Service Guide, page 1-20, for

remedy.

6. Check the high-humidity alarm light on the con

-

trol panel. If the light is on, refer to the Field Ser

-

vice Guide for remedy.

Weekly

1. Check prefilter and afterfilter differential pressure

indicators. Replace filter elements in accordance

with manufacturer’s directions.

2. Check exhaust muffler for discharge of air from

regenerating vessel. If no air discharges, disman-

tle and clean or replace muffler core. If no air dis-

charges when muffler is removed, call your local

distributor.

3. Check purge valves for leakage. Rebuild if any

leakage is evident.

Monthly

Inspect the internal float drain valve (if equipped)

every two to three weeks for excessive oil and water

by pressing the test valve on the bottom of the filter

unit. If more than one or two drops of oil leak out, the

drain valve should be cleaned or replaced as required.

Yearly

Note

Maintenance kits for yearly preventive

maintenance are available from your local

distributor. See Appendix A for the

maintenance kit part numbers.

1. Inspect desiccant in dryer vessels. Depressurize

dryer according to Shutdown section of this man

-

ual. Check for the following and correct as indi

-

cated:

•

Oil Contamination

If desiccant is contaminated with oil, check

drain valve on prefilter. Clean, repair or replace

drain valve as necessary. Replace prefilter ele

-

ment, then replace desiccant.

•

Broken Desiccant (excessive dusting)

Desiccant dusting may be caused by air flow

surges, excessive air flow or pulsating air pres

-

sure. Check and correct these conditions, then

replace desiccant.

2. Replace all solenoid and butterfly valve dia

-

phragms and seats.

3. Replace all prefilter and afterfilter elements.

Returns to Manufacturer

If the dryer or a component of the dryer must be re

-

turned to the manufacturer, first call your local dis

-

tributor for a return authorization number and a

shipping address. Your distributor will inform you

whether the dryer or only the component must be re

-

turned.

Desiccant Replacement

All dryers use activated alumina desiccant. To ensure

consistent dryer performance and to prevent excessive

dusting or premature desiccant breakdown, use only

factory-approved grades of activated alumina when re-

placing desiccant.

To replace desiccant:

DANGER

EXPLOSION HAZARD

Completely vent the internal air pressure to the

atmosphere before replacing the desiccant or

performing any maintenance work on your

dryer.

1. Depressurize dryer according to the shutdown in

-

structions (page 1-12). Pressure gauges on both

vessels must indicate 0 psig before service contin

-

ues.

2. Turn off power switch on control panel.

DANGER

SHOCK HAZARD

Portions of the electrical control circuit remain

energized when the power switch is turned

OFF. Disconnect the main power supply to the

dryer before performing maintenance on the

electrical system.

3. Disconnect the main power supply to the dryer.

4. Lock out and tag electrical power supply in accor

-

dance with OSHA requirements.

HRD and HRD-EM Series (Bulletin 378) 1-13

5. Place large containers under drain outlets at bot-

tom of vessels to collect desiccant.

6. Remove desiccant drain plug (refer to Figure 6).

7. Tap sides of vessels with rubber mallet to loosen

desiccant.

8. Remove fill plug at top of each vessel.

9. Shine flashlight through fill port and inspect in

-

side of vessels to be sure all desiccant is removed.

10. Replace desiccant drain plug.

11. Determine the amount of desiccant according to

Table 2, page 1-5.

CAUTION

Pouring desiccant creates a fine dust; safety

goggles, gloves and dust mask should be

worn by personnel installing desiccant. Refer

to the Material Safety Data Sheet (MSDS) on

page 1-23 for more complete information.

Do not tamp the desiccant in vessels. Tamping

damages desiccant and causes dusting.

12. Pour required desiccant into vessels through fill

ports.

13. Replace fill plugs at top of vessels.

Restart the dryer according to the start-up instructions

on page 1-9.

Filter Element Replacement

Coalescing and particulate filters are included with all

dryers. The filter elements should be replaced when

the D P gauge on top of the filter reads 7 to 10 or once

a year, whichever comes first. Refer to Table 4 for the

replacement element part numbers. Replace elements

in accordance with the following instructions.

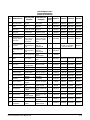

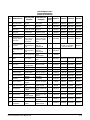

Table 4

REPLACEMENT ELEMENTS

DRYER MODEL NO.

REPLACEMENT ELEMENT

PART NO.

Coalescing

Prefilter

(CHE Series)

Particulate

Afterfilter

(PC Series)

HRD56 / HRD56EM 39240908 39241104

HRD100 / HRD100EM 39240916 39241112

HRD160 / HRD160EM 39240924 39241138

HRD200 / HRD200EM 39240932 39241146

HRD275 / HRD275EM 39240940 39241146

HRD350 / HRD350EM 39240940 39241153

HRD475 / HRD475EM 39240940 39241179

HRD600 / HRD600EM 39240957 39241179

HRD800 / HRD800EM 39240973 39241187

HRD1000 / HRD1000EM 39240973 39241195

HRD1200 / HRD1200EM 39240981 39241203

HRD1450 / HRD1450EM 39240965 (Qty 2) 39241187 (Qty 2)

HRD1710 / HRD1710EM 39240973 (Qty 2) 39241195 (Qty 2)

HRD2010 / HRD2010EM 39252440 39252580

HRD2250 / HRD2250EM 39252457 39252598

HRD2600 / HRD2600EM 39252465 39252606

HRD3250 / HRD3250EM 39252473 39252614

Dryers rated 56 to 1,200 scfm:

DANGER

Vent internal pressure to atmospheric

pressure before performing any maintenance.

1. Vent internal pressure to the atmosphere. Refer to

Shutdown instructions on page 1-12.

2. Disconnect drain lines at manual and automatic

drain valves (if installed).

1-14 HRD and HRD-EM Series (Bulletin 378)

Figure 6

DESICCANT DRAIN/FILL PORTS

(Side View of Dryer)

DANGER

A “hissing” sound while the bowl is being

removed indicates the filter has not been

properly depressurized. DO NOT continue to

remove the bowl until the filter has been

completely vented to atmospheric pressure.

CAUTION

Filter bowls may be heavy. Caution should be

taken when removing the bowl.

3. Remove the bottom bowl by unscrewing it from

the head. A strap wrench may be needed.

4. Remove the element from the filter head with a

brisk downward pull, or by working the element

back and forth and pulling down until it snaps

free. Discard the element in accordance with ap

-

plicable regulations. Used elements typically hold

contaminants, such as compressor lubricants and

particulate matter.

Note: The element may be unsnapped by DPin

normal operation. This will not affect filtra-

tion, as the O-ring on the element maintains a

positive seal.

5. Clean accumulated debris from the bowl with

soap and water, and dry thoroughly.

CAUTION

Lubricate the O-ring with a petroleum-based

lubricant compatible with your application.

6. Lightly lubricate the new O-ring before installing

the new element.

7. Insert new element, snapping it into place with a

firm push up into the head. The element will hang

from the head until the bowl is installed.

CAUTION

Lubricate the O-ring with a petroleum-based

lubricant compatible with your application.

8. Lightly lubricate the housing O-ring.

CAUTION

Do not use a pipe wrench to tighten the filter

bowl to the head.

9. Reattach bowl to head and hand tighten. As the

bowl is threaded onto the head, supports in the

bottom of the bowl ensure a proper seal between

the element and the filter head.

10. Reattach drain lines (if applicable).

11. Record the date of the element change in a record

book or on the provided “Maintenance Reminder”

label. A new element

change label with the up-

dated information should

be applied over the pre

-

vious label each time the

element is replaced.

Restart the dryer according to the start-up instructions

on page 1-9.

Dryers rated 1,450 to 3,250 scfm:

DANGER

Vent internal pressure to atmospheric

pressure before performing any maintenance.

1. Vent internal pressure to the atmosphere. Refer to

Shutdown instructions on page 1-12.

2. Disconnect drain lines at automatic drain valve (if

installed).

3. Remove bolts securing the filter top to the vessel.

4. Remove the filter top.

5. Remove the element retainer plate.

HRD and HRD-EM Series (Bulletin 378) 1-15

Figure 7

Filter

6. Remove the used element cartridges. Discard the

element in accordance with applicable regula-

tions. Used elements typically hold contaminants,

such as compressor lubricants and particulate mat-

ter.

7. Insert new element cartridges in filter.

8. Replace the element retainer plate.

9. Replace filter top.

10. Reinstall bolts to secure filter top.

11. Reattach drain lines (if applicable).

12. Record the date of the ele

-

ment change in a record

book or on the provided

“Maintenance Reminder”

label. A new element

change label with the up

-

dated information should be

applied over the previous

label each time the element

is replaced.

Restart the dryer according to the start-up instructions

on page 1-9.

Servicing The Internal Float Drain Valve (If

Equipped)

DANGER

Vent internal pressure to atmospheric

pressure before performing any maintenance.

1. Vent internal pressure to the atmosphere. Refer to

Shutdown instructions on page 1-12.

2. Disconnect drain lines and automatic drain valves

(if installed).

DANGER

A “hissing” sound while the bowl is being

removed indicates the filter has not been

properly depressurized. DO NOT continue to

remove the bowl until the filter has been

completely vented to atmospheric pressure.

CAUTION

Filter bowls may be heavy. Take caution when

removing the bowl.

3. Remove the bottom bowl by unscrewing it from

the head. A strap wrench may be needed.

4. Remove the nut from the bottom of the bowl.

5. Turn the bowl upside down. The float drain will

fall out.

6. Inspect the drain for damage. Replace if necessary

or clean with a mild soap and water. Do not use

solvents to clean the drain valve as they may dam

-

age the valve.

7. Hold the bowl upright and drop in the new or

cleaned drain so that the drain stem is through the

hole at the bottom of the filter.

8. Replace the nut and hand tighten.

CAUTION

Do not use a pipe wrench to tighten the filter

bowl to the head.

9. Reattach bowl to head and hand tighten.

10. Reattach the drain line (if applicable).

Restart the dryer according to the start-up instructions

on page 1-9.

1-16 HRD and HRD-EM Series (Bulletin 378)

Figure 8

Filter

Automatic Drain Valve (ADV) Disassembly

and Servicing

Dryers rated 200 scfm and larger have a timer-

controlled automatic drain valve.

CAUTION

Do not disassemble the ADV timer or attempt

to repair electrical parts. Replace timer if

defective.

The ADVs discharge condensate through a full-port

drain opening. The valve body may need to be cleaned

under conditions of gross particulate contamination.

To disassemble the ADV valve body for cleaning or

other maintenance (refer to Figure 9):

1. Turn power switch off.

2. Disconnect main power supply to dryer.

3. Lock out and tag power supply in accordance with

OSHA requirements.

WARNING

If power supply is not disconnected before

disassembly, serious personal injury and

valve damage may result.

4. Remove hose that connects the ADV to the filter.

5. Remove screw and washer from front of ADV.

6. Remove the power supply connector and gasket

(with the timer assembly, if attached) from the so

-

lenoid coil housing. Do not damage or lose the

gasket.

7. Remove 13 mm nut and spring washer from top of

solenoid coil housing.

8. Lift solenoid coil housing off solenoid core in

valve body.

9. Unscrew solenoid core from valve body.

Once the ADV is disassembled, the following mainte

-

nance can be performed:

1. Inspect diaphragm; clean or replace as required.

2. Remove debris from the valve body.

3. Wipe solenoid core components with a clean cloth

or blow out debris with compressed air from and

OSHA-approved air nozzle that limits the dis

-

charge pressure to 30 psig.

4. Check that small port in diaphragm assembly is

clear and solenoid coil moves freely in housing.

Viton diaphragm seals are compatible with com-

monly used synthetic lubricants.

5. If timer is attached to valve body, check electrical

continuity across timer assembly.

To reassemble the ADV, reverse the sequence of the

preceding steps. After the ADV is reassembled, con-

nect the main power supply to the dryer. When the

HRD and HRD-EM Series (Bulletin 378) 1-17

Figure 9

AUTOMATIC DRAIN VALVE COMPONENTS

dryer is returned to service, check the ADV for air or

condensate leaks; tighten connections as required to

correct leaks. Check the drain cycle; adjust the timer

according to the procedure in the ADV Adjustment

section.

High-Humidity Alarm Field Adjustment

(HRD-EM only)

The high-humidity alarm is a feature on the HRD-EM

Series dryers.

To set the high-humidity alarm:

1. Turn power switch OFF.

DANGER

SHOCK HAZARD

Portions of the electrical control circuit remain

energized when the power switch is turned

OFF. Disconnect the main power supply to the

dryer before performing maintenance on the

electrical system.

2. Open the door of the electrical control box.

3. Locate the high-humidity alarm circuit board (ref-

er to Figure 10).

4. A calibrated set plug (refer to Figure 11) is

shipped loose inside the electrical box. The set

plug is used to select the setting at which the

high-humidity alarm sounds.

5. Remove the conduit connector (¾-inch) from the

outlet piping.

6. Unplug the white receptacle and insert the set

plug into the ribbon cable socket.

7. Unplug CON 8 from bottom right hand corner of

the control board.

8. Unplug CON 10 from right side of the control

board.

9. Connect a continuity tester to cable R (CON 10

PIN 1) and cable S (CON 8 PIN 2). The continu

-

ity tester is now connected across normally open

alarm contacts.

10. Turn the power switch to ON.

11. Set the alarm silencer switch to OFF. This switch

is on the door of the control box.

12. With a small slotted screwdriver, adjust P1 on the

high-humidity circuit board (Figure 10) clockwise

and counterclockwise. Find the adjustment point

where the contacts open and close. Leave adjust-

ment where the contacts just close.

NOTE: DO NOT ADJUST POTENTIOME-

TER P3.

13. Put a drop of lacquer on potentiometer P1 to pre-

vent vibrations from altering the setting.

14. Turn the power switch to OFF.

1-18 HRD and HRD-EM Series (Bulletin 378)

Figure 11

SET PLUG

Figure 10

HIGH-HUMIDITY ALARM CIRCUIT BOARD

POTENTIOMETERS P1 & P3

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

dans d''autres langues

- English: Sigma HRD2250EM User manual

- español: Sigma HRD2250EM Manual de usuario

Autres documents

-

Ecolab MP-MA-Dual Pressure Series Mode d'emploi

-

Ingersoll-Rand HF50–PE Manuel utilisateur

-

Elster Vanne axiale (AFV) Mode d'emploi

-

Blitz HHD 81 Operation and Maintenance Manual

-

Ingersoll-Rand D54IN Manuel utilisateur

-

Ingersoll Rand 23231624 Manuel utilisateur

-

Ingersoll Rand 23231806 Manuel utilisateur

-

Ingersoll-Rand SSR UP6-7.5 Operation and Maintenance Manual

-

Ingersoll-Rand TS5A Operation and Maintenance Manual

-

Ingersoll-Rand UP6 30 HP Option Manual