REFRIGERATOR CARE

Explosion Hazard

Use nonflammable cleaner.

Failure to do so can result in death, explosion, or fire.

Both the refrigerator and freezer sections defrost automatically.

However, clean both sections about once a month to avoid

buildup of odors. Wipe up spills immediately.

IMPORTANT: Because air circulates between both sections, any

odors formed in one section will transfer to the other. You must

thoroughly clean both sections to eliminate odors. To avoid odor

transfer and drying out of food, wrap or cover foods tightly.

To Clean Your Refrigerator:

NOTE: Do not use abrasive or harsh cleaners such as window

sprays, scouring cleansers, flammable fluids, cleaning waxes,

concentrated detergents, bleaches or cleansers containing

petroleum products on plastic parts, interior and door liners or

gaskets. Do not use paper towels, scouring pads, or other harsh

cleaning tools.

1. Unplug refrigerator or disconnect power.

2. Hand wash, rinse, and dry removable parts and interior

surfaces thoroughly. Use a clean sponge or soft cloth and a

mild detergent in warm water.

3. Wash stainless steel and painted metal exteriors with a clean

sponge or soft cloth and a mild detergent in warm water.

• To keep your stainless steel refrigerator looking like new

and to remove minor scuffs or marks, it is suggested that

you use the manufacturer's approved Stainless Steel

Cleaner and Polish, Part Number 20000008. To order the

cleaner, call 1-877-232-6771 U.S.A. or 1-800-807-6777

Canada.

4.

IMPORTANT: This cleaner is for stainless steel parts only!

Do not allow the Stainless Steel Cleaner and Polish to come

into contact with any plastic parts such as the trim pieces,

dispenser covers or door gaskets. If unintentional contact

does occur, clean plastic part with a sponge and mild

detergent in warm water. Dry thoroughly with a soft cloth.

There is no need for routine condenser cleaning in normal

home operating environments. If the environment is

particularly greasy or dusty, or there is significant pet traffic in

the home, the condenser should be cleaned every 2 to

3 months to ensure maximum efficiency.

If you need to clean the condenser:

• Remove the base grille.

• Use a vacuum cleaner with a soft brush to clean the grille,

the open areas behind the grille and the front surface area

of the condenser.

• Replace the base grille when finished.

5. Plug in refrigerator or reconnect power.

NOTE: Not all appliance bulbs will fit your refrigerator. Be sure to

replace the bulb with an appliance bulb of the same size, shape,

and wattage (no greater than 40 watts).

1. Unplug the refrigerator or disconnect power.

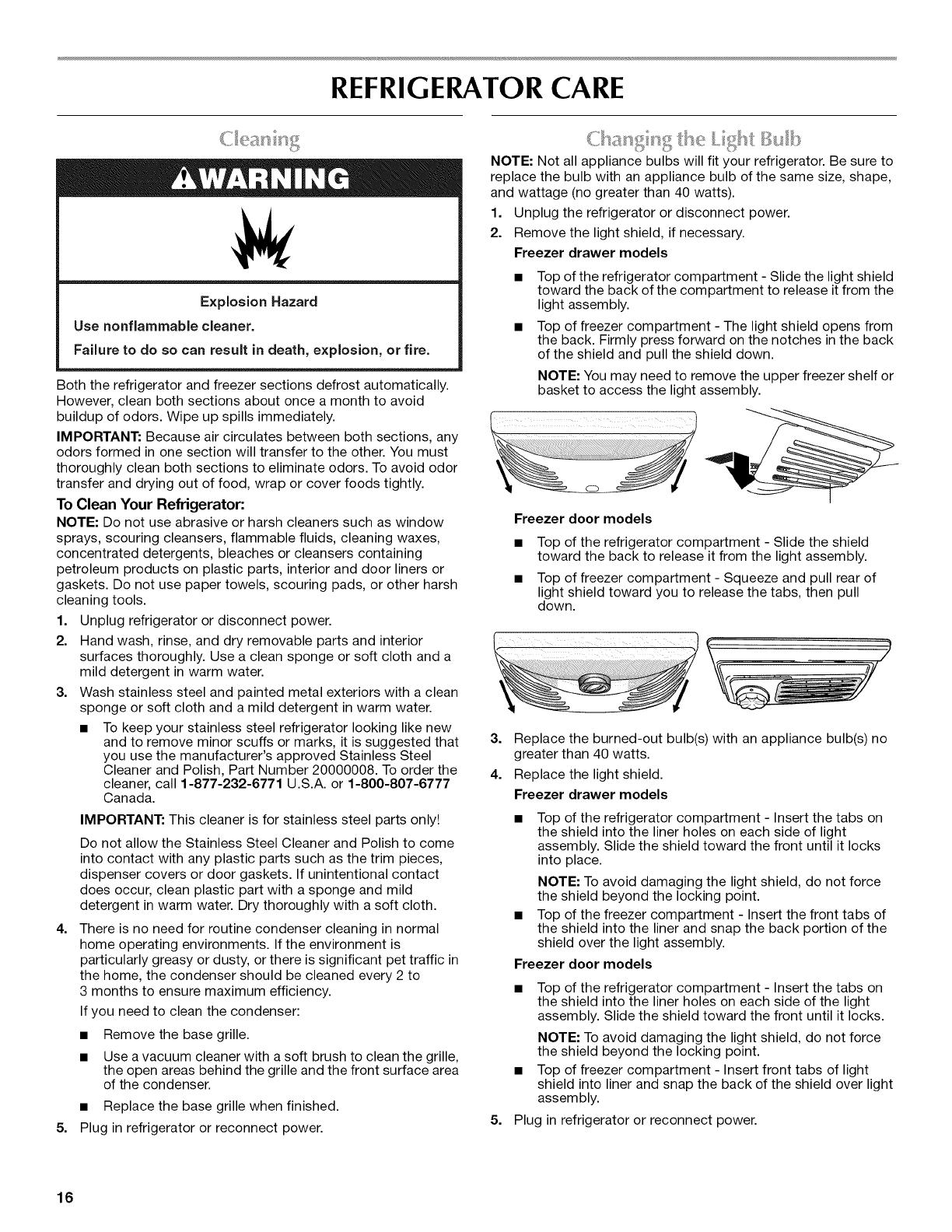

2. Remove the light shield, if necessary.

Freezer drawer models

Top of the refrigerator compartment - Slide the light shield

toward the back of the compartment to release it from the

light assembly.

Top of freezer compartment - The light shield opens from

the back. Firmly press forward on the notches in the back

of the shield and pull the shield down.

NOTE: You may need to remove the upper freezer shelf or

basket to access the light assembly.

Freezer door models

Top of the refrigerator compartment - Slide the shield

toward the back to release it from the light assembly.

Top of freezer compartment - Squeeze and pull rear of

light shield toward you to release the tabs, then pull

down.

3. Replace the burned-out bulb(s) with an appliance bulb(s) no

greater than 40 watts.

4. Replace the light shield.

Freezer drawer models

Top of the refrigerator compartment - Insert the tabs on

the shield into the liner holes on each side of light

assembly. Slide the shield toward the front until it locks

into place.

NOTE: To avoid damaging the light shield, do not force

the shield beyond the locking point.

Top of the freezer compartment - Insert the front tabs of

the shield into the liner and snap the back portion of the

shield over the light assembly.

Freezer door models

Top of the refrigerator compartment - Insert the tabs on

the shield into the liner holes on each side of the light

assembly. Slide the shield toward the front until it locks.

NOTE: To avoid damaging the light shield, do not force

the shield beyond the locking point.

Top of freezer compartment - Insert front tabs of light

shield into liner and snap the back of the shield over light

assembly.

5. Plug in refrigerator or reconnect power.

16