Miller DYNASTY 280 MODBUS EXPANSION Le manuel du propriétaire

- Catégorie

- Système de soudage

- Taper

- Le manuel du propriétaire

© 2020 MILLER Electric Mfg. LLC

OWNER’S MANUAL FORM: OM-265415J 2020-06

For Modbus Expansion On Dynasty

/Maxstar

Models

1. Safety Symbol Definitions

DANGER! − Indicates a hazardous situation which, if not

avoided, will result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained

in the text.

DANGER ! - Indique une situation dangereuse qui, si elle

n’est pas évitée, entraînera la mort ou des blessures

graves. Les éventuels risques sont représentés par les

symboles joints ou expliqués dans le texte.

Fsafe1 2013-10

Have only trained and qualified persons install, operate,

or service this unit. Read the safety information at the

beginning of these instructions and in each section. Call

your distributor if you do not understand the directions.

For WELDING SAFETY and EMF information, read own-

er’s manual(s).

Ne confiez l’installation, l’exploitation ou l’entretien de cet

appareil qu’à des personnes compétentes et qualifiées. Lire

les directives de sécurité au début de ces instructions et

dans chaque section. Appeler votre distributeur si vous

ne comprenez pas les directives. Lire le(s) manuel(s)

d’utilisateur pour des renseignements sur la SÉCURITÉ

DE SOUDAGE et les champs électromagnétiques.

Fsafe15 2013-10

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible ha-

zards are shown in the adjoining symbols or explained in

the text.

Indique une situation dangereuse qui, si elle n’est pas

évitée, entraînera la mort ou des blessures graves. Les

éventuels risques sont représentés par les symboles

joints ou expliqués dans le texte.

Fsafe2 2013-10

Wear safety glasses with side shields.

Porter des lunettes de sécurité avec écrans latéraux.

Fsafe8 2013-10

NOTICE

Indicates statements not related to personal injury.

Signale des consignes non associées aux dommages

corporels.

Indicates special instructions.

Fournit des instructions spéciales.

Fsafe3 2013-10

CALIFORNIA PROPOSITION 65 WARNINGS

WARNING: Cancer and Reproductive Harm −

www.P65W

arnings.ca.gov

PROPOSITION CALIFORIENNE 65 AVERTISSEMENTS

AVERTISSEMENT : cancer et troubles de la reproduction −

www.P65W

arnings.ca.gov

.

Fsafe26 2018-01

2. Software Expansion

1

2

. A software update is required to ensure proper

operation of all purchased feature expansions.

For instructions to download TIG Software up-

dates, see PDF file F26927 on software expan-

sion memory card.

Card Requirements:

. Purchased software expansion memory card

required.

1 Memory Card Port

2 Indicator LED

Enabling Software Expansion:

Insert card containing software expansion into port.

LED indicator blinks green while machine is reading

from or writing to the card. After successfully read-

ing from or writing to the card, the LED switches

from blinking green to continuous green. The ma-

chine is now ready to use software expansion. Do

not remove card while LED is blinking green.

. Software expansion card must remain in mem-

ory card port to enable software expansion.

Disabling Software Expansion:

Remove the software expansion card from the

memory card port.

Troubleshooting:

Problem: Indicator LED is continuous red.

Remedy: Remove and reinsert card. If problem

continues, the card is bad. Contact Factory Autho-

rized Service Center for a replacement card.

The memory card port uses an SD memory card.

The SD Logo is a trademark of the SD-3C LLC

Company.

Modbus Expansion − Enabling the Modbus expansion configures Remote 14 sockets L, M and N for Modbus control in Dynasty and Maxstar Models.

Modbus serial communication provides access to all front panel parameters and machine functionality. Modbus expansion also includes functionality

of Automation(OM-265411), AC Independent Expansion(Dynasty only, OM-267827), Hot Wire (OM-273055), and Hot Start Adjust (OM-276515).

. When Modbus Expansion is used in a Dynasty 210 or 280 DX CE machine, the user Menu ENEP selection is not accessible. AC Independent

is always enabled.

. Owner’s Manuals OM-265415 , OM-265411, OM-267827, OM-273055, and OM-276515 can be found on the memory card. Software updates

may make all OMs listed, and this OM obsolete. The latest revisions of all OMs can be downloaded from www

.Millerwelds.com

Additional Parts Required: Plug and pins required to connect to the Dynasty or Maxstar Remote 14 receptacle can be obtained from Miller Electric

Mfg. Co. Parts Dept.: Order Part No. 141162 − Housing Plugs + Pins (service kit), and install according to instructions provided with the kit.

OM-265415 Page 2

3. Software Licensing Agreement

The End User License Agreement and any third-party notices and terms and conditions pertaining to third-party software can be found at

https://www

.millerwelds.com/eula

and are incorporated by reference herein.

4. Information About Default Weld Parameters And Settings

NOTICE − Each welding application is unique. Although certain Miller Electric products are designed to determine and default to certain typical welding

parameters and settings based upon specific and relatively limited application variables input by the end user, such default settings are for reference

purposes only; and final weld results can be affected by other variables and application-specific circumstances. The appropriateness of all parameters

and settings should be evaluated and modified by the end user as necessary based upon application-specific requirements. The end user is solely

responsible for selection and coordination of appropriate equipment, adoption or adjustment of default weld parameters and settings, and ultimate

quality and durability of all resultant welds. Miller Electric expressly disclaims any and all implied warranties including any implied warranty of fitness

for a particular purpose.

5. Remote 14 Receptacle Information

805497-A

AJ

B

K

I

C

L

NH

D

M

G

E

F

Socket Socket Information

15 VOLTS DC

OUTPUT

CONTACTOR

A Contactor control +15 volts DC, referenced to G.

B Contact closure to A completes 15 volts DC

contactor control circuit and enables output.

REMOTE

OUTPUT

CONTROL

C Output to remote control; +10 volts DC output to

remote control.

D Remote control circuit common.

E 0 to +10 volts DC input command signal from

remote control.

*Reconfigurable as input for Output Enable (Weld

Stop) − used to remotely stop the weld outside the

normal welding cycle. Connection to the D socket

must be maintained at all times. If the connection

is broken, output stops, and Auto Stop is dis-

played.

Output

Signals

F Current feedback; +1 volt DC per 100 amperes.

H Voltage feedback; +1 volt DC per 10 volts output.

I* Valid arc indication closed to socket G with valid

arc. Electrical specifications: open collector tran-

sistor

J*

**

Arc length control lockout closed to socket G dur-

ing Initial and Final Amperage and Slope, and dur-

ing the background time of a <=10 Hz pulse wave-

form. Electrical specifications: open collector tran-

sistor

Touch Sense Detection closed to Socket G, with

Modbus’s Touch Sense enabled and machine not

triggered for weld output.

COMMON

G Return for all output signals: F, H, I, J and A.

CHASSIS

K Chassis

Serial

Communication

Bus

L** Modbus Common (RS485 Common)

M** Modbus D1 (RS485 B+)

N** Modbus D0 (RS485 A-)

. If a remote hand control, like the RHC-14, is connected to the Remote 14 receptacle, some current value above min. must be set on the remote

control before the Panel or Remote contactor is turned on. Failure to do so will cause current to be controlled by the panel control, and the remote

hand control will not function.

*Available with optional Automation Expansion memory card.

**Available with optional Modbus Expansion memory card. Modbus serial communication provides access to all front panel parameters and

machine functionality. See Owner’s Manual 265415 for a list of Modbus registers. Modbus expansion also includes functionality of Automation,

AC Independent Amplitude (Dynasty 210/280 only), Hot Wire and Hot Start Adjust Expansions.

Sockets G and K are electrically isloated from each other.

OM-265415 Page 3

6. Simple Automation Application

R

CR1

+

−

CR1

To User Equipment

Coil resistance plus R

should be chosen to

limit current to 75 mA

User supplied power

up to 27 volts DC

peak

Pin I, J: Collector

Pin G: Emitter

7. Communication Specifications

References: Modbus_Application_Protocol_V1_1b3.pdf

Modbus_over_serial_line_V1_02.pdf

. References available online via search engine.

Communication Hardware: 2-wire system RS−485

Compliant Standard: EIA RS−485

Baud Rate: 9600 bps, 19200bps

Maximum Communication Distance: 1200 m

Maximum Number Of Connectable Devices: 31

Transmission Mode: RTU

8. Modbus Slave Configuration

ADDR

SLAV

1

2

3

. See ADVANCED MENU FUNCTIONS in the Dynasty/Maxstar

Owner’s Manual for additional information on Accessing Tech

Menu options.

The Modbus slave configuration will appear at the end of the Tech

Menu.

1 Parameter Display

2 Setting Display

3 Encoder

Rotate Encoder to adjust parameter setting.

[SLAV] Slave Configuration - Right display will flash between slave configuration selection and its’ setting. Step through Modbus slave

configuration selection using the Dynasty/Maxstar “MENU” or the Dynasty/Maxstar DX “A” button. Rotate encoder to adjust setting.

[ADDR] − Slave Address − 1 (default) – 247 NOTICE: If more than one slave is set to the same address, an abnormal behavior of the

whole serial bus can occur.

[BAUD] − Slave Baud Rate - 19.2K (default) or 9600 baud.

[PRTY] − Slave Parity - EVEN (default), ODD or NONE.

OM-265415 Page 4

9. Modbus Implemented Function Codes

Table 5-1. Modbus Function Codes

Function Code

Read Coils 1

Read Discrete Inputs 2

Read Holding Registers 3

Read Input Registers 4

Write Single Coil 5

Write Single Register 6

Write Multiple Coils 15

Write Multiple Holding Registers 16

10. Modbus Implemented Exception Codes

Table 6-1. Modbus Exception Codes

Exception Code

Illegal Function 01

Illegal Data Address 02

Illegal Data Value 03

Server Device Failure 04

Server Device Busy 06

11. Modbus Coils, Discrete Inputs, Input Registers, Holding Registers

Notes:

See Dynasty Maxstar Owner’s Manual for further understanding of functions controlled by most Modbus Coils, Discrete Inputs, Input Registers and

Holding Registers.

Input and Holding Registers with L (Low) and H (High) indicate two 16 bit registers combined to form 32 bit values. Read both L/H paired Input or

Holding Registers at the same time to insure valid data values. Write L/H paired Holding Registers with function code “16 - Write Multiple Holding

Registers” with address range including both registers. Failure to do so will result in exception response ILLEGAL DATA VALUE.

* Coil, User Interface Disable, may need to be set True to allow ”*” marked Coils and Holding Registers to be set without User Interface interference.

With User Interface disabled, all “*” marked Coils and Holding Registers should be set for desired function.

** AC capable (Dynasty) power source only.

*** “AC Weld Amperage” (Aw), “AC EN Amperage” (Aen), “AC EP Amperage” (Aep) and “AC Balance”(%bal = % of “AC EN Amperage”) are linked

together where:

Setting “Aen”, “Aep” or “%bal”, will set “Aw” with:

Aw = ((Aen * %bal) + (Aep * (1 - %bal)))

Ratio of “Aen” to “Aep” will be stored to be referenced when “Aw” is set.

When setting “Aw”:

“Aen” and “Aep” will track their last stored ratio while adjusting “Aw”.

“Aw” will effectively be held to limits greater than “Preset Amps Min” or less than “PS Amps Max” when “Aen” or “Aep” reaches either

“Preset Amps Min” or “PS Amps Max”.

With “Aen” and “Aep” set to the same value, “Aen” and “Aep” will track to the same value set in “Aw”.

OM-265415 Page 5

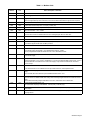

Table 7-1. Modbus Coils

PDU

Address Coil Name / Description / Resolution

0000 0001 *User Interface Disable: 1 True / 0 False.

0001 0002 Remote Trigger (14-Skt B / Contactor) Disable: 1 True / 0 False.

0002 0003 Trigger (Contactor) Request: 1 True(1 Second Time Out Return To False) / 0 False. To continue a weld se-

quence through Final Slope and or Final Time, Coil must be refreshed with False throughout these sequences.

0003 0004 Gas Request: 1 TRUE(1 Second Time Out Return To False) / 0 False.

0004 0005 *,**AC Power Source’s Output DC: 1 True (DC) / 0 False (AC).

0005 0006 *,**AC Power Source’s DC Polarity EP: 1 True (EP) / 0 False (EN).

0006 0007 *Stuck Check Enable: 1 True / 0 False.

0007 0008 *Hot Start Enable: 1 True / 0 False.

Note: Hot Start can also be Disabled with 0 time set in Holding Register 6215 Hot Start Time

0008 0009 *Boost Enable: 1 True / 0 False.

0009 0010 *Droop Enable: 1 True / 0 False.

0010 0011 *Open Circuit Voltage (OCV) Low Enable: 1 True (Low) / 0 False (Normal).

OCV selection applies to both Stick and MIG processes.

0011 0012 *Weld Gas Enable: 1 True / 0 False Enables Gas With Contactor.

0012 0013 Non CE Models Only

Cooler Power Supply (CPS) Enable: 1 True (Parallel With Coil 0014) / 0 False.

Note: Dynasty/Maxstar 210/280 CE Models Have No Control, Read Returns False.

0013 0014 *Cooler Power Supply (CPS) TIG Enable: 1 True (Parallel With Coil 0013) / 0 False TIG Process Control Of

Cooler Power Supply.

0014 0015 Dynasty/Maxstar 210/280 Models Only

*Cooler Error Enable: 1 True / 0 False Enables Error “1.3.6 No Cooler Detected With Output Current”. Error Is

Generated When No Load Detected On Cooler Power Supply’s Output With Load Detected On The Power

Source’s Output.

0015 0016 Touch Sense Enable: 1 True / 0 False.

Touch Sense Detection found at Modbus Discrete Input 2009 Or Remote 14 Receptacle Socket J.

0016 0017 RMS Enable: AC Amperage Preset And Meter And/Or DC Pulse Amperage Meter:1 True (RMS) / 0 False (Av-

erage)

Note: To Enable, Must Have Discrete Input 2013 RMS Hardware Detect = True.

0017 0018 *Pulser Enable: 1 True / 0 False.

Note: Can also be set TRUE / FALSE when writing values to Holding Register 6305 Pulser Pulses Per Second

(PPS).

When enabled and Holding Register 6305 PPS is found at “0”, PPS will be set to a default value.

0018 0019 Dynasty/Maxstar 400/800 Models Only

*AC Commutation Amperage LOW ENABLE: 1 TRUE (LOW) / 0 FALSE (High)

0019 0020 *AC Independent Enable: 1 True / 0 False. Enables/Disables Both Independent Amperage and Independent AC

Wave Shapes.

0020 0021 *Weld Timers Enable: 1 True / 0 False. Weld Timers Include Weld (Spot), Intial Amperage and Final

Amperage Timers.

OM-265415 Page 6

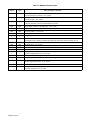

Table 7-2. Modbus Discrete Inputs

PDU

Address

Discrete

Input Name / Description / Resolution

2000 2001 Dynasty/Maxstar 210/280 Models Only

Cooler Power Supply (CPS) Detect: 1 True / 0 False.

2001 2002 Dynasty/Maxstar 210/280 Models Only

Cooler Load Detect: 1 True / 0 False.

2002 2003 Foot/Finger Tip Control Detect: 1 True / 0 False Note: Holding Register 6205 (Remote 14-Skt E) Must Be Con-

figured To 0 (Amperage Control) To Detect Foot/Finger Tip Control.

2003 2004 Remote Trigger (Contactor 14-Skt A-B) Enable: 1 True / 0 False.

2004 2005 Contactor Output Enabled: 1 True / 0 False (Contactor Output Or Sense Voltage Pre Contactor Output).

2005 2006 Gas Output Enabled: 1 True / 0 False.

2006 2007 Valid Arc: 1 True / 0 False.

2007 2008 Arc Length Control Lock Out: 1 True / 0 False.

2008 2009 Touch Sense Detect: 1 True / 0 False. Touch Sense Enable (Coil 16) Must Be Set True With Machine’s State

(Input Register 4101) In Standby, And Weld Output Shorted For Touch Sense Detect To Register As True.

2009 2010 CE Model Detect: 1 True / 0 False

2010 2011 STR Model Detect: 1 True / 0 False

2011 2012 DX Model Detect: 1 True / 0 False

2012 2013 RMS Hardware Detect: 1 True / 0 False

2013 2014 Low Line Detect: 1 True / 0 False (Dynasty/Maxstar 210 Only)

Note: Set True When Powered Up On 120 V Input.

2014 2015 Feature Enable for Hot Start Adjust: 1 True / 0 False.

2015 2016 Feature Enable for AC Independent: 1 True / 0 False.

2016 2017 Dynasty/Maxstar 210/280 Models Only

Volt Sensing (MIG) Model Detect: 1 True / 0 False

2017 2018 Syncrowave Model Detect: 1 True / 0 False

2018 2019 Syncrowave 300/400 Models Only

Non Cooler Supply Detect: 1 True / 0 False

OM-265415 Page 7

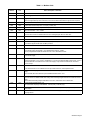

Table 7-3. Modbus Input Registers

PDU

Address

Input

Registers Name / Description / Resolution

4016 4017 L Dynasty/Maxstar 800 Models Only

Application Software Number And Revision,

4 Bytes Bit Mapped:

NNNN,NNNN NNNN,NNNN NNNN,NNRR RRRE,EEEE

NNNN,NNNN NNNN,NNNN NNNN,NN == Miller Part Number,

22 Bits 31 - 10, Bit Range 0 - 4,194,303, Actual 0-999999

RR RRR == Revision Level, 5 Bits 9 - 5, Bit Range 0 - 31,

Actual 0 - 26

where: 0 == “@” Preproduction Or Field Test Software

1,2,3... == Revision A,B,C…

E,EEEE == Evaluation / Test, 5 Bits 9 - 5, Bit Range 0 - 31,

Actual 0 - 26

Where: 0 == ”@” Released Software,

1,2,3... == Evaluation / Test Revision A,B,C…

PCB 7 Primary

4017 4018 H

4018 4019 L Application Software Number And Revision,

PCB 6 Gateway Interface

4019 4020 H

4020 4021 L

Dynasty/Maxstar 210/280 Models Only

Application Software Number And Revision,

PCB 5 Cooler Power Supply (CPS)

4021 4022 H

4022 4023 L Application Software Number And Revision,

PCB 4 Primary

4023 4024 H

4024 4025 L Application Software Number And Revision,

PCB 3 Process

4025 4026 H

4026 4027 L Application Software Number And Revision,

PCB 2 User Interface

4027 4028 H

4028 4029 L Application Software Number And Revision,

PCB 1 SD Card

4029 4030 H

OM-265415 Page 8

PDU

Address

Input

Registers

Name / Description / Resolution

4030 4031 L Serial Number:

4 Bytes Bit Mapped:

DDDY,YYYW WWWW,WSSS SSSS,SSSS SSSB,BBBB

DDD = Decade Code, 3 Bits 31 - 29, Bit Range 0 - 7,

actual “M” - “U” (For Decades 201*-208*), Skip “O”, See Note

Y,YYY = Year Code, 4 Bits 28 - 25, Bit Range 0 - 15, Actual 0 - 9

“A” - “K”, Skip “I”, See Note

W WWWW,W = Week Number, 6 Bits 24-19, Bit Range 0 - 63,

Actual 01 - 52

SSS SSSS,SSSS SSS = Serialized Number, 14 Bits 18 - 5,

Bit Range 0 - 16383, Actual 0001-9999

B,BBBB = Business Unit Code, 5 Bits 4 - 0, Bit Range 0 - 31,

Actual 0 - 25 “A”-”Z”, “I” And “O”, Not Used See Note

Note: Letters “I” And “O”, Similar To Numbers “1” And “0”

Skipped In Decade And Year.

Not used In Business Unit Code.

4031 4032 H

4032 4033 Power Source Configuration, Amperage Maximum: 0-1023, Res: 1A

4033 4034 Power Source Configuration, Amperage DC Minimum: 0-31, Res: 1A,

0 = DC Not Available

4034 4035 Power Source Configuration, Amperage AC Minimum: 0-31, Res: 1A,

0 = AC Not Available

4036 4037 L Machine’s Software Update Number, Revision.

4 Bytes Bit Mapped:

NNNN,NNNN NNNN, NNNN NNNN,NNMM MMML,LLLL

NNNN,NNNN NNNN,NNNN NNNN,NN = Miller Part Number, 22 Bits 31−10,

Bit Range 0−4,194,303, Actual 0−999999

MM MMM = Revision Level’s Most Significant Designator, 5 Bits 9−5, Bit

Range 0−31, Actual 0,1−26 (ASCII “@,A−Z”), 9 “I” & 15 “O”

Similar To “1” & “0” Not Used.

Typically Starts At 0 (“@”, Omitted When Displayed), Increases

By One With Each Wrap “Z” To “A” Of The Least Significant

Designator

L, LLLL = Revision Level’s Least Significant Designator, 5 Bits 4−0, Bit

Range 0−31, Actual 0,1−26 (ASCII “@,A−Z”), 9 “I” & 15 “O”

Similar To “1” & “0” Not Used.

0 “@” Used For Preproduction Only.

4037 4038 H

OM-265415 Page 9

PDU

Address

Input

Registers

Name / Description / Resolution

4099 4100 Sequence Timer:

Remaining / Elapsed Time of States:

Initial Amperage

Initial Slope Time

Main Amperage

Final Slope Time

Final Amperage

Preflow

Postflow (typically timed while in Standby State)

Resolution: 0.1 Second

4100 4101 State: 0 Initial Amperage 5 Preflow 13 Error

1 Initial Slope Time 6 Standby 14 Power Down

2 Main Amperage 7 Output Shorted 15 Power Up

3 Final Slope Time 8 Release Trigger

4 Final Amperage 9 Output Disabled

4101 4102 Errors1, 16(Bits) Possible Errors, 1 True / 0 False (Power Source Dependent)

Dynasty/Maxstar 210/280, Syncrowave 300 Process And User Interface:

Bit / Error# / Description

0 / 0.3.1 / Secondary Over Temp

1 / 0.3.2 / Ambient Over Temp

2 / 7.3.6 / Process Serial Communication With Gateway

3 / 3.3.1 / Secondary Thermistor Failure

4 / 3.3.2 / Ambient Thermistor Failure

5 / 1.3.1 / Fan Failure

6 / 1.3.2 / Clamp/Output Over Voltage

7 / 1.3.3 / AC Commutation Time Out

8 / 1.3.4 / Output Over Voltage

9 / 1.3.5 / Output Current Or Voltage Feedback With Output Off

10 / 1.3.6 / No Cooler Detected With Output Current

11 / 7.3.4 / Process Serial Communication With Primary

12 / 7.3.2 / Process Serial Communication With User Interface

13 / 7.3.1 / Process Serial Communication With Memory Card

14 / 7.3.5 / Process Serial Communication With CPS

15 / 7.2.3 / User Interface Serial Communication With Process

Dynasty/Maxstar 400/800:

Bit / Error# / Description

0 / 0.3.2 / Ambient Over Temp

1 / 0.3.1 / Secondary Over Temp RC20

2 / 0.3.1 / Secondary Over Temp RC30

3 / 0.4.1 / Primary Power Over Temp 400/800 Top

4 / 0.4.2 or 0.7.1 / Primary Power Over Temp 800 Bottom

5

6

7

8

9

10

11 / 7.3.7 / Process serial communication with Primary 800 Bottom.

12 / 7.3.4 / Process serial communication with Primary 400/800 Top.

13 / 3.3.2 / Ambient thermistor failure

14 / 3.3.1 / Secondary thermistor failure RC20

15 / 3.3.1 / Secondary thermistor failure RC30

OM-265415 Page 10

PDU

Address

Input

Registers

Name / Description / Resolution

4102 4103 Errors2, 16(Bits) Possible Errors, 1 True / 0 False (Power Source Dependent)

Dynasty/Maxstar 210/280, Syncrowave 300 Primary

Bit / Error# / Description

0 / 0.4.1 / Primary Power 1 Over Temp

1 / 0.4.2 / Primary Power 2 Over Temp

2 / 1.4.8 / Ground Current

3 / 1.4.0 / Primary Not Ready

4 / 1.4.1 / Primary Capacitor Imbalance

5 / 1.4.2 / Input Over Voltage

6 / 1.4.3 / Input Over Current

7 / 1.4.4 / Primary Bus Under Voltage

8 / 1.4.5 / Input Under Voltage

9 / 3.4.1 / Primary Power 1 Thermistor Failure

10 / 3.4.2 / Primary Power 2 Thermistor Failure

11 / 7.4.3 / Primary Serial Communication With Process

12 / 1.4.6 / Primary Capacitor Failure

13 / 1.4.7 / Primary Control Power

14 / 0.4.1L / Primary Power 1 Latched Over Temp

15 / 0.4.2L / Primary Power 2 Latched Over Temp

Dynasty/Maxstar 400/800, Syncrowave 400:

Bit / Error# / Description

0 / 3.4.1 / Primary Power Thermistor Failure 400/800 Top

1 / 3.4.2 or 3.7.1 / Primary Power Thermistor Failure 800 Bottom

2 / 1.3.2 / Clamp/Output over voltage

3 / 1.3.3 / AC Communication time out

4 / 1.3.4 / Output over voltage

5 / 1.3.5 / Output current or voltage feedback with output off

6 / 1.4.8 / Ground current

7 / 1.4.3 / Input over current 400/800 Top

8 / 1.4.3 or 1.7.3 / Input over current 800 Bottom

9 / 1.4.7 / Primary control power

10 / 1.4.5 / Input under voltage

11 / 1.4.4 / Primary bus under voltage

12 / 7.3.6 / Process serial communication with Gateway

13 / 7.3.2 / Process serial communication with User Interface

14 / 7.3.1 / Process serial communication with Memory Card

15 / 7.2.3 / User interface serial communication with Process

OM-265415 Page 11

PDU

Address

Input

Registers

Name / Description / Resolution

4103 4104 Errors3, 16(Bits) Possible Errors, 1 True / 0 False (Power Source Dependent)

Dynasty Maxstar 210 And 280 CPS

Bit / Error# / Description

0 / 0.5.1 / CPS Power Module 1 Over Temp

1 / 0.5.2 / CPS Power Module 2 Over Temp

2 / 0.5.3 / CPS Power Module 3 Over Temp

3 / 1.5.9 / CPS Primary Bus Under Voltage

4 / 7.5.3 / CPS Serial Communication With Process

5 / 3.5.1 / CPS Power Module 1 Thermistor Failure

6 / 3.5.2 / CPS Power Module 2 Thermistor Failure

7 / 3.5.3 / CPS Power Module 3 Thermistor Failure

8 / 1.5.1 / CPS Secondary Bus Under Voltage

9 / 1.5.2 / CPS Output Over Current

10 / 1.5.3 / CPS Secondary Bus Over Voltage

11 / 1.5.4 / CPS Current Or Voltage feedback With CPS off

12 / 1.5.5 / CPS Secondary Control Power

13 / 1.5.6 / CPS Capacitor Imbalance

14 / 1.5.7 / CPS Primary Control Power

15 / 1.5.8 / CPS Secondary Communication With CPS Primary

Syncrowave 300:

Bit/Error#/Description

3/1.5.9/CPS Primary Bus Under Voltage

Dynasty/Maxstar 400/800, Syncrowave 400:

Bit/Error#/Description

0 / 1.5.9 / CPS Primary Bus Under Voltage

1 / 1.4.4 / Primary Bus Under Voltage 400/800 Top

2 / 1.4.5 / Input Under Voltage 400/800 Top

3 / 1.4.2 / Input Over Voltage 400/800 Top

4 / 1.4.7 / Primary Control Power 400/800 Top

5 / 7.4.3 / Primary Serial Communication With Process 400/800 Top

6 / 1.4.0 / Primary Not Ready 400/800 Top

7 /

8 /

9 / 1.7.4 / Primary Bus Under Voltage 800 Bottom

10 / 1.7.5 / Input Under Voltage 800 Bottom

11 / 1.7.2 / Input Over Voltage 800 Bottom

12 / 1.7.7 / Primary Control Power 800 Bottom

13 / 7.7.3 / Primary Serial Communication With Process 800 Bottom

14 / 1.7.0 / Primary Not Ready 800 Bottom

15 /

OM-265415 Page 12

PDU

Address

Input

Registers

Name / Description / Resolution

4200 4201 Power Source Command Out Amperage, Res: 1A

4201 4202 Power Source Output Current, Res: 1A

4202 4203 Power Source Output Voltage, Res: 0.1V

4203 4204 Power Source Output Current DC Pulse Peak, Res: 1A

4204 4205 Power Source Output Voltage DC Pulse Peak, Res 0.1V

4205 4206 Power Source Output Current DC Pulse Back, Res: 1A

4206 4207 Power Source Output Voltage DC Pulse Back, Res 0.1V

4300 4301 Fan Out, 0(Off) - 100%

4301 4302 Temperature registers (Power Source Dependent):

Range: 0 - 254,

Resolution: 1 Celsius

Offset: -50 (i.e. 50 == 0 Deg. Celsius)

Possible Range: -50 - +204 C

Actual Range: Limited By Thermistor’s Hardware And Software

Temperature 1 (Dynasty/Maxstar 210/280, Syncrowave 300 - Primary Power 1)

(Dynasty/Maxstar 400/800, Syncrowave 400 - Ambient)

4302 4303 Temperature 2 (Dynasty/Maxstar 210/280, Syncrowave 300 - Primary Power 2)

(Dynasty/Maxstar 400/800 Top, Syncrowave 400 - Primary Power)

4303 4304 Temperature 3 (Dynasty/Maxstar 210/280, Syncrowave 300 - Secondary)

(Dynasty/Maxstar 800 Bottom - Primary Power)

4304 4305 Temperature 4 (Dynasty/Maxstar 210/280, Syncrowave 300 - Ambient)

(Dynasty/Maxstar 400/800, Syncrowave 400 - Secondary RC20)

4305 4306 Temperature 5 (Dynasty/Maxstar 210/280 - CPS Module 1)

(Dynasty/Maxstar 400/800, Syncrowave 400 - Secondary RC30)

4306 4307 Temperature 6 (Dynasty/Maxstar 210/280 - CPS Module 2)

4307 4308 Temperature 7 (Dynasty/Maxstar 210/280 - CPS Module 3)

4400 4401 Dynasty/Maxstar 210/280, Syncrowave 300 - Primary Line Current, Res: 1A

4401 4402 Dynasty/Maxstar 210/280, Syncrowave 300 - Primary Line Voltage, Res: 1V

4402 4403 Dynasty/Maxstar 210/280/400/800, Syncrowave 300/400 - Primary Line Voltage Peak, Res: 1V

4403 4404 Dynasty/Maxstar 210/280/400/800, Syncrowave 300/400 - Primary Bus Voltage, Res: 1V

4404 4405 Dynasty/Maxstar 210/280 - Cooler Power Output Voltage, Res: 1V

4405 4406 Dynasty/Maxstar 210/280 - Cooler Power Output Current, Res: 0.1A

4406 4407 Dynasty/Maxstar 210/280 - Cooler Power Bus Voltage, Res: 1V

4407 4408 Dynasty/Maxstar 800 - Primary 2(bottom) Line Voltage Peak, Res: 1V

4408 4409 Dynasty/Maxstar 800 - Primary 2(bottom) Bus Voltage Peak, Res: 1V

OM-265415 Page 13

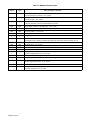

Table 7-4. Modbus Holding Registers

PDU

Address

Holding

Registers Name / Description / Resolution

6000 6001 Power Source’s Modbus Slave Address: 1 - 247.

6001 6002 Fan Request:

Dynasty/Maxstar 210/280 0(Off), 1(Min 27%) - 30(Max 100%)

Requires Request Of 3 Minimum To Start Fan

Dynasty/Maxstar 400/800 0(Off), 1 - 30(Max 100%)

Notes: 1 second time out return to 0(Off).

Parallel Request With All Machine Thermistors, Where Highest Fan Request Is Used.

0(Off) In This Register Will Not Turn Fan Off With A Fan Request Other Than Off.

From Any Machine’s Thermistors.

6002 6003 Meter Calibration, Amperage: +-50, Res: 0.1%, (+-50 == +-5.0%)

Note: With Discrete Input 2012 RMS Hardware Detect = True, Coil 17 RMS Enable Selects RMS (True)

Or Average (False) Amperage Calibration.

6003 6004 Meter Calibration, Voltage Average: +-50, Res: 0.1%, (+-50 == +-5.0%)

6100 6101

L

Arc Time, Res: 0.01 Minute, Maximum: 59999999 == 9999 Hours And 59.99 Minutes.

6101 6102

H

6102 6103

L

Arc Cycles, Res: 1 Cycle, Maximum: 999999 Cycles.

6103 6104

H

6200 6201 Dynasty/Maxstar 400/800 Models Only

Memory:

0 Memory control off typically defaults to memory 1 with no memory number displayed.

1 - Power Sources memory maximum

6201 6202 *Process: 0 Stick

1 TIG

2 MIG (Selectable only with Dynasty/Maxstar 210/280 Models and Dynasty’s Polarity DC)

3 Test

4 Hot Wire

6202 6203 *Process Start: 0 Scratch, 1 Lift, 2 HF.

6203 6204 *Trigger: 0 None-Output Off,

1 Panel-Output ON

2 Standard

3 2T Hold

4 3T Hold

5 4T Hold

6 4TL Mini Logic Hold

7 4TE Momentary Hold

8 4Tm Modified Hold

6204 6205 *Remote 14-skt E Configuration:

0 Amperage Control ( Slow Response, Finger Tip/Foot controls)

1 External Pulse Control ( Amperage, Fast Response)

2 Output Enable ( 14-Skt E-D Shorted Enables Power Source Output)

3 Disable ( 14-Skt E Has No Function)

6205 6206 *Tungsten (Canned Arc Start Parameters):

0 0.020 in. (0.5mm)

1 0.040 in. (1.0mm)

2 1/16 in. (1.6mm)

3 3/32 in. (2.4mm)

4 1/8 in. (3.2mm)

5 5/32 in. (4.0mm)

6 3/16 in. (4.8mm)

7 1/4 in. (6.4mm)

8 General (User Defined With Holding Registers 6207 Through 6212)

<9 Power Source Dependent, Typically Used With Process TIG

9 Disabled (Typically Used With Non TIG Processes)

6206 6207 Preset Amperage Minimum: Power Source AC / DC Amperage Minimum -

25A(Tungsten General) Or 63A(Tungsten Disabled), Res 1A

Write Only With Tungsten General Or Disabled

6207 6208 Arc Start Amperage: 5A - 200A, Res: 1A

Write Only With Tungsten General Or Disabled

OM-265415 Page 14

PDU

Address

Holding

Registers Name / Description / Resolution

6208 6209 Arc Start Time: 0(Off) - 25(x10ms), Res: 1(x10ms)

Write Only With Tungsten General

6209 6210 Arc Start Slope Time: 0(Off) - 25(x10ms), Res: 1(x10ms)

Write Only With Tungsten General

6210 6211 **Arc Start AC Time: 0(Off) - 25(x10ms), Res: 1(x10ms)

Write Only With AC Power Source’s AC Output And Tungsten General

6211 6212 **Arc Start Polarity Phase: 1 EP, 0 EN

Write Only With AC Power Source And Tungsten General or Disabled

6212 6213 *,**AC EN Wave Shape, 0 Advance Square, 1 Soft Square, 2 Sine, 3 Triangle

6213 6214 *,**AC EP Wave Shape, 0 Advance Square, 1 Soft Square, 2 Sine, 3 Triangle

6214 6215 Hot Start Time:

Range: 0(Off) -20

Resolution: 0.1 Second

Hot Start Enable / Disabled with Coil 8 Hot Start Enable.

6215 6216 Remote Hold:

0 / 2T

1 / 3T

2 / 4T

3 / 4TL Mini Logic

4 / 4TE Momentary

5 / 4Tm Modified

Resolution: 0.1 Second

Remote Hold can also be changed with Holding Register 6204 Trigger.

6217 6218 *Dig, 0(Off) - 100%, Res: 1%

101% will set Process Stick for Carbon Arc Gouging, turning Dig off and disabling

Boost (Coil 0009).

With Processes (Holding Register 6201) MIG selection:

*Inductance 0 - 99% Res: 1%

100% will set Inductance and optimize Digital Voltage Control for Flux Core Wire.

6300 6301 *,**,***AC EN Amperage, Preset Amps Min - PS Amps Max, Res: 1A

6301 6302 *,**,***AC EP Amperage, Preset Amps Min - PS Amps Max, Res: 1A

6302 6303 *,**,***AC Balance, 30-99%, Res: 1%

6303 6304 *,**AC Frequency, 20-400Hz, Res: 1Hz

6304 6305 *,***Weld Amperage(DC or AC), Preset Amps Min - PS Amps Max, Res: 1A

6305 6306 *Pulser - Pulses Per Second (PPS)

Range: 0(Off) – 50000 / 5000 Power Source Dependent,

Resolution: 0.1 Hertz

Can be set to a default value when writing a TRUE to coil 18 Pulser Enable and PPS is found at 0(Off).

Writing a non “0” value will set coil 18 Pulser Enable to TRUE.

Writing a “0” value will set coil 18 Pulser Enable to FALSE.

Dependent on configuration of the slave, the slave may or may not retain the PPS non “0” value.

6306 6307 *Pulser - Peak Time, 5-95%, Res: 1%

6307 6308 *Pulser - Background Amperage, 5-95%, Res: 1%

6308 6309 *Prelow Time, 0(Off) - 250, Res: 1(x0.1Sec)

6309 6310 *Initial Amperage, Preset Amps Min - PS Amps Max, Res: 1A

6310 6311 *Initial Time, 0(Off) - 250, Res: 1(x0.1Sec)

6311 6312 *Initial Slope Time, 0(Off) - 500, Res: 1(x0.1Sec)

6312 6313 *Main Time, 0(Off) - 9990, Res: 1(x0.1Sec)

6313 6314 *Final Slope Time, 0(Off) - 500, Res: 1(x0.1Sec)

6314 6315 *Finial Amperage, Preset Amps Min - PS Amps Max, Res: 1A

6315 6316 *Final Time, 0(Off) - 250, Res: 1(x0.1Sec)

6316 6317 *Postflow Time, 0(Off) - 50S & Auto(51), Res: 1Sec

6317 6318 *Dig, 0(Off) - 100%, Res: 1%

101% will set Process Stick for Carbon Arc Gouging, turning Dig off and disabling Boost (Coil 0009).

6318 6319 *Hot Wire Voltage, 5-20, Res: 1V

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

Miller DYNASTY 280 MODBUS EXPANSION Le manuel du propriétaire

- Catégorie

- Système de soudage

- Taper

- Le manuel du propriétaire

dans d''autres langues

Documents connexes

-

Miller 1 FT REMOTE CABLE ADAPTER Le manuel du propriétaire

-

Miller Maxstar 280 Le manuel du propriétaire

-

Miller MK100209L Le manuel du propriétaire

-

Miller MJ390493L Le manuel du propriétaire

-

Miller MJ220349L Le manuel du propriétaire

-

Miller Maxstar 280 Le manuel du propriétaire

-

Miller Maxstar 280 Le manuel du propriétaire

-

Miller MH420693L Le manuel du propriétaire

-

Miller Maxstar 280 Le manuel du propriétaire

-

Miller Maxstar 280 Le manuel du propriétaire