Unitronics V130-33-TR34 Rugged Programmable Logic Controllers Mode d'emploi

- Taper

- Mode d'emploi

Unitronics

1

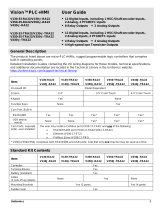

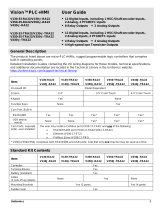

Vision™PLC+HMI

User Guide

V130-33-TR34/V130-J-TR34

V350-35-TR34/V350-J-TR34

V430-J-TR34

▪ 22 Digital Inputs, including 3 HSC/Shaft-encoder Inputs,

2 Analog inputs

▪ 8 Relay Outputs

▪ 4 high-speed npn Transistor Outputs

V130-33-R34/V130-J-R34

V350-35-R34/V350-J-R34

V430-J-R34

▪ 22 Digital Inputs, including 3 HSC/Shaft-encoder Inputs,

2 Analog Inputs

▪ 12 Relay Outputs

General Description

The products listed above are micro-PLC+HMIs, rugged programmable logic controllers that comprise

built-in operating panels.

Detailed Installation Guides containing the I/O wiring diagrams for these models, technical specifications,

and additional documentation are located in the Technical Library in the Unitronics website:

https://unitronicsplc.com/support-technical-library/

Item

V130-TR34

V130J-TR34

V130-R34

V130J-R34

V350-TR34

V350J-TR34

V350-R34

V350J-R34

V430J-TR34

V430J-R34

On-board I/O

Model Dependent

Screen

2.4"

3.5" Color Touch

4.3" Color

Touch

Keypad

Yes

None

Function Keys

None

Yes

Com Port, Built-in

RS232/485

Yes

Yes

Yes*

Yes*

Yes*

USB device, mini-B

None

None

Yes*

Com Ports, separate

order, user-installed

The user may install a CANbus port (V100-17-CAN), and one of the following:

• RS232/RS485 port (V100-17-RS4/V100-17-RS4X)

• Ethernet (V100-17-ET2)

• Profibus Slave (V100-17-PB1)

* V430J/V350/V350J comprises both RS232/485 and USB ports; note that only one channel may be

used at a time.

Standard Kit Contents

Item

V130-TR34

V130J-TR34

V130-R34

V130J-R34

V350-TR34

V350J-TR34

V350-R34

V350J-R34

V430J-TR34

V430J-R34

Controller

Yes

Terminal Blocks

Yes

Battery (installed)

Yes

Mounting Brackets

Yes (2 parts)

Yes (4 parts)

Rubber Seal

Yes

Vision™PLC+HMI Installation Guide

2

Unitronics

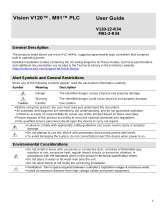

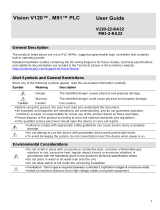

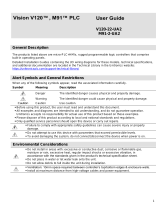

Alert Symbols and General Restrictions

When any of the following symbols appear, read the associated information carefully.

Symbol

Meaning

Description

Danger

The identified danger causes physical and property damage.

Warning

The identified danger could cause physical and property damage.

Caution

Caution

Use caution.

▪ Before using this product, the user must read and understand this document.

▪ All examples and diagrams are intended to aid understanding, and do not guarantee operation.

Unitronics accepts no responsibility for actual use of this product based on these examples.

▪ Please dispose of this product according to local and national standards and regulations.

▪ Only qualified service personnel should open this device or carry out repairs.

▪ Failure to comply with appropriate safety guidelines can cause severe injury or property

damage.

▪ Do not attempt to use this device with parameters that exceed permissible levels.

▪ To avoid damaging the system, do not connect/disconnect the device when power is on.

Environmental Considerations

▪ Do not install in areas with: excessive or conductive dust, corrosive or flammable gas,

moisture or rain, excessive heat, regular impact shocks or excessive vibration, in

accordance with the standards given in the product’s technical specification sheet.

▪ Do not place in water or let water leak onto the unit.

▪ Do not allow debris to fall inside the unit during installation.

▪ Ventilation: 10mm space required between controller’s top/bottom edges & enclosure walls.

▪ Install at maximum distance from high-voltage cables and power equipment.

Mounting

Note that figures are for illustrative purposes only.

Dimensions: V130/V350/V130J/V350J

* Note that for models V130/V350, the bezel width is up to 8.4 mm (0.33”).

Vision™PLC+HMI

Unitronics

3

Dimensions: V430J

Model

Cut-out

View area

V130V130J

92x92 mm (3.622”x3.622”)

58x30.5mm (2.28"x1.2")

V350/V350J

92x92 mm (3.622”x3.622”)

72x54.5mm (2.95"x2.14")

V430J

122.5x91.5 mm (4.82”x3.6”)

96.4x55.2mm (3.79"x2.17")

Panel Mounting

Before you begin, note that the mounting panel cannot be more than 5 mm thick.

1. Make a panel cut-out of the appropriate size:

2. Slide the controller into the cut-out, ensuring that the rubber seal is in place.

3. Push the mounting brackets into their slots on the sides of the panel as shown in the figure below.

4. Tighten the bracket’s screws against the panel. Hold the bracket securely against the unit while

tightening the screw.

5. When properly mounted, the controller is squarely situated in the panel cut-out as shown in the

accompanying figures.

V130/V350/V130J/V350J

Vision™PLC+HMI Installation Guide

4

Unitronics

V430J

DIN-rail Mounting (V130/V350/V130J/V350J)

1. Snap the controller onto the DIN rail as

shown in the figure to the right.

2. When properly mounted, the controller is

squarely situated on the DIN-rail as

shown in the figure to the right.

UL Compliance

The following section is relevant to Unitronics’ products that are listed with the UL.

The following models: V130-33-R34, V130-J-R34, V130-T4-ZK1, V350-35-RA22, V350-J-RA22,

V350-35-R34, V350-J-R34, V430-J-R34

are UL listed for Hazardous Locations.

The following models: V130-33-B1,V130-J-B1,V130-33-TA24,V130-J-TA24,V130-33-T38,V130-J-T38

V130-33-TR20,V130-J-TR20,V130-33-TR34,V130-J-TR34,V130-33-RA22,V130-J-RA22,

V130-33-TRA22,V130-J-TRA22,V130-33-T2,V130-J-T2,V130-33-TR6,V130-J-TR6,V130-33-R34,

V350-35-B1, V130-T4-ZK1, V350-J-B1,V350-35-TA24,V350-J-TA24,V350-35-T38,V350-J-T38,

V350-35-TR20,V350-J-TR20,V350-35-TR34,V350-J-TR34,V350-35-TRA22,V350-J-TRA22,

V350-35-T2,V350-J-T2,V350-35-TR6,V350-J-TR6,V350-S-TA24,V350-JS-TA24,V350-35-RA22,

Vision™PLC+HMI

Unitronics

5

V350-J-RA22,V350-35-R34, V430-J-B1,V430-J-TA24,V430-J-T38, V430-J-R34,V430-J-RH2,

V430-J-TR34,V430-J-RA22,V430-J-TRA22,V430-J-T2,V430-J-RH6

are UL listed for Ordinary Location.

For models from series V130, V130-J, V430, that include “T4” or “J4” in the Model name, Suitable for

mounting on the flat surface of Type 4X enclosure.

For examples: V130-T4-R34, V130-J4-R34, V430-J4-T2

UL Ordinary Location

In order to meet the UL ordinary location standard, panel-mount this device on the flat surface

of Type 1 or 4 X enclosures

UL Ratings, Programmable Controllers for Use in Hazardous Locations,

Class I, Division 2, Groups A, B, C and D

These Release Notes relate to all Unitronics products that bear the UL symbols used to mark products

that have been approved for use in hazardous locations, Class I, Division 2, Groups A, B, C and D.

Caution

▪ This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D, or Non-

hazardous locations only.

▪ Input and output wiring must be in accordance with Class I, Division 2 wiring methods and in

accordance with the authority having jurisdiction.

▪ WARNING—Explosion Hazard—substitution of components may impair suitability for Class I,

Division 2.

▪ WARNING – EXPLOSION HAZARD – Do not connect or disconnect equipment unless power

has been switched off or the area is known to be non-hazardous.

▪ WARNING – Exposure to some chemicals may degrade the sealing properties of material

used in Relays.

▪ This equipment must be installed using wiring methods as required for Class I, Division 2 as

per the NEC and/or CEC.

Panel-Mounting

For programmable controllers that can be mounted also on panel, in order to meet the UL Haz Loc

standard, panel-mount this device on the flat surface of Type 1 or Type 4X enclosures.

Relay Output Resistance Ratings

The products listed below contain relay outputs:

Programmable controllers, Models: V430-J-R34, V130-33-R34,V130-J-R34 and V350-35-R34,

V350-J-R34

▪ When these specific products are used in hazardous locations, they are rated at 3A res.

▪ Except for models V430-J-R34, V130-33-R34, V130-J-R34, V130-T4-ZK1 and V350-35-R34,

V350-J-R34,when these specific products are used in non-hazardous environmental conditions,

they are rated at 5A res, as given in the product’s specifications.

Communication and Removable Memory Storage

When products comprise either USB communication port, SD card slot, or both, neither

the SD card slot nor the USB port are intended to be permanently connected, while the USB port is

intended for programming only.

Removing / Replacing the battery

When a product has been installed with a battery, do not remove or replace the battery unless the

power has been switched off, or the area is known to be non-hazardous.

Vision™PLC+HMI Installation Guide

6

Unitronics

Please note that it is recommended to back up all data retained in RAM, in order to avoid losing data

when changing the battery while the power is switched off. Date and time information will also need to

be reset after the procedure.

UL des zones ordinaires:

Pour respecter la norme UL des zones ordinaires, monter l'appareil sur une surface plane de type de

protection 1 ou 4X

Certification UL des automates programmables, pour une utilisation en

environnement à risques, Class I, Division 2, Groups A, B, C et D.

Cette note fait référence à tous les produits Unitronics portant le symbole UL - produits qui ont été

certifiés pour une utilisation dans des endroits dangereux, Classe I, Division 2, Groupes A, B, C et D.

Attention

▪ Cet équipement est adapté pour une utilisation en Classe I, Division 2, Groupes A, B, C et

D, ou dans Non-dangereux endroits seulement.

▪ Le câblage des entrées/sorties doit être en accord avec les méthodes

de câblage selon la Classe I, Division 2 et en accord avec l’autorité compétente.

▪ AVERTISSEMENT: Risque d’Explosion – Le remplacement de certains composants rend

caduque la certification du produit selon la Classe I, Division 2.

▪ AVERTISSEMENT - DANGER D'EXPLOSION - Ne connecter pas ou ne débranche pas

l'équipement sans avoir préalablement coupé l'alimentation électrique ou la zone est

reconnue pour être non dangereuse.

▪ AVERTISSEMENT - L'exposition à certains produits chimiques peut dégrader les propriétés

des matériaux utilisés pour l'étanchéité dans les relais.

▪ Cet équipement doit être installé utilisant des méthodes de câblage suivant la norme Class I,

Division 2 NEC et /ou CEC.

Montage de l'écran:

Pour les automates programmables qui peuvent aussi être monté sur l'écran,

pour pouvoir être au standard UL, l'écran doit être monté dans un coffret avec une surface plane de

type 1 ou de type 4X.

Certification de la résistance des sorties relais

Les produits énumérés ci-dessous contiennent des sorties relais:

▪ Automates programmables, modèles : V430-J-R34, V130-33-R34,V130-J-R34 and

V350-35-R34,V350-J-R34

▪ Lorsque ces produits spécifiques sont utilisés dans des endroits dangereux, ils supportent

un courant de 3A charge résistive.

▪ Excepté les modèles: V430-J-R34, V130-33-R34,V130-J-R34, V130-T4-ZK1 et V350-35-R34,

V350-J-R34 lorsque ces produits spécifiques sont utilisés dans un environnement non dangereux, ils

sont évalués à 5A res, comme indiqué dans les specifications du produit Plages de températures

Communication et de stockage amovible de mémoire (carte mémoire)

Produits comprend un port USB de communication, soit un port carte SD ou les deux, ni le port SD, ni

le port USB ne sont censés être utilisés en permanence, tandis que l'USB est destiné à la

programmation uniquement.

Retrait / Remplacement de la batterie

Lorsqu'un produit a été installé avec une batterie, retirez et remplacez la batterie seulement si

l’alimentation est éteinte ou si l’environnement n’est pas dangereux.

Veuillez noter qu'il est recommandé de sauvegarder toutes les données conservées dans la RAM, afin

d'éviter de perdre des données lors du changement de la batterie lorsque l'alimentation est coupée. Les

informations sur la date et l'heure devront également être réinitialisées après la procédure

Vision™PLC+HMI

Unitronics

7

Wiring

▪ Do not touch live wires.

▪ Install an external circuit breaker. Guard against short-circuiting in external wiring.

▪ Use appropriate circuit protection devices.

▪ Unused pins should not be connected. Ignoring this directive may damage the device.

▪ Double-check all wiring before turning on the power supply.

Caution

▪ To avoid damaging the wire, do not exceed a maximum torque of 0.5 N·m (5 kgf·cm).

▪ Do not use tin, solder, or any substance on stripped wire that might cause the wire

strand to break.

▪ Install at maximum distance from high-voltage cables and power equipment.

Wiring Procedure

Use crimp terminals for Use crimp terminals for wiring;

- Controllers offering a terminal block with pitch of 5mm: 26-12 AWG wire (0.13 mm2 –3.31 mm2).

- Controllers offering a terminal block with pitch of 3.81mm: 26-16 AWG wire (0.13 mm2 – 1.31 mm2).

1. Strip the wire to a length of 7±0.5mm (0.270–0.300“).

2. Unscrew the terminal to its widest position before inserting a wire.

3. Insert the wire completely into the terminal to ensure a proper connection.

4. Tighten enough to keep the wire from pulling free.

▪ Input or output cables should not be run through the same multi-core cable or share

the same wire.

▪ Allow for voltage drop and noise interference with I/O lines used over an extended distance.

Use wire that is properly sized for the load.

▪ The controller and I/O signals must be connected to the same 0V signal.

I/Os

V130/V350/V130J/V350J/V430J-TR34 models comprise a total of 22 inputs and 8 relay, 4 npn

outputs.

V130/V350/V130J/V350J/V430J-R34 models comprise a total of 22 inputs and 12 relay outputs.

Input functionality can be adapted as follows:

22 inputs may be used as digital inputs. They may be wired, in a group, and set to either

npn or pnp via a single jumper.

In addition, according to jumper settings and appropriate wiring:

- Inputs 14 and 15 can function as either digital or analog inputs.

- Inputs 0, 2, and 4 can function as high-speed counters, as part of a shaft-encoder,

or as normal digital inputs.

- Inputs 1, 3, and 5 can function as either counter reset, as part of a shaft-encoder,

or as normal digital inputs.

- If inputs 0, 2 and 4 are set as high-speed counters (without reset), inputs 1, 3 and 5

can function as normal digital inputs.

Vision™PLC+HMI Installation Guide

8

Unitronics

Input Jumper Settings

The tables below show how to set a specific jumper to change input functionality. To access the I/O

jumpers, you must open the controller according to the instructions beginning on page 12.

▪ Incompatible jumper settings and wiring connections may seriously damage the controller.

Digital Inputs 0-21: Set Type

Set to

JP3 (all Inputs)

npn (sink)

A

pnp (source)*

B

Inputs 14/15: Set as Digital or Analog

Set to

JP1 (Input 14)

JP2 (Input 15)

Digital*

B

B

Analog

A

A

Analog Inputs AN0/AN1: Set Type

Set to

JP5 (AN0)

JP4 (AN1)

Voltage

A

A

Current*

B

B

*Default settings

I/O Wiring

npn (sink) Input Wiring

Input wiring

HSC input wiring

Vision™PLC+HMI

Unitronics

9

pnp (source) Input Wiring

Input wiring

HSC input wiring

Shaft-encoder

Analog Input Wiring

Analog input wiring, current (2 wire)

Analog input wiring, current (3-wire)

Vision™PLC+HMI Installation Guide

10

Unitronics

Analog input wiring, current (4-wire)

Analog input wiring, voltage

▪ Shields should be connected at the signal’s source.

▪ The 0V signal of the analog input must be connected to the controller’s 0V.

npn Outputs

TR34

Relay Outputs

TR34

R34

Vision™PLC+HMI

Unitronics

11

Increasing Contact Life Span

To increase the life span of the

relay output contacts and protect

the device from potential damage

by reverse EMF, connect:

▪ A clamping diode in parallel with each

inductive DC load

▪ An RC snubber circuit in parallel with each

inductive AC load

Power Supply

The controller requires an external 24VDC power supply.

▪ The power supply must include double insulation. Outputs must be rated as

SELV/PELV/Class2/Limited Power.

▪ Use separate wires to connect the functional

earth line (pin 3) and the 0V line (pin 2) to the

system earth ground.

▪ Install an external circuit breaker. Guard

against short-circuiting in external wiring.

▪ Double-check all wiring before turning

on the power supply.

▪ Do not connect either the ‘Neutral’ or ‘Line’

signal of the 110/220VAC to device’s 0V pin

▪ In the event of voltage fluctuations or non-

conformity to voltage power supply

specifications, connect the device to

a regulated power supply.

▪

Earthing the PLC+HMI

To maximize system performance, avoid electromagnetic interference by:

▪ Mounting the controller on a metal panel.

▪ Connect each common and ground connection directly to the earth ground of your system.

▪ For ground wiring uses the shortest and thickest possible wire.

Communication

▪ V130/ V130J

These models comprise a built-in RS232/RS485 serial port (Port 1)

▪ V430J/V350/V350J

These models comprise built-in ports: 1 USB and 1 RS232/RS485 (Port 1).

Note that physically connecting a PC to the controller via USB suspends RS232/RS485

communications via Port 1. When the PC is disconnected, RS232/RS485 resumes.

Vision™PLC+HMI Installation Guide

12

Unitronics

RS232/RS485 Port

▪ Turn off power before making communications connections.

Caution

▪ Always use the appropriate port adapters.

Caution

▪ Signals are related to the controller’s 0V; the same 0V is used by the power supply.

▪ The serial port is not isolated. If the controller is used with a non-isolated external device,

avoid potential voltage that exceeds ± 10V.

▪ Use RS232 to download programs from a PC, and to communicate with serial devices and

applications, such as SCADA.

▪ Use RS485 to create a multi-drop network containing up to 32 devices.

Pinouts

The pinouts below show the PLC port signals.

RS232

RS485**

Controller Port

Pin #

Description

Pin #

Description

Pin #1

1*

DTR signal

1

A signal (+)

2

0V reference

2

(RS232 signal)

3

TXD signal

3

(RS232 signal)

4

RXD signal

4

(RS232 signal)

5

0V reference

5

(RS232 signal)

6*

DSR signal

6

B signal (-)

* Standard programming cables do not provide connection points for pins 1 and 6.

** When a port is adapted to RS485, Pin 1 (DTR) is used for signal A,

and Pin 6 (DSR) signal is used for signal B.

Note that it is possible to establish a PC to PLC connection using RS232 even when the PLC is set to

RS485 (this eliminates the need to open the controller to set jumpers).

To do so, remove the RS485 connector (pins 1 & 6) from the PLC and connect a standard RS232

programming cable.

Note that this is possible only if DTR and DSR signals of RS232 are not used (which is the standard

case).

Vision™PLC+HMI

Unitronics

13

Setting RS232/RS485 Communication Parameters, V130/V350/V130J/V350J

This port may be set to either RS232 or RS485 via jumper.

The accompanying figure shows the jumper factory

default settings.

These jumpers may be used to:

▪ Set communications to RS485, by setting both COMM

jumpers to ‘485’.

▪ Set RS485 termination, by setting both TERM jumpers to

‘OFF’.

To access the jumpers, you must open the controller

according to the instructions on page 12.

Setting RS232/RS485 Communication Parameters, V430J

This port may be set to either RS232 or RS485 via DIP switches:

The table shows the DIP switches factory default settings. Use the table to adapt the settings.

Switch Settings

1

2

3

4

5

6

RS232*

ON

OFF

OFF

ON

OFF

OFF

RS485

OFF

ON

ON

OFF

OFF

OFF

RS485 with

termination**

OFF

ON

ON

OFF

ON

ON

* Default factory setting

** Causes the unit to function as an end unit in an RS485 network

USB Port

Caution

▪ The USB port is not isolated.

Make sure that the PC and the controller are grounded to same potential.

The USB port may be used for programming, OS download, and PC access.

Vision™PLC+HMI Installation Guide

14

Unitronics

Opening the Controller

Note that the V130 photograph is for illustrative purposes only.

▪ Before performing these actions, touch a grounded object to discharge any electrostatic charge.

▪ Avoid touching the PCB board directly. Hold the PCB board by its connectors.

1. Turn off the power supply, disconnect, and dismount the controller.

2. The back cover of the controller comprises 4 screws, located in the corners.

Remove the screws, and pull off the back cover.

Changing I/O Settings

After opening the controller and exposing the I/O board, you can change the jumper settings according

to the table shown above.

Changing Communication Settings (V130/V350/V130J/V350J Only)

1. To access the communication jumpers, hold the I/O PCB board by its top and bottom connectors

and steadily pull the board off.

2. Locate the jumpers, and then change the settings as required, according to the jumpers’ settings

shown on page 11.

Closing the Controller

1. Gently replace the board.

Make certain that the pins fit correctly into

their matching receptacle.

Do not force the board into place;

doing so may damage the controller.

2. Replace the back cover of the

controller and fasten the corner screws.

Vision™PLC+HMI

Unitronics

15

Vision™PLC+HMI

V130-33-TR34/V130-J-TR34

V350-35-TR34/V350-J-TR34

V430-J-TR34

Technical Specifications

Order Information

Item

V130-33-TR34

PLC with Classic panel, Monochrome display 2.4"

V130-J-TR34

PLC with Flat panel, Monochrome display 2.4"

V350-35-TR34

PLC with Classic panel, Color touch display 3.5’’

V350-J-TR34

PLC with Flat panel, Color touch display 3.5’’

V430-J-TR34

PLC with Flat panel, Color touch display 4.3’’

Power Supply

Item

V130-TR34

V130J-TR34

V350-TR34

V350J-TR34

V430J-TR34

Input voltage

24VDC

Permissible range

20.4VDC to 28.8VDC with less than 10% ripple

Max. current consumption

See Note 1

npn inputs

245mA@24VDC

265mA@24VDC

265mA@24VDC

pnp inputs

170mA@24VDC

180mA@24VDC

180mA@24VDC

Notes:

1. To calculate the actual power consumption, subtract the current for each unused element from the maximum

current consumption value according to the values below:

Backlight

Ethernet

card

Relay Outputs

(per output)

V130/J

10mA

35mA

5mA

V350/J/V430J

20mA

35mA

5mA

Digital Inputs

Number of inputs

22. See note 2

Input type

See note 2

Galvanic isolation

None

Nominal input voltage

24VDC

Input Voltage

Normal digital input

High Speed input. See Note 3

pnp (source)

0-5 VDC for Logic ‘0’

17-28.8 VDC for

Logic ‘1’

0-3 VDC for Logic ‘0’

20.4-28.8 VDC for Logic ‘1’

npn (sink)

17-28.8 VDC for

Logic ‘0’

0-5 VDC for Logic ‘1’

20.4-28.8 VDC for Logic ‘0’

0-3 VDC for Logic ‘1’

Input Current

I0-5

5.4mA@24VDC

I6-21

3.7mA@24VDC

Input impedance

I0-5

4.5KΩ

I6-21

6.5KΩ

Response Time

10ms typical, when used as normal digital input

Input Cable length

Normal digital Input

Up to 100 meters

High Speed Input

Up to 50 meters, shielded, see Frequency table below

High speed inputs

Specifications below apply when wired as HSC/shaft-encoder.

See Note 2.

Vision™PLC+HMI Installation Guide

16

Unitronics

Frequency, HSC

Driver type

pnp/npn

Push-pull

Cable length (max.)

10m

95kHz maximum

200kHz maximum

25m

50kHz maximum

200kHz maximum

50m

25kHz maximum

200kHz maximum

Frequency, Shaft-encoder

Driver type

pnp/npn

Push-pull

Cable length (max.)

10m

35kHz maximum

100kHz maximum

25m

18kHz maximum

100kHz maximum

50m

10kHz maximum

100kHz maximum

Duty cycle

40-60%

Resolution

32-bit

Notes:

2. V130/V350/V130J/V350J/V430J-TR34 models comprise a total of 22 inputs and 8 relay, 4 npn outputs.

Input functionality can be adapted as follows:

22 inputs may be used as digital inputs. They may be wired, in a group, and set to either

npn or pnp via a single jumper.

In addition, according to jumper settings and appropriate wiring:

- Inputs 14 and 15 can function as either digital or analog inputs.

- Inputs 0, 2, and 4 can function as high-speed counters, as part of a shaft-encoder,

or as normal digital inputs.

- Inputs 1, 3, and 5 can function as either counter reset, as part of a shaft-encoder,

or as normal digital inputs.

- If inputs 0, 2 and 4 are set as high-speed counters (without reset), inputs 1, 3 and 5 can function as normal

digital inputs.

3. If you configure an input as high-speed, you can use an end-device that comprises push-pull drive type. In this

case, the high-speed input voltage ratings for npn/pnp apply.

Analog Inputs

Number of inputs

2, according to wiring as described above in Note 2

Input type

Multi-range inputs: 0-10V, 0-20mA, 4-20mA

Input range

0-20mA, 4-20mA

0-10VDC

Input impedance

243Ω

>150KΩ

Maximum input rating

25mA, 6V

15V

Galvanic isolation

None

Conversion method

Successive approximation

Resolution (except 4-20mA)

10-bit (1024 units)

Resolution (at 4-20mA)

204 to 1023 (820 units)

Conversion time

One configured input is updated per scan. See Note 4

Precision

0.9%

Status indication

Yes – if an analog input deviates above the permissible range,

its value will be 1024.

Notes:

4. For example, if 2 inputs are configured as analog, it takes 2 scans to update all analog values.

Vision™PLC+HMI

Unitronics

17

Relay Outputs

Number of outputs

8 relay (in 2 groups). See Note 5

Output type

SPST-NO (Form A)

Galvanic isolation

By relay

Type of relay

Tyco PCN-124D3MHZ or compatible

Output current

(resistive load)

3A maximum per output

8A maximum total per common

Rated voltage

250VAC/30VDC

Minimum load

1mA, 5VDC

Life expectancy

100k operations at maximum load

Response time

10ms (typical)

Contact protection

External precautions required (see Increasing Contact Life Span in the product’s

Installation Guide)

Notes:

5. Outputs 4, 5, 6, and 7 share a common signal.

Outputs 8, 9, 10, and 11 share a common signal.

Transistor Outputs

Number of outputs

4 npn (sink). See Note 6

Output type

N-MOSFET, (open drain)

Galvanic Isolation

None

Maximum output current

(resistive load)

100mA per output

Rated voltage

24VDC

Maximum delay OFF to ON

1s

Maximum delay ON to OFF

10s

HSO freq. range with

resistive load

5Hz-200kHz (at maximum load resistance of 1.5kΩ)

Maximum ON voltage drop

1VDC

Short-circuit protection

None

Voltage range

3.5V to 28.8VDC

Notes:

6. Outputs 0, 1, 2 and 3 share a common 0V signal.

The 0V signal of the output must be connected to the controller’s 0V.

Graphic Display Screen

Item

V130-TR34

V130J-TR34

V350-TR34

V350J-TR34

V430J-TR34

LCD Type

STN, LCD display

TFT, LCD display

TFT, LCD display

Illumination backlight

White LED

White LED

White LED

Display resolution

128x64 pixels

320x240 pixels

480x272 pixels

Viewing area

2.4"

3.5"

4.3"

Colors

Monochrome

65,536 (16-bit)

65,536 (16-bit)

Screen Contrast

Via software

(Store value to SI 7,

values range: 0 to 100%)

Fixed

Fixed

Touchscreen

None

Resistive, analog

Resistive, analog

‘Touch’ indication

None

Via buzzer

Via buzzer

Screen brightness control

Via software

(Store value to SI 9,

0 = Off, 1 = On)

Via software

(Store value to SI 9, values range: 0 to 100%)

Virtual Keypad

None

Displays virtual keyboard when the application requires

data entry.

Vision™PLC+HMI Installation Guide

18

Unitronics

Keypad

Item

V130-TR34

V130J-TR34

V350-TR34

V350J-TR34

V430J-TR34

Number of keys

20 keys,including 10

user-labeled keys

5 programmable function keys

Key type

Metal dome, sealed membrane switch

Slides

Slides may be installed in

the operating panel

faceplate to custom-label

the keys. Refer to V130

Keypad Slides.pdf.

A complete set of blank

slides is available by

separate order

Slides may be installed in

the operating panel

faceplate to custom-label

the keys. Refer to V350

Keypad Slides.pdf.

Two sets of slides are

supplied with the

controller: one set of

arrow keys, and one

blank set.

None

Program

Item

V130-TR34

V130J-TR34

V350-TR34

V350J-TR34

V430J-TR34

Memory size

Application Logic

512KB

1MB

1MB

Images

128KB

6MB

12MB

Fonts

128KB

512KB

512KB

Operand type

Quantity

Symbol

Value

Item

V130-TR34

V130J-TR34

V350-TR34

V350J-TR34

V430J-TR34

Memory Bits

4096

8192

MB

Bit (coil)

Memory Integers

2048

4096

MI

16-bit signed/unsigned

Long Integers

256

512

ML

32-bit signed/unsigned

Double Word

64

256

DW

32-bit unsigned

Memory Floats

24

64

MF

32-bit signed/unsigned

Fast Bits

1024

1024

XB

Fast Bits (coil) – not retained

Fast Integers

512

512

XI

16 bit signed/unsigned

(fast, not retained)

Fast Long Integers

256

256

XL

32 bit signed/unsigned

(fast, not retained)

Fast Double Word

64

64

XDW

32 bit unsigned (fast, not retained)

Timers

192

384

T

Res. 10 ms; max 99h, 59 min, 59.99s

Counters

24

32

C

32-bit

Data Tables

120K dynamic data (recipe parameters, datalogs, etc.)

192K fixed data (read-only data, ingredient names, etc)

Expandable via SD card. See Removable Memory below

HMI displays

Up to 1024

Program scan time

20µs per 1kb

of typical

application

15µs per 1kb

of typical

application

Removable Memory

Micro SD card

Compatible with standard SD and SDHC; up to 32GB store datalogs, Alarms,

Trends, Data Tables, backup Ladder, HMI, and OS.

See Note 7

Notes:

7.User must format via Unitronics SD tools utility.

Vision™PLC+HMI

Unitronics

19

Communication Ports

Port 1

1 channel, RS232/RS485 and USB device (V430/V350/V350J only). See Note 8

Galvanic isolation

No

Baud rate

300 to 115200 bps

RS232

Input voltage

±20VDC absolute maximum

Cable length

15m maximum (50’)

RS485

Input voltage

-7 to +12VDC differential maximum

Cable type

Shielded twisted pair, in compliance with EIA 485

Cable length

1200m maximum (4000’)

Nodes

Up to 32

USB device

(V430/V350/V350J only)

Port type

Mini-B, See Note 10

Specification

USB 2.0 complaint; full speed

Cable

USB 2.0 complaint; up to 3m

Port 2 (optional)

See Note 9

CANbus (optional)

See Note 9

Notes:

8. This model is supplied with a serial port: RS232/RS485 (Port 1). The standard is set to either RS232 or RS485

according to jumper settings. Refer to the product’s Installation Guide.

9. The user may order and install one or both of the following modules:

- An additional port (Port 2). Available port types: RS232/RS485 isolated/non-isolated, Ethernet

- A CANbus port

Port module documentation is available on the Unitronics website.

10. Note that physically connecting a PC to the controller via USB suspends RS232/RS485 communications

via Port 1. When the PC is disconnected, RS232/RS485 resumes.

I/O Expansion

Additional I/Os may be added. Configurations vary according to module.

Supports digital, high-speed, analog, weight and temperature measurement I/Os.

Local

Via I/O Expansion Port. Integrate up to 8 I/O Expansion Modules comprising up

to 128 additional I/Os. Adapter required (P.N. EX-A2X).

Remote

Via CANbus port. Connect up to 60 adapters to a distance of 1000 meters from

controller; and up to 8 I/O expansion modules to each adapter (up to a total of

512 I/Os). Adapter required (P.N. EX-RC1).

Miscellaneous

Clock (RTC)

Real-time clock functions (date and time)

Battery back-up

7 years typical at 25°C, battery back-up for RTC and system data, including

variable data

Battery replacement

Yes. Coin-type 3V, lithium battery, CR2450

Vision™PLC+HMI Installation Guide

20

Unitronics

Dimensions

Item

V130-TR34

V130J-TR34

V350-TR34

V350J-TR34

V430J-TR34

Size

See Note 11

Vxxx

109 x 114.1 x 68mm

(4.29 x 4.49 x 2.67”).

109 x 114.1 x 68mm

(4.29 x 4.49 x 2.67”).

Vxxx-J

109 x 114.1 x 66mm

(4.92 x 4.49 x 2.59”).

109 x 114.1 x 66mm

(4.92 x 4.49 x 2.59”).

136 x 105.1 x 61.3mm

(5.35 x 4.13 x 2.41”).

Weight

227g (8 oz)

235g (8.28 oz)

260g (9.17 oz)

Notes:

11. For exact dimensions, refer to the product’s Installation Guide.

Environment

Operational temperature

0 to 50ºC (32 to 122ºF)

Storage temperature

-20 to 60ºC (-4 to 140ºF)

Relative Humidity (RH)

10% to 95% (non-condensing)

Mounting method

Panel mounted (IP65/66/NEMA4X)

DIN-rail mounted (IP20/NEMA1)

Operating Altitude

2000m (6562 ft)

Shock

IEC 60068-2-27, 15G, 11ms duration

Vibration

IEC 60068-2-6, 5Hz to 8.4Hz, 3.5mm constant amplitude,

8.4Hz to 150Hz, 1G acceleration.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

Unitronics V130-33-TR34 Rugged Programmable Logic Controllers Mode d'emploi

- Taper

- Mode d'emploi

dans d''autres langues

Documents connexes

-

Unitronics Vision PLC+HMI Programmable Logic Controller Manuel utilisateur

Unitronics Vision PLC+HMI Programmable Logic Controller Manuel utilisateur

-

Unitronics V1210-T20BJ Mode d'emploi

-

Unitronics V530-53-B20B Mode d'emploi

-

Unitronics JZ20-R31 HMI Display Unit Mode d'emploi

-

Unitronics V120-22-R34 Display units and HMIs Mode d'emploi

Unitronics V120-22-R34 Display units and HMIs Mode d'emploi

-

Unitronics IO-ATC8 Manuel utilisateur

-

Unitronics Vision 120 Programmable Logic Controller Mode d'emploi

Unitronics Vision 120 Programmable Logic Controller Mode d'emploi

-

Unitronics V120 Rugged Programmable Logic Controllers Mode d'emploi

Unitronics V120 Rugged Programmable Logic Controllers Mode d'emploi

-

Unitronics V120-22-R1 PLC Controllers Mode d'emploi

Unitronics V120-22-R1 PLC Controllers Mode d'emploi

Autres documents

-

Lincoln Electric Invertec V130-S Mode d'emploi

-

Hyundai 22B-7 Le manuel du propriétaire

-

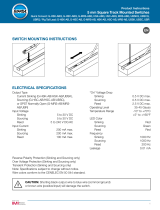

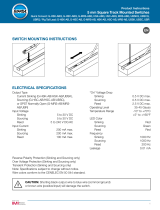

Bimba 5mm Square Thick Mounted Switches Assembly Instructions

Bimba 5mm Square Thick Mounted Switches Assembly Instructions

-

Lincoln Electric IM708 Manuel utilisateur

-

Lincoln Electric INVERTEC V350-PRO Manuel utilisateur

-

Lincoln Electric INVERTEC V350-PRO Mode d'emploi

-

Lincoln Electric Invertec V350-Pipe Manuel utilisateur

-

Epson Perfection V 100 photo Le manuel du propriétaire