Miller DS-64M Swingarc Le manuel du propriétaire

- Catégorie

- Système de soudage

- Taper

- Le manuel du propriétaire

Ce manuel convient également à

Miller

July

1996

Form:

OM-1588C

Effe

ctive

With

Serial

No.

KG0471

32

t~llL~

~

~r'

~

OWNERS

MANUAL

DS-64M

SWINGARCTM

12

And

16

Foot

For

GMAW-P,

GMAW,

And

FCAW

Welding

Type

of

Input

Power

Welding

Power

Source

Type

Wire

Feed

Speed

Range

Wire

Diameter

Range

Welding

Circuit

Rating

Weight

24

Volts

AC

Single-Phase

10

Amperes

50/60

Hertz

Constant

Voltage

(CV)

DC

For

GMAW

Or

Constant

Voltage

(CV)

/

Constant

Current

(CC)

DC

For

GMAW-P

All

Need

14-Pin

And

Contactor

Control

Standard:

50

To

780

ipm

(1.3

To

19.8

mpm)

Optional

High

Speed:

92

To

1435

ipm

(2.3

To

36.5

mpm)

.023

To

1/8

in

(0.6

To

3.2

mm)

Max

Spool

Weight:

60

lb

(27

kg)

ioo

Volts,

750

Amperes,

100%

Duty

Cycle

12

ft

(3.7

m):

207

lb

(94

kg)

16

ft

(4.9

m):

280

lb

(127

kg)

I

cover_om

4/95

ST-BOO

172

'

1996

MILLER

Electnc

Mfg.

Co.

PRINTED

IN

USA

j-

I

MILLERS

TRUE

BLUEfi

LIMITED

WARRANTY

Effective

February

7,

1996

(Equipment

with

a

serial

number

preface

of

KD

or

newer)

This

limited

warranty

supersedes

sll

previous

MILLER

wsnanties

snd

is

exclusive

with

no

other

gusrsntees

or

wsrrsnties

expressed

or

implied.

LIMITED

WARRANTYSubject

tothe

terms

snd

conditions

below,

MILLER

Electric

Mfg.

Co.,

Appleton,

Wisconsin,

wsrrerrts

to

its

originsl

retsil

purchsser

thst

new

MILLER

equipment

sold

sfter

the

effective

dste

of

this

limited

wsrrsnty

is

free

of

de

fects

in

meterisl

snd

workmsnship

st

the

time

it

is

shipped

by

MILLER.

ThIS

WAR

RANTY

IS

EXPRESSLY

IN

UEU

OF

ALL

OTHER

WARRANTIES,

EXPRESS

OR

IMPUED,

INCLUDING

ThE

WARRAN11ES

OF

MERCHANTABIUTY

AND

FIT

NESS.

Within

the

wsrrenty

periods

listed

below,

MILLER

will

mpsir

or

replsce

eny

wsr

mnted

parts

or

components

thst

tsil

due

to

such

defects

in

msterisl

orworknrsnship.

MILLER

must

be

notified

in

writing

within

thirty

(30)

dsys

of

such

defect

orfsilure,

at

which

time

MILLER

will

provide

instructions

on

the

wsrranty

claim

procedures

to

be

followed.

MILLER

shsll

honor

warranty

clsims

on

wsrranted

equipmsint

listed

below

in

the

event

of

such

s

failure

within

the

warranty

time

periods.

All

wsrmnty

time

peflods

start

on

the

dste

that

the

equipment

wss

delivered

to

the

originsl

retail

purchaser,

or

one

year

sfter

the

equipment

is

sent

to

s

North

American

distributor

or

eighteen

months

after

the

equipment

is

sent

to

en

International

distributor.

1.

5YearaParta3YeamLsbor

*

Original

main

power

rectifiers

*

Invertem

(input

end

output

rectifiem

only)

2.

3YeamPartaandLabor

Tmnaformer/Rectifier

Power

Sources

*

Plasma

Arc

Cutting

Power

Sources

*

Semi-Automatic

end

Automatic

Wire

Feeders

Inverler

Power

Supplies

*

Intellitig

*

Robots

(1

year

labor)

3.

2YeamPartsandLabor

*

Engine

Driven

Welding

Generatom

(NOTE:

Engines

are

warranted

separately

by

the

engine

manufacturer.)

Air

Compressors

4.

1

Year

ParIs

and

Labor

Motor

Driven

Guns

Process

Controllers

IHPS

Power

Sources

Water

Coolant

Systems

HF

Units

Grids

*

Spot

Welders

*

Load

Banks

*

SDX

Transformers

*

Miller

Cyclomatic

Equipment

Running

Gear/Trailers

Plasma

Cutting

Torches

(except

APT,

ZIPCUT

&

PLAZCUT

Models)

*

Tecumaeh

Engines

*

Deulz

Engines

(outside

North

America)

*

Field

Options

(NOTE:

Field

options

are

covered

under

True

Bluefi

tor

the

remaining

warranty

period

of

the

product

they

are

installed

in,

or

for

a

minimum

of

one

year

whichever

is

greater.)

5.

6

Months

Batteries

6.

90

Days

Parts

and

Labor

*

MIG

Guna/TIG

Torches

*

APT,

ZIPCUT

&

PLAZCUT

Model

Plasma

Cutting

Torches

Remote

Controls

Accessory

Kits

Replacement

Parts

MILLERS

True

Bluefi

Umited

Warranty

shall

not

apply

to:

1.

Items

furnished

by

MILLER,

but

manufactured

by

others,

such

as

engines

or

trade

accessories.

These

items

are

covered

by

the

manufacturers

warranty,

if

any.

2.

Consumable

components;

such

as

contact

tips,

cutting

nozzles,

conlactom

and

relays

or

parts

that

fail

due

to

normal

wear.

3.

Equipment

that

has

been

modified

by

any

party

other

than

MILLER,

or

equip

ment

that

has

been

improperfy

installed,

improperly

operated

or

misused

based

upon

industry

standards,

or

equipment

which

has

not

had

reasonable

and

necessary

maintenance,

or

equipment

which

has

bean

used

for

operation

outside

of

the

specifications

for

the

equipment.

MILLER

PRODUCTSARE

INTENDED

FOR

PURCHASEAND

USE

BY

COMMER

CIAL11NDUSTRIAL

USERS

AND

PERSONS

TRAINED

AND

EXPERIENCED

IN

ThE USE

AND

MAINTENANCE

OF

WELDING

EQUIPMENT

In

the

event

of

a

warranty

claim

covered

by

this

warranty,

the

exclusive

remedies

shall

be,

at

MILLERS

option:

(1)

repair;

or

(2)

replacement;

or,

where

authorized

in

writing

by

MILLER

in

appropriate

cases,

(3)

the

resaonable

coat

01

repairor

replace

ment

at

an

authorized

MILLER

service

station;

or

(4)

payment

of

orcredit

forthe

pur

chase

price

(less

reasonable

depreciation

based

upon

actual

use)

upon

return

of

the

goods

at

customers

risk

and

expense.

MILLERS

option

of

repair

or

replacement

will

be

P.0.5.,

Factory

at

Appleton,

Wisconsin,

or

FOB.

at

a

MILLER

authorized

ser

vice

facility

as

determined

by

MILLER.

Therefore

no

compensation

or

reimburse

ment

for

transportation

costs

of

any

kind

will

be

allowed.

TO

ThE

EXTENT

PERMITTED

BY

LAW,

THE

REMEDIES PROVIDED

HEREIN

ARE

ThE

SOLE

AND

EXCLUSIVE

REMEDIES.

IN

NO

EVENT

SHALL

MILLER

BE

UABLE

FOR

DIRECT,

INDIRECt

SPECIAL,

INCIDENTAL

OR

CONSEQUENTIAL

DAMAGES

(INCLUDING

LOSS

OF

PROFIT),

WHETHER

BASED

ON

CON

TRACT,

TORT

OR

ANY

OTHER

LEGAL

ThEORY.

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

ANDANY

IMPUED

WAR

RANTY,

GUARANTY

OR

REPRESENTA11ON

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

TORT

OR

ANY

OThER

LEGAL

ThEORY

WHICH,

BUT

FOR

THIS

PROVISION,

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW,

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING,

IN

CLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

PARTICULAR

PURPOSE,

WITh

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EXCLUDED

AND

DISCLAIMED

BY

MILLER.

Some

states

in

the

U.S.A.

do

not

allow

limitations

of

how

long

an

implied

warranty

lasts,

or

the

exclusion

of

incidental,

indirect,

special

or

consequential

damages,

so

the

above

limitation

or

exclusion

may

not

apply

to

you.

This

warranty

provides

ape

cific

legal

rights,

and

other

rights

may

be

available,

but

may

vary

from

state

to

state.

In

Canada,

legislation

in

some

provinces

provides

forcertain

additional

warranties

or

remedies

other

than

as

stated

herein,

and

to

the

estent

that

they

may

not

be

waived,

the

limitations

and

exclusions

set

out

above

may

not

apply.

This

Umited

Warranty

provides

specific

legal

rights,

and

other

rights

may

be

available,

but

may

vary

from

province

to

province.

WHO

DO

I

CONTACT?

For

help,

To

file

a

claim

for

loss

or

damage

during

Miller

Electric

Mfg.

Co.

contact

your

distributor

For

additional

information,

such

as

TeChnical

Manuals

(Service

And

Parts)

Engine

Manuals

Circuit

And

Wiring

Diagrams

shipment,

contact

tho

deliVering

Carrier

For

assistance

in

filing

or

settling

claims,

contact

your

distributor

and/or

equipment

manufaCturers

Transportation

Department

~j~jjj~j~

-

1T1

CALL:

414-735-4505

FAX:

800-637-2348

(in

USA),

or

414-735-4136

(outside

USA)

Process

Handbooks

.

Users

Guides

Distributor

Directories

r

i

WRITE:

Miller

Electric

Mfg.

Co.

contact

your

distributor

P0.

Box

1079

Appleton,

WI

54912

USA

Always

provide

Model

Name

and

Serial

or

Style

Number

L

.

.1

I

miIIeLwarl

3/96

SECTION

1

-

SAFETY

PRECAUTIONS

FOR

ARC

WELDING

ELECTRIC

SHOCK

can

kill.

Touching

!ive

electrical

parts

can

cause

fatal

shocks

or

severe

burns.

The

electrode

and

work

circuit

is

electrically

live

whenever

the

output

is

on.

The

input

power

circuit

and

machine

internal

circuits

are

also

live

when

power

is

on.

In

semiautomatic

or

automatic

wire

welding,

the

wire,

wire

reel,

drive

roll

housing,

and

all

metal

parts

touching

the

welding

wire

are

electrically

live.

Incorrectly

installed

or

improperly

grounded

equipment

is

a

hazard.

1.

Do

not

touch

live

electrical

parts.

2.

Wear

dry,

hole-free

insulating

gloves

and

body

protection.

3.

Insulate

yourself

from

work

and

ground

using

dry

insulating

mats

or

covers

big

enough

to

prevent

any

physical

contact

with

the

work

or

ground.

4.

Disconnect

input

power

or

stop

engine

before

installing

or

servicing

this

equipment.

Lockout/tagout

input

power

according

to

OSHA

29

CFR

1910.147

(see

Safety

Standards).

5.

Properly

install

and

ground

this

equipment

according

to

its

Owners

Manual

and

national,

state,

and

local

codes.

6.

Always

verify

the

supply

ground

check

and

be

sure

that

input

nower

cord

around

wire

is

orooerlv

connected

to

around

terminal

in

disconnect

box

or

that

cord

plug

is

connected

to

a

properly

grounded

receptacle

outlet.

7.

When

making

input

connections,

attach

proper

grounding

conductor

first

double-check

connections.

8.

Frequently

inspect

input

power

cord

for

damage

or

bare

wiring

replace

cord

immediately

if

damaged

bare

wiring

can

kill.

9.

Turn

off

all

equipment

when

not

in

use.

10.

Do

not

use

worn,

damaged,

undersized,

or

poorly

spliced

cables.

11.

Do

not

drape

cables

over

your

body.

12.

If

earth

grounding

of

the

workpiece

is

required,

ground

it

directly

with

a

separate

cable

do

not

use

work

clamp

or

work

cable.

13.

Do

not

touch

electrode

if

you

are

in

contact

with

the

work,

ground,

or

another

electrode

from

a

different

machine.

14.

Use

only

well-maintained

equipment.

Repair

or

replace

damaged

parts

at

once.

Maintain

unit

according

to

manual.

15.

Wear

a

safety

harness

if

working

above

floor

level.

16.

Keep

all

panels

and

covers

securely

in

place.

17.

Clamp

work

cable

with

good

metal-to-metal

contact

to

workolece

or

worktable

as

near

the

weld

as

oractical.

OM-1

588C

7196

safety_somi

4/95

.

1-1.

Symbol

Usage

4A

Means

Warning!

Watch

Out!

There

are

possib!e

hazards

with

this

A

Marks

a

special

safety

message.

procedure!

The

possib!e

hazards

are

shown

in

the

adjoining

symbols.

~

Means

NOTE;

not

safety

related.

I

This

group

of

symbols

means

Warning!

Watch

Out!

possib!e

ELECTR!C

SHOCK,

MOVING

PARTS,

and

HOT

PARTS

hazards.

Consu!t

symbo!s

and

related

instructions

below

for

necessary

I

________________________________

actions

to

avoid

the

hazards.

1-2.

Arc

Welding

Hazards

A~

WARNING

The

symbols

shown

below

are

used

throughout

this

manual

to

call

attention

to

and

identify

possible

hazards.

When

you

see

the

symbol,

watch

out,

and

follow

the

related

instructions

to

avoid

the

hazard.

The

safety

information

given

below

is

only

a

summary

of

the

more

complete

safety

information

found

in

the

Safety

Standards

listed

in

Section

1-4.

Read

and

follow

all

Safety

Standards.

Only

qualified

persons

should

install,

operate,

maintain,

and

repair

this

unit.

During

operation,

keep

everybody,

especially

children,

away.

ARC

RAYS

can

burn

eyes

and

skin;

ARC

RAYS

NOISE

can

damage

hearing;

FLYING

~

SLAG

OR

SPARKS

can

injure

eyes.

2.

Wear

a

welding

helmet

fitted

with

a

proper

shade

of

filter

to

protect

yourface

and

eyes

when

welding

or

watching

(see

ANSI

Arc

rays

from

the

welding

process

produce

intense

Z49.1

and

Z87.1

listed

in

Safety

Standards).

visible

and

invisible

(ultraviolet

and

infrared)

rays

3.

Wear

approved

safety

glasses

with

side

shields.

that

can

bum

eyes

and

skin.

Noise

from

some

processes

can

damage

hearing.

Chipping,

4.

Use

protective

screens

or

barriers

to

protect

others

from

flash

grinding,

and

welds

cooling

throw

off

pieces

of

metal

or

slag.

and

glare;

warn

others

not

to

watch

the

arc.

NOISE

5.

Wear

protective

clothing

made

from

durable,

flame-resistant

1.

Use

approved

ear

plugs

or

ear

muffs

if

noise

level

is

high.

material

(wool

and

leather)

and

foot

proteclion.

FUMES

AND

GASES

can

be

5.

Work

in

a

confined

space

only

if

it

is

well

ventilated,

or

while

~

hazardous

to

your

health.

wearing

an

air-supplied

respirator.

Always

have

a

trained

Welding

produces

fumes

and

gases.

Breathing

watchperson

nearby.

Welding

fumes

and

gases

can

displace

air

these

fumes

and

gases

can

be

hazardous

to

your

and

lower

the

oxygen

level

causing

injury

or

death.

Be

sure

the

health,

breathing

air

is

safe.

-.

6.

Do

not

weld

in

locations

near

degreasing,

cleaning,

or

spraying

1.

Keep

your

head

out

of

the

fumes.

Do

not

breathe

the

fumes.

operations.

The

heat

and

rays

of

the

arc

can

react

with

vapors

to

form

highly

toxic

and

irritating

gases.

2.

If

inside,

ventilate

the

area

and/or

use

exhaust

at

the

arc

to

remove

welding

fumes

and

gases.

7.

Do

not

weld

on

coated

metals,

such

as

galvanized,

lead,

or

3.

If

ventilation

is

poor,

use

an

approved

air-supplied

respirator.

cadmium

plated

steel,

unless

the

coating

is

removed

from

the

4.

Read

the

Material

Safety

Data

Sheets

(MSDSS)

and

the

weld

area,

the

area

is

well

ventilated,

and

if

necessary,

while

manufacturers

instruction

for

metals,

consumables,

coatings,

wearing

an

air-supplied

respirator.

The

coatings

and

any

metals

deaners,

and

degreasers.

containing

these

elements

can

give

off

toxic

fumes

if

welded.

OM-1588

Page

1

CYLINDERS

can

explode

if

damaged.

Shielding

gas

cylinders

contain

gas

under

high

pressure.

If

damaged,

a

cylinder

can

explode.

Since

gas

cylinders

are

normally

partof

the

welding

process,

be

sure

to treat

them

carefully.

1.

Protect

compressed

gas

cylinders

from

excessive

heat,

mechanical

shocks,

slag,

open

flames,

sparks,

and

arcs.

2.

Install

cylinders

in

an

upright

position

by

securing

to

a

stationary

support

or

cylinder

rack

to

prevent

falling

or

tipping.

3.

Keep

cylinders

away

from

any

welding

or

other

electrical

circuits.

4.

Never

drape

a

welding

torch

over

a

gas

cylinder.

5.

Never

allow

a

welding

electrode

to

touch

any

cylinder.

6.

Never

weld

on

a

pressurized

cylinder

explosion

will

result.

7.

Use

only

correct

shielding

gas

cylinders,

regulators,

hoses,

and

fithngs

designed

for

the

specific

application;

maintain

them

and

associated

parts

in

good

condition.

8.

Turn

face

away

from

valve

outlet

when

opening

cylinder

valve.

9.

Keep

protective

cap

in

place

over

valve

except

when

cylinder

is

in

use

or

connected

for

use.

10.

Read

and

follow

instructions

on

compressed

gas

cylinders,

associated

equipment,

and

CGA

publication

P-i

listed

in

Safety

Standards.

WELDING

can

cause

fire

or

explosion.

Welding

on

closed

containers,

-such

as

tanks,

drums,

or

pipes,

can

cause

them

to

blow

up.

Sparks

can

fly

oft

from

the

welding

arc.

The

flying

sparks,

hot

workpiece,

and

hot

equipment

can

cause

fires

and

bums.

Accidental

contact

of

electrode

to

metal

objects

can

cause

sparks,

explosion,

overheating,

or

fire.

Check

and

be

sure

the

area

is

safe

before

doing

any

welding.

1.

Protect

yourself

and

others

from

flying

sparks

and

hot

metal.

2.

Do

not

weld

where

flying

sparks

can

strike

flammable

material.

3.

Remove

all

flammables

within

35

ft

(10.7

m)

of

the

welding

arc.

If

this

is

not

possible,

tightly

cover

them

with

approved

covers.

4.

Be

alert

that

welding

sparks

and

hot

materials

from

welding

can

easily

go

through

small

cracks

and

openings

to

adjacent

areas.

5.

Watch

for

fire,

and

keep

a

fire

extinguisher

nearby.

6.

Be

aware

that

welding

on

a

ceiling,

floor,

bulkhead,

or

partition

can

cause

fire

on

the

hidden

side.

7.

Do

not

weld

on

closed

containers

such

as

tanks,

drums,

or

pipes,

unless

theyare

property

prepared

according

t0AWS

F4.1

(see

Safety

Standards).

8.

Connect

work

cable

to

the

work

as

close

to

the

welding

area

as

practical

to

prevent

welding

current

from

traveling

long,

possibly

unknown

paths

and

causing

electric

shock

and

fire

hazards.

9.

Do

not

use

welder

to

thaw

frozen

pipes.

10.

Remove

stick

electrode

from

holder

or

cut

off

welding

wire

at

contact

tip

when

not

in

use.

11.

Wearoil-free

protective

garments

such

as

leathergloves,

heavy

shirt,

cuftless

trousers,

high

shoes,

and

a

cap.

12.

Remove

any

combustibles,

such

as

a

butane

lighter

or

matches,

from

your

person

before

doing

any

welding.

FIRE

OR

EXPLOSION

can

result

from

placing

unit

on,

over,

or

near

combustible

surfaces.

1.

Do

not

locate

unit

on,

over,

or

near

combustible

surfaces.

2.

Do

not

install

unit

near

flammables.

FALLING

EQUIPMENT

can

cause

serious

personal

injury

and

equipment

damage.

1.

Use

lifting

eye

to

lift

unit

only,

NOT

running

gear,

gas

cylinders,

or

any

other

accessories.

Use

equipment

of

adequate

capacity

to

lift

unit.

~f

using

lift

forks

to

move

unit,

be

sure

forks

are

long

enough

to

extend

beyond

opposite

side

of

unit.

HOT

PARTS

can

cause

severe

burns.

1.

Do

not

touch

hot

parts

bare

handed.

2.

Allow

cooling

period

before

working

on

gun

or

torch.

MOVING

PARTS

can

cause

injury.

1.

Keep

away

from

moving

parts

such

as

fans.

2.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

MAGNETIC

FIELDS

FROM

HIGH

CURRENTS

can

affect

pacemaker

operation.

1.

Pacemaker

wearers

keep

away.

2.

Wearers

should

consult

their

doctor

before

going

near

arc

welding,

gouging,

or

spot

welding

operations.

MOVING

PARTS

can

cause

injury.

1.

Keep

away

from

moving

parts.

2.

Keep

away

from

pinch

points

such

as

drive

rolls.

FLYING

PIECES

OF

METAL

or

DIRT

can

injure

eyes.

1.

Wear

safety

glasses

with

side

shields

or

face

shield.

1.

Do

not

press

gun

trigger

until

instructed

to

do

so.

2.

Do

not

point

gun

toward

any

part

of

the

body,

other

people,

or

any

metal

when

threading

welding

wire.

HIGH-FREQUENCY

RADIATION

can

interfere

with

radio

navigation,

safety

services,

computers,

and

communications

equipment.

Have

only

qualified

persons

familiar

with

electronic

equipment

perform

this

installation.

The

user

is

responsible

for

having

a

qualified

electrician

promptly

correct

any

interference

problem

resulting

from

the

installation.

If

notified

by

the

FCC

about

interference,

stop

using

the

equipment

at

once.

Have

the

installation

regularly

checked

and

maintained.

Keep

high-frequency

source

doors

and

panels

tightly

shut,

keep

spark

gaps

at

correct

setting,

and

use

grounding

and

shielding

to

minimize

the

possibility

of

interference.

.

1-3.

Additional

Installation,

Operation,

And

Maintenance

Hazards

~i1~

2.

3.

,4~

WELDING

WIRE

can

cause

puncture

~

wounds.

.

OM-i588

Page

2

<~

~

~y

I

I

OVERUSE

can

cause

OVERHEATED

1.

Allow

cooling

penod.

EQUiPMENT.

2.

Reduce

current

or

reduce

duty

cycle

before

starting

to

weld

again,

3.

Follow

rated

duty

cycle,

SIGNIFICANT

DC

VOLTAGE

exists

after

1.

Turn

Off

inverter,

disconnect

input

power~

and

removal

of

input

power

on

inverters.

discharge

input

capacitors

according

to

instructions

in

Maintenance

Section

before

touching

any

parts.

on

circuit

boards.

1.

Put

on

grounded

wrist

strap

BEFORE

handling

STATIC

ELECTRICITY

can

damage

parts

boards

or

parts.

2.

Use

proper

static-proof

bags

and

boxes

to

store,

move,

or

ship

PC

boards.

I

BUILDUP

OF

SHIELDING

GAS

can

harm

health

or

kill.

1.

Shutoff

shielding

gas

supply

when

not

in

use.

1-4.

Principal

Safety

Standards

Safety

in

Welding

and

Cutting,

ANSI

Standard

Z49.1,

from

Safe

Handling

of

Compressed

Gases

in

Cylinders,

CGA

Pamphlet

American

Welding

Society,

550

N.W.

LeJeune

Rd,

Miami

FL 33126

P-i,

from

Compressed

Gas

Association,

1235

Jefferson

Davis

Safety

and

Health

Standards,

OSHA

29

CFR

1910,

from

Superintendent

of

Documents,

U.S.

Government

Printing

Office,

Washington,

D.C.

20402.

Highway,

Suite

501,

Arlington,

VA

22202.

Code

for

Safety

in

Welding

and

Cutting,

CSA

Standard

W117.2,

from

Canadian

Standards

Association,

Standards

Sales,

178

Rexdale

Boulevard,

Rexdale,

Ontario,

Canada

M9W

1

R3.

Recommended

Safe

Practices

for

the

Preparation

for

Welding

and

Cutting

of

Containers

That

Have

Held

Hazardous

Substances,

American

Welding

Society

Standard

AWS

F4.i,

from

American

Welding

Society,

550

N.W.

LeJeune

Rd,

Miami,

FL

33126

Safe

Practices

For

Occupation

And

Educational

Eye

And

Face

Protection,

ANSI

Standard

Z87.1

from

American

National

Standards

Institute,

1430

Broadway,

New

York,

NY

10018.

Cutting

And

Welding

Processes,

NFPA

Standard

51

B,

from

National

Electrical

Code,

NFPA

Standard

70,

from

National

Fire

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

MA

02269.

1-5.

EMF

Information

Considerations

About

Welding

And

The

Effects

Of

Low

Frequency

To

reduce

magnetic

fields

in

the

workplace,

use

the

following

Electric

And

Magnetic

Fields

procedures:

The

following

is

a

quotation

from

the

General

Conclusions

Section

of

the

U.S.

Congress,

Office

of

Technology

Assessment,

Biological

1.

Keep

cables

close

together

by

twisting

or

taping

them.

Effects

of

Power

Frequency

Electric

&

Magnetic

Fields

Background

Papei

OTA-BP-E-53

(Washington,

DC:

U.S.

2.-

Arrange

cables

to

one

side

and

away

from

the

operator.

Government

Printing

Office,

May

1989):.

. .

there

is

now

a

very

large

volume

of

scientific

findings

based

on

experiments

at

the

3.

Do

not

coil

or

drape

cables

around

the

body.

cellular

level

and

from

studies

with

animals

and

people

which

clearly

4.

Keep

welding

power

source

and

cables

as

far

away

as

establish

that

low

frequency

magnetic

fields

can

interact

with,

and

practical.

produce

changes

in,

biological

systems.

While

most

of

this

work

is

of

very

high

quality,

the

results

are

complex.

Current

scientific

5.

Connect

work

clamp

to

workpiece

as

close

to

the

weld

as

understanding

does

not

yet

allow

us

to

interpret

the

evidence

in

a

possible.

single

coherent

framework.

Even

more

frustrating,

it

does

not

yet

allow

us

to

draw

definite

conclusions

about

questions

of

possible

About

Pacemakers:

risk

or

to

offer

clear

science-based

advice

on

strategies

to

minimize

The

above

procedures

are

also

recommended

for

pacemaker

or

avoid

potential

risks.

wearers.

Consult

your

doctor

for

complete

information.

OM-1588

Page

3

SECTION

1

-

CONSIGNES

DE

SECURITE

POUR

LE

SOUDAGE

A

LARC

safetysoml_fr

4/95

1-1.

Signification

des

symboles

I

I

I

I

I

~

I

a

Signifie

Mise

en

garde!

Soyez

vigilant!

Cette

procedure

prØsente

A

Identifie

un

message

de

sØcuritØ

particulier.

des

nsques

de

danger!

Ceux-ci

sont

identifies

par

des

symboles

07

Sign/tie

NOTA;

nestpas

relatif

Ia

sØcuntØ.

adjacents

aux

directives.

I

Ce

groupe

de

symboles

signifie

Mise

en

garde!

Soyez

vigilant!

II

y

a

des

risques

de

danger

relies

~

aux

CHOCS

ELECTF1IQUES,

aux

PI¨CES

EN

MOUVEMENT

et

aux

PI¨CES

CHAUDES.

Reportez-vous

aux

symboles

et

aux

directives

ci-dessous

atm

de

connaitre

les

mesures

a

prendre

I

pour

Øviter

tout

danger.

1-2.

Dangers

relatifs

au

soudage

a

Iarc

4A

MISE

EN

GARDE

Les

symboles

prØsentØs

ci-aprŁs

sont

utilisØs

tout

au

long

du

present

manuel

pour

attirer

votre

attention

et

identifier

les

risques

de

danger.

Lorsque

vous

voyez

un

symbole,

soyez

vigilant

et

suivez

les

directives

mentionnØes

afin

dØviter

tout

danger.

Les

consignes

de

securitepresentees

ci-aprŁs

ne

font

que

rØsumer

linformation

contenue

dans

les

normes

de

sØcuritØ

ØnumØrØes

a a

section

1-4.

Veuillez

lire

et

respecter

toutes

ces

normes

de

sØcuritØ.

Linstallation,

lutilisation,

Ientretien

et

les

reparations

ne

doivent

Øtre

confiØs

qua

des

personnes

qualifiØes.

Au

cours

de

Iutilisation,

tenir

toute

personne

a

lØcart

et

plus

particuliŁrement

les

enfants.

.

.

UN

CHOC

ELECTRIQuE

peut

tuer.

Un

simple

contact

avec

des

piŁces

electnques

peut

provoquer

une

electrocution

ou

des

blessures

graves.

LØlectrode

et

Ic

circuit

de

soudage

sont

sous

tension

des

que

lappareil

est

sur

ON.

Le

circuit

dentrØe

et

les

circuits

intemes

de

lappareil

sont

Øgatement

sous

tension

a

ce

moment-l.

En

souda9e

semi-automati

que

ou

automatique,

le

fit,

le

dØvidoir,

le

logement

des

galets

dentrainement

et

tes

piŁces

mØtal!iques

en

contact

avec

le

fit

de

soudage

sont

sous

tension.

Des

matØriels

mat

installØs

ou

mal

mis

ala

terre

prØsentent

___________

un

danger.

1.

Ne

jamais

toucher

les

piŁces

electriques

sous

tension.

2.

Porter

des

gants

et

des

vŒtements

do

protection

secs

ne

com

portant

pas

de

trous.

3.

Sisoler

de

Ia

piŁce

et

de

Ia

terre

au

moyen

de

tapisou

dautres

moyens

isolants

suffisamment

grands

pour

empŒcher

le

contact

physique

Øventuel

avec

a

piŁce

ou

Ia

terre.

4.

Couper

latimentation

ou

arrŒter

Ic

moteur

avant

de

procØder

a

linstallation,

ala

reparation

ou

a

lentretien

de

lappareil.

DØver

rouiller

lalimentation

seton

Ia

norrrie

OSHA

29

CFR

1910.147

(voir

normes

de

sØcuntØ).

5.

Installer

et

mettre

a

Ia

terre

correctement

cot

appareil

contormØ

ment

a

son

manuel

dutilisation

et

au

codes

nationaux,

provin

ciaux

et

municipaux.

6.

Toujours

verifier

Ia

terre

du

cordon

dalimentation

Verifier

et

sassurer

quo

le

fil

do

terre

du

cordon

dalimentation

est

bien

rac

cordØ

ala

bome

de

terre

du

sectionneur

ou

quo

Ia

fiche

du

cor

don

est

raccordØe

a

une

prise

correctement

mise

a

Ia

terre.

7.

En

effectuant

les

raccordements

dentrØe

fixer

dabord

le

con

ducteurde

misc a

laterre

appropiie

et

contre-vØrifier

los

connex

ions.

8.

VØnfierfrequemment

Ic

cordon

dalimentation

pour

voir

sil

nest

pas

endommage

ou

dØnudØ

remplacer

Ic

cordon

immediate

ment

sil

est

endommage

un

cable

dØnudØ

pout

provoquer

une

electrocution.

9.

Mettre

tappareil

hors

tension

quand

on

ne

Iutilise

pas.

10.

Ne

pas

utiliser

des

cables

uses,

endommagØs,

de

grosseur

insuffisante

ou

mat

episses.

11.

Ne

pas

enrouler

los

cables

autour

du

corps.

12.

Si

Ia

piŁce

soudØe

dolt

Œtre

misc

a

Ia

terre,

Ic

faire

directement

avec un

cable

distinct

ne

pas

utiliser

Ic

connecteur

de

piŁce

ou

Ic

cable

de

retour.

13.

Ne

pas

toucher

electrode

quand

on

est

en

contact

avec

Ia

piŁce,

Ia

terre

ou

une

electrode

provenant

dune

autre

machine.

14.

Nutiliserquun

materiel

en

bon

Øtat.

Reparerou

remplacersur

Ic-champ

les

piŁces

endommagees.

Entretenir

lappareil

confor

mØment

a

cc

manuel.

15.

Porter

un

hamais

de

sØcuntŁ

quand

on

travaille

en

hauteur.

16.

Mamntenir

solidement

en

place

tous

les

panneaux

et

capots.

17.

Fixer

Ic

cable

de

retour

de

faon

a

obtenir

un

bon

contact

metal

metal

avec

Ia

piŁce

a

souder

ou

Ia

table

de

travail,

Ic

plus

pres

possible

de

Ia

soudure.

LE

RAYONNEMENT

DE

LARC

peut

RAVONNEMENT

DE

LARC

brGler

les

yeux

et

Ia

peau.

Le

BRUIT

peut

endommager

louIe;

les

~

ECTIONS

~

DE

LAITIER

OU

LES

ETINCELLES

peuvent

blesser

les

yeux.

Larc

de

soudage

produit

des

rayons

visibles

et

invi-

sibles

intenses

(ultravio!ets

et

infrarouges)

qui

peuv-

ent

brUler

les

yeux

et

Ia

peau.

Le

bruit

produit

par

cer

tains

procedØs

peut

endommager

louie.

Des

projec-

tions

de

metal

ou

de

laitier

sont

produites

par

le

piquage,

Ie

meulage

ou

le

refroidissement

des

sou-

dures.

BRUIT

1.

Utiliser

des

bouche-oreilles

ou

des

serre-tŒte

antibruit

approu-

yes

si

le

niveau

de

bruit

est

Øleve.

2.

3.

4.

5.

Porter

un

masque

a

serre-tŒte

muni

dun

verre

filtrant

de

nuance

appropnee

pour

proteger

le

visage

et

les

yeux

quand

on

soude

ou

observe

Ia

travail

de

soudage

(voir

les

nomies

ANSI

Z49.1

et

Z87.1

donnØes

sous

Ia

rubrique

Principales

nomies

de

sØcu

rite).

Porter

des

Iunettes

de

sØcuntØ

approuvØes

avec

Øcrans

late

raux.

Utiliser

des

paravents

ou

des

bamŁres

de

protection

pour

pro

tØger

les

personnes

a

proximitO

contre

les

coups

darc

et

lØ

btouissement;

avertir

les

autres

personnes

de

ne

pas

regarder

larc.

Porter

des

vŁtements

de

protection

en

tissu

ignifuge

durable

(lame

et

cuir)

et

des

chaussures

de

sØcuritØ.

OM-1

588

Page

4

~

LES

VAPEURS

ET

LES

FUMEES

~

peuvent

Œtre

dangereuses

pour

Ia

~

sante.

=~

~

Le

soudage

produit

des

vapeurs

et

des

fumØes

quiI

____________

est

dangereux

de

respirer.

1.

Garder

Ia

tŒte

a

lextØrieur

des

vapeurs

et

des

fumØes

et

ne

pas

les

respirer.

2.

A

IintØneur~

ventiler

le

poste

de

travail

ou

utiliser

un

dispositif

place

au

niveau

de

larc

pour

Øvacuer

les

vapeurs

et

fumØes

de

soudage.

3.

Si

Ia

ventilation

est

mauvaise,

utiliser

un

appareil

respiratoire

a

adduction

dair

pur

approuve.

4.

Consulter

les

fiches

signaletiques

et

les

consignes

du

fabncant

relatives

au

mØtaux,

produits

dapport,

revŒtements,

nettoyants

et

LES

BOUTEILLES

peuvent

exploser

Si

elles

sont

endommagØes.

Les

bouteilles

contenant

des

gaz

de

protection

sont

a

haute

pre~sion.

Une

bouteille

endommagØe

peut

exploser.

Etant

donnØ

que

es

bouteilles

de

gaz

font

normalement

partie

du

materiel

de

soudage,

les

traiter

avec

le

plus

grand

soin.

1.

Proteger

es

bouteilles

de

gaz

comprime

centre

Ia

chaleur

intense,

les

chocs,

le

laitier,

es

flammes

nues,

es

Øtincelles

et

arc.

2.

Placer

es

bouteilles

a

Ia

verticale

en

les

fixant

a

un

support

fixe

ou

a

un

chariot

pour

Øviter

quelles

ne

tombent

ou

ne

basculent.

3.

Tenir

les

bouteilles

a

lØcart

du

poste

de

soudage

ou

dautres

circuits

electnques.

LE

SOUDAGE

peut

causer

un

incendie

ou

une

explosion.

Ne

pas

souder

sur

des

recipients

fermØs

comme

des

reservoirs,

des

fUts

ou

des

tuyaux

:

ils

peuvent

exploser.

Larc

de

soudage

peut

produire

des

Øtincelles.

Des

Øtincelles,

une

piŁce

chaude

et

un

materiel

chaud

peuvent

provoquer

des

incendies

et

des

blessures.

Le

contact

accidentel

de

electrode

sur

des

objets

mØtalliques

peut

produire

des

Øtincelles,

lexplosion,

Ia

surchaufte

ou

un

incendie.

Sassurerque

le

lieu

ne

presente

pas

de

dangeravant

deffectuer

le

soudage.

1.

Se

protØger

et

protØger

les

personnes

a

proximite

des

Øtincelles

et

du

metal

chaud.

2.

Ne

pas

souder

dans

un

endroit

oCi

les

Øtincelles

peuvent

atteindre

des

matØrlaux

inflammables.

3.

Enlever

toutes

les

matiŁres

inflammables

dans

un

rayon

de

moms

de

10

m

de

arc.

Si

cela

nest

pas

possible,

bien

les

recouvrir

en

utilisant

des bches

approuvØes.

4.

Prendre

garde

que

les

Øtincelles

et

les

projections

ne

penetrent

dans

des

zones

adjacentes

en

sinfiltrant

dans

des

petites

fissures

et

ouvertures.

5.

Ne

travailler

dans

un

espace

confine

que

511

est

bien

ventilØ,

ou

en

portant

un

appareil

respiratoire

a

adduction

dair

pur.

Demander

a

un

observateur

ayant

reu

Ia

bonne

formation

de

toujours

se

tenir

a

proximitØ.

Les

vapeurs

et

fumØes

de

soudage

peuvent

dØplacer

Iai

ret

abaisser

le

niveau

doxygene

et

causer

des

blessures

graves

voire

mortelles.

Sassurer

que

lair

est

propre

a

Ia

respiration.

6.

Ne

pas

souder

a

proximitØ

dopØrations

de

degraissage,

de

nettoyage

ou

de

pulverisation.

La

chaleur

et

les

rayons

de

Iarc

peuvent

rØagir

avec

les

vapeurs

pour

former

des

gaz

hautement

toxiques

et

irritants.

7.

Ne

pas

souder

sur

des

mØtaux

revŒtus

comme

Iacier

galvanisØ,

au

p10mb

ou

cadmiØ

a

moms

que

Ia

piŁce

nait

ØtØ

entiŁrement

dØcapØe,

que

le

poste

de

travail

soit

bien

ventilØ.

Sil

y

a

lieu,

porter

un

appareil

respiratoire

a

adduction

dair

pur.

Les

revŒtements

et

les

mØtaux

qui

contiennent

de

tels

ØlØments

peuvent

degager

des

vapeurs

toxiques

lors

du

soudage.

4.

Nejamais

poser

un

chalumeau

soudeursurune

bouteille

de

gaz.

5.

Ne

jamais

laisser

une

electrode

de

soudage

toucher

une

bouteille.

6.

Ne

jamais

souder

sur

une

bouteille

sous

pression

:

elle

exploserait.

7.

Nutiliser

que

des

bouteilles

de

gaz

de

protection,

des

dØtendeurs,

des

tuyaux

souples

et

des

raccords

appropriØs

conus

pour

lapplication

particuliŁre;

conserverces

matØnels

et

leurs

piŁces

en

bon

Øtat.

8.

Eloigner

le

visage

de

Ia

sortie

du

robinet

de

a

bouteille

quand

on

louvre.

9.

Replacer

le

chapeau

sur

Ia

bouteille

aprŁs

utilisation.

10.

Lire

et

suivre

les

consignes

relatives

aux

bouteilles

de

gaz

compnmØ,

au

materiel

connexe

ainsi

que

Ia

publication

P-i

de

Ia

CGA

donnØe

sous

Ia

rubrique

Pnncipales

norrnes

de

sØcuritØ.

5.

Prendre

garde

aux

incendies

et

toujours

avoir

Un

extincteur

a

proximitØ.

6.

Se

rappeler

que

si

on

soude

sur

un

plafond,

un

plancher,

une

-

cloison

ou

autre,

le

feu

peut

prendre

de

lautre

ctØ.

7.

Ne

pas

souder

sur

des

recipients

fermØs

comme

des

reservoirs,

des

fCits

ou

des

tuyaux

a

moms

quits

ne

soient

prepares

de

facon

appropnØe

confom,Øment

a

Ia

norme

F4.1

de

lAWS

(voir

Ia

rubrique

Principales

normes

de

secuntØ).

8.

Raccorder

le

cable

de

retour

Ia

piŁce,

le

plus

prŁs

possible

de

Ia

zone

de

soudage,

pour

empŒcher

que

le

courant

de

soudage

ne

suive

une

trajectoire

longue

et

Øventuellement

inconnue

et

quil

ne

provoque

des

nsques

dØlectrocution

et

dincendie.

9.

Ne

pas

utiliser

le

chalumeau

soudeur

pour

degeler

des

tuyaux.

10.

EnleverlØlectrode

enrobØe

du

porte-electrode

ou

couper

le

fil

de

soudage

au

ras

du

bec

contact

quand

on ne

lutilise

pas.

11.

Porter

des

vŒtements

de

protection

non

huileux

comme

des

gants

en

cuir,

une

chemise

epaisse,

des

pantalons

sans

revers,

des

chaussures

montantes

et

un

casque.

12.

Ne

pas

porter

des

matiŁres

combustibles

sur

soi

comme

un

bnquet

a

gaz

ou

des

allumettes

quand

on

soude.

1-3.

Autres

dangers

relatifs

a

Iinstallation,

Iutilisation

et

Ientretien

UN

INCENDIE

OU

UNE

EXPLOSION

peut

Œtre

cause

par

un

appareil

place

au

contact,

au-dessus

ou

a

ctØ

dune

surface

combustible.

1.

Ne

pas

placer

lappareil

au

contact,

au-dessus

ou

prŁs

de

surfaces

combustibles.

Ne

pas

installer

Iappareil

a

ct~

dun

objet

ou

dun

prod

uit

inflammable.

LES

CHUTES

DOBJETS

peuvent

causer

des

blessures

graves

et

endommager

IØquipement.

1.

Nutiliser

Ianneau

de

levage

que

pour

soulever

lappareil

Iui-mŒme;

sans

train

de

roulement,

de

bouteilles

de

gaz

ou

autres

accessoires.

Pour

sou

lever

lappareil,

utiliser

des

equipements

de

puissance

suffisante.

Si

un

chariot-ØlØvateur

est

utilise

pour

dØplacer

lappareil,

les

fourches

doivent

Œtre

plus

longues

que

Ia

largeur

de

Iappareil.

LES

PI¨CES

CHAU

DES

peuvent

causer

des

brlures

graves.

1.

Ne

pas

toucher

aux

piŁces

chaudes

les

mains

nues.

2.

Laisser

le

pistolet

ou

Ia

torche

refroidir

avant

dy

toucher.

LES

PI¨CES

EN

MOUVEMENT

peuvent

causer

des

blessures.

1.

Rester

a

IØcart

des

piŁces

en

mouvement

comme

les

ventilateurs.

2.

Sassurer

que

les

portes,

les

panneaux,

les

capots

et

les

protecteurs

sont

bien

ferrnØs

et

bien

a

leur

place.

LES

PARTICULES

DE

METAL

OU

DE

SALETE

peuvent

provoquer

des

blessures

aux

yeux.

1.

Porter

des

Iunettes

de

sØcuritØ

avec

ecrans

latØraux

ou

un

Øcran

facial.

Ti

OM-1

588

Page

5

LES

CHAMPS

MAGNETIQUES

PRO

DUITS

PAR

LES

COURANTS

MAGNETI

QUES

ELEVES

peuvent

nuire

au

fonc

tionnement

dun

stimulateur

cardiaque.

1.

Les

personnes

qui

portent

un

stimulateur

cardia

que

doivent

se

tenir

Øloignees

des

postes

de

sou

dage.

Elles

devraient

consulter

leur

mØdecin

avant

de

sapprocherdun

poste

de

soudage

a

Iarc,

de

gou

geage

ou

de

soudage

par

points.

LES

PI¨CES

EN

MOUVEMENT

peuvent

causer

des

blessures.

1.

Rester

a

lØcart

des

piŁces

en

mouvement.

2.

Eviter

les

risques

de

pincement

relies

parexemple

aux

galets

dentrainement.

LE

FIL

DE

SOUDAGE

peut

percer

Ia

peau.

Attendre

les

instructions

avant

dappuyer

sur

Ia

gchette.

Ne

pas

pointer

le

pistolet

vers

vous,

ou

vers

toute

autre

personne

ou

piŁce

metallique

au

moment

denfiler

le

fil

de

soudage.

UNE

SURUTILISATION

peut

SUR

CHAUFFER

LAPPAREIL.

Laisser

lappareil

refroidir.

RØduire

le

courant

ou

le

facteur

de

marche

avant

de

poursuivre

le

soudage.

Respecter

le

facteur

de

marche

nominal.

LACCUMULATION

DE

GAZ

DE

PROTECTION

peut

Œtre

nocif

a

Ia

sante

ou

mortelle.

1.

Fermer

lalimentation

du

gaz

de

protection

lors

quon

ne

lutilise

pas.

LELECTRICITE

STATIQUE

peut

endom

mager

les

piŁces

des

cartes

PC.

1.

Porter

un

bracelet

antistatique

AVANT

de

manipuler

une

carte

ou

une

piŁce.

2.

Utiliserdes

sacs

et

des

boites

antistatiques

appro

priØs

pour

ranger,

dØplacerou

expedierdes

caries

PC.

LE

RAVONNEMENT

A

HAUTE

FRE

QUENCE

peut

perturber

le

fonctionne

ment

de

Ia

radionavigation,

de

services

de

securitØ,

dordinateurs

et

dappareils

de

communications.

1.

Linstallation

de

materiel

Ølectronique

doit

Œtre

ef

fectuØe

par

des

personnes

qualitiees.

2.

Si

des

problŁmes

dinterfØrence

surviennent

aprŁs

linstallation,

lutilisateur

de

lappareil

doit

avoir

recours

immØdiatement

au

service

dun

Ølectncien

afin

de

les

cornger.

3.

Si

un

avis

de

Ia

Commission

fØdØrale

des

commu

nications

vous

est

transmis

concemant

votre

ap

pareil,

arrØtez

de

lutiliser

sur-le-champ.

4.

Faire

verifier

et

entretenir

lappareil

penodique

ment.

5.

Tenir

les

portes

et

les

panneaux

de

Ia

source

de

haute

frequence

bien

fermØs,

maintenir

lØcarte

ment

des

electrodes

a

une

position

appropiiee,

et

utiliser

une

mise

a

Ia

terre

et

un

Øcran

de

protec

tion

pour

reduire

les

interferences.

UNE

TENSION

CC

IMPORTANTE

est

toujours

prØsente

mØme

aprŁs

que

Ionduleur

alt

ØtØ

dØbranchØ.

1.

Avant

de

toucher

a

une

piŁce,

mettre

hors

tension

londuleur,

dØbrancher

lappareil

et

decharger

les

condensateurs

selon

les

directives

de

(a

section

Entretien.

1-4.

Principales

normes

de

sØcuritØ

.

.

.

a

Safety

in

Welding

and

Cutting,

norrne

ANSI

Z49.1,

de

American

Safe

Handling

of

Compressed

Gases

in

Cylinders,

CGA

Pamphlet

Welding

Society,

550

N.W.

Lejeune

Rd,

Miami

FL 33126

P-i,

de

Ia

Compressed

Gas

Association,

1235

Jefferson

Davis

Safety

and

Health

Sandards,

OSHA

29

CFR

1910,

du

Highway,

Suite

501,

Arlington,

VA

22202.

Superintendent

of

Documents,

U.S.

Govemment

Printing

Office,

Regles

de

sØcuritØ

en

soudage,

coupage

et

procØdØs

connexes,

Washington,

D.C.

20402.

norme

CSA

Wi

17.2,

de

lAssociation

canadienne

de

normalisation,

vente

de

normes,

178

Rexdale

Boulevard,

Rexdale

(Ontario)

Recommended

Safe

Practice

for

the

Preparation

for

Welding

and

Canada

M9W

1

R3.

Cutting

of

Containers

That

Have

Held

Hazardous

Substances,

Safe

Practices

For

Occupation

And

Educational

Eye

And

Face

norme

AWS

F4.i

,

de

lAmerican

Welding

Society,

550

N.W.

Lejeune

Protection,

nomie

ANSI

Z87.1,

de

lAmencan

National

Standards

Rd,

Miami

FL

33126

Institute,

1430

Broadway,

New

York,

NY

10018.

National

Electrical

Code,

NFPA

Standard

70,

de

a

National

Fire

Cutting

and

Welding

Processes,

norme

NFPA

51

B,

de

a

National

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

1-5.

Information

sur

les

champs

ØlectromagnØtiques

DonnØes

sur

le

soudage

electrique

et

sur

es

effets,

pour

Atm

de

rØduire

les

champs

electromagnØtiques

dans

Iorganisme,

des

champs

magnetiques

basse

frequence

lenvironnement

de

travail,

respectez

les

consignes

suivantes

Lextrait

suivant

est

tire

des

conclusions

generales

du

document

1.

Gardez

es

cables

ensembles

en

les

torsadant

ou en

les

intitulØ

Biological

Effects

of

Power

Frequency

Electric

&

Magnetic

attachant

avec

du

ruban

adhØsit.

Fields

Background

Paper,

OTABPE53

(Washington

DC:

U.S.

Government

Printing

Office,

mai

1989),

publiØ

par

le

Office

of

2.

Mettre

tous

les

cables

du

cotØ

oppose

de

IopØrateur.

Technology

Assessment

du

CongrŁs

amØricain

:

...

1

existe

maintenant

dabondantes

donnØes

scientifiques

compilees

a

Ia

3.

Ne

courbez

pas

et

nentourez

pas

les

cables

autour

de

vous.

suite

dexperiences

sur

Ia

cellule

ou

dØtudes

sur

des

animaux

et

~

Gardez

le

poste

de

soudage

et

les

cables

le

plus

loin

des

humains,

qui

montrent

clairement

que

les

champs

possible

de

vous.

Ølectromagnetiques

basse

frequence

peuvent

avoir

des

effets

sur

Iorganisme

et

mŒme

y

produire

des

transformations.

MŒme

sil

5.

Reliez

Ia

pince

de

masse

le

plus

prŁs

possible

de

Ia

zone

de

sagit

de

travaux

de

trØs

grande

qualite,

les

rØsultats

sont

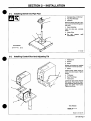

soudure.