La page est en cours de chargement...

T

o

O

p

e

n

{

P

a

r

a

A

b

r

i

r

s

e

}

[

P

o

u

r

S

'

o

u

v

r

i

r

]

T

o

C

l

o

s

e

{

P

a

r

a

C

e

r

r

a

r

s

e

}

[

P

o

u

r

S

e

f

e

r

m

e

r

]

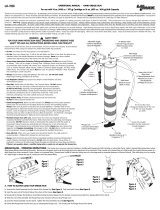

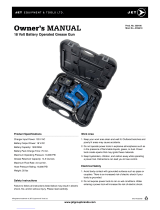

OPERATIONAL MANUAL - HAND GREASE GUN

For use with 14 oz. (400 cc / 397 g) Cartridge or 16 oz. (500 cc / 454 g) Bulk Capacity

LX-1145 : For use with 14 oz. (400 cc / 397 g) Cartridge or 24 oz. (750 cc / 680 g) Bulk Capacity

Thank you for purchasing Lumax

®

Grease Gun. By selecting Lumax

®

Grease Gun you have chosen a high-quality, precision engineered product which is built for heavy-duty service and a lifetime of

performance. Your safety is very important to us. Please read this Operational Manual carefully. The instructions contained in this manual MUST be read and understood by the operator prior to operating

this equipment. It is important that you read the entire manual to become familiar with the unit before you begin to operate the unit. Please store this Operational Manual in a safe place for later reference.

Lumax Lubrication products are precision engineered tools, which are capable of creating pressures well above 10,000 PSI (690 BAR). Only professional use assures danger-free operation of these

products. Warning :

Extreme pressure may cause nozzle extension or Grease Hose to burst. Always follow Grease Hose instructions and warnings. Keep hands clear of the extension during operation

of the Grease Gun. Be extra careful while working with Needle point Grease Adapters and Dispensers. Keep your hands away from the Needle point at all times and when injecting Grease.

Maintain your equipment periodically and check before each use that all connections are securely fastened. High Working Pressures may result in liquid being injected into flesh upon malfunction of

one of the components.

Only use components that show no indications of damage. While working on the Grease Gun barrel, make certain that the open, threaded barrel-end always points away from

yourself or others! Never touch a hose that is under pressure. Never point the outlet at yourself or others. Hoses are subject to rapid aging. Never use a hose that is older than 2 years. Hoses must never

be bent or twisted with force. The smallest bending radius for hose is 4” (100 mm). Seek immediate medical care after an injury.

WARNING : SAFETY FIRST ! FOR YOUR OWN PROTECTION READ, UNDERSTAND AND OBSERVE THESE SAFETY TIPS AND ALL INSTRUCTIONS BEFORE USING THIS PRODUCT!

Grease Guns should only be used as recommended. Any tool can fail if it is misused. To avoid Serious Personal Injury when using your Grease Gun, follow these Safety Tips and Rules :

• Do Not use Grease Gun for the purpose it is not intended for. Do Not Force use Grease Gun. It will do the job Better and Safer at the Rate for which it was Intended. Never Use Handle Extensions to

Increase Leverage. Never try to stop or deflect material from dispensing-end of the Grease Gun with your hand or body.

• Always Wear Appropriate Protective Clothing and Equipment. Do Not wear Loose Clothing or Jewelry. They can be caught in Moving Parts. Protective Gloves and Non-skid Footwear are

recommended when working with Grease Gun. Approved Guards and Protective Equipment, such as, Impact Resistant Safety Glasses, Safety or Chemical Splash Goggles, Full Face Shield, Safety Shoes,

Arm Guards and Apron Must be used

for Operator Protection. Wear Protective Hair Covering to contain Long Hair. Use Respirator. Always wear proper Face Mask to avoid Inhalation of Fumes and

Hazardous Gases. Keep Visitors Away. All Visitors should be kept away from Work Area. Do Not let Visitors operate Grease Gun.

• Always ensure there is adequate lighting in the work area. Do not Over-reach. Keep Proper Footing and Balance at all times.

• Stay Alert. Watch what you are doing. Use Common Sense. Do Not operate Grease Gun when you are tired or under the influence of any medications. Be Alert at All Times, especially, during

Repetitive, Monotonous Operations. You may have demonstrated a certain product hundreds of times, but do not be lulled into complacency due to a False Sense of Security. Tools can be extremely

unforgiving, if not used carefully and as per instructions.

• Check Damaged Parts. Before use of the Grease Gun, Always check it for proper operation before each use and make sure all safety devices are in place and operating properly. Always make

sure all grease connections are securely tightened. Carefully check for any Damaged Parts to determine that the Grease Gun will operate Properly and Perform its intended function. Check for

Alignment of Moving Parts, Binding of Moving Parts, Breakage of Parts, Mounting, and any other Conditions that may affect its Operation. Any Part that is damaged should be properly Repaired or

Replaced by an Authorized Service Center.

• Maintain Grease Guns with care. Keep Grease Gun Clean and regularly serviced or maintained for Better and Safe Performance. Follow Instructions for Lubricating and changing Accessories.

DO NOT attempt to repair or disassemble the equipment while the system is pressurized. Inspect Grease Gun periodically and if Grease Gun or any of its parts are Damaged - have it Repaired by

an Authorized Service Facility. Always keep your Grease Gun Inspected and Replace Immediately, if damaged or Worn. Do Not alter or modify any part of this equipment. Grease Guns Must only

be repaired by Qualified Technicians.

• Store Idle Tool. When not in use, Grease Guns should be Stored in Dry, High and/or in Locked-up place. Childproof the Grease Gun and work area.

• Always check local area Laws and Ordinances regarding Handling, Pumping and Disposing of Liquids. Dispose of pumped fluid properly. Do Not drain into street drains, house drains, or backyards.

Contact your local Municipal Waste Management officials for proper disposal methods. If there is any question about a condition being safe or unsafe, do not operate the Grease Gun.

!

LX-1142

LX-1144

LX-1145

GREASE FILLING : OPERATING INSTRUCTIONS : The Grease Gun can use a Lubricant Cartridge or be filled with

Grease from Bulk Container or with a Filler Pump. Refer to Grease Filling Instructions, below. Wipe grease fittings clean before

lubricating. Remove any old grease and/or dirt that might get into the equipment to be Lubricated. Push coupler onto grease

fitting at a slight angle (the coupler attaches easier at a slight angle than when centered). Center coupler on the grease fitting.

Operate lever handle to lubricate, taking care not to damage seals by excessive pressure or lubricant volume. After lubricating,

turn the coupler at a slight angle to release the grip of coupler jaws from the grease fitting.

Figure 2

Figura 2

Figure 2

Figure 3

Figura 3

Figure 3

Figure 1

Figura 1

Figure 1

A. HOW TO SUCTION LOAD YOUR GREASE GUN :

1. Unscrew the Head Assembly from the barrel of the Grease Gun (See Figure 1). Pack head with Grease (See Figure 2).

2.Unscrew the end-cap from the barrel. Pull on the Plunger T-handle to extract the Plunger Assembly and spring from the barrel. Visually inspect the follower seal lip direction before fiiling the Gun.

The follower seal lip must be “flipped over” toward the Head Assembly [flip the follower seal lip over and away from the follower spring by grasping follower between thumb and forefinger and flip

the follower lip from the rear to the front side toward the Head Assembly]. (See Figure 3). Re-assemble the Follower Assembly into barrel and tighten the end-cap onto the barrel.

3.Insert the open end of the barrel below the surface of the Grease (See Figure 4).

4.Slowly pull the Follower-rod while pushing the barrel deeper into the Grease to prevent air pockets from being pulled into the barrel.

5.When the Follower-rod is fully extended, pull it sideways to latch the rod groove into the keyhole slot in the end-cap to lock the Follower-rod in place

(See Figure 5). Screw the Head Assembly loosely onto the barrel.

Figure 4

Figura 4

Figure 4

Front Side

{ Parte delantera }

[ Partie antérieure ]

Figure 6

Figura 6

Figure 6

Figure 5

Figura 5

Figure 5

Form : LX-1142-45-IS

Coupler

{ Acoplador }

[ Coupleur ]

(LX-1400)

6” (150 mm)

Extension Pipe, 1/8” NPT

{ Pipa De la Extensión }

[ Pipe De Prolongation ]

(LX-1424)

Piston

{ Pistón }

[ Piston ]

Lever Handle

{ Maneta Palanca }

[ Poignée De Levier ]

Air Bleeder Valve

{ Grifo De Purga Del Aire }

[ Robinet purgeur D’Air ]

(LX-1422)

Toggle

{ Palanca }

[ Cabillot ]

Steel Barrel

{ Barril De acero }

[ Baril en Acier ]

Follower

{ Seguidor }

[ Palpeur ]

Follower Spring

{ Resorte Del Seguidor }

[ Ressort De Palpeur ]

Follower Rod

{ Seguidor Barra }

[ Palpeur Tige ]

T-handle

{ Manilla en forma de T }

[ Poignée en “T” ]

Non-slip Grip

{ Apretón Antideslizante }

[ Poignée Antidérapante ]

End Cap

{ Casquillo De Extremo }

[ Monture D’embout ]

Heavy-duty LuCast

TM

Alloy Head

{ Cabeza Resistente

De la Aleación De LuCast

TM

}

[ Tête Résistante

D’Alliage De LuCast

TM

]

Filler Nipple

{ Entrerrosca Del Llenador }

[ Mamelon De Remplisseur ]

(LX-1420)

Flip-over Follower toward Head Assembly (for Bulk-filling)

{ Embutidor de disparo hacia el

Ensamblaje del Cabezal (Para llenado en masa) }

[ Retourner le piston plongeur vers

l’assemblage principal (pour un remplissage en vrac) ]

Accessible Check Valve

{ Válvula De Cheque Accesible }

[ Clapet Anti-retour Accessible ]

6.Unlock the Follower-rod from the end-cap. This would push it into the barrel. Disengage the Follower-rod from the follower by rotating the follower “T”

handle. Slowly unscrew the barrel from the Head Assembly until lubricant oozes from the interface. Tighten the Head Assembly securely (See Figure 6).

7. Prime the Gun (Priming is the act of removing air and introducing Grease into the Grease Gun’s pumping mechanism). When filling the Grease Gun, it is very

important to prevent air pockets and to purge any air that may be trapped in the barrel. Caution : Air pockets in the lubricant will cause the Lever Grease

Gun to lose its prime. Prime the Grease Gun while pressing the Air Bleeder Valve to vent Air Pockets in the Grease Chamber. In most cases the

Grease Gun will prime simply by operating the Lever handle several times. Should Grease fail to appear, the Head Assembly must be bled.

8.Pump the Lever handle several times until Grease flows from the Coupler.

B. HOW TO BULK-LOAD YOUR GREASE GUN USING A GREASE FILLER PUMP : CAUTION : The Filler Nipple on the Grease Gun

must mate with the Loader Coupler on the Pump. The Pump may not operate if the components are not compatible. WARNING : The Grease Gun

is equipped with a low-pressure Filler Nipple. Do not substitute with a high-pressure Grease Fitting. Personal injury can occur due to excessive

pressure. The use of a Grease Fitting will also void the warranty.

1. Wipe the Filler Nipple with a clean cloth.

2.Unscrew the end-cap from the barrel. Pull on the Plunger T-handle to extract the Plunger Assembly and spring from the barrel. Visually inspect

the follower seal lip direction before fiiling the Gun. The follower seal lip must be “flipped over” toward the Head Assembly [flip the follower seal lip

over and away from the follower spring by grasping follower between thumb and forefinger and flip the follower lip from the rear to the front side

toward the Head Assembly]. (See Figure 3).

3.Re-assemble the Follower Assembly into barrel and tighten the end-cap onto the barrel. Engage the Follower-rod by rotating the follower “T” handle.

4.Insert the Filler Nipple into the Filler Socket on the Pump and extend the lever handle away from the barrel (See Figure 7).

5.Operate the pump until the Grease Gun barrel is full of Grease. The Follower-rod will be fully extended when the barrel is full.

Remove the Filler Nipple from the Filler Socket on the Pump.

6.Disengage the follower rod from the follower by rotating the follower “T” handle. This would push the Follower-rod into the barrel.

7. Refer to Point A (7), above

8.Pump the Lever handle several times until Grease flows from the Coupler.

C. HOW TO LOAD YOUR GREASE GUN WITH A LUBRICANT CARTRIDGE :

1. Unscrew the Head Assembly from the barrel of the Grease Gun (See Figure 1). Pack head with Grease (See Figure 2).

2.Unscrew the end-cap from the barrel. Pull on the Plunger T-handle to extract the Plunger Assembly and spring

from the barrel. Visually inspect the follower seal lip direction before loading a new cartridge. The follower seal lip must

be “flipped over” toward the “T” Handle [flip the follower seal lip over and away from the Head Assembly by grasping follower

between thumb and forefinger and flip the follower lip from the front to the rear side toward the “T” handle]. (See Figure 3-A).

3.Re-assemble the Follower Assembly into barrel and tighten the end-cap onto the barrel. Pull back the Follower-rod. When the Follower-rod

is fully extended, pull it sideways to latch the rod groove into the keyhole slot in the end-cap to lock the Follower-rod in place. (See Figure 5).

4.Remove the plastic cap from the end of Grease Cartridge and, insert open end first, into the barrel of Grease Gun (See Figure 8).

Push the Grease Cartridge into the barrel until the rim of the pull-tab end contacts the rim of the barrel (See Figure 9). Then remove the pull-tub

seal from the end of the Grease Cartridge (See Figure 10). Screw the head back onto the barrel. Screw the Head Assembly loosely onto the barrel.

5.Unlock the Follower-rod from the end-cap. This would push it into the barrel. Disengage the Follower-rod from the follower by rotating the follower

“T” handle. Slowly unscrew the barrel from the Head Assembly until lubricant oozes from the interface. Tighten the Head Assembly securely (See Fig. 6).

6.Refer to Point A (7), above

7. Pump the Lever handle several times until Grease flows from the Coupler.

TROUBLESHOOTING CHART

Problem :

Gun will not dispense Grease

Possible Cause :

1. Grease Cartridge or Barrel is empty. 2. Air is trapped in the Grease Gun head.

Solution :

• Replace the grease cartridge or refill the barrel.

• Expel the trapped air, while pressing the Air Bleeder Valve, and pushing the Plunger (Follower) Rod handle.

Problem :

Grease Cartridge will not empty completely. Also, if you are not sure whether the Cartridge is completely empty or not.

Possible Cause :

Tabs on rod are binding to rubber plunger assembly.

Solution :

• Connect the rod to the rubber plunger assembly. • Push the rod into the barrel as far as it will go to move the grease forward.

• Measure the rod handle from the end cap on the barrel to the tip of the rod handle.

• If the measurement is more than 1-3/4", the grease cartridge is not empty.

• If not completely empty, disconnect rod from rubber plunger assembly after grease has been pushed forward.

Problem :

Grease leakage visible between Barrel and Head Assembly

Possible Cause :

Initial tightening of Barrel into Head Assembly not sufficient or the Rubber Seal inside the Head Assembly is damaged or missing.

Solution :

• Tighten Barrel into Head Assembly securely or replace the Rubber Seal

Problem :

Grease leakage visible at Extension or at Head Assembly

Possible Cause :

1. Initial tightening of extension into Head Assembly and/or Coupler not sufficient 2. Filler Nipple may be loose

3. Worn or damaged piston and/or bore in Head Assembly 4. Worn Air Bleeder Valve “O” Ring

Solution :

• Tighten Extension into Head Assembly and Coupler into the Extension • Tighten Filler Nipple into Head Assembly securely

• Replace “O” Ring or Air Bleeder Valve

LIMITED WARRANTY POLICY ON NEW EQUIPMENT. PLEASE READ THE FOLLOWING CAREFULLY

Lumax

®

warrants all lubrication equipment manufactured by Lumax

®

to be free from defects in material and workmanship on the date of sale by an authorized Lumax

®

distributor to the original purchaser for use. Lumax

®

will

during one (1) year, following the date of purchase, repair, or replace any part of the equipment determined by Lumax

®

to be defective. This warranty applies only when the equipment is installed, operated, and maintained in accordance

with Lumax

®

written recommendations. Lumax

®

does not make any representation or warranty of any kind to the buyer that he or she is qualified to make any repairs to the product or that he or she is qualified to replace any

parts of the product. In fact, Lumax

®

expressly states that all repairs and parts replacements should be undertaken by certified and licensed technicians and not by the buyer. The buyer assumes all risk and liability arising out

of his or her repairs to the original product or replacement parts thereto, or arising out of his or her installation of replacement parts thereto. If equipment proves to be defective during this warranty period, it will be repaired or

replaced without charge, provided that factory examination indicates the equipment to be defective.

This warranty does not cover, and Lumax

®

shall not be liable for general wear and tear, accident, overload, or any malfunction, damage, or wear caused by faulty installation, misapplication, misuse, abuse, abrasion, corrosion,

inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Lumax

®

component parts. Nor shall Lumax

®

be liable for the equipment repaired or altered by anyone not authorized by Lumax

®

to

repair or alter the equipment. Lumax

®

will also not be liable for malfunction, damage, or wear caused by the incompatibility of Lumax

®

equipment with accessories, equipment or materials not supplied by Lumax

®

. This warranty

is extended to the original retail purchaser only and is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Lumax

®

distributor for verification of the claimed defect. If the claimed defect

is verified, Lumax

®

will repair or replace free of charge any defective parts. The equipment will be returned to the original buyer, transportation prepaid. If inspection of the equipment does not disclose any defect in material or

workmanship, repairs will be made at a reasonable charge, which charges may include the cost of parts, labor, and transportation. This warranty is exclusive, and is in lieu of any other warranties, express or implied, including

but not limited to warranty of merchantability or warranty of fitness for a particular purpose. Lumax

®

sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including but not limited to, incidental or consequential damage for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall be available. In no event shall Lumax

®

be liable

for incidental or consequential damages. The liability of Lumax

®

on any claim for loss or damage arising out of the sale, resale, or use of lubrication equipment, materials dispensing equipment, and other related equipment should

in no event exceed the purchase price. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights, and you may also have other rights, which vary from state to state. Any action for breach of warranty must be brought within two (2) years from the date of sale.

Lumax

®

makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection with accessories, equipment, materials, or components sold but not manufactured by Lumax

®

(such as Electric Motors, Switches, Hoses, etc.) are subject reasonable assistance in making any claim for breach of these warranties. In no event will Lumax

®

be liable for indirect, incidental, special, or consequential damages

resulting from Lumax

®

supplying equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Lumax

®

or

otherwise. Any implied warranties applicable to lubrication equipment, materials dispensing equipment, and other related equipment manufactured by Lumax

®

, including the warranties of merchantability and fitness for a particular

purpose, will last only for one (1) year from the date of purchase. Some states do not allow limitations on how long an implied warranty last, so the above limitation may not apply to you.

© 2003 Lumax

®

. All Rights Reserved.

Lumax

®

and the Products described in it are Copyrighted by Lumax

®

, with All Rights Reserved.

This Form may not be Copied in Whole or Part, without the Express Written Consent of Lumax

®

.

T

w

i

s

t

{

T

o

r

c

e

d

u

r

a

}

[

T

o

r

s

i

o

n

]

Figure 7

Figura 7

Figure 7

Filler Socket

{ Zócalo del

Llenador }

[ Douille de

Remplisseur ]

(LX-1305)

Filler Nipple

{ Entrerrosca

del Llenador }

[ Mamelon de

Remplisseur ]

(LX-1420)

G

r

e

a

s

e

C

a

r

t

r

i

d

g

e

{

C

a

r

t

u

c

h

o

D

e

l

a

G

r

a

s

a

}

[

C

a

r

t

o

u

c

h

e

D

e

G

r

a

i

s

s

e

]

P

l

a

s

t

i

c

C

a

p

{

C

a

s

q

u

i

l

l

o

P

l

á

s

t

i

c

o

}

[

C

h

a

p

e

a

u

e

n

P

l

a

s

t

i

q

u

e

]

B

a

r

r

e

l

{

B

a

r

r

i

l

}

[

B

a

r

i

l

]

Figure 9

Figura 9

Figure 9

B

a

r

r

e

l

{

B

a

r

r

i

l

}

[

B

a

r

i

l

]

P

u

l

l

-

T

a

b

S

e

a

l

{

T

i

r

e

D

e

l

S

e

l

l

o

D

e

l

a

L

e

n

g

ü

e

t

a

}

[

J

o

i

n

t

D

'

T

i

r

e

r

-

É

t

i

q

u

e

t

t

e

]

Figure 8

Figura 8

Figure 8

Lumax

®

3705 Centre Circle, Fort Mill, SC 29715, USA

Fax : 803-547-0800 www.LumaxLubrication.com

Flip-over Follower toward the

“T” handle (for Cartridge loading)

{ Embutidor de disparo hacia el hacia

el mango “T” (para carga del cartucho) }

[ Retourner le piston plongeur vers la manche

en “T” (pour remplir avec une cartouche) ]

Rear Side

{ Lado Trasero }

[ Arrière Côté ]

Figure 3-A

Figura 3-A

Figure 3-A

Figure 10

Figura 10

Figure 10

MANUAL DE OPERACIONES PISTOLA MANUAL DE GRASA

LX-1142 / LX-1144 : Para usar con el Cartucho de 14oz. (400 cc / 397 g) o cartucho de 16 oz. (500 cc / 454 g) de Capacidad Bruta

LX-1145 : Para usar con el Cartucho de 14oz (400 cc / 397 g) o Cartucho de 24 oz. (750 cc / 680 g) de Capacidad Bruta

Gracias por comprar la pistola manual de grasa Lumax

®

. Al seleccionar la pistola de grasa Lumax

®

, usted ha seleccionado un producto de ingeniería de alta calidad y precisión, diseñado para brindar

servicio de trabajo pesado y un rendimiento de por vida. Su seguridad es muy importante para nosotros. Sírvase leer cuidadosamente este Manual de Funcionamiento. Las instrucciones contenidas

en este manual DEBEN ser leídas y entendidas por el operario antes de funcionar el equipo. Es importante que usted lea todo el manual para familiarizarse con la unidad antes de comenzar a funcionar

la unidad. Sírvase mantener este Manual de Funcionamiento en un lugar seguro para referencia futura.

Los productos de lubricación Lumax son herramientas de ingeniería de precisión, que son capaces de crear presiones sobre 10.000 PSI (690 BAR). Solamente el uso profesional asegura el funcionamiento

libre de peligros de estos productos. Advertencia: La presión extrema puede hacer que la extensión de la boquilla o Manguera de Grasa se reviente. Siempre siga las instrucciones y

precauciones de la Manguera de Grasa. Mantenga las manos fuera de la extensión durante el funcionamiento de la Pistola de Grasa.

Tenga sumo cuidado mientras trabaje mientras trabaja

con los adaptadores y dispensadores de punta de aguja. Mantenga sus manos lejos de la punta de aguja en todo momento y cuando inyecte la grasa.

Mantenga su equipo periódicamente y antes de cada uso, verifique que todas las conexiones estén cerrados de forma segura. Las presiones altas de trabajo pueden dar como resultado que el liquido

sea inyectado en el interior debido al mal funcionamiento de los componentes. Utilice

solamente componentes que no muestren indicios de daño. Mientras trabaje en el barril de la Pistola de Grasa,

asegúrese que este abierto, los extremos de rosca del barril siempre apuntan lejos de usted o de los demás! Nunca toque una manguera que este bajo presión. Nunca apunte la salida hacia usted

o hacia otras personas. Las mangueras están sujetas a envejecimiento rápido. Nunca utilice una manguera que tenga mas de 2 años. Las mangueras nunca deben ser dobladas o enroscada a la

fuerza. El radio más pequeño para doblar la manguera es de 4" (100 mm). Busque asistencia médica inmediatamente después de una lesión.

PRECAUCIÓN ¡PARA SU PROPIA PROTECCIÓN: LEA, ENTIENDA Y SIGA ESTOS TIPS DE SEGURIDAD

SEGURIDAD PRIMERO! Y TODAS LAS INSTRUCCIONES ANTES DE UTILIZAR ESTE PRODUCTO!

Las pistolas de grasa solamente deberían ser utilizadas según se recomienda. Si no es utilizada correctamente, cualquier herramienta puede fallar. Para evitar graves lesiones personales al utilizar

su pistola de grasa, siga los siguientes tips y normas de seguridad:

•No utilice la pistola de grasa para otro propósito.

•No forje la pistola de grasa. Funcionará mejor y más segura a la velocidad para la cual fue diseñada. Nunca utilice extensiones de palanca para aumentar el brazo de la palanca. Nunca trate de

detener o desvíe el material del extremo dispensador de la pistola de grasa con su mano o con su cuerpo.

• Vista siempre el traje y el equipo protector apropiado. No vista ropa suelta o joyas. Éstas pueden ser atrapadas en las partes movibles. Los guantes protectores y calzado que no resbale son

recomendables cuando trabaje con bombas. Protectores adecuados y equipo de protección tales como anteojos de seguridad resistentes a los impactos, anteojos protectores contra salpicaduras

químicas o de seguridad, pantalla completa para la cara, zapatos de seguridad, protectores para brazos, guantes protectores y delantal deben ser utilizados para la protección del operador. Utilice

una cubierta protectora para el cabello, para cubrir el cabello largo.

• Asegúrese siempre de que exista la iluminación adecuada en el área de trabajo.

• Use Respirador. Siempre use la mascara facial adecuada para evitar la inhalación de vapores y gases peligrosos.

• Manténgase alerta. Vigile siempre lo que hace. Utilice el sentido común. No funcione la pistola de grasa cuando usted esté cansado o bajo la influencia de algún medicamento. Manténgase alerta

en todo momento especialmente durante operaciones repetitivas y monótonas. Usted puede haber demostrado un producto varios cientos de veces, sin embargo, no se confíe demasiado debido

a un falso sentido de seguridad. Si no se utilizan cuidadosamente y según las instrucciones, las herramientas pueden ser extremadamente implacables.

• No se estire. Mantenga el equilibrio y el balance adecuado en todo momento.

• Mantenga a los visitantes alejados. Todos los visitantes deberán mantenerse lejos del área de trabajo. No deje que los visitantes funcionen la pistola de grasa.

• Revise las piezas dañadas. Antes de utilizar la pistola de grasa, revise siempre que funcione adecuadamente antes de cada uso y asegúrese que todos los dispositivos de seguridad estén en su

sitio y funcionen adecuadamente. Asegúrese siempre que todas las conexiones de grasa estén apretadas firmemente. Revise cuidadosamente si hay alguna pieza dañada para determinar que

la pistola de grasa funcionará adecuadamente y realizará la función para la que fue diseñada. Revise la alineación de las piezas movibles, unión de las piezas movibles, ruptura de las piezas, montaje

y cualquier otra condición que pueda afectar su funcionamiento. Cualquier pieza que esté dañada deberá ser reparada o reemplazada adecuadamente por un Centro de Servicio Autorizado.

• Mantenga las pistolas de grasa con cuidado. Mantenga las pistolas de grasa limpias y hágales servicio o mantenimiento regularmente para un mejor y más seguro rendimiento. Siga las

instrucciones para lubricar y cambiar los accesorios. NO intente reparar o desensamblar el equipo mientras el sistema está presurizado. Inspeccione la pistola de grasa periódicamente y si se daña

la pistola de grasa o alguna de sus piezas, haga que sea reparada por un Centro de Servicio Autorizado. Mantenga siempre su pistola de grasa inspeccionada y reemplácela inmediatamente si

se daña o se desgasta.

• Guarde la herramienta. Cuando no estén en uso, las pistolas de grasa deberán ser guardadas en un lugar seco, en alto y/o cerrado. Mantenga la pistola de grasa y el área de trabajo fuera del

alcance de los niños.

• No altere o modifique ninguna pieza de este equipo. Las pistolas de grasa solamente deben ser reparadas por técnicos calificados.

• Revise siempre las leyes y ordenanzas locales relacionadas con el manejo, bombeo y disposición de líquidos. Deseche los fluidos bombeados adecuadamente. No drene los fluidos en los drenajes

de la calle, drenajes de la casa o patios traseros. Contacte a sus funcionarios municipales locales de desecho sobre los métodos adecuados de desecho. Si tiene alguna pregunta sobre si es

seguro funcionar la bomba o no, no funcione la pistola de grasa.

LLENADO DE GRASA: INSTRUCCIONES DE OPERACION : La pistola de grasa puede usar un cartucho lubricante o ser llenado de grasa desde un recipiente bruto o con una bomba de llenado.

Vea las instrucciones de llenado de grasa a continuación. Mantenga los ensamblajes de grasa limpios antes de lubricar. Elimine los restos de grasa vieja y sucio que puedan entrar en el equipo a

ser lubricado. Empuje el acoplador hacia el embutidor en un ángulo leve (el acoplador se fija más fácilmente en un ángulo leve que cuando esta centrado). Centre el acoplador en el embutidor de grasa.

Opere la manilla de palanca para lubricar, teniendo cuidado de no dañar los sellos mediante una presión excesiva de volumen. Después de lubricar, voltee el acoplador en un ángulo leve para liberar

el mango de las mandíbulas del acoplador del embutidor de grasa.

A. COMO CARGAR LA SUCCIÓN DE SU PISTOLA DE GRASA :

1. Desatornille el cabezal de ensamblaje del bidón de la pistola de grasa (Véase la Figura 1). Guarde el cabezal con grasa (Véase la Figura 2).

2.Desatornille el tapón del bidón. Hale la manilla T del émbolo para extraer el ensamblaje del émbolo y los resortes del bidón. Inspeccione visualmente el borde del sello de embutidor antes de llenar

la pistola. El borde del sello del embutidor debe estar dirigido hacia el ensamblaje del cabezal, doble el borde del sello de embutidor lejos del resorte de embutidor tomando el embutidor entre el

dedo pulgar y el dedo índice y voltee el embutidor de la parte de atrás hacia la parte de adelante hacia el ensamblaje del cabezal. (Véase la Figura 3). Reensamble el ensamblaje del embutidor

en el bidón y apriete el tapón en el bidón.

3.Inserte el lado abierto del bidón debajo de la superficie de la grasa (Véase la Figura 4).

4.Lentamente hale la biela del embutidor mientras empuja el bidón más profundamente en la Grasa para prevenir la introducción de bolsas de aire en el bidón.

5.Cuando la biela del embutidor esté totalmente extendida, hálela hacía los lados para enganchar la acanaladura de la biela en la ranura de la llave en el tapón para asegurar la biela del embutidor

en su lugar (Véase la Figura 5). Atornille el ensamblaje del Cabezal libremente en el bidón.

6.Quite el seguro de la biela del Embutidor del tapón. Esto lo empujará hacía el bidón. Desconecte la biela del embutidor del embutidor rotando el mango “T” del embutidor. Desatornille lentamente

el bidón del ensamblaje del cabezal hasta que la grasa filtre de la interfase. Apriete el Ensamblaje del cabezal con seguridad (Véase la Figura 6).

7. Cebe la pistola (Cebar es el acto de remover el aire e introducir la grasa en el mecanismo de bombeo de la pistola de grasa). Cuando se lle na la pistola de grasa, es muy importante evitar que

las bolsas de aire y purgar cualquier aire que pueda estar atrapado en el bidón. Precaución: Las bolsas de aire en el lubricante pueden causar que la palanca de la pistola de grasa pierda

su ceba. Cebe la pistola de grasa mientras presiona la válvula de purga de aire para ventilar las bolsas de aire en la cámara de grasa. En la mayoría de los casos la pistola de Grasa se ceba

simplemente presionando el mango de la palanca varias veces. Si la grasa no aparece, se debe purgar el Ensamblaje del Cabezal.

8.Bombee el mango de la palanca varias veces hasta que la Grasa fluya del Acoplador.

B. COMO CARGAR MASIVAMENTE SU PISTOLA DE GRASA USANDO UN BOMBA DE LLENADO DE GRASA : Cuando la biela del embutidor esté totalmente extendida, hálela hacía los lados

para enganchar la acanaladura de la biela en la ranura de la llave en el tapón para asegurar la biela del embutidor en su lugar (Véase la Figura 5). PRECAUCION: El niple llenador en la pistola de

Grasa debe cazar con el Acoplador del Cargador en la bomba. La bomba podría no operar si los componentes no son compatibles. ADVERTENCIA: La Pistola De Grasa está equipada con un niple

de llenado de baja presión. No substituya con un aditamento de Grasa de alta presión. Daños personales podrían ocurrir debido a una presión excesiva. El uso de aditamentos de Grasa también

anulará la garantía.

1. Escurra el nipple de llenado con un trapo limpio.

2.Desatornille el tapón del bidón. Hale el la manilla T del émbolo para extraer el ensamblaje del émbolo y los resortes del Bidón. Inspeccione visualmente el borde de sellado del embutidor antes

de llenar la pistola. El borde del sello del embutidor debe estar *”flipped over” hacia el Ensamblaje del Cabezal doblar el borde del sello de embutidor lejos del resorte de embutidor tomando el

embutidor entre el dedo pulgar y el dedo índice y voltear el embutidor de la parte de atrás hacia la parte de adelante hacia el Ensamblaje del Cabezal. (Véase la Figura 3)

!

LX-1142 / LX-1144 / LX-1145

B. COMO CARGAR MASIVAMENTE SU PISTOLA DE GRASA USANDO UN BOMBA DE LLENADO DE GRASA :

3.Reensamble el ensamblaje del embutidor en el bidón y apriete el tapón en el bidón. Conecte la biela del embutidor rotando la manilla “T” del embutidor.

4.Inserte el conector de llenado en el Casquillo de llenado de la Bomba y extienda la palanca fuera del bidón (Véase la Figura 7).

5.Opere la bomba hasta que el bidón de la pistola de grasa esté lleno. La biela del embutidor estará completamente extendida cuando el bidón esté lleno.

Remueva el conector de llenado del casquillo de llenado de la bomba.

6.Desconecte la biela del embutidor del embutidor rotando el mango “T” del embutidor. Esto empujariá a la biela del Embutidor dentro del bidón.

7. Refiera al punto A (7), arriba

8.Bombee la manilla de la bomba varias veces hasta que la grasa fluya del acoplador.

C. CÓMO CARGAR SU PISTOLA DE GRASA CON UN CARTUCHO LUBRICANTE :

1. Desatornille el ensamblaje del cabezal del bidón de la pistola de grasa (Véase la Figura 1). Guarnezca el cabezal con grasa (Véase la Figura 2).

2.Desatornille el tapón del bidón. Hale la manilla T del émbolo para extraer el ensamblaje del émbolo y los resortes del bidón. Inspeccione visualmente la dirección del borde del sello de embutidor

antes de cargar un nuevo cartucho. El borde del sello del embutidor debe estar dirigido hacia el mango “T” del embutidor (doble el borde del sello del embutidor lejos del resorte de embutidor tomando

el embutidor entre el dedo pulgar y el dedo índice y voltee el embutidor de la parte de atrás hacia la parte de adelante, hacia el ensamblaje del cabezal. (Véase la Figura 3-A). Reensamble el

ensamblaje del embutidor en el bidón y apriete el tapón en el bidón

3.Reensamble el ensamblaje del embutidor en el bidón y apriete el tapón en el bidón. Hale hacia atrás la biela del embutidor. Cuando la biela del embutidor esté totalmente extendida, hálela hacia

los lados para enganchar la acanaladura de la biela en la ranura de la llave en el tapón para asegurar la biela del embutidor en su lugar (Véase la Figura 5)

4.Retire la tapa plástica del cartucho de Grasa e inserte primero el lado abierto en el bidón de la pistola de grasa (Véase la Figura 8). Empuje el cartucho de grasa en el bidón hasta que el canto de

la lengüeta contacte el borde del bidón (Véase la Figura 9). Luego retire el sello del tubo del final del cartucho de grasa (Véase la Figura 10). Atornille el cabezal en el bidón. Atornille el ensamblaje

del cabezal libremente en el bidón.

5.Quite el seguro de la biela del embutidor del tapón. Esto lo empujará hacía el bidón. Desconecte la biela del embutidor del embutidor rotando el mango “T” del embutidor. Desatornille lentamente

el bidón del ensamblaje del cabezal hasta que la grasa filtre de la interfase. Apriete seguramente el ensamblaje del cabezal (Véase la Figura 6).

6.Refiera al punto A (7)

7. Bombee la manilla de la bomba varias veces hasta que la grasa fluya del acoplador.

Tabla para Resolver Problemas

Problema :

La pistola de dispensa grasa

Posible Causa :

1. El cartucho de grasa o el barril está vacío. 2. El aire está atrapado en el cabezal de la pistola de grasa.

Solución :

• Remplace el cartucho de grasa o vuelva a llenar el barril.

• Saque el aire atrapado presionando la válvula del purgador de aire, y empuje la manilla de la varilla del émbolo (engranaje).

Problema :

El cartucho de grasa no se vaciará completamente. También si usted no está seguro si el cartucho está completamente vacío o no.

Posible Causa :

Las lengüetas en la varilla están unidas al ensamblaje del émbolo de caucho.

Solución :

• Conecte la varilla al ensamblaje del émbolo de caucho. • Empuje la varilla en el barril tan lejos como pueda para mover la grasa hacia adelante.

• Mida la manilla de la varilla desde la tapa del extremo en el barril hasta la punta de la manilla de la varilla.

• Si la medida es superior a 1-3/4", el cartucho de grasa no está vacío.

• Si no está completamente vacío, desconecte la varilla del ensamblaje de émbolo de caucho después que la grasa haya sido empujada hacia adelante.

Problema :

Fuga de grasa visible entre el barril y el ensamblaje del cabeza.

Posible Causa :

El ajuste inicial del barril en el ensamblaje del cabezal no es suficiente o el sello de caucho adentro está dañado o no está presente.

Solución :

Apriete firmemente el barril en el ensamblaje del cabezal

Problema :

Fuga de grasa visible en la extensión

Posible Causa :

Fuga de grasa visible en el ensamblaje del cabezal

Posible Causa :

1. El ajuste inicial de la extensión en el ensamblaje del cabezal y/o acoplador no es suficiente

2. La boquilla de llenado puede estar floja

3. Válvula de aro “O” del purgador de aire está desgastado

4. Pistón y/o ánima desgastada y/o dañada en el ensamblaje del cabezal

Solución :

• Apriete la extensión en el ensamblaje del cabezal y el acoplador en la extensión

• Apriete firmemente la boquilla de llenado en el ensamblaje del cabezal

• Reemplace el aro “O” o la válvula del purgador de aire

POLÍTICA DE GARANTÍA LIMITADA DEL EQUIPO NUEVO. SÍRVASE LEER CUIDADOSAMENTE LO SIGUIENTE

Lumax

®

garantiza que todo equipo de lubricación fabricado por Lumax

®

esté libre de defectos en cuanto al material y mano de obra a la fecha de la venta por parte de un distribuidor autorizado Lumax

®

al comprador original

para el uso. Durante un (1) año después de la fecha de compra, Lumax

®

reparará o reemplazará cualquier pieza del equipo que Lumax

®

determine que está defectuosa. Esta garantía se aplica solamente cuando el equipo está

instalado, operado y mantenido de conformidad con las recomendaciones escritas de Lumax

®

. Lumax

®

no entrega ninguna representación o garantía de ningún tipo al comprador de que él o ella está calificado para realizar

ninguna reparación al producto o que él o ella está calificado para reemplazar alguna pieza del producto. De hecho, Lumax

®

manifiesta expresamente que todas las reparaciones y piezas de reemplazo deberían ser realizados

por técnicos certificados y licenciatarios y no por el comprador. El comprador asume todos los riesgos y responsabilidades que surjan de sus reparaciones hechas al producto original o a las piezas de reemplazo del mismo,

o que surjan de la instalación de piezas de reemplazo al mismo. Si el equipo demuestra estar defectuoso durante este período de garantía, será reparado o reemplazado sin cargos, siempre que el examen de la fábrica indique

que el equipo está defectuoso.

Esta garantía no cubre, y Lumax

®

no será responsable del desgaste general, accidentes, sobrecarga, o algún malfuncionamiento, daño o desgaste causado por una mala instalación, aplicación errada, maluso, abuso, abrasión

corrosión, mantenimiento inadecuado, o impropio, negligencia, accidente, manipulación o sustitución de piezas componentes que no sean Lumax

®

. Lumax

®

tampoco será responsable del equipo reparado o alterado por alguien

que no esté autorizado por Lumax

®

para reparar o alterar el equipo. Lumax

®

tampoco será responsable por el mal funcionamiento, daño, o desgaste causado por la incompatibilidad del equipo Lumax

®

con accesorios, equipo

o materiales que no sean suministrados por Lumax

®

. Esta garantía sólo se extiende al comprador original al detal y está condicionada a la devolución prepagada del equipo considerado defectuoso a un distribuidor Lumax

®

autorizado para la verificación del defecto reclamado. Si se verifica el defecto reclamado, Lumax

®

reparará o hará el reemplazo sin costo alguno sobre las piezas defectuosas. El equipo será devuelto al comprador original con

transporte prepagado. Si la inspección del equipo no revela ningún defecto en los materiales o mano de obra, las reparaciones serán hechas a un precio razonable, cuyos cargos pueden incluir los costos de piezas, mano de

obra y transporte.

Esta garantía es exclusiva, y es in lieu de cualquier otra garantía, expresa o implícita, incluyendo pero no limitada a la garantía de mercadeabilidad o garantía de aptitud para un fin específico. La única obligación de Lumax

®

y

el único remedio del comprador en caso de alguna violación de la garantía deberá ser como se establece arriba. El comprador acuerda que ningún otro remedio estará disponible (incluyendo pero no limitado al daño, incidental

o a consecuencia de las ganancias perdidas, ventas perdidas, daños a la persona o a la propiedad, o cualquier pérdida incidental o consecuencia). Lumax

®

no será responsable en ningún momento por los daños incidentales

o consecuenciales. La responsabilidad de Lumax

®

por cualquier reclamo o pérdida que surja de la venta, reventa o uso del equipo de lubricación, equipo dispensador de materiales, y otro equipo relacionado no deberá en ningún

momento exceder el precio de compra. Algunos estados no permiten la exclusión o límite de daños incidentales o consencuenciales, por lo que la limitación anterior puede no aplicarse a usted. Esta garantía le otorga a usted

derechos legales específicos, y usted también puede tener otros derechos, que pueden variar de estado a estado. Cualquier acción por la violación de la garantía deberá ser presentada dentro de los dos (2) años a partir de la fecha

de la venta.

Lumax

®

no otorga ninguna garantía y renuncia a todas las garantías implícitas sobre la mercadeabilidad y aptitud para un fin especifico en relación con los accesorios, equipos, materiales o componentes vendidos pero no fabricados

por Lumax

®

(tales como motores eléctricos, interruptores, mangueras, etc.) están sujetos a la asistencia razonable para realizar cualquier reclamo por el incumplimiento de estas garantías. Lumax

®

no será responsable en

ningún caso por los daños indirectos, incidentales, especiales o consecuenciales resultantes del suministro de parte de Lumax

®

del equipo bajo el presente, o el suministro, rendimiento o uso de cualquier producto u otros bienes

vendidos en el presente, sea debido a un incumplimiento del contrato, incumplimiento de la garantía, la negligencia de Lumax

®

o de otro modo.

Cualquier garantía implícita aplicable al equipo de lubricación, equipo dispensador de materiales, y otro equipo relacionado fabricado por Lumax

®

, incluyendo las garantías de mercadeabilidad y aptitud para un fin específico,

solamente durará un (1) año a partir de la fecha de compra. Algunos estados no permiten límites sobre la duración de una garantía implícita, por lo que el limite arriba expresado puede variar para usted.

© 2003 Lumax

®

. Todos los derechos reservados.

Lumax

®

y los productos descritos están registrados por Lumax

®

como propiedad literaria, con todos los derechos reservados.

Este documento no puede ser copiado en todo o en parte sin el consentimiento expreso por escrito de Lumax

®

.

Lumax

®

3705 Centre Circle, Fort Mill, SC 29715, USA Fax : 803-547-0800 www.LumaxLubrication.com

Forma :

LX-1142-45-IS

MANUEL D’EMPLOI - PISTOLET GRAISSEUR Á MAIN

LX-1142 / LX-1144 : Pour utiliser avec une cartouche de 14 oz. (400 cc / 397 g) ou capacité en vrac de 16 oz. (500 cc / 454 g)

LX-1145 : Pour utiliser avec une cartouche de 14 oz. (400 cc / 397 g) ou capacité en vrac de 24 oz. (750 cc / 680 g)

Nous vous remercions d’avoir acheté le Pistolet Graisseur Lumax

®

. En choisissant le Pistolet Graisseur Lumax

®

, vous avez choisi un produit de bonne qualité, de haute technologie, construit pour un

service à grand rendement et une performance pour la vie. Votre sécurité est très important pour nous. Lisez ce manuel d’emploi attentivement. L’opérateur de cet équipement DOIT lire et comprendre

les instructions de ce manuel avant d’utiliser l’équipement. C’est important de lire le manuel en entier pour se familiariser avec le produit avant de commencer à l’utiliser. Conserver ce manuel d’emploi

dans un endroit sûr pour pouvoir l’utiliser dans le futur.

Les produits lubrifiants Lumax sont des instruments de haute technologie, capables de créer des pressions bien au-dessus de 10.000 PSI (690 BAR.) Seul l’utilisation professionnelle assurera l’exécution

sans danger de ces produits. Mise en Garde: Une pression extrême peut provoquer le prolongement du bec ou l’éclatement du tuyau graisseur. Suivez toujours les instructions et les mises

en garde du tuyau graisseur. Maintenez les mains dégagées du prolongement quand vous utilisez le Pistolet Graisseur.

Soyez extra attentif quand vous utilisez des adaptateurs et des

distributeurs graisseurs à pointe d’aiguille. Tenez toujours vos mains à l’écart de la pointe d’aiguille quand vous injectez de la graisse.

Entretenez votre équipement régulièrement et avant chaque emploi, vérifiez que toutes les connexions sont solidement attachées. Si vous travaillez avec des pressions élevées, le liquide peut être injecté

sur la peau lors du défaut de fonctionnement d’une des pièces. Utilisez

uniquement des pièces qui ne montrent aucun signe d’endommagement. Quand vous travaillez avec le tube du Pistolet Graisseur,

assurez-vous de que la partie ouverte et filetée du bout du tube soit détournée de vous et des autres! Ne touchez jamais un tuyau qui est sous pression. Ne dirigez jamais le débouchement vers vous-

même ou d’autres personnes. Les tuyaux vieillissent rapidement. N’utilisez jamais un tuyau qui est plus ancien que 2 ans. Des tuyaux ne doivent jamais être pliés ou tordus par force. Le plus petit rayon

de cintrage pour le tuyau est 4" (100 millimètres.) Rechercher soin médical immédiat si vous vous blessez.

MISE EN GARDE POUR VOTRE PROTECTION LISEZ, COMPRENEZ ETOBSERVEZ CES INDICATIONS DE SÉCURITÉ.

LA SECURITÉ EN PREMIER ! ET TOUTES LES INSTRUCTIONS AVANT D’UTILISER CE PRODUIT!

Les Pistolets Graisseurs doivent être utilisés uniquement comme recommandé. Tout outil peut tomber en panne en cas de mauvais usage. Pour éviter des blessures corporelles sérieuses lors de l’usage

de votre Pistolet Graisseur, respectez les instructions et les règles de sécurité suivantes:

• N’utilisez pas le Pistolet Graisseur pour un usage pour lequel il n’est pas destiné.

• Ne forcez pas le Pistolet Graisseur. Il fonctionnera mieux et sera moins dangereux s’il est utilisé à la vitesse programmée. N’utilisez jamais les manches prolongées pour augmenter la puissance

de levier. N’essayez jamais d’arrêter ou de détourner des matériaux qui se déchargent du bout du Pistolet Graisseur avec votre main ou votre corps.

• Portez toujours des vêtements et équipements convenables. Ne mettez pas des habits amples ou de bijoux pendants. Ils peuvent être pris dans les pièces qui bougent. Des gants protecteurs

et des chaussures antidérapantes sont recommandés lorsque vous travaillez avec les Pistolets Graisseurs. Des dispositifs et équipements protecteurs comme lunettes de sécurité qui résistent à

l’impact, lunettes protectrices contre les éclaboussures chimiques, masque protectrice du visage, chaussures protectrices, garde bras, gants et tablier protecteurs doivent être utilisés pour la protection

de l’opérateur. Portez un couvre cheveux protecteur pour contenir les cheveux longs.

• Assurez-vous que le milieu de travail est toujours suffisamment éclairé.

• Utilisez le Respirateur. Portez toujours un masque protecteur convenable pour éviter d’avaler les vapeurs des gaz dangereux.

• Soyez vigilant. Faites attention à ce que vous faites. Utilisez le bon sens. N’utilisez pas le Pistolet Graisseur quand vous êtes fatigué ou quand vous prenez des médicaments. Soyez alerte à tout

moment, surtout pendant des exécutions répétitives et monotones. Même si vous avez essayé un produit une centaine de fois, ne diminuez jamais votre vigilance. Les instruments peuvent être

extrêmement impitoyables s’ils ne sont pas utilisés soigneusement et selon les instructions.

• Ne présumez pas de vos forces. Maintenez un maintien et un équilibre appropriés.

• N’acceptez pas de visiteurs. Tous les visiteurs doivent être à l’écart du milieu de travail. Ne laissez pas les visiteurs opérer le Pistolet Graisseur.

• Vérifier les pièces endommagées. Avant d’utiliser le Pistolet Graisseur, vérifiez toujours qu’il fonctionne correctement avant chaque emploi et assurez-vous que tous les dispositifs de sécurité

sont en place et fonctionnent correctement. Assurez-vous toujours que toutes les connexions graisseuses sont solidement attachées. Vérifiez soigneusement le Pistolet Graisseur pour trouver toutes

les pièces endommagées, pour déterminer si le Pistolet Graisseur va fonctionner correctement et s’exécutera pour l’usage pour lequel elle est destinée. Vérifiez le cadrage des pièces mobiles, le

liage des pièces mobiles, la rupture des pièces, l’assemblage, et toutes autres conditions qui peuvent affecter son exécution. Toute pièce endommagée doit être réparée correctement ou remplacée

par un centre de service autorisé.

• Entretenez les Pistolet Graisseurs avec soin. Gardez les Pistolets Graisseurs propres et entretenez-les régulièrement pour une performance supérieure et sans danger. Suivez les instructions

pour lubrifier et changer les accessoires. N’essayez pas de réparer ou désassembler l’équipement lorsque le système est sous pression. Examinez les Pistolets Graisseurs périodiquement et si le

Pistolet Graisseur ou la moindre de ses pièces sont endommagés - faites-les réparer par un centre de service autorisé. Les Pistolets Graisseurs doivent toujours être maintenus et remplacés

immédiatement s’ils sont endommagés ou usés

• Mettez en dépôt tout instrument au repos. Quand les Pistolets Graisseurs ne sont pas utilisés, ils doivent être conservés dans un endroit sec, élevé et/ou enfermés sous verrous. If ne faut pas que

les enfants puissent avoir accès au Pistolet Graisseur et au milieu de travail

• Ne changer et ne modifier aucune partie de cet équipement. Les Pistolets Graisseurs doivent seulement être réparés par des techniciens qualifiés.

• Vérifiez toujours les lois et les ordonnances locales concernant la manipulation, le pompage et le rejet des fluides. Rejetez le fluide pompé correctement. Ne le videz pas dans les égouts de la rue,

de la maison ou du jardin. Contactez vos fonctionnaires locaux de gestion de déchets municipaux pour connaître les méthodes appropriées de rejet des fluides. S’il y a le moindre doute concernant

une condition dangereuse, n’utilisez pas le Pistolet Graisseur.

REMPLISSAGE DE GRAISSE : MODE D’EMPLOI : Le Pistolet Graisseur peut utiliser une cartouche lubrifiante ou peut être rempli de graisse d’un récipient en masse ou avec une pompe remplisseuse.

Consulter les instructions pour le remplissage de graisse, ci-dessous. Nettoyez les ajustages graisseurs avant de les lubrifier. Enlevez toute graisse ancienne et/ou saleté qui peut entrer dans

l’équipement qui va être lubrifié. Appuyez le coupleur sur l’ajustage graisseur à angle léger (le coupleur s’attache plus facilement à angle léger qu’une fois centré.) Mettez le coupleur au centre de

l’ajustage graisseur. Actionnez le traitement de levier pour lubrifier, en faisant attention de ne pas endommager les joints en utilisant une pression ou un volume de lubrifiant excessif. Après la

lubrification, tournez le coupleur légèrement à angle pour libérer l’ajustage graisseur des mâchoires du coupleur.

A. COMMENT CHARGER VOTRE PISTOLET GRAISSEUR EN ASPIRANT :

1. Dévissez l’assemblage principal du tube du Pistolet Graisseur. (Voir Figure 1) Fourrez l’assemblage principal avec de la graisse. (Voir Figure 2)

2.Dévissez le bouchon du bout du tube. Enfilez la manche en « T » du plongeur pour extraire l’assemblage et le ressort du plongeur du tube. Inspectez la direction du bec étanche du plongeur

visuellement avant de remplir le Pistolet. Le bec étanche du plongeur doit être retourné vers l’assemblage principal [retournez le bec étanche du plongeur en l’éloignant du ressort du plongeur en

empoignant le plongeur entre le pouce et l’index et retournez le bec du plongeur de l’arrière à l’avant vers l’assemblage principal.] (Voir Figure 3) Re-assemblez l’assemblage du plongeur au tube

et serrez le bouchon du bout au tube.

3.Insérez l’extrémité ouverte du tube en dessous de la surface de la graisse. (Voir Figure 4)

4.Tirez le piston plongeur lentement tout en insérant le tube plus profondément dans la graisse pour empêcher des trous d’air d’être tirés dans le tube.

5.Quand le piston plongeur est entièrement étendu, tirez-le sur le côté pour verrouiller sa rainure dans la serrure du bouchon du bout pour enfermer le piston plongeur sur place. (Voir Figure 5)

Vissez l’assemblage principal au tube sans le serrer.

6.Déverrouillez le piston plongeur du bouchon du bout. Cela le poussera dans le tube. Dégagez le piston du plongeur en tournant la manche en “T” du plongeur. Devissez le tube de l’assemblage

principal doucement jusqu’à ce que le lubrifiant suinte de l’interface. Serrez l’assemblage principal solidement. (Voir Figure 6)

7. Amorcez le Pistolet (l’amorçage est l’acte d’enlever l’air et d’introduire la graisse dans le mécanisme de pompage du pistolet graisseur.) Durant le remplissage du Pistolet Graisseur, il est très

important d’empêcher des trous d’air et de videz l’air bloqué dans le tube. Précaution: Le levier du Pistolet Graisseur va perdre son amorçage s’il reste des trous d’air dans le lubrifiant.

Amorcez le Pistolet Graisseur tout en appuyant sur la valve d’air purgeur pour vider les trous d’air du compartiment de graisse. Pour la plupart le Pistolet Graisseur amorcera simplement en

actionnant le traitement de levier plusieurs fois. Si la graisse n’apparaît pas, l’assemblage principal doit être vidé.

8.Pompez le traitement de levier plusieurs fois jusqu’à ce que la graisse coule du coupleur.

B. COMMENT CHARGER VOTRE PISTOLET GRAISSEUR D’UN RÉCIPIENT EN MASSE EN UTILISANT UNE POMPE REMPLISSEUSE :

PRECAUTION : Le raccord remplisseur du Pistolet Graisseur doit s’accoupler avec le raccord chargeur de la pompe. Il est possible que la pompe ne marche pas si les parties sont incompatibles. MISE

EN GARDE: Le Pistolet Graisseur est équipé d’un raccord remplisseur à basse pression. Ne substituez pas avec un ajustage graisseur à haute pression. Une pression excessive peut provoquer des

blessures corporelles. L’utilisation d’un ajustage graisseur annulera également la garantie.

1. Essuyez le raccord remplisseur avec un tissu propre.

2.Dévissez le bouchon du bout du tube. Enfilez la manche en « T » du plongeur pour extraire l’assemblage et le ressort du plongeur du tube. Inspectez la direction du bec étanche du plongeur

visuellement avant de remplir le Pistolet. Le bec étanche du plongeur doit être retourné vers l’assemblage principal [retournez le bec étanche du plongeur en l’éloignant du ressort du plongeur

en empoignant le plongeur entre le pouce et l’index et retournez le bec du plongeur de l’arrière à l’avant vers l’assemblage principal.] (Voir Figure 3)

!

LX-1142 / LX-1144 / LX-1145

B. COMMENT CHARGER VOTRE PISTOLET GRAISSEUR D’UN RÉCIPIENT EN MASSE EN UTILISANT UNE POMPE REMPLISSEUSE :

3.Re-assemblez l’assemblage du plongeur au tube et serrez le bouchon du bout au tube. Engagez le piston plongeur en tournant la manche en « T » du plongeur.

4.Insérez le raccord remplisseur dans la prise remplisseuse de la pompe et étendez le traitement de levier dans la direction opposée du tube. (Voir Figure 7)

5.Actionnez la pompe jusqu’à ce que le tube du Pistolet Graisseur soit rempli de graisse. Le piston plongeur sera entièrement étendu quand le tube est rempli. Dégagez le raccord remplisseur de la

prise remplisseuse de la pompe.

6.Dégagez le piston du plongeur en tournant la manche en “T” du plongeur. Cela le poussera dans le tube.

7. Référez-vous au point A (7)

8.Pompez le traitement de levier plusieurs fois jusqu’à ce que la graisse coule du coupleur.

C. COMMENT CHARGER VOTRE PISTOLET GRAISSEUR AVEC UNE CARTOUCHE LUBRIFIANTE :

1. Dévissez l’assemblage principal du tube du Pistolet Graisseur. (Voir Figure 1) Remplissez-le avec de la graisse. (Voir Figure 2)

2.Dévissez le bouchon du bout du tube. Enfilez la manche en « T » du plongeur pour extraire l’assemblage et le ressort du plongeur du tube. Inspectez la direction du bec étanche du plongeur

visuellement avant de charger une nouvelle cartouche. Le bec étanche du plongeur doit être retourné vers la manche en « T » [retournez le bec étanche du plongeur en l’éloignant de l’assemblage

principal en empoignant le plongeur entre le pouce et l’index et retournez le bec du plongeur de l’arrière à l’avant vers la manche en « T »]. (Voir Figure 3-A)

3.Re-assemblez l’assemblage du plongeur au tube et serrez le bouchon du bout au tube. Retirez le piston plongeur. Quand il est entièrement étendu, tirez-le sur le côté pour verrouiller sa rainure dans

la serrure du bouchon du bout pour enfermer le piston plongeur sur place. (Voir Figure 5)

4.Retirez le bouchon en plastique du bout de la cartouche de graisse et insérez le bout ouvert dans le tube du pistolet. (Voir Figure 8) Poussez la cartouche de graisse dans le tube jusqu’à ce que le

bord du dispositif d’étanchéité touche le bord du tube. (Voir Figure 9) Enlevez alors le dispositif d’étanchéité de l’extrémité de la cartouche de graisse. (Voir Figure 10) Vissez l’assemblage principal

dans le tube. Vissez l’assemblage principal au tube sans le serrer.

5.Déverrouillez le piston plongeur du bouchon du bout. Cela le poussera dans le tube. Dégagez le piston du plongeur en tournant la manche en “T” du plongeur. Devissez le tube de l’assemblage

principal doucement jusqu’à ce que le lubrifiant suinte de l’interface. Serrez l’assemblage principal solidement. (Voir Figure 6)

6.Référez-vous au point A (7)

7. Pompez le traitement de levier plusieurs fois jusqu’à ce que la graisse coule du coupleur.

DIAGRAMME DE DÉPANNAGE

Problème :

Le pistolet ne distribue pas de graisse

Raison Possible :

1. La cartouche de graisse ou le tube est vide. 2. De l’air est emprisonné dans l’assemblage principal du Pistolet Graisseur.

Solution :

• Remplacez la cartouche de graisse ou remplissez le tube.

• Videz l’air emprisonné en appuyant sur la valve d’air purgeur, et poussant la manche du piston plongeur.

Problème

: La cartouche de graisse ne se vide pas complètement. Aussi si vous n’êtes pas sûr que la cartouche est complètement vide.

Raison Possible :

Les languettes du piston sont liées à l’assemblage du plongeur en caoutchouc.

Solution :

• Relier le piston à l’assemblage du plongeur en caoutchouc.

• Insérez le piston dans le tube aussi loin que possible pour faire avancer la graisse.

• Mesurez la manche du piston du bout du bouchon du tube jusqu’au bout de la manche du piston.

• Si cette distance est plus grande que 1-3/4 “, la cartouche de graisse n’est pas vide.

• Si l’nest pas complètement vide, détachez le piston de l’assemblage du plongeur en caoutchouc, après avoir poussez la graisse en avant.

Problème :

Fuite de graisse visible entre le tube et l’assemblage principal.

Raison Possible :

Le serrage initial du tube dans l’assemblage principal n’est pas suffisant ou le sceau en caoutchouc à l’intérieur de l’assemblage principal est endommagé ou il manque.

Solution :

• Resserrez le tube bien fort a l’assemblage principal.

Problème

: Fuite de graisse visible au prolongement.

Raison Possible :

Fuite de graisse visible à l’assemblage principal.

1. Le serrage initial du prolongement dans l’assemblage principal et/ou coupleur n’est pas suffisant. 2. Le raccord remplisseur pourrait être lâche.

3. Anneau ‘O’ de la valve d’air purgeur est usé. 4. Piston usé ou endommagé et/ou alésage de l’assemblage principal.

Solution :

• Resserrez le prolongement a l’assemblage principal et le coupleur au prolongement.

• Resserrez le raccord remplisseur bien fort a l’assemblage principal.

• Remplacez l’Anneau ‘O’ ou la valve d’air purgeur.

METHODE DE GARANTIE LIMITÉE POUR NOUVEL ÉQUIPEMENT. LISEZ ATTENTIVEMENT LES INSTRUCTIONS CI-DESSUS

Lumax

®

garantit que tout équipement lubrifiant manufacturé par Lumax

®

est sans défaut en matériel et en exécution à la date de vente par un distributeur autorisé par Lumax

®

a l’acheteur initial. Lumax

®

, pendant une (1) année

suivant la date de vente, réparera ou remplacera toute pièce de l’équipement déterminée défectueuse par Lumax

®

. Cette garantie s’applique seulement quand le matériel est installé, opérationnel et mis à jour selon des

recommandations écrites de Lumax

®

.

Lumax

®

ne fait aucune représentation ou garantie (d’aucune façon) aux acheteurs qu’ils soient qualifiés de réparer le produit ou de remplacer des pièces du produit. En fait, Lumax

®

déclare expressément que toutes réparations

et tous remplacements de pièces doivent être entrepris par les techniciens certifiés et autorisés et non par l’acheteur. L’acheteur assume tous risques et responsabilités provenant de ses réparations aux pièces initiales du produit

ou à ces mêmes pièces de rechange ou provenant de son installation de ces mêmes pièces de rechange. Si l’équipement s’avère défectueux pendant cette période de garantie, il sera réparé ou substitué sans frais, à condition

que l’examen de l’usine indique que l’équipement est défectueux.

Cette garantie ne couvre pas, et Lumax

®

ne sera pas responsable de l’usure et de la dégradation normale, l’accident, la surcharge ou tout défaut de fonctionnement, endommagements ou usure provoquée par l’installation

défectueuse, mauvaise usage, emploi abusif, l’abrasion, la corrosion, l’entretien insatisfaisant ou inexact, la négligence, l’accident, tripatouillage ou la substitution des pièces non-Lumax

®

. Lumax

®

ne sera également pas

responsable pour l’équipement réparé ou modifié par toute personne non autorisée par Lumax

®

de réparer ou modifier l’équipement. Lumax

®

ne sera également pas responsable du défaut de fonctionnement, des endommagements

ou de l’usure provoquée si l’équipement Lumax

®

est inconciliable avec des accessoires, des équipements et des matériaux non fournis par Lumax

®

. Cette garantie est uniquement présentée à l’acheteur initial, et elle est conditionnée

sur le retour payé de l’équipement prétendu défectueux à un distributeur autorisé de Lumax

®

pour la vérification du défaut réclamé. Si le défaut réclamé est vérifié, Lumax

®

réparera ou remplacera gratuitement toutes les pièces

défectueuses. L’équipement sera retourné à l’acheteur initial, transport payé. Si l’inspection de l’équipement ne révèle aucun défaut dans le matériel ou l’exécution, les réparations seront faites pour des frais raisonnable, qui peuvent

inclure les frais des pièces, de travail, et de transport.

Cette garantie est exclusive, et elle tient lieu de toutes autres garanties, explicites ou implicites, incluant mais non limitées à la garantie de la valeur marchande ou à la garantie d’ajustage pour un but particulier. L’unique obligation

de Lumax

®

et l’unique recours de l’acheteur pour toute infraction de garantie seront déterminés comme ci-dessus. L’acheteur convient qu’aucun autre recours (y compris mais non limité aux dommages fortuits ou consécutifs

pour des profits perdus, des ventes perdues, des dommages à la personne ou à la propriété ou toute autre perte fortuite ou consécutive) ne sera disponible. Dans aucun cas Lumax

®

ne sera responsable des dommages fortuits

ou consécutifs. La responsabilité de Lumax

®

pour toutes réclamations ou pertes ou dommages provenant de la vente, revente ou utilisation de matériel lubrifiant, équipement disposant des matériaux, et tout autre équipement

ayant rapport ne devrait dans aucun cas excéder le prix d’achat. Quelques États ne permettent pas l’exclusion ou la limitation des dommages fortuits ou consécutifs, ainsi la limitation ou l’exclusion ci-dessus peut ne pas s’appliquer

à vous. Cette garantie vous donne des droits légaux spécifiques, et vous pouvez également avoir d’autres droits, qui changent d’État à État. Toute action pour l’infraction de la garantie doit être réclamée dans une période de deux

(2) ans depuis la date de la vente.

Lumax

®

ne fait aucune garantie, et dément toute garantie implicite de valeur et d’ajustage pour un but particulier en liaison avec accessoire, équipement, matériaux ou parties composantes vendues mais non fabriqués par Lumax

®

(moteurs électriques, commutateurs, tuyaux, etc.) en faisant toutes réclamations pour l’infraction de ces garanties. Lumax

®

ne sera responsable dans aucun cas des endommagements indirects, fortuits, spéciaux ou indirects

résultant du matériel fourni par Lumax

®

ci-compris ou la fourniture, l’exécution ou l’utilisation de tous produits ou d’autres marchandises vendues ci-joint, si bien en raison d’une infraction du contrat, l’infraction de la garantie,

la négligence de Lumax

®

ou autrement.

Toutes les garanties implicites applicables à l’équipement lubrifiant, équipement disposant des matériaux, et tout autre équipement lié construit par Lumax

®

, y compris les garanties de la valeur marchande et l’ajustage pour

un but particulier, dureront seulement pendant une (1) année depuis la date de l’achat. Certains états ne permettent pas des limitations en fonction de la durée d’une garantie implicite, ainsi la limitation ci-dessus peut ne pas s’appliquer

à vous.

© 2003 Lumax

®

. Tous droits réservés.

Lumax

®

et ses produits décrits sont les droits d’auteur de Lumax

®

, avec tous droits réservés.

Ce mode d’emploi ne peut être copiée en entier ou en partie, sans consentement par écrit exprès de Lumax

®

.

Lumax

®

3705 Centre Circle, Fort Mill, SC 29715, USA Fax : 803-547-0800 www.LumaxLubrication.com

Forme :

LX-1142-45-IS

/