Lincoln Electric 1860 Instructions Manual

- Catégorie

- Outils électroportatifs

- Taper

- Instructions Manual

Page

Section - D7 - 83

Form 404264

DEC - 2011

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium Ion)

Series “A”

Basic PowerLuber Model 1860

EC Declaration of Confomrity

MACHINERY DIRECTIVE

Lincoln declares that these products described under

“Technical Data” are in compliance with

2006/42/EC and EN 60745-1

Page Number - 2

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

GENERAL POWER TOOL SAFETY

WARNINGS

Table of Contents

Page

General Power Tool Safety Warnings.......2

Specic Safety........................................3

Service..........................................4

Tool Use and Care...................................4

Specications........................................4

General Description.................................5

Inspection...........................................6

Operation.........................................6-7

Charger Operation...................................8

Safety Instruction for Charger

and Batteries.................................10-11

Exploded View and Parts List...........12-14

Troubleshooting...........................15

French Version.....................................16

German Version.................................TBD

Spanish Version.................................TBD

Read all safety warnings and

instructions. Failure to follow the warnings

and instructions may result in electric shock,

re and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite acci-

dents.

b) Do not operate power tools in ex-

plosive atmospheres, such as in the

presence of ammable liquids, gases

or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away

while operating a power tool. Distrac-

tions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs with

earthed (grounded) power tools. Un-

modied plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of elec-

tric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of electric

shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool out-

doors, use an extension cord suitable

for outdoor use. Use of a cord suitable

for outdoor use reduces the risk of elec-

tric shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of

electric shock.

NOTE: The term “residual current device

(RCD)” may be replaced by the term

“ground fault circuit interrupter (GFCI)” or

“earth leakage circuit breaker (ELCB)”.

3) Personal safety

a) Stay alert, watch what you are do-

ing and use common sense when

operating a power tool. Do not use

a power tool while you are tired or

under the inuence of drugs, alcohol

or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protec-

tion used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying

the tool. Carrying power tools with your

nger on the switch or energizing power

tools that have the switch on invites

accidents.

d) Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

ORIGINAL INSTRUCTIONS

Page Number - 3

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

e) Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewelery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewelery or long

hair can be caught in moving parts.

g) If devices are provided for the connec-

tion of dust extraction and collection

facilities, ensure these are connected

and properly used. Use of dust collec-

tion can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the

correct power tool for your applica-

tion. The correct power tool will do the

job better and safer at the rate for which it

was designed.

b) Do not use the power tool if the

switch does not turn it on and off. Any

power tool that cannot be controlled with

the switch is dangerous and must be

repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools. Such preventive

safety measures reduce the risk of start-

ing the power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools. Check for mis-

alignment or binding of moving parts,

breakage of parts and any other condi-

tion that may affect the power tool’s

operation. If damaged, have the power

tool repaired before use. Many ac-

cidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

5) Battery Tool Use and Care

a) Recharge only with the battery charger

specied by the manufacturer. A char-

ger that is suitable for one type of battery

pack may create a risk of re when used

with another battery pack.

b) Use power tools only with specically

designated battery packs. Use of any

other battery packs may create risk of

injury and re.

c) When battery pack is not in use, keep

it away from other metal objects, like

paper clips, coins, keys, nails screws

or other small metal objects, that can

make a connection from one terminal

to another. Shorting the battery terminals

together may cause burns or a re.

d) Under abusive conditions, liquid may

be ejected from the battery; avoid

contact. If contact accidentally occurs,

ush with water. If liquid contacts eyes

additionally, seek medical help. Liquid

ejected from battery may cause irritation or

burns.

6) Service

a) Have your power tool serviced by a

qualied repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

Specic Safety

1. Always wear eye protection. The Power-

Luber can generate up to 7,500 psi (517

bar).

2. Use only Lincoln 1218, 1224, 1230 or

1236 outlet whip hoses. Grease injection

injuries are a very serious injury. Hold the

hose only in the area of the spring guard.

3. Avoid accidental starting. Be sure switch

is not depressed when inserting battery

pack.

4. Do not bend the hose so that it becomes

kinked.

5. Replace the hose at the rst sign of wear,

kink or damage to the outside jacket.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enable better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection.

Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used

for appropriate conditions.

Page Number - 4

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

Any other use not in accordance with instruc-

tions will result in loss of claim for warranty or

liability.

SERVICE

Tool service must be performed only by quali-

ed repair personnel. Service or maintenance

performed by unqualied personnel may void

warranty and result in a risk of injury.

When servicing a tool, use only identical

replacement parts.

Extreme pressure may cause nozzle

extension or whip hose to burst. Use only

Lincoln APPROVED hoses and follow whip

hose instructions and warnings.

TOOL USE AND CARE

Do not use tool if switch does not turn it on or

off. A tool that cannot be controlled with the

switch is dangerous and must be repaired.

Do not continue to hold down trigger if grease

gun is stalled. This could damage the motor or

cause re.

Disconnect battery pack from tool before mak-

ing any adjustments, changing accessories,

or storing the tool. Such preventive safety

measures reduce the risk of starting the tool

accidentally.

Store the tools out of reach of children and

other untrained persons. Tools are dangerous

in the hands of untrained users.

When battery pack is not in use, keep it away

from other metal objects like: paper clips,

coins, keys, nails, screws, or other small metal

objects that can make a connection from

one terminal to another. Shorting the battery

terminals together may cause sparks, burns,

or a re.

Maintain tools with care. Check for misalign-

ment or binding of moving parts, breakage of

parts, and any other condition that may affect

the tool’s operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools.

Use only accessories that are recommended

by Lincoln.

Only accessories that are capable of handling

7500 psi (517 bar) should be used. Accesso-

ries that may be suitable for one tool may cre-

ate a risk of injury when used on another tool.

Appropriate use

The PowerLuber was exclusively designed to

pump and dispense lubricant using 18 volt bat-

tery power. The maximum specication ratings

should not be exceeded.

Grease gun can develop high pressure - up

to 7,500 psi (517 Bar). Use safety glasses

and gloves for protection during operation.

Keep hands clear of the exposed rubber

portion of hose.

Warning! To reduce the risk of

injury, the user must read the

instruction manual.

Separate collection. This product

must not be disposed of with

normal household waste.

The gun uses lubricants, that may be am-

mable and poisonous if ingested. Do not use

gun near open ame or other re hazards.

Greases are often marketed as high tempera-

ture because it must maintain their lubricating

properties in hot areas, but the lubricants may

be ammable if the temperature is too high.

Please read all warnings on lubricants before

using this gun. It is best if the lubricants can

not be ammable.

Page Number - 5

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

SPECIFICATIONS

Basic PowerLuber Model 1860

Operating Power, Volt 18

Maximum Operating Pressure, psi (bar)

- Low Output - 7,500 (517)

- High Output - 3,000 (206)

Grease Reservoir Capacity, oz. (g) 14.5 (411)

Operating Temperature Range, °F (°C) 0 to 122

(-18 to +50)

Operating Current, Amp 4.0

Rated Current, Amp 5.0

Lubricant (Grease) Up to NLGI #2

Grease output oz./min. (gram/min)

- Low Output (L) 3.5 (99)

- High Output (H) 8.9 (252)

Weight, Lbs. (Kg) 8.8 (4.0)

Accessories:

Battery Li-Ion Model 1861

Output, VDC 18

Capacity, mAh 3000

Battery Charger Model 1850

Charge time 1 Hour

Input, VAC (3.0 A) 120 V, 50-60 Hz

Battery Charger Model 1850E

Charge time 1 Hour

Input, VAC (3.0 A) 230 V, 50 Hz

Outlet Hose Model 1236

Pressure Rating, psi (Bar) 7,500 (510)

Length of the Hose, In (mm) 36 (914)

Sound pressure (Lp) 70.0 dB(A), uncertainty (K) 3 dB(A)

Acoustic power (Lw) 81 dB(A), uncertainty (K) 3 dB(A)

Vibration emission value (ah) 1.1 m/s2, uncertainty (K)

1.5 m/s2

NOTE 1: Operating current and grease output data at

1,000 Psi (69 bar).

Models

Sales Model Components Included

1860 Grease Gun (W/ Battery)

1862 Grease Gun (W/ Battery)

Charger

Carrying Case

1862E Grease Gun (W/ Battery)

Charger (220v European)

Carrying Case

1864 Grease Gun (W/ Battery)

Extra Battery

Charger

Carrying Case

1850 Charger

1850E Charger (220v European)

1861 Battery Pack

1236 Hose (36”)

1230E Hose (RoHS European- 30”)

5852 Coupler, Midget Hyd.

251-10124-7 Coupler (European)

NOTE 2: The declared vibration total value has been

measured in accordance with a standard test method

and may be used for comparing one tool with another;

that the declared vibration total value may also be used

in a preliminary assessment of exposure.

Note 3: The vibration emission during actual use of

the power tool can differ from the declared total value

depending on the ways in which the tool is used; and

of the need to identify safety measures to protect the

operator that are based on an estimation of exposure in

the actual conditions of use (taking account of all parts

of the operating cycle such as the limes when the tool

is switched off and when it is running idle in addition to

the trigger time).

Page Number - 6

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

GENERAL DESCRIPTION

The Lincoln PowerLuber is a Lithium-Ion

battery operated grease gun. The gun was

developed for manual lubrication of grease

points and includes a pressure relief valve,

LED and electronic control center.

The PowerLuber is driven by a small, low

voltage electric motor connected to a three-

stage planetary gear transmission. The rotary

motion of the motor is converted into a recip-

rocating motion of the plunger using a yoke

mechanism. The PowerLuber is a positive

displacement single acting pump.

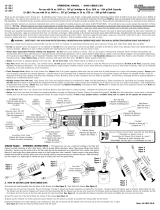

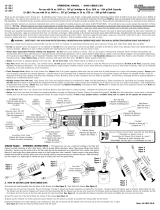

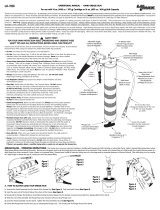

Relief Valve

The safety valve (g. 1) is factory set to

relieve pressure above 7500 psi (517 bar).

The valve also is an indicator of the bearing

and lubrication line conditions. If grease

comes out of the relief valve, it indicates a

clogged or tight bearing or tting or line. Cor-

rect this before continuing lubrication with the

PowerLuber.

Figure 1

(1860 Grease Gun)

Control center

The tool is equipped with a control center that

consists of: PC Board with Display, LED light and

Set keys “A” and “B”. Control center provides the

following functions:

• Motor protection. It will stop the motor if the

gun runs continuously at maximum pressure.

The display will ash red until the thermal

protector self resets;

• Displays the current level of battery charge;

• Monitors the level of the grease in tube;

• Calculates and displays the amount of the

grease delivered in, oz. PCB converts stroke

count to grease delivery.

• Allows control of an exact amount of grease

to lubricate critical bearings;

• Illuminates the LED light.

Page Number - 7

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

To prevent damage to the gears in the

transmission, the motor must be com-

pletely stopped before changing the lever

to the “L” or “H” (low or high) mode of

operation.

INSPECTION

Visually inspect for damaged, loose or miss-

ing parts. If equipment is worn or damaged,

remove from service. Contact an authorized

service center for damage assessment or

repair.

OPERATION

Changing “L” or “H” Mode

To change the mode of operation:

“L” (low output/high pressure)

“H” (high output/low pressure)

When motor is not running, push the lever

(Fig. 1) until letter “L” or “H” will be completely

visible in the window.

In case the lever is not completely shifted/

engaged, hold this lever and bump the switch

to engage gears.

High output is recommended if the tool is

used to lubricate large bearings not requiring

high pressure, beyond 3,000 psi (206 bar).

Also, high output is recommended if tool is

used to rell small reservoirs.

Low output is recommended if the tool is

used in construction, mining applications and

general lubrication. Low output will provide

the maximum pressure of up to 7,500 psi

(517 bar) the tool is capable of producing.

It is normal for batteries to lose their power

retention capacity over hundreds of charge

cycles. Replace the battery when this hap-

pens.

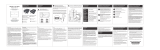

Turning Display and LED light

“ON”/”OFF”

To turn display and LED light “ON”:

-push either key or

-gently squeeze the trigger/switch;

To turn it “OFF”:

-push key “B” 3 sec. or

-wait 30seconds for self shutoff.

Display “ON” Display “OFF”

Grease ow monitoring.

Some OEM’s recommends the exact amount of

grease to lubricate critical bearings.

To deliver the desired amount of grease:

1. Press set key “A” 3sec. to set display reading

to zero.

2. Run and stop the gun at desired output.

3. Reset with Key A and lubricate next bearing.

4. Press key “B” 1 sec to view total (accumu-

lated) output.

Figure 2

Figure 3

Replacing the grease cartridge or

relling the tube.

1. Prime the Power Luber after each rell or

grease cartridge change. To prime, operate

the gun until grease ows from hose. Use

vent valve (Fig.1) to expel air pockets.

2. Press set key “A” and “B” simultaneously 3

sec to reset all. (output, accumulated output

and grease level indicator.)

3. Press set key “A” 1 sec to display symbol

“grease level full”.

Figure 4

Page Number - 8

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

Installing Grease Cartridge

1. Unscrew the grease tube assembly from

the PowerLuber.

2. Visually check the follower seal lip direc-

tion before loading a new cartridge. The

follower seal lip must be directed toward

the follower handle or rear side for

cartridge loading. See Fig. 5. (To change

the direction of the follower seal, unscrew

tube cap from grease tube assembly and

pull on the handle to remove follower seal

from tube. Flip follower seal over and

reassemble.)

3. Pull back on the follower handle and latch

the follower rod groove into the slot on the

tube cap.

4. Remove the plastic cap from the grease

cartridge and insert cartridge into the

container tube.

5. Remove the pull tab from grease cartridge

and screw grease tube assembly into

pump assembly.

6. Thread grease tube assembly back onto

the Powerhead.

7. Release follower rod from slot. Purge

air from pump. See air purging instruc-

tions.

8. Reset display reading after purging air.

Air pockets in the cartridge lubricant will

cause the gun to lose its prime and will

cause grease output measurements and

cartridge level readings to be inaccurate.

(See page 8).

Removing Empty Grease Cartridge

1. Pull back on the follower handle until the

follower rod is fully extended and latch the

follower rod groove into the slot on the

tube cap.

2. Unscrew the grease tube assembly from

the PowerLuber.

3. Carefully release the follower handle to

eject the empty cartridge from container

tube.

To Convert Gun to Allow Filling From

Bulk Containter or Filler Pump

1. Unscrew the grease tube assembly cap

from the grease tube assembly. Pull on the

follower handle to extract the follower and

spring from the grease tube assembly.

2. Grasp follower between thumb and foren-

ger and ip the follower lip from the rear to

the front side.

NOTE. The follower resembles a cup.

When the gun is assembled for use with

bulk lubricant, the cup opens toward the

pump assembly.

3. Reassemble follower into grease tube and

tighten onto the container tube.

To Fill The Gun from Bulk Container

1. Remove pump assembly from grease tube

assembly.

2. Pack lubricant into cavity of the pump as-

sembly.

3. Insert the open end of the grease tube

assembly into lubricant (see Fig. 6). Slowly

pull the follower handle back while pushing

the grease tube assembly deeper into the

lubricant to prevent air pockets from being

pulled into the grease tube.

4. When the follower rod is fully extended,

pull it sideways to latch the rod groove

into the keyhole slot in the grease tube

assembly cap.

5. Loosely assemble the pump to the grease

tube assembly. Release the follower

rod from the grease tube assembly cap

and disengage the follower rod from the

follower by rotating the follower handle.

Push the follower rod into the grease tube

assembly. Slowly unscrew the grease tube

assembly from the pump until lubricant

oozes from the interface. Tighten grease

tube assembly into the pump assembly.

6. Reset display reading after purging air

Figure 5

Rear Side Front Side

Figure 6

Page Number - 9

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

rod into the grease tube assembly.

CHARGER OPERATION

CHARGING THE BATTERY PACK

Before using your PowerLuber for the rst time,

the battery pack should be fully charged. If the

battery pack is installed in the PowerLuber,

remove it and follow “Charging Procedure”

below.

Lincoln chargers are designed to charge

Lincoln Lithium batteries in 30-60 minutes

depending on the battery’s state of charge and

temperature.

CHARGING PROCEDURE

Make sure power circuit voltage is the same

as that shown on the charger specication

plate.

1. Plug the charger into an appropriate outlet

before inserting battery pack.

2. Insert the battery pack into the charger. The

green (charging) light will blink continuously

indicating that the charging process has

started.

3. The completion of charge will be indicated

by the green light remaining ON continu-

ously. The pack is fully charged and may be

used at this time.

4. Disconnect charger from power source

120/230 volts present at charging terminals. Do

not probe with conductive objects. Danger of

electric shock or electrocution.

when not in use.

(see page 8).

To Fill The Gun with a Filler Pump

1. Engage the follower rod with the follower by

rotating the follower handle.

2. Insert the gun vent/bulk ll valve into the ller

pump socket (see Fig. 7).

3. Operate the ller pump to ll the container.

When the follower rod groove is exposed,

the grease tube assembly is lled. The fol-

lower rod will be extended approximately 8

inches (20 cm). Do not overll!

4. Disengage the follower rod from the follower

by rotating the follower handle. Push the

follower rod into the grease tube assembly.

5. Reset display reading after purging air.

To Expel Air Pockets (Air Purging)

1. Withdraw the follower rod from the grease tube

assembly cap and engage it with the follower by

rotating the follower handle.

2. Unscrew the plug of vent valve 3-4 turns. Exert

force on the follower handle until grease ows

through the small hole in the side of the vent

valve.

3. Tighten the vent valve.

4. Pull the trigger in short bursts to operate gun

until trapped air is expelled. Disengage the

follower rod from the follower by rotating the

follower handle. Push the follower rod into the

grease tube assembly.

5. If step 2 fails, unscrew the grease tube assem-

bly 3 turns from the pump assembly.

6. Exert force on the follower handle until lubricant

oozes from the grease tube assembly and

pump assembly interface.

7. Retighten grease tube into the pump assembly.

Disengage the follower rod from the follower by

rotating the follower handle. Push the follower

Remove Air Pocket! Air pocket at grease

inlet will prevent grease from being pumped.

Unscrew the vent valve three to four turns to

remove small air pockets trapped in this area.

If the air pocket is substantial and no grease

ows from coupler after trigger is pulled for 15

seconds, see following steps.

Figure 7

Page Number - 10

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

INDICATOR LIGHT OPERATION

NOTE: Battery temperature will increase during

and shortly after use. Batteries may not accept

a full charge if they are charged immediately

after use. Allow the battery pack to cool to

Important Charging Notes

1. Longest life and best performance can be

obtained if the battery is charged when the

air temperature is between 65° F and 75° F

(18° - 24° C). DO NOT charge the battery in

an air temperature below +40° F (4.5° C) or

above 105° F (+40.5° C). This is important

and will prevent serious damage to the bat-

tery.

2. The charger and battery may become warm

to the touch while charging. This is a normal

condition, and does not indicate a problem.

3. If the battery does not charge properly:

a. Check current at receptacle by plugging in

a lamp or other appliance.

b. Check to see if the receptacle is con-

nected to a light switch which turns power

off when you turn out the lights.

c. Move charger and battery to a location

where the surrounding air temperature is

approximately 65° F - 75° F (18 - 24° C).

d. If charging problems persist, take the tool,

battery and charger to your local service

center.

room temperature before charging for best

results.

Vent slots in top and bottom of charger must

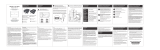

Figure 8

Don’t allow any liquid to get inside charger.

Electric shock may result. To facilitate the

cooling of the battery pack after use, avoid

placing the charger or battery pack in a

warm environment such as a metal shed or

an uninsulated trailer.

1861

Battery

1850 or 1850E

Battery Charger

4. The battery should be recharged when it

fails to produce sufcient power on jobs.

DO NOT CONTINUE to use under these

conditions. Follow the charging procedure.

You may also charge a partially used pack

whenever you desire with no adverse affect

on the battery.

5. Under certain conditions, with the charger

plugged into the power supply, the exposed

charging contacts of the charger can be

shorted by foreign material. Foreign materi-

als of a conductive nature such as, but not

limited to, steel wool, aluminum foil, or any

buildup of metallic particles should be kept

away from charger cavities. Always unplug

the charger from the power supply when

there is no battery in the cavity. Unplug

charger before attempting to clean.

6. Do not freeze or immerse charger in water

or any other liquid.

Page Number - 11

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

not be obstructed. Do not charge battery when

temperature is BELOW 40° F (4.5° C) or ABOVE

104° F (40° C).

SAFETY INSTRUCTIONS FOR CHARGER AND BATTERIES

SAVE THESE INSTRUCTIONS

This manual contains important safety and

operating instruction for Lincoln Model 1850 or

1850E Battery Charger.

1. Before using a battery charger, read all

instructions and cautionary markings on

Battery Charger, Battery Pack, and prod-

uct using battery.

2. CAUTION: To reduce the risk of injury,

Lincoln Model 1850 and 1850E Chargers

should only be used to charge Lincoln

battery pack Model 1861. Other types

of batteries may burst causing personal

injury and damage. Do not charge Lincoln

Model 1861 Battery Packs with any other

charger.

3. Do not expose charger to rain, snow or

frost.

4. Do not abuse cord. Never carry charger by

cord or yank it to disconnect from recep-

tacle. Pull by plug rather than cord when

disconnecting charger. Have damaged

or worn power cord and strain reliever

replaced immediately. DO NOT ATTEMPT

TO REPAIR POWER CORD.

5. Make sure cord is located so that it will not

be stepped on, tripped over, or otherwise

subjected to damage or stress.

6. Do not use an extension cord unless

absolutely necessary. Use of improper

extension cord could result in a risk of re

and electric shock.

7. Do not operate charger with damaged cord

or plug. Have them replaced immediately,

to avoid a hazard DO NOT ATTEMPT TO

REPAIR POWER CORD.

8. Do not operate charger if it has received

a sharp blow, been dropped, or otherwise

damaged in any way, take it to a qualied

service center.

9. Do not disassemble charger or bat-

tery pack. Take it to a qualied service

center when service or repair is required.

Incorrect reassembly may result in risk of

electrical shock or re.

10. Unplug charger from outlet before attempt-

ing any maintenance or cleaning to reduce

risk of electric shock.

11. Charge the battery pack in a well venti-

lated place; do not cover the charger and

battery with a cloth, etc., while charging.

12. Do not store the charger or battery packs

in locations where the temperature may

reach or exceed 122° F (50° C) such as

Risk of Electric Shock 120 VAC or 230 VAC

present at charger terminals. Do not probe

with conductive objects. Do not charge dam-

aged battery. Replace immediately.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it

is severely damaged or is completely worn

out. The battery pack can explode in a re.

Toxic fumes and materials are created when

Ll-ION battery packs are burned.

• Do not charge or use battery in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust. Inserting

or removing the battery from the charger may

ignite the dust or fumes.

• If battery contents come into contact with

the skin, immediately wash area with mild

soap and water. If battery liquid gets into

the eye, rinse water over the open eye for 15

minutes or until irritation ceases. If medical at-

tention is needed, the battery electrolyte for

LI-ION batteries is composed of a mixture of

liquid organic carbonates and lithium salts.

• Contents of opened battery cells may

cause respiratory irritation. Provide fresh

air. If symptoms persists, seek medical atten-

tion.

Burn hazard. Battery liquid may be ammable

if exposed to spark or ame. Charge the

battery packs only in Lincoln Industrial

chargers.

DO NOT splash or immerse in water or

other liquids. This may cause premature cell

failure.

Never attempt to open the battery pack for

any reason. If the plastic housing of the

battery pack breaks or cracks, return to a

service center for recycling.

• Do not store or use the tool and battery in

locations where the temperature may reach

or exceen 105°F (40°C) such as outside

sheds or metal buildings in summer.

Page Number - 12

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

a metal tool shed, or a car in the summer

which can lead to deterioration of the stor-

age battery.

13. Do not charge battery pack when the

temperature is BELOW 40° F (4.5° C) or

ABOVE 104° F (40° C). This is very impor-

tant for proper operation.

14. Do not incinerate battery pack. It can

explode in a re.

15. Do not charge battery in damp or wet loca-

tions.

16. Do not attempt to charge any other cord-

less tool or battery pack with the Lincoln

Model 1850 or 1850E charger.

17. Do not short across the terminals of the

battery pack. EXTREMELY HIGH TEM-

PERATURES COULD CAUSE PERSON-

AL INJURY OR FIRE.

18. This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge, un-

less they have been given supervision or

instruction concerning use of the appliance

by a person responsible for their safety.

19. Children should be supervised to ensure

that they do not play with the appliance.

20. Dispose of expended batteries properly.

The Lincoln Model 1861 Battery Pack

contains rechargeable, lithium-ion batter-

ies. These batteries must be recycled or

disposed of properly. Drop off expended

battery packs at your local replacement

battery retailer, or your recycling center.

Users in the United States NOTE:

Applicable fees for the collection and recy-

cling of these batteries have been paid to

the RBRCTM. For further information, call

1-800-8BATTERY.

Page Number - 15

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

Service Parts List

Item Description Part Number

1 FLEXIBLE HOSE 36” W/GASKET(MODEL 1860) 1236

FLEXIBLE HOSE 30” W/GASKET(MODEL 1860E) 1230E

2 COUPLER (MODEL 1860) 5852

COUPLER (MODEL 1860E) 251-10124-7

3 PACKING 34793

4 FOLLOWER ASSEMBLY KIT 93485

5 GREASE TUBE ASSEMBLY 271882

6 GASKET KIT (HOSE) 271884

7 SEAL 271889

8 HANDLE KIT (GREASE TUBE) 286090

9 ROD, FOLLOWER KIT 286091

10 HOSE CLIP KIT 286367

11 COUPLER CAP KIT 286093

12 ELECTRICAL COMPONENTS KIT 286377

13 RESERVED

14 GEAR SELECTOR KIT 286097

15 HANDLE HARDWARE 286393

16 DECAL KIT 286378

17 MOTOR WITH ADAPTER KIT 286399

18 PUMP HARDWARE KIT 286391

19 COVER PUMP KIT 286379

20 YOKE KIT 286380

21 LED COVER KIT 286381

22 PLUNGER KIT 286109

23 STUD KIT 286110

24 ROLLER 286111

25 SPRING SELECTOR 286113

26 VENT/BULK VALVE KIT 286134

27 RESERVED

28 DRIVER ASSEMBLY 286285

29 GEAR SET KIT 286286

30 HANDLE WITH ELECTRICAL COMPONENT KIT 286382

31 HANDLE WITH SCREW KIT 286383

32 PUMP ASSEMBLY KIT 286384

33 CHECK VALVE KIT 286306

34 HOUSING PUMP WITH BEARING 286394

35 VENT VALVE KIT 286315

36 GASKET KIT (RELIEF VALVE) 286316

37 RELIEF VALVE KIT 286317

38 BATTERY 18V (LITHIUM) 1861

(NOT PICTURED) CHARGER (LITHIUM) 1850

(NOT PICTURED) STRAP 1414

CASE KIT 286392

Page Number - 16

Models 1860, 1862, 1862E, 1864

PowerLuber Grease Gun (Lithium)

Form 404264

TROUBLESHOOTING

Condition Possible Cause Corrective Action

Motor fails to run. - Battery needs charging. Recharge battery.

- Faulty wiring to motor. Remove battery, disassemble

handle and check wiring

for loose connection.

PowerLuber fails to - Grease tube assembly is out of grease. Check that grease tube

dispense grease. assembly has grease.

- Loss of prime. Repeat priming operation.

- Ball check item 33 is not functioning. Remove Item 33, clean and

inspect ball seat area.

PowerLuber continues - Air may be trapped in several locations Empty grease tube

to lose prime. in container after bulk lling. assembly, rell and repeat

priming instructions.

- Follower may be binding in grease Replace grease tube assembly

tube assembly. Item 5.

Disassemble grease tube

assembly and clean.

Be sure that follower has properly

entered the grease cartridge.

Or

Verify that the follower is not

caught on the rim of the grease

cartridge.

Battery fails to take - Charger may not have power. Check that receptacle has power.

a charge. - Battery may be bad. Replace battery.

Page Numéro - 17

Formulaire 404264

Modèles 1860, 1862, 1862E, 1864

Graisseur PowerLuber (Lithium)

Page

Section - D7 - 83

DEC – 2011

Modèles 1860, 1862, 1862E, 1864

Graisseur PowerLuber (lithium)

Série « A »

PowerLuber de base modèle 1860

Déclaration de conformité CE

DIRECTIVE « MACHINES »

Lincoln déclare que les produits décrits à

la rubrique « Caractéristiques techniques

» sont conformes à la directive 2006/42/

CE et à la norme EN 60745-1.

Page Numéro - 18

Modèles 1860, 1862, 1862E, 1864

Graisseur PowerLuber (Lithium)

Formulaire 404264

Table des Matières

Page

Consignes de sécurité générales

relatives à l’outillage électrique ................18

Consignes spéciques de sécurité.................18

Entretien ........................................................20

Utilisation et soin de l’outil .................................20

Caractéristiques .............................................21

Description générale .....................................22

Contrôle...................................................23

Fonctionnement.........................................23

Fonctionnement du chargeur .........................25

Instructions de sécurité pour chargeur

et batteries ..........................................27

Vue éclatée liste des pièces détachées .........29

Dépannage ....................................................32

Anglise.........................................................2

Allemand ................................. (à déterminer)

Espagnol ................................. (à déterminer)

Prière de lire toutes les instructions et

consignes de sécurité. Le non-respect des

instructions et consignes de sécurité risque

d’entraîner un risque d’électrocution, d’incendie

et (ou) de blessures graves.

AVERTISSEMENTS GÉNÉRAUX

DE SÛRETÉ DE MACHINE-OUTIL

Conserver toutes les instructions et consignes

de sécurité pour référence ultérieure.

Le terme « outil électrique » dans les con-

signes de sécurité fait référence à votre outil,

qu’il fonctionne sur secteur (avec cordon) ou

sur batterie (sans cordon).

1) Sécurité de la zone de travail

a) Maintenir la zone de travail propre et

bien éclairée.

Les zones encombrées ou mal éclai-

rées sont propices aux accidents.

b) Ne pas faire fonctionner d’outils

électriques en atmosphère explosive,

en présence de liquides ou de gaz

inammables, ou de poussière. Les

outils électrique causent des étincelles

susceptibles d’enammer la poussière ou

les vapeurs.

c) Tenir les enfants et autres personnes

à l’écart d’un outil électrique en fonc-

tionnement. Une distraction risque de

vous faire perdre le contrôle de l’outil.

2) Sécurité électrique

a) La che d’un outil électrique doit

obligatoirement correspondre à la

prise. Il est interdit de modier la che

de quelque manière que ce soit. Il est

interdit d’utiliser un adaptateur de che

avec un outil électrique nécessitant une

mise à la terre. Les ches non modiées

et les prises appropriées réduisent le

risque d’électrocution.

b) Éviter tout contact du corps avec des

surfaces reliées à la terre (tuyaux, ra-

diateurs, cuisinières et réfrigérateurs,

entre autres). Le risque d’électrocution

est plus grand si votre corps est relié à

la terre.

c) Ne pas exposer un outil électrique à

la pluie ou à l’humidité. La pénétration

d’eau dans un outil électrique augmente

le risque d’électrocution.

d) Ne pas malmener le cordon. Il est in-

terdit d’utiliser le cordon pour porter, tirer

ou débrancher l’outil électrique. Tenir le

cordon à l’écart de la chaleur, de l’huile,

des arêtes vives et des pièces mobiles.

Un cordon endommagé ou emmêlé aug-

mente le risque d’électrocution.

e) Lors de l’emploi d’un outil électrique

à l’extérieur, utiliser une rallonge ap-

propriée à une utilisation en extérieur.

L’emploi d’une rallonge appropriée à

un usage en extérieur réduit le risque

d’électrocution.

f) Si l’utilisation d’un outil électrique

dans un endroit humide est inévitable,

alimenter celui-ci à l’aide d’une protec-

tion différentielle. Une protection dif-

férentielle réduit le risque d’électrocution.

NOTA : Le terme « protection différen-

tielle » est synonyme de « disjoncteur

différentiel ».

3) Sécurité des personnes

a) Restez vigilant, faites attention à ce

que vous faites et utilisez votre bon

sens en utilisant un outil électrique.

Ne pas utiliser un outil électrique sous

l’effet de la fatigue, ou sous l’inuence

de médicaments, d’alcool ou de

drogue. Un simple moment d’inattention

pendant l’utilisation d’un outil électrique

risque d’entraîner une blessure grave.

b) Utiliser un équipement de protection.

Toujours porter une protection ocu-

laire. Le port d’équipements de sécurité

(masque anti-poussière, chaussures

de sécurité antidérapantes, casque ou

protection auditive, en fonction des condi-

tions) réduit le risque de blessures.

c) Éviter le démarrage intempestif de

l’outil. S’assurer que l’interrupteur est

en position arrêt avant de brancher

l’appareil et (ou) sa batterie, de le sou-

lever ou de le transporter. Le transport

d’un outil électrique avec le doigt sur

Page Numéro - 19

Formulaire 404264

Modèles 1860, 1862, 1862E, 1864

Graisseur PowerLuber (Lithium)

l’interrupteur, ou le branchement d’un

outil dont l’interrupteur est en position «

March », ouvre la porte aux accidents.

d) Retirer les éventuelles clefs de réglage

avant la mise en marche de l’outil.

Une clef restée xée à une pièce rotative

d’un outil électrique risque de causer une

blessure.

e) Ne pas se pencher en porte à faux.

Conserver son équilibre en perma-

nence. Ceci permet de mieux contrôler

l’outil en cas de situation imprévue.

f) Porter des vêtements appropriés. Ne

pas porter de vêtements amples ni

de bijoux. Tenir les cheveux, les vête-

ments et les gants à l’écart des pièces

mobiles. Les vêtements amples, les bi-

joux et les cheveux longs risquent d’être

happés par les pièces en mouvement.

g) Si les outils sont équipés de disposi-

tifs de dépoussiérage, s’assurer que

ceux-ci sont raccordés et correcte-

ment utilisés. L’emploi d’un dispositif

de dépoussiérage pourra réduire les

dangers liés aux poussières.

4) Utilisation et soin d’un outil électrique

a) Ne pas forcer un outil électrique.

Utiliser un outil électrique convenant

au travail à effectuer. Un outil électrique

approprié effectuera le travail mieux et

avec davantage de sécurité à la vitesse

pour laquelle il a été étudié.

b) Ne pas utiliser un outil électrique si

son interrupteur ne fonctionne pas.

Un outil qui ne peut pas être contrôlé

au moyen de son interrupteur est

dangereux, et doit obligatoirement être

réparé.

c) Débrancher la che de la prise

d’alimentation et (ou) débrancher la

batterie de l’outil avant d’effectuer un

réglage, un changement d’accessoire,

ou de ranger l’outil. Ces mesures de

sécurité préventives réduisent le risque

de démarrage par inadvertance.

d) Ranger les outils électriques hors de

portée des enfants, et ne pas laisser

des personnes connaissant mal l’outil

ou ces instructions le faire fonction-

ner. Un outil électrique entre les

mains d’une personne non formée est

dangereux.

e) Entretien des outils électriques. Véri-

er le bon alignement et l’absence de

grippage des pièces en mouvement,

vérier le bon état des pièces ainsi

que toute autre condition susceptible

d’affecter le fonctionnement de l’outil.

Si un outil électrique est endommagé,

le faire réparer avant de l’utiliser. De

nombreux accidents sont causés par des

outils électriques mal entretenus.

f) Maintenir les outils de coupe bien ai-

guisés et propres. Des outils de coupe

entretenus correctement et ayant

des arêtes bien aiguisées sont moins

susceptibles au grippage et sont plus

faciles à contrôler.

g) Utiliser les outils, accessoires, em-

bouts, etc., conformément aux présen-

tes instructions, en tenant compte des

conditions de travail et de la tâche à

effectuer. L’emploi d’un outil électrique

pour un usage différent de celui pour

lequel il est prévu risque de causer une

situation dangereuse.

5) Utilisation et soin d’un outil à batterie

a) Ne recharger la batterie qu’avec le

chargeur spécié par le fabricant.

Un chargeur adapté à un type de

bloc-batterie risque de créer un risque

d’incendie avec un bloc-batterie d’un type

différent.

b) N’utiliser des outils électriques

qu’avec des blocs-batteries prévus

pour ceux-ci. L’emploi d’autres blocs-

batteries pourra créer des risques de

blessures et d’incendie.

c) Hors utilisation, tenir un bloc-batte-

rie à l’écart des objets métalliques

(trombones, pièces de monnaie, clefs,

clous, vis et autres petits objets en

métal) qui risquent de mettre ses

bornes en court-circuit. Un court-circuit

entre les bornes d’une batteries risque

d’entraîner des brûlures ou un incendie.

d) En cas d’utilisation abusive, du liquide

risque d’être éjecté de la batterie ;

éviter le contact. En cas de contact

accidentel, rincer à l’eau. Si le liquide

touche les yeux, consulter un méde-

cin. Le liquide éjecté de la batterie peut

provoquer de l’irritation ou des brûlures.

6) Réparations

a) Faire réparer votre outil par un

technicien qualié, et ne remplacer

des pièces que par des pièces de

rechange identiques. Ceci permettra

de maintenir la sécurité de votre outil

électrique.

Consignes spéciques de sécurité

1. Toujours porter une protection oculaire. Le

Power-Luber peut produire une pression de

517 bars.

2. N’utiliser que des exibles de sortie courts

Lincoln 1218, 1224, 1230 ou 1236. Les

blessures par injection de graisse sont très

graves. Ne tenir le exible que par le ressort

de protection.

Page Numéro - 20

Modèles 1860, 1862, 1862E, 1864

Graisseur PowerLuber (Lithium)

Formulaire 404264

Attention danger ! Pour réduire

le risque de blessure, l’utilisateur

doit impérativement lire le manuel

d’instruction.

Rebutage séparé. Ce produit ne doit

pas être rebuté avec les ordures

ménagères.

Le graisseur peut produire une pression très

élevée, pouvant atteindre 517 bars. Porter des

lunettes de sécurité et des gants pendant son

fonctionnement. Tenir les mains à l’écart de la

partie du exible en caoutchouc visible.

Toute autre utilisation non conforme aux instruc-

tions risque d’entraîner la perte de la garantie ou

un refus de responsabilité.

ENTRETIEN

La réparation de l’outil ne peut être effectué que

par un technicien compétent. Une réparation ou

un entretien effectué par une personne non com-

pétente pourra annuler la garantie et entraîner un

risque de blessure.

Lors d’une réparation de l’outil, n’utiliser que des

pièces de rechange identiques.

Une pression extrême peut entraîner

l’éclatement d’une rallonge de buse ou d’un

exible court. N’utiliser que des exibles

AGRÉÉS par Lincoln et respecter les instruc-

tions et consignes de sécurité du exible court.

UTILISATION ET SOIN DE L’OUTIL

Ne pas utiliser l’outil si son interrupteur ne fonc-

tionne pas. Un outil ne pouvant pas être contrôlé

au moyen de son interrupteur est dangereux, et

doit obligatoirement être réparé.

Ne pas maintenir l’appui sur la gâchette si le

graisseur est bloqué. Ceci risque d’endommager le

moteur ou de provoquer un incendie.

Débrancher la batterie de l’outil avant d’effectuer

un réglage, un changement d’accessoire, ou de

ranger l’outil. Ces mesures de sécurité préven-

tives réduisent le risque d’un démarrage par

inadvertance.

Ranger les outils hors de portée des enfants et des

personnes inexpérimentées. Des outils entre les

mains de personnes non formées sont dangereux.

Tenir les blocs-batteries inutilisés à l’écart d’objets

en métal tels que : trombones, pièces de monnaie,

clefs, clous, vis et autres petits objets en métal

qui risquent de mettre ses bornes en court-circuit.

Un court-circuit entre les bornes d’une batteries

risque de causer des étincelles, des brûlures ou

un incendie.

Entretenir les outils avec soin. Vérier le bon

alignement et l’absence de grippage des pièces

en mouvement, vérier le bon état des pièces ainsi

que toute autre condition susceptible d’affecter le

fonctionnement de l’outil. Si un outil est en mau-

vais état, le faire réparer avant toute utilisation. De

nombreux accidents sont causés par des outils

mal entretenus.

N’utiliser que les accessoires recommandés par

Lincoln.

Seuls les accessoires prévus pour une pression

de 517 bars peuvent être utilisés. Des accessoires

pouvant convenir à un outil peuvent créer un

risque de blessure sur un autre outil.

Utilisation appropriée

Le PowerLuber a été étudié exclusivement pour

pomper et distribuer des produits de graissage

avec une batterie de 18 V. Le dépassement des

caractéristiques maximales est interdit.

3. Éviter les démarrages accidentels. S’assurer

que l’interrupteur n’est pas enfoncée lors de

l’insertion du bloc-batterie.

4. Ne pas courber le exible au point qu’il soit

plié.

5. Remplacer le exible au premier signe d’usure,

de torsion ou de dommage à sa gaine externe.

Ne pas se pencher en porte à faux. Conserver

son équilibre en permanence. Une position stable

et bien équilibrée permet un meilleur contrôle de

l’outil dans une situation inattendue.

Utiliser des équipements de sécurité. Toujours

porter une protection oculaire.

Un masque anti-poussière, des chaussures de

sécurité antidérapantes, un casque ou une protec-

tion auditive doivent impérativement être portés,

en fonction des conditions.

Le graisseur contient des produits lubriants, qui

sont susceptibles d’être inammables et toxiques

en cas d’ingestion. Ne pas utiliser le graisseur à

proximité d’une amme nue ou d’autres dangers

d’incendie.

Bien que de nombreuses graisses mentionnent «

haute température », car elles doivent conserver

leurs propriétés lubriantes à chaud, elles peuvent

malgré tout être inammables si la température

est trop élevée. Bien lire toutes les consignes de

sécurité des produits lubriants avant d’utiliser ce

graisseur. Il est préférable que les produits lubri-

ants ne soient pas inammables.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

Lincoln Electric 1860 Instructions Manual

- Catégorie

- Outils électroportatifs

- Taper

- Instructions Manual

dans d''autres langues

- English: Lincoln Electric 1860

- español: Lincoln Electric 1860

- Deutsch: Lincoln Electric 1860

Autres documents

-

Jet EQUIPMENT & TOOLS JCGG18 Le manuel du propriétaire

Jet EQUIPMENT & TOOLS JCGG18 Le manuel du propriétaire

-

Lumax LX-1142 Manuel utilisateur

Lumax LX-1142 Manuel utilisateur

-

ororo Mini 5K Mode d'emploi

ororo Mini 5K Mode d'emploi

-

Powerfist 4270328 Le manuel du propriétaire

-

Lumax LX-1112 Manuel utilisateur

-

TOOLCRAFT 2582931 Manuel utilisateur

-

Lumax LX-1153 Manuel utilisateur

Lumax LX-1153 Manuel utilisateur

-

Lumax LX-1161 Manuel utilisateur

-

Power Fist 8254534 Le manuel du propriétaire

-

pro.point 8886384 Le manuel du propriétaire

pro.point 8886384 Le manuel du propriétaire