BE Cold Water PW Manuel utilisateur

- Catégorie

- Nettoyeurs haute pression

- Taper

- Manuel utilisateur

OPERATOR’s

MANUAL

PRESSURE WASHER

MANUEL D’UTILISATION DU LAVEUSES À PRESSION

MANUAL DEL OPERADOR DE LA LAVADORA A PRESIÓN

04-2022

08-2023

85.609.006

2www.bepowerequipment.com

TABLE OF CONTENTS

INTRODUCTION 3

SAFETY OVERVIEW 4

PRESSURE WASHER COOLING SYSTEM 9

FUEL AND OIL TYPES 10

COMPONENT DIAGRAMS GAS PRESSURE WASHERS 11

COMPONENT DIAGRAMS ELECTRIC PRESSURE WASHERS 15

ASSEMBLY 17

PRE-OPERATION 19

GAS ENGINE START PROCEDURE 20

GAS ENGINE STOP PROCEDURE 23

ELECTRIC MOTORS WITH AUTO STOP-START SYSTEM 24

ELECTRIC MOTOR STOP PROCEDURE 24

CLEANING WITH DETERGENTS 25

STORAGE 26

MAINTENANCE 27

TROUBLESHOOTING 29

WARRANTY 33

3

www.bepowerequipment.com

INTRODUCTION

Congratulations on your purchase of a BE Power Equipment pressure washer.

You can be confident that this machine is constructed and tested with optimum

performance and quality in mind.

Reading this manual will help get you the best results for set-up, operation,

maintenance and avoid personal injury or damage to your machine. By knowing

how best to operate this machine, you will be better positioned to show others

who may also operate the unit.

All the information in this manual is based on the latest product information

available at the time of printing. BE Power Equipment reserves the right to make

changes at any time without notice or incurring any obligation.

Owner/Operator Responsibility

The owner/operator must have a thorough understanding of the operation,

maintenance and dangers associated with using this machine. It must be

understood that it is ultimately up to the owner/operator to safely use this

machine as outlined in this manual.

This manual is considered a part of the machine and needs to be kept in a safe

location. If the machine is resold or given to someone else, this manual needs to

be included.

Product Registration

Please register your product online to get the maximum benefit from your

warranty. Use the QR code below or register online at: bepowerequipment.com/

product-registration

It is recommended that you record the product identification numbers in this

manual. These numbers are important to have on hand if you need to contact

technical support (1-866-850-6662). The model and serial number can be found

on the box and on decal on the machine.

PRODUCT IDENTIFICATION

Model Number:

Serial Number:

Date of Purchase:

Dealer Name:

4www.bepowerequipment.com

SAFETY OVERVIEW

The safety alert symbol ( ) is used with a signal word (DANGER, CAUTION,

WARNING), a pictorial and a safety message to alert you to hazards.

DANGER indicates a hazard that, if not avoided, will result in death or serious

injury.

WARNING indicates a hazard that, if not avoided, could result in death or serious

injury.

CAUTION indicates a hazard that, if not avoided, might result in minor or

moderate injury.

NOTICE indicates a situation that could result in equipment or property damage.

SAVE THESE INSTRUCTIONS - SAFETY RULES

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

IMPORTANT WARNINGS

Failure to observe warnings will void the warranty or cause injury.

1. Do not let the pressure washer overheat. Excess heat will cause serious

damage (see page 10 for details).

2. Never run the unit without water. Running the pump dry will cause it to fail

quickly.

3. Do not let the unit freeze. Frozen water in the pump will cause severe

damage.

4. Always wear eye protection when operating the unit.

5. High-pressure spray can cause serious bodily injury or damage to soft

material. Use with caution.

6. Never adjust the unloader to exceed the preset pressure. Premature wear,

equipment failure, or injury may occur.

IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS

WARNING – When using this product, the following precautions should always

be observed and adhered to.

1. Read all instructions before using the product.

2. To reduce the risk of injury, close supervision is necessary when a product is

used near children.

3. Know how to stop the product and bleed pressures quickly. Be thoroughly

familiar with the controls.

4. Stay alert. Watch what you are doing.

5. Do not operate the product when fatigued or under the inuence of alcohol or

drugs.

6. Keep operating area clear of other people.

7. Do not overreach or stand on unstable support. Instead, keep solid

footing and balance at all times.

8. Follow the maintenance instructions specied in the manual.

5

www.bepowerequipment.com

SAFETY OVERVIEW

PERSONAL SAFETY

WARNING - Always wear correct personal protection equipment because the

high-pressure spray can launch debris at high velocity creating a risk of injury or

damage.

• ALWAYS wear safety goggles for eye protection. Other protective equipment

such as hearing protection, steel toe boots, safety apparel, work gloves and

face shield are all recommended.

• NEVER pressure wash without closed-toe foot protection in case of accidental

spray.

• ALWAYS be aware of where the spray gun is pointing and your environment

• NEVER point it at people or animals.

• DO NOT let children or unqualied people operate this machine.

• DO NOT use the machine when fatigued or under the inuence of alcohol or

drugs.

GENERAL PRESSURE WASHER SAFETY

DANGER – High-Pressure Spray

• NEVER point the gun at yourself, anyone else, or animals.

• The high-pressure water stream can cut through clothing, skin and underlying

tissues leading to serious injury.

• If this type of injury occurs, DO NOT TREAT AS A SIMPLE CUT. SEEK

EMERGENCY MEDICAL ATTENTION IMMEDIATELY. If you are using

cleaning detergents, be prepared to tell the physician exactly what kind.

• Spray guns can have signicant kickback. ALWAYS brace yourself and have

rm footing when operating.

• NEVER attempt to repair high-pressure hose, ttings or gun. Always replace

parts if they are leaking or damaged.

• NEVER bypass the trigger assembly. This is an important safety feature of the

system.

• NEVER leave a running machine unattended.

• Use CAUTION even when the machine has been turned o. Pressure can be

trapped in the pump and hose assembly and still inict injury or damage. After

turning the machine o, always squeeze the trigger to release any trapped

pressure.

• ALWAYS ensure all component connections and ttings are securely fastened.

High-pressure water can turn loose ttings or spray nozzles into projectiles

causing injury or damage.

• NEVER look directly into the gun or high-pressure hose.

• NEVER place your hand in front of the spray nozzle to test pressure.

DANGER – ELECTROCUTION

• NEVER spray near electric power source or cords.

• NEVER let run-o water pool and ow into power sources or cords.

WARNING – GENERAL SAFETY

• ONLY use cold water to feed into the machine. Unless specically instructed

that the machine can use hot water.

• Check the work area to make sure it is clear of hazards and debris which can

be thrown by pressure spray causing injuries or damage.

• ALWAYS be aware of surfaces that will become wet and may become

slippery.

• ALWAYS have a secure grip of the gun and stable footing.

6www.bepowerequipment.com

• ALWAYS ensure proper drainage to avoid water ooding into unwanted areas.

• NEVER operate machinery that is damaged or missing components.

• NEVER modify the machine in any way.

• DO NOT move the machine by pulling on the hoses or cords. Instead, use the

handle on the frame to move the machine when needed.

• Use CAUTION when spraying soft materials such as plants or wood because

the high-pressure spray can damage them quickly.

• Use CAUTION when spraying brittle materials such as glass, that may break

apart, creating dangerous projectiles.

• Use only recommended accessories. DO NOT force or modify parts to t.

• ALWAYS turn o the engine and disconnect the spark plug for any

maintenance procedures.

• NEVER attempt to maintain the machine while it is operating. Moving parts

and pressure can cause serious injuries.

• Keep machine out of the rain and elements.

• ALWAYS operate the machine on a level surface. It may seize if operated at

an angle.

WARNING – CHEMICAL DETERGENTS/SOAPS

• ALWAYS use detergents explicity designed for a pressure washer.

• NEVER use any ammable, corrosive or acidic solutions.

• NEVER modify the chemical injector system.

• ALWAYS ush the system after using a detergent. Run the machine for

at least two minutes with clean water to prevent detergent from drying and

building up residue. If residue builds up, it may cause the chemical injector

system to fail.

• ALWAYS BE PREPARED for an emergency involving detergents. Know

exactly what the detergent contains. If an emergency occurs and a physician

needs this information, Safety Data Sheets (SDS) are available and should be

easily accessible.

• ALWAYS keep detergents away from children and animals.

• Keep an eyewash kit available in case of emergency.

GAS ENGINE SAFETY

If your pressure washer has a gas engine, the engine will have it’s own manual.

Thoroughly review and understand the engine manual.

DANGER – TOXIC FUMES

• ALWAYS operate the machine outdoors in well-ventilated spaces.

• The emissions from the engine include the poisonous gas carbon monoxide.

It is a colorless, odorless gas that will displace oxygen and be lethal in high

enough concentrations.

• Symptoms of carbon monoxide poisoning include headache, fatigue,

dizziness, nausea, confusion, vomiting, and seizures. If poisoning continues,

unconsciousness and death will occur.

• At the rst sign of any symptoms, IMMEDIATELY shut o the machine and

move into a well-ventilated area and seek medical attention.

• Carbon monoxide is heavier than atmospheric air and will ll in low spaces

rst. Use EXTREME CAUTION when operating in low spaces such as

trenches, tunnels or ditches.

• NEVER position the machine where the exhaust can go through windows,

doors, ventilation or other access points that lead indoors or to conned areas.

• NEVER use a respirator as protection against carbon monoxide. The ONLY

protection that can be relied on is a positive pressure fresh air supply system,

such as a SCUBA system.

SAFETY OVERVIEW

7

www.bepowerequipment.com

SAFETY OVERVIEW

DANGER – FUEL RELATED FIRE AND EXPLOSIONS

• Fuel and its vapors are highly ammable and explosive.

• Fire and explosion can cause severe burns and death.

• NEVER ll the fuel tank while the unit is running.

• ALWAYS turn the engine o and let it cool at least two minutes before

removing fuel cap. Loosen the fuel cap slowly to relieve tank pressure.

• ALWAYS ll or drain the fuel tank outdoors.

• DO NOT overll the tank. Leave an airspace in the neck of the fuel tank to

allow it to breathe and for fuel expansion.

• NEVER have any spark or ame near the fuel, including cigarettes, open

ame, pilot lights and other ignition sources.

• If fuel spills, wait until it evaporates completely. Move the unit to a new location,

then wait at least two minutes before starting the engine.

• NEVER crank the engine with the spark plug removed and still in its boot.

• When transporting or putting the unit into storage, drain the fuel tank and

carburetor and store the fuel in an airtight container. Then, move the fuel valve

into the closed position.

• Never store fuel near any ignition source or hot surface.

CAUTION – HOT SURFACES

• The muer on the engine will heat up rapidly and can cause severe burns if

touched.

• Muer exhaust will be hot and can cause burns to people and objects.

• Keep ammables away from the muer.

• Keep at least a ve-foot clearance from the exhaust to prevent damaging other

surfaces such as house siding and vehicles.

• The pump will also become hot during operation and should be avoided.

• After the pressure washer has been started, DO NOT touch any part of the

pressure washer other than the on/o switch, handle, hose and gun.

CAUTION – RECOIL KICKBACK

• Starter cord kickback (rapid retraction) can result in bodily injury.

• Kickback can pull your hand and arm back towards the engine faster than you

can let go causing sprains, cuts, bruising and bone fractures.

• NEVER pull the starter cord without rst relieving the spray gun pressure.

• When starting an engine, the best practice is to have the trigger squeezed to

prevent pressure from building up in the system.

• Pull the starter cord until you feel resistance. Allow the cord to retract back and

then pull the starter to avoid kickback and injury.

ELECTRIC PRESSURE WASHER SAFETY

DANGER – RISK OF ELECTROCUTION

• NEVER spray an electric pressure washer, its cord, or power source.

• NEVER leave the machine exposed to rain or the elements.

• NEVER modify the plug or cord.

• NEVER use an adapter so the plug will t into a dierent outlet.

• NEVER touch the cord or plug with wet hands or when standing in water.

• ALWAYS replace damaged components, including plug and cord. DO NOT

attempt to repair.

• ALWAYS ensure power source matches the pressure washers’ requirements.

• ALWAYS use a licensed electrician if any electrical work needs to be done.

• ALWAYS unplug the motor from the power source before attempting repairs or

maintenance.

8www.bepowerequipment.com

SAFETY OVERVIEW

DANGER – GROUNDING

• This product must be grounded. If this machine malfunctions, grounding

provides a path of least resistance for electric current, reducing the risk of

electrocution.

• Ensure the plug has all three prongs it came with and is plugged into an

appropriate outlet that is grounded in accordance with local regulations.

• If your machine is equipped with a Ground Fault Circuit Interrupter (GFCI), DO

NOT remove or alter it. Replace if damaged.

• If the GFCI is dropped or damaged, be certain to test it to make sure it is still

working correctly.

WARNING – EXTENSION CORDS

• The use of extension cords is not recommended.

• If the use of an extension cord is unavoidable, then it must be plugged into a

GFCI found in circuit boxes or protected receptacles

• ALWAYS use a 3-wire extension cord that has three prongs for proper

grounding.

• DO NOT yank or pull on extension cords.

• ALWAYS replace if damaged.

• The extension cord gauge MUST be adequate for the power demands of the

pressure washer to prevent stalling, overheating or short-circuiting.

BATTERY – WHERE APPLICABLE

• NEVER use a battery that is cracked or shows other signs of visible damage.

• ALWAYS connecct postive lead to positive terminal, and negative lead to

negative terminal. NEVER cross-wire.

• The engine is equipped with an alternator and will charge the battery during

operation. If recharging battery with an auxillary charger it is your responsiblity

to use the appropriate equipment and settings.

• NEVER operate when battery is wet. Avoid contact with water when not in use.

• Do not tamper with battery, alter it anyway, or try to open it up.

9

www.bepowerequipment.com

PRESSURE WASHER

COOLING SYSTEM

DO NOT OVERHEAT YOUR MACHINE

Do not let your machine overheat. Failure to do so will result in damage, void

warranty, or cause injury.

Gas engines and electric motors are air-cooled. Always ensure that the machine

is operated in a well-ventilated area where it can draw a steady supply of fresh

air. If the motor overheats, it may shut down, rapidly burn oil, and result in

component failure. The arrows below show an example of locations for air intake

on an engine.

Pumps are cooled on the front end by having fresh water run into the pump,

then spray out of the gun wand. To maintain the water flow, keep the trigger of

the gun depressed to keep spraying out water. Do not let the machine run for

more than 30 seconds without pressing down on the trigger. If the pump is left to

overheat (not spraying water), it may experience thermal shock when cold water

is introduced to the system once water is sprayed out again. This thermal shock

can result in multiple component failures.

Most pumps are protected by a thermal valve. The thermal valve releases

water if a pump starts to run too hot. It will prevent catastrophic heat failure.

However, the pump may have suffered damage and need maintenance, repair, or

replacement. The thermal valve will need to be replaced once it is triggered.

The back end of the pump is cooled by maintaining the proper level and quality of

pump oil. Always check the oil level on the back of the pump by using the dipstick

or sight gauge. Use 30w non-detergent oil if it needs to be added or replaced.

Axial Pump Triplex Pump

Threaded into pump

with teflon tape

Leaks water to

prevent overheating

10 www.bepowerequipment.com

FUEL AND OIL TYPES

ENGINE FUEL TYPE

Use only regular unleaded gasoline rated at 86 octane or higher. The best fuel

to use will have a 0% ethanol blend. However, the engine can use a fuel with an

ethanol blend of up to 10%.

ENGINE OIL TYPE

Use only SAE 10W30 motor oil for the engine. To check the oil, unscrew the

engine dipstick. Then, wipe off the oil with a clean rag and dip it back into the

engine. The oil should be well within the oil level markings.

Note* the engine will have two oil caps. Only one will have a dipstick.

PUMP OIL TYPE

For pressure washer pumps, use only SAE 30W non-detergent oil. Never use

motor oil in your pressure washer pump because it will destroy the seals.

Never overfill the pump.

• If your pump has a sight glass, then ll halfway up to the middle of the red dot.

• If your pump has a dipstick, then ll to the mark on the dipstick.

• If your pump doesn’t have a sight glass or dipstick, then it is a sealed unit, and

the owner doesn’t have to be concerned with maintaining the pump oil.

ENGINE TYPE FUEL TANK

CAPACITY OIL CAPACITY

Powerease 212 3.6 L / 0.95 US Gal 0.6 L / 0.63 US qt

Powerease 225 3.6 L / 0.95 US Gal 0.6 L / 0.63 US qt

Powerease 420 6.7 L / 1.7 US Gal 1.1 L / 1.16 US qt

Kohler SH270 3.3 L / 0.87 US Gal 0.6 L / 0.63 US qt

Kohler CH440 7.0 L / 1.85 US Gal 1.3 L / 1.4 US qt

Honda GC160 1.8 L / 0.48 US Gal 0.58 L / 0.61 US qt

Honda GC190 1.8 L / 0.48 US Gal 0.58 L / 0.61 US qt

Honda GX200 3.1 L / 0.82 US Gal 0.6 L / 0.63 US qt

Honda GX270 5.3 L / 1.4 US Gal 1.1 L / 1.16 US qt

Honda GX390 6.1 L / 1.6 US Gal 1.1 L / 1.16 US qt

Honda GX690 N/A 2.0 L / 2.1 US qt

Vanguard 200 3.1 L / 0.82 US Gal 0.59 L / 0.6 US qt

Vanguard 400 5.7 L / 1.5 US Gal 0.94 L / 1.0 US qt

11

www.bepowerequipment.com

COMPONENT DIAGRAMS

The following diagrams are intended for general reference.

Your pressure washer may dier from the models shown in the following

pages. For specic model information, please visit bepowerequipment.com

1. Split Lance Spray Gun

2. High-pressure Hose to the outlet. Connections vary by model.

3. Muer/Exhaust - Reduces noise of the engine and expels heat.

4. Air Filter housing

5. (Above) Choke rod - Prepares a cold engine for starting.

(Down) Throttle Lever - Controls engine RPM speed.

6. Recoil Starter - Used to manually start the engine.

7. Soap Tank: (not included on all models) Fill with pressure washer detergent

only.

8. Pump: develops high pressure. Connect the garden hose to the water pump

inlet and connect the high pressure hose to the outlet. Connections vary

by model.

9. Gas tank

10. Detergent suction hose: used to draw detergent into the low pressure stream.

11. Spray nozzles: 0°, 15°, 40° Detergent: For various cleaning applications.

2. 10.

11.

5.

6.

7.

8.

3.

9.

4.

1.

12 www.bepowerequipment.com

COMPONENT DIAGRAMS

1. Spray Gun - Controls the application of water onto the cleaning surface with a trigger

device. Includes trigger lock. Allows you to switch between various spray nozzles.

2. Spray Nozzles - 0°, 15°, 40° and Detergent: for various high-pressure cleaning

applications.

3. High-Pressure Hose - Designed to withstand the pressure generated by the pump.

4. Unloader - Pressure is preset at the factory.

5. Pump - Develops high pressure. Connect the garden hose to the inlet of the water

pump, and connect the high-pressure hose to the outlet.

6. Oil Level Indicator - Level should be at halfway (not included for all models).

7. Detergent Siphoning Hose - Use to siphon pressure washer-safe detergent into the

low-pressure stream.

8. Fuel Tank - Fill tank with regular unleaded fuel. Always leave room for fuel expansion.

9. Air Filter - Protects engine by ltering dust and debris out of the intake air.

10. Throttle Lever - Controls RPM speed of engine.

11. (Top) Choke Lever - Prepares a cold engine for starting.

(Bottom) Fuel Valve - Used to turn fuel supply on and o to the engine.

12. Recoil Starter - Used for starting the engine manually.

13. Engine Switch - Set switch to “On” for recoil starting. Set switch to “O” to stop a

running engine.

1.

11.

13.

12.

8.

5.

7.

6.

10.

9.

2.

3.

4.

13

www.bepowerequipment.com

COMPONENT DIAGRAMS

1. Spray Gun - Controls the application of water onto the cleaning surface with a trigger

device. Includes trigger lock. Allows you to switch between various spray nozzles.

2. High-Pressure Hose - Designed to withstand the pressure created by the pump.

3. Fuel Tank - Fill tank with regular, unleaded fuel. Always leave room for fuel expansion.

4. Unloader - Pressure is preset from the factory.

5. Pump - Develops high-pressure. Connect the garden hose to the inlet of the water

pump, and connect the high-pressure hose to the outlet. Connections vary by model.

6. Detergent Siphoning Hose - Used to draw detergent into the low-pressure stream.

7. Muer/Exhaust - Reduces noise of the engine and expels heat.

8. Air Filter - Protects engine by ltering dust and debris out of the intake air.

9. Spray Nozzles - 0°, 15°, 40° and Detergent: for various cleaning applications.

3.

4.

5. 7.

8.

2.

9.

1.

6.

14 www.bepowerequipment.com

COMPONENT DIAGRAMS

1. Spray Gun - Controls the application of water onto the cleaning surface with a trigger

device. Includes trigger lock. Allows you to switch between various spray nozzles.

2. Spray Nozzles - 0°, 15°, 40° and Detergent: for various high-pressure cleaning

applications.

3. High-Pressure Hose - Designed to withstand the pressure generated by the pump.

4. Unloader - Pressure is preset from the factory.

5. Pump - Develops high pressure. Connect the garden hose to the inlet of the water

pump, and connect the high-pressure hose to the outlet.

6. Detergent Siphoning Hose - Use to siphon detergent into the low-pressure stream.

7. Engine Switch - Set switch to “On” for recoil starting. Set switch to “O” to stop a

running engine.

8. Recoil Starter - Used for starting the engine manually.

9. (Top) Choke Lever - Prepares a cold engine for starting.

(Bottom) Fuel Valve - Used to turn fuel supply on and o to the engine.

10. Throttle Lever - Controls RPM speed of engine.

11. Air Filter - Protects engine by ltering dust and debris out of the intake air.

12. Fuel Tank - Fill tank with regular unleaded fuel. Always leave room for fuel expansion.

13. Belt Drive Cover - Shields the belt and pulley drive system.

1.

2.

3.

6.

4.

5.

13.

7.

8.

9.

10.

11. 12.

15

www.bepowerequipment.com

COMPONENT DIAGRAMS

2.

3.

1.

1. Spray Gun - Controls the application of water onto the cleaning surface with a trigger

device. Includes trigger lock. Allows you to switch between various spray nozzles.

2. High Pressure Hose - Designed to withstand the pressure created by the pump.

3. Spray Nozzles - 0°, 15°, 40° and Detergent: for various cleaning applications.

4. Detergent Siphoning Hose - Used to draw detergent into the low-pressure stream.

5. Unloader - Pressure is preset from the factory.

6. Pump - Develops high pressure. Connect the garden hose to the inlet of the water

pump, and connect the high-pressure hose to the outlet. Connections vary by model.

7. Inlet - Connection for the water source such as a garden hose.

8. Outlet - Connection for the high-pressure hose.

9. Motor - Power source that spins the pump

4.

5.

4.

8.

7.

6. 9.

16 www.bepowerequipment.com

COMPONENT DIAGRAMS

2.

3.

1.

4.

1. Spray Gun - Controls the application of water onto the cleaning surface with a trigger

device. Includes trigger lock. Allows you to switch between various spray nozzles.

2. High Pressure Hose - Designed to withstand the pressure created by the pump.

3. Spray Nozzles - 0°, 15°, 40° and Detergent: for various cleaning applications.

4. Detergent Siphoning Hose - Used to draw detergent into the low-pressure stream.

5. Unloader - Pressure is preset from the factory.

6. Pump - Develops high pressure. Connect the garden hose to the inlet of the water

pump, and connect the high-pressure hose to the outlet. Connections vary by model.

7. Inlet - Connection for the water source such as a garden hose.

8. Outlet - Connection for the high-pressure hose.

9. Motor - Power source that spins the pump

5.

9.

8.

7.

6.

17

www.bepowerequipment.com

Your pressure washer will require some assembly. If you have any trouble with

this process, please call our tech support department (1-866-850-6662) with your

model number.

Unpack your pressure washer

• Remove all the components, including bags and manuals.

• Inspect components to make sure there is no visible damage.

ATTACH HANDLE

1. Remove any plastic coverings that may be on the handle. Place handle (A)

onto handle supports (B) connected to the frame. Make sure holes (C) in

handle align to the holes on the frame supports.

NOTE: These diagrams are intended for general reference. As a result, they may

not fully reect the appearance of your product.

2. Insert the bolts through holes. The carriage bolts will have hex heads that

need to be matched to the side of the handles with a hex shaped hole pattern

to help secure them.

3. Insert colored quick connect spray nozzles, high-pressure hose, gun wand

assembly into the spaces provided.

4. If needed, attach the provided detergent siphoning hose to brass barb coming

out of the pump near the high-pressure outlet. (Do not attach to the black

plastic thermal relief valve barb.)

ASSEMBLY

C

B

A

18 www.bepowerequipment.com

ASSEMBLY

5. Assemble the gun wand. The trigger assembly will be threaded onto the wand.

Hand tighten only.

HOSE CONNECTIONS

• Quick connect ttings: pull back the collar of the coupler, insert plug, and

release the collar. Tug on ttings to conrm a secure lock.

• M22 Fittings: Line up the insert and thread together so it is hand tight. Do not

overtighten.

• Spray Nozzles: To attach a spray nozzle to the end of the wand, pull back on

the collar of the brass tting. Insert the spray nozzle and release the collar. Tug

on the nozzle to make sure it is secure. If it is loose, the high-pressure water

will launch it out and may cause injury or damage.

Your pressure washer will come with several colored spray nozzles that will have

dierent spray patterns and abilities.

0° Nozzle (Red) Concentrated stream to break apart baked-on mud

or dirt. Use with caution.

15° Nozzle (Yellow) Narrow spray pattern that is aggressive and best used

on hard surface to remove tough dirt.

25° Nozzle (Green) General purpose spray pattern. Slightly wider, but still

fairly aggressive.

40° Nozzle (White) Wider spray pattern for large areas or softer surfaces.

Black Soaper Nozzle Low pressure nozzle. This is the only nozzle that can

be used with the chemical injector system.

19

www.bepowerequipment.com

PRE-OPERATION

1. Before operating the pressure washer, ensure you are familiar with all the

warnings and safety recommendations.

2. Wear proper clothing and eye protection.

3. Always setup the machine where:

3.1 It is on a level surface. If the machine is not level, it may not start or cause

failures.

3.2 There is sucient ventilation.

3.3 There are no signs of oil or gas leaks, including gas vapors.

3.4 The machine is not exposed to rain, snow or freezing temperatures. These

harsh conditions can lead to component failure causing damage or injury.

4. Ensure that oil levels for the engine and pump are correct.

4.1 Use 10W30 oil to ll the engine if needed.

4.2 Use 30W non-detergent oil to ll the pump if needed.

5. If the pump has an oil cap dipstick, make sure it is the breathing oil cap

instead of the sealed travel oil cap. If the sealed travel oil cap is left in, the

pump will over pressurize and blow it out.

6. Inspect the overall condition of the unit. Make sure there are no fuel or oil

leaks or damaged parts. If any leaks or damaged parts are detected DO NOT

start the pressure washer until it is xed.

7. Connect the high-pressure hose to the pump and the gun wand assembly to

the other end of the hose.

8. Connect the garden hose to the pump.

8.1 Ensure the inlet lter on the pump is present, intact, and clean before

connecting the garden hose.

WATER SUPPLY MUST BE SUFFICIENT TO SUPPLY THE PUMP

ADEQUATELY.

Every pressure washer has a Gallons Per Minute (GPM)/ Liters Per Minute (LPM)

rating that must be adhered to. If the pump does not get enough water, it will

cavitate (starve for water). This will cause internal damage and pending failure.

To measure your water source GPM/ LPM, you will need a container that you

know the exact size such as a 5-gallon/20-Liter bucket. When you’re ready, start

lling it from your water source while timing it for one minute. The amount of

water in the 5-gallon/20-liter bucket after one minute is the GPM/LPM rating.

The water source GPM/ LPM should exceed the GPM/ LPM rating of the machine

by one GPM/ LPM to account for any uctuations from the water source.

The water source should have 20 to 60 PSI/1.38 to 4.1 BAR pressure going into

the pump. Do not use a hose longer than 50ft/15m to the water source.

PRIME THE PUMP WITH WATER

Once all the hoses are connected, turn on your water supply and hold down the

spray gun’s trigger. Let water ow through it until all the air bubbles are worked

through, and there is a constant stream of water coming out the nozzle.

Insert the color spray nozzle that you plan to use. Make sure the nozzle is clean

with no damage or blockages.

20 www.bepowerequipment.com

GAS ENGINE START PROCEDURE SET UP

1. Fill the fuel tank with gasoline. Use regular unleaded, 86 octane or higher that

has no more than 10% ethanol blend.

2. Do not overll the fuel tank. Always leave a space to allow the tank to breathe

and the fuel to expand.

3. Set to full throttle. The lever will be all the way LEFT on all models except the

Honda GC which will have the lever all the way UP.

4. Turn the fuel valve to the ON position which is all the way to the RIGHT on all

models except the Vanguard and Honda GC which do not have a separate

fuel valve.

5. Activate the choke if the engine is cold. Move the choke lever to the LEFT on all

models except the Honda GC where the choke tab is pulled OUT.

∙ HONDA GC

3

3

5

5

4

∙ VANGUARD

5

∙ HONDA GX

∙ POWEREASE

∙ KOHLER SH270

3

∙ KOHLER CH440

4

5

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

BE Cold Water PW Manuel utilisateur

- Catégorie

- Nettoyeurs haute pression

- Taper

- Manuel utilisateur

dans d''autres langues

- English: BE Cold Water PW User manual

- español: BE Cold Water PW Manual de usuario

Autres documents

-

Echo PW-3100 Manuel utilisateur

-

BE Pressure Supply 9178468 Le manuel du propriétaire

BE Pressure Supply 9178468 Le manuel du propriétaire

-

Echo PW3100B Mode d'emploi

-

Briggs & Stratton 20221 Le manuel du propriétaire

-

Simplicity 020533-01 Manuel utilisateur

-

Simplicity PRESSURE WASHER, CRAFTSMAN [email protected] MODEL 020533-03 Manuel utilisateur

-

Simplicity 020533-00 Manuel utilisateur

-

Westinghouse WPX2700 Mode d'emploi

-

Honda 9202011 Le manuel du propriétaire

-

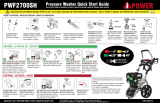

A-iPower PWF2700SH Pressure Washer Mode d'emploi

A-iPower PWF2700SH Pressure Washer Mode d'emploi