Pottinger ROLLPROFI G 400 S Mode d'emploi

- Taper

- Mode d'emploi

AVVOLGITORE PER BALLE CILINDRICHE

BALE WRAPPER

ENRUBANNEUSE

,"*,"ÊÊ{ää

Nr. 99 8422GB.80A.0

USAGE ET ENTRETIEN

F

USE AND MAINTENANCE

GB

MANUALE D'USO E MANUTENZIONE

I

ALLG./BA SEITE 2 / 0000-GB

Important information concerning Product

Liability.

According to the laws governing product liability, the manufacturer and dealer are obliged to hand the

operating manual to the customer at the time of sale, and to instruct them in the recommended operating,

safety, and maintenance regulations. Confirmation is necessary to prove that the machine and operating

manual have been handed over accordingly.

For this purpose,

- document A is to be signed and sent to Pöttinger,

- document B remains with the dealer supplying the machine,

- and the customer receives document C.

In accordance with the laws of product liability, every farmer is an entrepreneur.

According to the laws of product liability, property damage is damage caused by a machine and not to

it. An excess of Euro 500 is provided for such a liabilioty.

In accordance with the laws of product liability, entrepreneurial property damages are excluded from

the liability.

Attention! Should the customer resell the machine at a later date, the operating manual must be given

to the new owner who must then be instructed in the recommended regulations referred to herein.

GB Dear Farmer

You have just made an excellent choice. Naturally we are very happy

and wish to congratulate you for having chosen Pöttinger. As your

agricultural partner, we offer you quality and efficiency combined with

reliable servicing.

In order to assess the spare-parts demand for our agricultural machines

and to take these demands into consideration when developing new

machines, we would ask you to provide us with some details.

Furthermore, we will also be able to inform you of new developments.

G400

AVVOLGITORE PER BALLE CILINDRICHE

BALE WRAPPER

ENRUBANNEUSE

MANUALE D’USO E MANUTENZIONE

MANUAL FOR USE AND MAINTENANCE

MANUEL D’EMPLOI ET D’ENTRETIEN

I

GB

F

Cod.

98 20 643 Ed. 07/00

217.091 Ed.3

217.091

G400

AVVOLGITORE PER BALLE CILINDRICHE

BALE WRAPPER

ENRUBANNEUSE

Cod.

98 20 643 Ed. 07/00

Per approvazione .............................................

2000 mm

Kg 950

2000 mm

2000 mm

Kg 850

2000 mm

2000 mm

Kg 950

2000 mm

217.091

INDICE

1

INFORMAZIONI GENERALI

1.1. SCOPO DEL MANUALE

..................................................4

1.2. COSTRUTTORE

................................................................6

1.3. IDENTIFICAZIONE DELLA MACCHINA

......................6

1.4. ALLEGATI

..........................................................................6

2

INFORMAZIONI TECNICHE

2.1. DESCRIZIONE DELLA MACCHINA

..............................8

2.1.1 Descrizione dei modelli

.................................................10

2.1.2 Gruppi operatori

.............................................................12

2.1.3 Dotazione accessori

......................................................14

2.2. DESCRIZIONE DEL MODO

DI FUNZIONAMENTO

...................................................16

2.2.1 G400 P

..............................................................................16

2.2.2 G400 S/F

.........................................................................16

2.3. DIMENSIONI D’INGOMBRO

........................................18

2.4. CARATTERISTICHE TECNICHE

..................................20

2.4.1 Requisiti trattore

..............................................................20

2.5. DISPOSITIVI DI SICUREZZA

........................................22

2.6. ZONA DI PERICOLO

.....................................................24

2.7. LAVORO NOTTURNO

................................................24

3

INFORMAZIONI SULLA SICUREZZA

3.1. NORME GENERALI DI SICUREZZA

...........................26

3.1.1 Circolazione su strada

...................................................28

3.1.2 Movimentazione balle

....................................................28

3.1.3 Impianto idraulico

...........................................................28

3.2. TARGHETTE ADESIVE PER LA SICUREZZA

............30

4

ISTRUZIONI PER L’INSTALLAZIONE

4.1. IMBALLO/DISIMBALLO

................................................34

4.2. SOLLEVAMENTO

...........................................................34

4.3. ACCOPPIAMENTO AL TRATTORE

.............................36

4.3.1 Accoppiamento al trattore della

versione portata

..............................................................36

4.3.2 Accoppiamento al trattore della

versione trainata

.............................................................36

4.4. IMPIANTO IDRAULICO - ALLACCIAMENTO

............38

4.5. COLLEGAMENTO DELL’AVVOLGITORE

A TRATTORI A CIRCUITO AD ANNULLAMENTO

DI PORTATA

....................................................................40

4.6. CONTAGIRI ELETTRONICO -

COLLEGAMENTO ELETTRICO (OPT)

........................40

5

REGOLAZIONI DI IMPIEGO E

REGISTRAZIONI

5.1. PREMESSA

......................................................................42

5.2. REGOLAZIONE TENSIONE CATENA

TRASMISSIONE ALLA TAVOLA ROTANTE

...............44

5.3. REGOLAZIONE TENSIONE CATENA

TRASMISSIONE RULLI

..................................................44

5.4. SOVRAPPOSIZIONE DEL FILM -

(50%-66%)

.......................................................................46

5.5. GRUPPO DI STIRO DA 750 mm -

VARIAZIONE TRASMISSIONE PER

BOBINA DA 500 mm

.....................................................46

5.6. SUPPORTO BOBINA - REGOLAZIONE ALTEZZA ..

46

5.7. DISPOSITIVO PRE-STIRAMENTO FILM

.....................48

5.8. REGISTRAZIONE RULLI DEL GRUPPO

SVOLGITORE

.................................................................50

5.9. DISPOSITIVO PER INSERIMENTO E TAGLIO

AUTOMATICO DEL FILM

..............................................52

5.9.1 Percorso e fissaggio cavo

............................................52

5.9.2 Registrazione delle camme

..........................................52

5.9.3 Registrazione del sistema di riarmo automatico

.......52

5.9.4 Registrazione del gruppo di taglio...........................

54

5.9.5 Registrazione interasse rulli di trascinamento

balla

..................................................................................58

6

NORME DI FUNZIONAMENTO

6.1. NUMERO GIRI TAVOLA PER RICOPRIMENTO

COMPLETO DELLA BALLA

..........................................60

6.2. QUANTITÀ DI FILM PER IL RICOPRIMENTO

DELLA BALLA

.................................................................60

6.3. CONTROLLI GENERALI PRIMA

DELL’AVVOLGIMENTO

.................................................64

6.4. COMANDI IDRAULICI - DESCRIZIONE

.........................64

6.5. INSERIMENTO BOBINA

................................................66

6.6. ISTRUZIONI DI AVVOLGIMENTO

...............................70

6.7. INDICAZIONI PER PRODURRE OTTIMO INSILATO

......78

6.8. CONTAGIRI ELETTRONICO

........................................94

6.8.1 Pulsantiera - Descrizione dei comandi

.......................94

7

MANUTENZIONE

7.1. NORME GENERALI DI MANUTENZIONE

................102

7.2. PROGRAMMA DI LUBRIFICAZIONE

........................104

7.3. CONTROLLI E REGISTRAZIONI

...............................106

7.3.1 Catena di trasmissione alla tavola girevole

.............106

7.3.2 Catena di trasmissione ai rulli

....................................106

7.4. GRUPPO TAGLIO

.........................................................108

7.5. GRUPPO SVOLGITORE

..............................................108

7.6. CONTROLLO DI FINE STAGIONE IN OFFICINA

......108

8

DIAGNOSTICA GUASTI E DIFETTI

8.1. INCONVENIENTI: CAUSE E RIMEDI

........................110

9

RIPARAZIONE E SOSTITUZIONE

PARTI

9.1. RIPARAZIONE E SOSTITUZIONE PARTI

.................116

9.2. DOTAZIONE

..................................................................116

SCHEMI

SCHEMA TRASMISSIONE PIATTAFORMA

.............118

SCHEMA IMPIANTO IDRAULICO (G400 S/F)

.........119

SCHEMA IMPIANTO IDRAULICO (G400 P)

...............120

ITALIANO

217.091

ENGLISH

INDEX

1

GENERAL INFORMATION

1.1. PURPOSE OF THIS MANUAL

......................................5

1.2. THE MANUFACTURER

..................................................7

1.3. MACHINE IDENTIFICATION

.........................................7

1.4. ENCLOSURES

.................................................................7

2

TECHNICAL INFORMATION

2.1. MACHINE DESCRIPTION

..............................................9

2.1.1 Description of the models

.............................................11

2.1.2 Working units

...................................................................13

2.1.3 Attachments

.....................................................................15

2.2. OPERATION DESCRIPTION

......................................17

2.2.1 GP400 P

...........................................................................17

2.2.2 G400 S/F

.........................................................................17

2.3. OVERALL DIMENSIONS

..............................................19

2.4. TECHNICAL REQUIREMENTS

..................................21

2.4.1 Tractor features

..............................................................21

2.5. SAFETY DEVICES

........................................................23

2.6. DANGEROUS AREA

.....................................................25

2.7. NIGHT WORK

.................................................................25

3

INFORMATION ABOUT SAFETY

3.1. GENERAL SAFETY RULES

........................................27

3.1.1 Road transport

................................................................29

3.1.2 Bale handling

...................................................................29

3.1.3 Hydraulic system

............................................................29

3.2. SAFETY ADHESIVE LABELS

.....................................31

4

INSTALLATION INSTRUCTIONS

4.1. PACKING/UNPACKING

................................................35

4.2. LIFTING

............................................................................35

4.3. COUPLING TO THE TRACTOR

.................................37

4.3.1 Connection to the tractor; carried version

..................37

4.3.2 Trailed model hitching to the tractor

............................37

4.4. HYDRAULIC SYSTEM - CONNECTION

...................39

4.5. LINKING THE WRAPPER TO TRACTORS

WITH DELIVERY BRAKING CIRCUIT

.......................41

4.6. OPTIONAL ELECTRONIC REVOLUTION

COUNTER - ELECTRIC CONNECTION

...................41

5

ADJUSTMENTS AND SETTING-UP

5.1. PREAMBLE .............................................................

43

5.2. ADJUSTING THE REVOLVING TABLE

TRANSMISSION CHAIN TIGHTENING

....................45

5.3. ADJUSTING THE ROLLER TRANSMISSION

CHAIN TIGHTENING

....................................................45

5.4. FILM OVERLAP - (50% - 66%)

...................................47

5.5. 750 MM STRETCHING UNIT - TRANSMISSION

CHANGE FOR 500 MM REEL

.....................................47

5.6. REEL SUPPORT - HEIGHT ADJUSTMENT

.............47

5.7. FILM PRE-STRETCHING DEVICE

...........................49

5.8. ADJUSTMENT OF THE UNWINDING

UNIT ROLLERS

..............................................................51

5.9. AUTOMATIC FILM INSERTING AND

CUTTING DEVICE

.........................................................53

5.9.1 Cable path and fastening

..............................................53

5.9.2 Adjusting cams

................................................................53

5.9.3 Adjusting the automatic resetting system

.................53

5.9.4 Adjusting the cutting unit

...............................................55

5.9.5 Adjusting the centre distance of the bale

driving rollers

..................................................................59

6

MACHINE WORKING

6.1. NUMBER OF TURNS FOR THE COMPLETE

BALE COATING

.............................................................61

6.2. FILM QUANTITY NEEDED TO THE

BALE COATING

.............................................................61

6.3. GENERAL CHECKS BEFORE THE

WRAPPING OPERATION

............................................65

6.4. HYDRAULIC CONTROLS DESCRIPTION .............

65

6.5. INSERTING THE REEL

................................................67

6.6. WRAPPING INSTRUCTIONS

.....................................71

6.7. HOW TO OBTAIN THE BEST SILAGE

.....................79

6.8. ELECTRONIC REVOLUTION COUNTER ..............

95

6.8.1 Push-button panel - Control description

.....................95

7

MAINTENANCE

7.1. MAINTENANCE GENERAL RULES

........................103

7.2. LUBRICATION SCHEDULE

.......................................105

7.3. CHECKS AND ADJUSTMENTS

...............................107

7.3.1 Revolving table transmission chain

...........................107

7.3.2 Roller transmission chain

............................................107

7.4. CUTTING UNIT

............................................................109

7.5. UNWINDING UNIT

.......................................................109

7.6. END-OF-SEASON CHECKS

.....................................109

8

FAULTS/DEFECTS DIAGNOSTIC

8.1. TROUBLES: CAUSES AND REMEDIES

................111

9

REPAIR AND REPLACEMENTS OF

PARTS

9.1. REPAIR AND REPLACEMENT OF PARTS

...........117

9.2. TOOLS

...........................................................................117

DIAGRAMS

PLATFORM TRANSMISSION DIAGRAM

...............118

HYDRAULIC SYSTEM DIAGRAM (G400 S/F)

.......119

HYDRAULIC SYSTEM DIAGRAM (G400 P)

..........120

217.091

FRANÇAIS

INDEX

1

REINSEGNEMENTS GENERAUX

1.1. BUT DU MANUEL

............................................................5

1.2. MAISON CONSTRUCTRICE

.........................................7

1.3. IDENTIFICATION DE LA MACHINE

............................7

1.4. ANNEXES

..........................................................................7

2

INFORMATIONS TECHNIQUES

2.1. DESCRIPTION DE LA MACHINE

.................................9

2.1.1 Description des modèles

...............................................11

2.1.2 Groupes de travail

..........................................................13

2.1.3 Accessoires

.....................................................................15

2.2. DESCRIPTION DU CYCLE DE

FONCTIONNEMENT

.....................................................17

2.2.1 GP400 P

...........................................................................17

2.2.2 G400 S/F

.........................................................................17

2.3. DIMENSIONS D'ENCOMBREMENT

..........................19

2.4. CARACTERISTIQUES TECHNIQUES

......................21

2.4.1 Caractéristiques du tracteur

........................................21

2.5. DISPOSITIFS DE SECURITE

......................................23

2.6. ZONE DANGEREUSE

..................................................25

2.7. TRAVAIL DE NUIT

.........................................................25

3

INFORMATIONS

POUR LA SECURITE

3.1. NORMES GENERALES DE SECURITE

...................27

3.1.1 Déplacement sur route

..................................................29

3.1.2 Manutention des balles

.................................................29

3.1.3 Installation hydraulique

..................................................29

3.2. PLAQUETTES ADHESIVES POUR LA SECURITE ...

31

4

INSTRUCTIONS POUR

L’INSTALLATION

4.1. EMBALLAGE/DEBALLAGE

.........................................35

4.2. LEVAGE

...........................................................................35

4.3. ATTELAGE AU TRACTEUR

........................................37

4.3.1 Attelage au tracteur modèle porté

...............................37

4.3.2 Attelage au tracteur de la variante traînée

.................37

4.4. INSTALLATION HYDRAULIQUE -

RACCORDEMENT

........................................................39

4.5. ATTELAGE DE LʼENROULEUSE AUX

TRACTEURS AVEC CIRCUIT À

DÉCLENCHEMENT DE DÉBIT

..................................41

4.6. COMPTEUR DE TOURS ELECTRONIQUE -

CONNEXION ELECTRIQUE (OPTION)

....................41

5

REGLAGES POUR L’EMPLOI ET

MISES AU POINT

5.1. INTRODUCTION

............................................................43

5.2. REGLAGE DE LA TENSION DE LA CHAINE DE

TRANSMISSION A LA TABLE TOURNANTE

..........45

5.3. REGLAGE DE LA TENSION DE LA CHAINE DE

TRANSMISSION DES ROULEAUX

..........................45

5.4. SUPERPOSITION DU FILM (50%-66%)

..................47

5.5. GROUPE DʼETIRAGE DE 750 mm - VARIATION

DE TRANSMISSION POUR BOBINE DE 500 mm

..47

5.6. SUPPORT BOBINE - REGLAGE EN HAUTEUR

....47

5.7. DISPOSITIF DE PRE-ETIRAGE DU FILM

................49

5.8. REGLAGE ROULEAUX DU GROUPE

DEROULEUR

..................................................................51

5.9. DISPOSITIF POUR LʼINTRODUCTION ET LA

COUPE AUTOMATIQUE DU FILM

...........................53

5.9.1 Parcours et fixation du câble

..........................................53

5.9.2 Réglage des cames

.......................................................53

5.9.3 Réglage du système de réarmement automatique..

....53

5.9.4 Réglage du groupe de coupe

.......................................55

5.9.5 Réglage de lʼentraxe des rouleaux entraîneurs

de la balle

........................................................................55

6

NORMES DE FONCTIONNEMENT

6.1. NOMBRE DES TOURS DE LA TABLE POUR

LʼENRUBANNAGE COMPLET DE LA BALLE

.........61

6.2. QUANTITE DE FILM POUR LʼENVELOPPEMENT

DE LA BALLE

..................................................................61

6.3. CONTROLES GENERAUX AVANT

L'ENRUBANNAGE

.........................................................65

6.4. COMMANDES HYDRAULIQUES -

DESCRIPTION

...............................................................65

6.5. INTRODUCTION DE LA BOBINE

...............................67

6.6. INSTRUCTIONS DʼENRUBANNAGE

........................71

6.7. INDICATIONS POUR PRODUIRE UN ENSILAGE

DE HAUTE QUALITE

....................................................79

6.8. COMPTEUR DE TOURS ELECTRONIQUE

.............95

6.8.1 Tableau de commande - Description des

commandes

.....................................................................95

7

ENTRETIEN

7.1. NORMES GENERALES D'ENTRETIEN

..................103

7.2. PROGRAMME DE GRAISSAGE

..............................105

7.3. CONTROLES ET REGLAGE

.....................................107

7.3.1 Chaîne de transmission à la table tournante

...........107

7.3.2 Chaîne de transmission aux rouleaux

.....................107

7.4. GROUPE DE COUPE

.................................................109

7.5. GROUPE DEROULEUR

.............................................109

7.6. CONTROLE DE FIN DE SAISON EN ATELIER

....... 109

8

RECHERCHE DES PANNES ET DES

DEFAUTS

8.1. INCONVENIENTS: CAUSES ET REMEDES

.........111

9

REPARATIONS ET REMPLACEMENT

DES PIECES

9.1. REPARATION ET REMPLACEMENT

DES PARTIES

..............................................................117

9.2. MATERIEL DʼEQUIPEMENT

.....................................117

SCHEMAS

SCHEMA DE TRANSMISSION DE LA

PLATEFORME...

..........................................................118

SCHEMA INSTALLATION HYDRAULIQUE

(G400 S/F).............................................................

119

SCHEMA INSTALLATION HYDRAULIQUE

(G400 P)

.........................................................................120

217.091

1

INFORMAZIONI GENERALI

&RQVXOWDUHDWWHQWDPHQWHTXHVWRPDQXDOHSULPDGL

SURFHGHUHDTXDOVLDVLLQWHUYHQWRVXOODPDFFKLQD

4XHVWRPDQXDOHGHYHHVVHUHFRQVHUYDWRFRQODPDVVLPD

FXUDDOOLQWHUQRGHOODVXDEXVWDGLSODVWLFDHULSRVWR

DOOLQWHUQRGLXQDSSRVLWRFRQWHQLWRUH

1.1. SCOPO DEL MANUALE

Questo manuale è stato redatto dal Costruttore e

costituisce parte integrante del corredo della mac-

china(1).

Le informazioni contenute sono dirette a personale

qualificato(2) (operatori).

Il manuale definisce lo scopo per cui la macchina è

stata costruita e contiene tutte le informazioni neces-

sarie per garantirne un uso sicuro e corretto.

La costante osservanza delle indicazioni in esso con-

tenute garantisce la sicurezza dellʼuomo e della mac-

china, lʼeconomia di esercizio ed una più lunga durata

di funzionamento della macchina stessa.

Per dare maggior risalto ai brani di testo da non tra-

scurare, essi sono evidenziati in grassetto e preceduti

da simboli qui di seguito illustrati e definiti.

3(5,&2/2$77(1=,21(LQGLFDSHULFROLLPPLQHQWL

FKHSRVVRQRSURYRFDUHJUDYLOHVLRQLpQHFHVVDULR

SUHVWDUHDWWHQ]LRQH

&$87(/$35(&$8=,21(LQGLFDFKHqQHFHVVDULR

DGRWWDUHFRPSRUWDPHQWLLGRQHLDOÀQHGLHYLWDUH

LQFLGHQWLRGDQQHJJLDPHQWLDOOHFRVH

6RQRLQGLFD]LRQLWHFQLFKHGLSDUWLFRODUHLPSRUWDQ]D

Fotografie e disegni sono forniti a scopo esemplifica-

tivo.

(1) La definizione macchina, sostituisce la denominazione commerciale

a cui fa riferimento il manuale in oggetto (vedi copertina).

(2) Sono le persone in possesso di esperienza, preparazione tecnica,

conoscenza normativa e legislativa, in grado di svolgere le attività

necessarie ed in grado di riconoscere ed evitare possibili pericoli

nellʼeseguire la movimentazione, lʼinstallazione, lʼuso e la manuten-

zione della macchina.

GENERAL INFORMATION 1

REINSEGNEMENTS GENERAUX 1

GENERAL INFORMATION

1

REINSEGNEMENTS GENERAUX

217.091

&DUHIXOO\FRQVXOWWKLVPDQXDOEHIRUHGRLQJDQ\

DGMXVWPHQWRUPDLQWHQDQFHVHUYLFHV

7KLVPDQXDOVKRXOGEHNHSWZLWKWKHXWPRVWFDUHLQLWV

SODVWLFEDJDQGLQWKHWZLQHER[

1.1. PURPOSE OF THIS MANUAL

This manual has been drawn up by the manufacturer

and is enclosed with the machine(1).

The information contained is intended for skilled oper-

ators(2) (operators).

This manual defines the purpose for which the

machine has been manufactured and contains all the

necessary information for safe, correct use.

Constant observance of the stated standards guaran-

tees both machine and personnel safety, economic

running and longer working life.

To better stress the importance of some basic pas-

sages, they have been written in heavy type and

marked by some preceding symbols:

'$1*(5:$51,1*VKRZVLPZKLFKPLJKWFDXVH

LQMXULHVJLYHLWWKHJUHDWHVWDWWHQWLRQ

&$87,21VKRZVWKDWLWLVQHFHVVDU\WRJLYHSDUWLFXODU

DWWHQWLRQWRDYRLGDFFLGHQWVRUGDPDJHVWRWKLQJV

6KRZVSDUWLFXODUO\LPSRUWDQWWHFKQLFDO

Photographs and drawings are provided by way of

example.

(1) The word “machine” replaces the commercial denomination which

this manual refers to (see the cover).

(2) Only experienced people having the proper technical ability and

knowledge of the regulations and laws will be able to carry out the

necessary operations and to identify and avoid possible damages

during handling, installation, operation and maintenance of the

machine.

/LUHFHPDQXHODYHFDWWHQWLRQDYDQWG·HIIHFWXHU

Q·LPSRUWHTXHOOHRSpUDWLRQVXUODPDFKLQH&HPDQXHO

GRLWrWUHJDUGpDYHFOHSOXVJUDQGVRLQGDQVVRQ

HQYHORSSHHQSODVWLTXHjO·LQWpULHXUGHODERvWHjÀFHOOH

1.1. BUT DU MANUEL

Ce manuel a été rédigé par la maison constructrice et

fait partie intégrante des pièces livrées avec la

machine(1).

Les renseignements y contenus sʼadressent à du per-

sonnel qualifié(2) (opérateurs).

Ce manuel indique le but pour lequel cette machine a

été construite et donne tous les renseignements

nécessaires pour que son emploi soit sûr et correct.

Le respect scrupuleux des normes y contenues garan-

tit la sécurité de lʼutilisateur et de la machine et permet

dʼobtenir une certaine économie de service et une plus

longue durée de vie de la machine.

Pour mettre en évidence les parties du texte à ne pas

oublier, on les a mises en gras et précédées par les

symboles montrés et définis ci de suite.

'$1*(5$77(17,21VLJQDOHGHVGDQJHUV

LPPLQHQWVTXLSHXYHQWrWUHjORULJLQHGHEOHVVXUHV

JUDYHVLOIDXWIDLUHWUqVDWWHQWLRQ

35(&$87,21VLJQDOHTXLOIDXWSUHQGUHFHUWDLQHV

SUpFDXWLRQVDÀQGHSUpYHQLUGHVDFFLGHQWVRXGHV

GRPPDJHV

,OVDJLWGHSUHVFULSWLRQVWHFKQLTXHVSDUWLFXOLqUHPHQW

LPSRUWDQWHV

Les photos et les plans ne sont donnés quʼà titre

dʼexemple.

(1) La définition “machine” remplace celle commerciale à laquelle on fait

référence dans ce manuel (voir couverture).

(2) Sont des personnes entraînées et avec une préparation technique,

ainsi quʼune connaissance des normes et des lois à même dʼaccom-

plir les opérations nécessaires, de connaître et donc dʼéviter de pos-

sibles danger pendant la manutention, lʼinstallation, lʼemploi et

lʼentretien de la machine même.

INFORMAZIONI GENERALI

1

217.091

Anche se la macchina in vostro possesso si differenzia

sensibilmente dalle illustrazioni contenute in questo

documento, la sicurezza e le informazioni sulla stessa

sono garantite.

Il costruttore, nel perseguire una politica di costante

sviluppo ed aggiornamento del prodotto, può appor-

tare modifiche senza alcun preavviso.

1.2. COSTRUTTORE

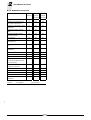

1.3. IDENTIFICAZIONE DELLA MACCHINA

(fig. 1)

Il modello é identificabile dalla targhetta che riporta i

seguenti dati:

A-Numero di identificazione

B-Tipo di macchina

C-Numero di omologazione (*)

D-Massa max totale

E-Massa max su occhione (*)

F-Massa max su assale (*)

G- Nome commerciale

H-Anno di costruzione

L-Giri massimi consentiti (*)

M- Costruttore

(*)

Dove necessario

4XHVWLGDWLGHYRQRHVVHUHVHPSUHSUHFLVDWLDOFRVWUXWWRUH

SHULQIRUPD]LRQLULFKLHVWHULFDPELHFF

Se necessitano parti di ricambio, richiedere esclusiva-

mente ricambi originali “Gallignani”. Lʼutilizzo di ricambi

non originali e lavorazioni non autorizzate effettuate sulla

macchina, ne invalidano le condizioni di garanzia.

1.4. ALLEGATI

– Dichiarazione CE di Conformità.

– Certificato di collaudo.

Tali documenti sono da conservare in luogo apposito

al riparo dagli agenti atmosferici e devono essere

custoditi per lʼintero arco di vita della macchina.

NOME

COMMERCIALE

ANNO DI

COSTRUZIONE

GIRI MAX

P.d.F.

MASSA MAX. SU

ASSALE

MASSA MAX. SU

OCCHIONE

MASSA MAX.

TOTALE

NUMERO

OMOLOGAZIONE

TIPO

NUMERO DI

IDENTIFICAZIONE

(KG)

(KG)

(KG)

(RPM)

1

091.002 Ec. 2

A

M

B

C

D

E

F

G

H

L

GENERAL INFORMATION

1

REINSEGNEMENTS GENERAUX

217.091

Même si votre machine présentait des caractéristiques

différente des illustrations contenues dans le présent

livret, la sûreté ainsi que les avertissements sur celle-

ci seraient garantis.

Le constructeur, suivant une politique de développement

et de mise à jour de ses produits continuelles, peut

apporter des modifications dans ce manuel sans préavis.

1.2. MAISON CONSTRUCTRICE

1.3. IDENTIFICATION DE LA MACHINE (fig. 1)

Le modèle de la machine peut être identifié par la pla-

quette avec les données suivantes:

A-Numéro dʼidentification

B-Type de machine

C-Numéro dʼhomologation (*)

D-Masse maxi totale

E-Masse maxi sur anneau (*)

F-Masse maxi sur essieu (*)

G- Nom commercial

H-Année de fabrication

L-Tours maxi admissibles (*)

M- Constructeur

(*)

Si nécessaire

&HVGRQQpHVGRLYHQWrWUHWRXMRXUVIRXUQLHVDXFRQVWUXFWHXU

SRXUWRXWUHQVHLJQHPHQWGHPDQGHGHSLqFHGHUHFKDQJHHWF

Ne commander que des pièces détachées originales

“Gallignani”. Lʼemploi de pièces non originales et toute

opération non autorisée exécutée sur la machine

entraînent lʼannulation des conditions de garantie.

1.4. ANNEXES

– Déclaration CE de Conformité

– Certificat d'épreuve

Ces documents doivent être gardés dans un lieu spé-

cialement prévu à l'abri d'agents atmosphériques pen-

dant toute la vie utile de la machine.

Should your machine be quite different from the illus-

trations contained in this manual, the safety regula-

tions and relevant information are always guaranteed.

The manufacturerʼs policy of constant development

and updating may lead to modifications without prior

notice.

1.2. THE MANUFACTURER

1.3. MACHINE IDENTIFICATION (fig. 1)

The machine model can be identified through the data

plate detailing the following information:

A-Identification number

B-Type of machine

C-Approval number (*)

D-Total max. weight

E-Max. weight on eye (*)

F-Max. weight on axle (*)

G- Trade name

H-Year of manufacturing

L-Max. allowable revolutions (*)

M- Manufacturer

(*)

If required

$OZD\VVSHFLI\WKLVGDWDWRWKHPDQXIDFWXUHUIRUDQ\

LQIRUPDWLRQUHTXHVWRIVSDUHSDUWVHWF

If spare parts are needed, only order original “Gallig-

nani” spare parts. The use of other parts or any unau-

thorized intervention which may be carried out on the

machine will invalidate the guarantee conditions.

1.4. ENCLOSURES

– EC Conformity Declaration

– Test certificate

The a.m. documents must be kept in a special place

sheltered from the atmospheric agents and must be

kept for the whole machine life.

217.091

2

INFORMAZIONI TECNICHE

2.1. DESCRIZIONE DELLA

MACCHINA (fig. 1)

Lʼavvolgitore G400 consente il ricoprimento con film

plastico delle balle cilindriche di insilato e prodotti

umidi per una loro migliore conservazione.

É una macchina prodotta nella versione trainata o por-

tata; nella versione portata necessita di una trattrice

dotata di adeguati bracci di sollevamento ed eventual-

mente di zavorra anteriore.

La macchina consente la fasciatura di balle con dia-

metro compreso fra i 120 e 160 cm tramite due movi-

menti di rotazione secondo gli assi AA’ e BB’. La

rotazione secondo lʼasse AA’ é generata da due rulli

sui quali viene posizionata la balla.

I due rulli sono solidali con la piattaforma che ruota

secondo lʼasse BB’. Questʼultima rotazione provoca lo

svolgimento della bobina di film che gira attorno ad un

asse fisso.

Lʼentità della sovrapposizione degli strati di film pla-

stico dipende dalla velocità di rotazione della balla

attorno al suo asse longitudinale.

La rotazione dei rulli che genera il movimento della

balla lungo il suo asse longitudinale viene derivata da

quella della piattaforma, il che consente di mantenere

costante, una volta stabilita, la sovrapposizione fra i

successivi strati di film plastico.

La coppia di rulli laterali fissati sulla piattaforma gire-

vole impediscono che la balla si sposti durante la

fasciatura e permettono lʼavvolgimento anche di balle

a forma irregolare.

Le operazioni di avvolgimento, taglio del film e scarico

della balla sono controllate e comandate dallʼoperatore

direttamente dalla cabina del trattore o da bordo mac-

china.

Il gruppo di svolgimento del film può utilizzare bobine

di diverse altezze: 500 mm/750 mm (a seconda del

tipo di svolgitore presente sulla macchina ed é regi-

strabile per il tensionamento del film dal 45% al 90%).

Il pretensionamento del film viene ottenuto tramite la

frenatura tangenziale della bobina dovuta ad una

diversa velocità periferica del rullo frenante R1 e del

rullo svolgitore R2.

/DPDFFKLQDpVWDWDFRQFHSLWDSHUHVVHUHXWLOL]]DWDGDXQ

VRORRSHUDWRUH

1

091.003 Ec. 1

B

B’

A’

A

R2

R1

TECHNICAL INFORMATION 2

INFORMATIONS TECHNIQUES 2

TECHNICAL INFORMATION

2

INFORMATIONS TECHNIQUES

217.091

2.1. MACHINE DESCRIPTION (fig. 1)

Bale wrapper G400 wraps silage round bales and

wet products withplastic film, thus allowing a better

preservation.

The machine is available both in the trailed and

mounted version; the mounted version requires a trac-

tor supplied with suitable lifting arms and front counter-

weight whenever necessary.

The machine performs the wrapping of bales with a

diameter between 120 and 160 cm by means of two

rotary motions, around the axes AA' and BB'. The

rotation around the AA' axis is generated by two roll-

ers on which the bale is positioned.

The two rollers are an integral part of the platform

which rotates around the BB' axis. This rotation

causes the unwinding of the film reel which turns

around a fixed axis.

The overlap of the plastic film layers depends on the

bale rotation speed around its longitudinal axis.

The rollers rotation, generating the bale movement

around its longitudinal axis, derives from the rotation of

the platform, thus keeping constant, once it has been

set, the overlap of the following plastic film layers.

The pair of side rollers which are fixed on the rotating

platform, prevent the bale from moving during the

wrapping operation and enable the wrapping of bales

with irregular shapes.

The wrapping, film cutting and bale unloading opera-

tions are checked and controlled by the operator

directly from the tractor cab or from the machine side.

The film unwinding unit can use reels of different

heights: 500 mm / 750 mm (according to the type of

unwinder mounted on the machine and is adjustable

for the film tensioning from 45% to 90%).

The film pre-stretching is obtained by means of the

reel tangential braking which is the result of a different

rim speed of the braking roller R1 and of the unwinding

roller R2.

7KHPDFKLQHKDVEHHQGHVLJQHGIRUEHLQJXVHGE\D

VLQJOHRSHUDWRU

2.1. DESCRIPTION DE LA MACHINE (fig. 1)

Lʼenrubanneuse G400 permet dʼenrubanner sous film

plastique des balles cylindriques de produits ensilés et

humides pour leur meilleure conservation.

Il sʼagit dʼune machine produite dans la variante traî-

née ou portée. Dans cette dernière variante est néces-

saire un tracteur doté de bras de levage convenables

et éventuellement dʼun contrepoids antérieur.

La machine permet d'envelopper des balles ayant un

diamètre compris entre 120 et 160 cm par deux mou-

vements de rotation selon les axes AA' et BB'. La

rotation selon l'axe AA' est commandée par deux rou-

leaux sur lesquels est posée la balle.

Les deux rouleaux sont solidaires de la plate-forme qui

tourne selon l'axe BB'. Cette rotation entraîne le

déroulement de la bobine de film qui tourne autour

d'un axe fixe.

La mesure de la superposition des couches de film

plastique dépend de la vitesse de rotation de la balle

autour de son axe longitudinal.

La rotation des rouleaux qui entraîne la balle en mou-

vement sur son axe longitudinal est dérivée de la rota-

tion de la plate-forme, ce qui permet de maintenir

constante, une fois établie, la superposition entre les

couches successives de film plastique.

Le deux rouleaux latéraux fixés à la plate-forme tour-

nante empêchent la balle de se déplacer pendant

l'enveloppement et permettent ainsi l'enrubannage de

balles de forme irrégulière.

Les opérations d'enrubannage, de coupe du film et de

déchargement de la balle sont contrôlées et comman-

dées par l'opérateur directement de la cabine de con-

duite du tracteur ou d'à bord de la machine.

Le groupe de déroulement du film peut utiliser des

bobines de hauteurs différentes: 500 mm/750 mm

(selon le type de dérouleur monté sur la machine,

réglage pour une tension du film de 45% à 90%).

Le pré-étirage du film est obtenu par le freinage tan-

gentiel de la bobine, dû à une vitesse périphérique dif-

férente entre le rouleau de freinage R1 et le rouleau

dérouleur R2.

/DPDFKLQHDpWpFRQoXHSRXUOHPSORLSDUXQVHXO

RSpUDWHXU

INFORMAZIONI TECNICHE

2

217.091

2.1.1 Descrizione dei modelli (fig. 2)

La macchina viene fornita sulla base delle esigenze di

lavoro nelle seguenti versioni.

G400 P - Portato: é la versione base, più consiglia-

bile quando le operazioni di fasciatura avvengono sul

luogo di stoccaggio, in quanto necessita di un altro

attrezzo per il carico delle balle.

G400 S - Portato con forca: é la versione con forca

di carico balla e può lavorare direttamente sul campo,

ove opera autonomamente.

G400 S - Trainato con forca: é la versione con

forca di carico balla e può lavorare direttamente sul

campo, ove opera autonomamente.

2

091.004 Ec. 2

G400 P

G200 P

G400 F

G400 S

G400 P

G400 F

G400 S

TECHNICAL INFORMATION

2

INFORMATIONS TECHNIQUES

217.091

2.1.1 Description of the models (fig. 2)

According to working requirements, the machine can

be supplied in the following models.

- Mounted: is the standard model, recom-

mended if wrapping occurs in the place of storage,

being a bale loader necessary.

- Mounted unit with fork: supplied with

bale loading fork, it can work in the field, being it auton-

omous.

- Trailed unit with fork: supplied with bale

loading fork, it can work in the field, being it autono-

mous.

G400 P

G400 F

G400 S

2.1.1 Description des modèles (fig. 2)

La machine est fournie sur la base des exigences de

travail dans les variantes suivantes.

- Variante portée: est la variante de base,

plus conseillée lorsque les opérations dʼenrubannage

se font sur le lieu de stockage, parce quʼelle nécessite

dʼun autre outil pour le chargement des balles.

- Porté avec fourche

: est la variante avec

fourche de chargement de la balle et peut travailler

directement sur le champ, où elle travaille de manière

autonome.

- Tracté avec fourche

: est la variante avec

fourche de chargement de la balle et peut travailler

directement sur le champ, où elle travaille de manière

autonome.

G400 P

G400 F

G400 S

INFORMAZIONI TECNICHE

2

217.091

2.1.2 Gruppi operatori (fig. 3)

A-Struttura portante [Con predisposizione per il fis-

saggio attacco 3 punti (G400 P/F)].

B-Timone con occhione di traino (G400 S).

C-Piattaforma girevole.

D-Rulli di sostegno della balla.

E-Gruppo svolgitore del film.

F-Dispositivo di inserimento e taglio automatico del

film.

G- Rulli di contenimento laterale.

H-Cinghie.

L-Martinetto di ribaltamento della piattaforma girevole.

M- Motore idraulico per la rotazione della piattaforma.

N- Forca per il carico della balla (G400 S/F).

P- Martinetto di azionamento della forca (G400 S/F).

Q- Piede di appoggio (G400 S).

R- Ruote con pneumatici (G400 S/F).

S-Distributore idraulico.

T-Cavi flessibili per comandi a distanza.

V-Gruppo di comando per lʼazionamento della rota-

zione della tavola, della tavola ribaltabile e della

forca di carico balla.

(Il gruppo di comando può essere ospitato sul trat-

tore o a bordo macchina).

3

091.005 Ec. 1

E

V

T

QL A F M

H

D

C

G

R

B

N

S

P

TECHNICAL INFORMATION

2

INFORMATIONS TECHNIQUES

217.091

2.1.2 Working units (fig. 3)

A-Bearing structure [Allows the hitching of the three-

point linkage (G400P/F)].

B-Drawbar with towing eye (G400S).

C-Revolving platform.

D-Bale supporting rollers.

E-Film unwinding unit.

F-Automatic film inserting and cutting device.

G- Side holding rollers.

H-Belts.

L-Revolving platform tilting jack.

M- Hydraulic motor for revolving platform.

N-Bale loading fork (G400S/F).

P-Fork actuating jack (G400S/F).

Q- Support (G400S).

R-Wheels with tyres (G400S/F).

S-Hydraulic control valve.

T-Flexible cables for remote controls.

V-Control unit to rotate the table, the tilting table and

the bale loading fork.

(The control unit can be fitted either on the tractor

or on the machine).

2.1.2 Groupes de travail (fig. 3)

A-Structure porteuse [Avec dispositif pour la fixation

de lʼattelage à trois points (G400P/F)]

B-Timon avec anneau de remorquage (G400 S).

C-Plateforme tournante.

D-Galet de support de la balle.

E-Ensemble dérouleur du film.

F-Dispositif dʼintroduction et de coupe automatique

du film.

G- Rouleaux de guidage latéral.

H-Courroies.

L-Vérin de basculement de la plateforme tournante.

M- Moteur hydraulique pour la rotation de la plateforme.

N-Fourche pour le chargement de la balle (G400 S/F).

P-Vérin dʼactionnement de la fourche (G400 S/F).

Q- Béquille dʼappui (G400 S).

R-Roues avec pneus (G400 S/F).

S-Distributeur de commande.

T-Câbles flexibles pour commande à distance.

V-Unité de commande pour lʼactionnement de la

rotation de la table, de la table basculante et de la

fourche de chargement de la balle.

(Lʼunité de commande peut être logée sur le trac-

teur ou à bord de la machine).

INFORMAZIONI TECNICHE

2

217.091

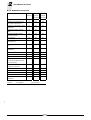

2.1.3 Dotazione accessori

Modello - Tipo G400P

(portato)

G400 F

(portato

con forca)

G400S

(trainato

con forca)

Forcone carico balla ST ST

Dispositivo pre-stiramento film

per bobina H=500/750 mm

ST ST ST

Dispositivo di regolazione rapida

altezza film

ST ST ST

Rulli di contenimento laterale

balla

ST ST ST

Tenditore automatico trasmis-

sione rullo motore

ST ST ST

Set di cinghie ST ST ST

Dispositivo inserimento e taglio

automatico film

ST ST ST

Contagiri elettronico programma-

bile

OP OP OP

Sicurezza per arresto rotazione

piattaforma

OP OP OP

Comandi flessibili a distanza ST ST ST

Asta con pannelli retroriflettenti OP OP OP

Impianto di illuminazione OP OP OP

Kit per collegamento a trattori a

circuito ad annullamento di por-

tata (John Deere).

ST ST ST

Rullo di guida per bobina

(l=500 mm. e 750 mm)

ST ST ST

Rotelle folli per gruppo di taglio ST ST ST

Supporti per bobine di scorta OP OP OP

Pneumatico 20x10. 0-10/6pr - ST ST

Pneumatico 23x10. 5-12/6pr - OP OP

Regolatore di portata olio per

distributore

OP OP OP

/HJHQGD 676WDQGDUG 232S]LRQDOH

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126