NewMac NM-175K Operating Instructions Manual

- Catégorie

- Cheminées

- Taper

- Operating Instructions Manual

Portable Forced Air Heaters

NM-75K / NM-125K / NM-175K / NM-215K

852945C-3304H

PRO

NEWMAC

NEWMAC

227 Industrial Park Road

South Pittsburg, TN 37380

(800) 750-2723

DANGER:

Improper use of this heater can result in serious injury or death from burns, re, explosion, electrical shock, and/

or carbon monoxide poisoning.

DANGER:

Service must be performed by a qualied service technician. Unvented portable heaters use air (oxygen) from

the area in which it is used. Adequate combustion and ventilation air must be provided. Refer to instructions.

WARNING:

Before using this heater, please read this OPERATING INSTRUCTION very carefully. This USER’S MANUAL has been

designed to instruct you as to the proper manner in which to assemble, maintain, store, and most importantly,

how to operate the heater in a safe and efcient manner. Do not allow anyone who has not read these

instructions to assemble, light, adjust or operate the heater.

CALIFORNIA PROPOSITION 65 WARNING:

This product can expose you to chemicals including carbon monoxide, which

is known to the State of California to cause cancer, birth defects and/or other

reproductive harm. For more information, go to www.P65warnings.ca.gov

Ce produit peut vous exposer à des produits chimiques, y compris le

monoxyde de carbone, qui est connu dans l'État de Californie pour causer

le cancer, des malformations congénitales et / ou d'autres problèmes de

reproduction. Pour plus d'informations, visitez www.P65warnings.ca.gov

Product Information

Specication

NM-75K NM-125K NM-175K / NM-215K

H 15.9 inch (405 mm) 26.4 inch (670 mm) 25 inch (635 mm)

W 11.8 inch (300 mm) 21.5 inch (545 mm) 23.2 inch (590 mm)

L 29.1 inch (740 mm) 35.2 inch (893 mm) 39.5 inch (1003 mm)

H

L

W

Model NM-75K

H

L

W

Model NM-125K, NM-175K, NM-215K

DIMENSIONS

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Description

Models NM-75K, NM-125K, NM-175K, NM-215K heaters are 75,000 to 210,000btu/hr heaters. These heaters use

1-K Kerosene for combustion, and electricity to run the fan. It is primarily intended for temporary heating of well

ventilated buildings under construction, alteration, or repair. This heater may be used in agricultural, industrial and

commercial environments.

Unpacking

1. Remove all packing items applied to heater for shipment.

2. Remove all items from carton.

3. Check all items for shipping damage. If heater is damaged, promptly inform dealer where you purchased

heater.

Introduction

Please read this USER’S MANUAL carefully. It will show you how to assemble, maintain and operate this heater

safely and efciently to obtain the full benets of its many features.

Consumer

Save these instructions for future reference

-3-

Upper Shell

Fan Guard

Fuel Gauge

Fuel Cap

Lower Shell

Side Cover Lamp

Power/Reset Switch

Fuel Tank

Power Cord

Handle

Upper Shell

Handle Rear

Fan Guard

Fuel Gauge

Fuel Cap

Side Cover Lamp

Thermostat Knot

Power/Reset Switch

Fuel Tank

Power Cord

Model NM-75K Model NM-125K, NM-175K, NM-215K

PRODUCT FEATURES

GENERAL SAFETY INFORMATION

DANGER:

Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury.

WARNING:

Never leave the heater unattended while burning!

For optimal performance of this heater it is strongly suggested that 1-K kerosene be used. 1-K kerosene has

been rened to virtually eliminate contaminants, such as sulfur, which can cause a rotten egg odor during the

operation of the heater.

Electrical Specications

Model Electrical Input Watt Fuse Spark Plug Gap

NM-75K 120V, 60Hz 160 250V/10 amp. .140”(3.5mm)

NM-125K 120V, 60Hz 250 250V/10 amp. .140”(3.5mm)

NM-175K 120V, 60Hz 298 250V/10 amp. .140”(3.5mm)

NM-215K 120V, 60Hz 324 250V/10 amp. .140”(3.5mm)

General Specications

Model

Type of

Fuel

Input Rating

(Btu/kW)

Pump

Pressure

Fuel Tank

Capacity

Fuel

Consumption

Size L x W x H Weight

NM-75K

Kerosene 75,000/21.8 4.7 PSI

5.3 gal

(20 Liter)

0.55 gal/h

(2.1 l/h)

29.1X11.8X15.9(inch)

740X300X405(mm)

28.2 lbs

(12.8 Kg)

NM-125K

Kerosene 125,000/36.3 4.9 PSI

10.6 gal

(40 Liter)

0.95 gal/h

(3.6 l/h)

35.2X21.5X26.4(inch)

893X545X670(mm)

53.8 lbs

(24.4 Kg)

NM-175K

Kerosene 175,000/50.9 4.9 PSI

13.2 gal

(50 Liter)

1.32 gal/h

(5.0 l/h)

39.5X23.2X25(inch)

1003X590X635(mm)

60 lbs

(27.2 Kg)

NM-215K

Kerosene 210,000/61 5.5 PSI

13.2 gal

(50 Liter)

1.58 gal/h

(6.0 l/h)

39.5X23.2X25(inch)

1003X590X635(mm)

62 lbs

(28.2 Kg)

-4-

Safety Information

RISK OF INDOOR AIR POLLUTION

• Use this heater only in well ventilated areas! Provide at least a three square foot (2,800 sq cm) opening of

outside air for every 100,000 Btu/hr of heater rating.

• People with breathing problems should consult a physician before using the heater.

• Carbon Monoxide Poisoning: Early signs of carbon monoxide poisoning resemble u-like symptoms such as

headaches, dizziness, and/or nausea. If you have these symptoms, your heater may not be working properly.

• Get fresh air at once! Have the heater serviced.

• Some people are more affected by carbon monoxide than others. These include pregnant women, those

with heart or lung problems, anemia, or those under the inuence of alcohol, or at high altitudes.

• Never use this heater in living or sleeping areas.

• Service must be performed by a qualied service technician. Unvented portable heaters use air (oxygen)

from the area in which it is used. Adequate combustion and ventilation air must be provided. Refer to

instructions.

RISK OF BURNS/FIRE/EXPLOSION

• NEVER use fuels such as gasoline, benzene, paint thinners, or other oil compounds in this heater (RISK OF FIRE

OR EXPLOSION).

• NEVER use this heater where ammable vapors may be present.

• NEVER rell the heater’s fuel tank while heater is operating or still hot. This heater is EXTREMELY HOT while in

operation.

• Keep all combustible materials away from this heater.

PROPER COOLING BEFORE UNPLUGGING

• Allow the unit to cool for three minutes before unplugging.

• Before heater is moved, it must be stopped and unplugged. BEFORE MOVING the heater, wait until it has

totally cooled off and make sure the oil tank cap is securely xed.

MINIMUM CLEARANCES

• NEVER block air inlet (rear) or air outlet (front) of heater.

• NEVER use duct work in front or at rear of

• NEVER move or handle heater while still hot.

• NEVER transport heater with fuel in its tank.

• When used with optional thermostat or if equipped with a thermostat, the heater may start at any time.

• ALWAYS locate heater on a stable and level surface.

• ALWAYS keep children and animals away from heater.

• Use 1-K kerosene in this heater. #1 fuel (oil is a suitable substitute).

• Bulk fuel storage should be a minimum of 25 ft. from heaters, torches, portable generators, or other sources

of ignition. All fuel storage should be in accordance with federal, state, or local authorities.

RISK OF ELECTRIC SHOCK

• Use only the electrical power (voltage and frequency) specied on the model plate of the heater. Use only

a three-prong, grounded outlet and extension cord.

• ALWAYS install the heater so that it is not directly exposed to water spray, rain, dripping water, or wind.

• ALWAYS unplug the heater when not in use.

Front 110” (2.8m)

Ceiling 59” (1.5m)

Side/Rear 37.4” (0.95m)

CANADIAN RESIDENTS:

THE INSTALLATION OF THE EQUIPMENT SHALL BE

IN ACCORDANCE WITH THE REGULATION OF

AUTHORITIES HAVING JURISDICTION AND CSA

STANDARD B139

US RESIDENTS:

THE INSTALLATION OF THE EQUIPMENT SHALL BE

IN ACCORDANCE WITH THE REGULATION OF

AUTHORITIES HAVING JURISDICTION AND NFPA 31

-5-

Handle Front

Rear Handle

Axle

Height Adjustable Pipe

Handle

Wheels

Washer

Screws and Nuts

Screws, and Nuts

(NM-125K / NM-175K / NM-215K)

Screws

(NM-75K)

Component Identification

Shaft fixed Bkt

Cap Nut

NM-125K, NM-175K, NM-215K

Height Adjustable Pipe

Assembly

Model NM-75K NM-125K NM-175K NM-215K

Height Adjustment Pipe No Yes Yes Yes

Wheels No Yes Yes Yes

Shaft xed Bracket No Yes Yes Yes

Front-Handle No Yes Assembly Assembly

Rear-Handle No Yes Assembly Assembly

Axle No No Yes Yes Yes

Handle Yes No No No

Screws Yes No No No

Screws and Nuts No Yes Yes Yes

Cotter Pin and Washer No Yes Yes Yes

-6-

Assembly

FOR MODELS NM-75KONLY

TOOLS REQUIRED

• Medium Phillips screwdriver (size #1, #2, #3).

1. Align the holes in the upper housing with the two mounting holes on the handle as shown.

2. Secure handle through holes provided.

FOR MODELS NM-125K

This model is furnished with wheels and

handles. Wheels, handles and mounting

hardware are found in shipping carton.

TOOLS REQUIRED

• Medium Phillips screwdriver. (2.75inch)

• M5 open, or adjustable wrench.

• Long nose pliers

1. Slide axle through wheel support

frame. Install wheels on axle, pointing

extended hub of wheel toward wheel support frame.

2. Place at washers and cotter pin on axle ends and bend cotter pin with long nose pliers to secure.

3. Place heater on wheel support frame. Make sure air inlet end (rear) of heater is over wheels. Align the holes

on fuel tank ange with holes on support frame.

4. Position handle on top of fuel tank ange. Insert screws through handles, fuel tank ange and wheel support

frames as shown, and attach nuts nger tight after each screw is inserted.

5. After all screws are inserted, rmly tighten all nuts.

FOR MODELS NM-175K, NM-215K

These models are already assemble with handles and adjustable pipe. Only wheels with shaft by brackets

assemble.

CAUTION: Fully assemble the support frame to the tank.

Models NM-125K, NM-175K, NM-215K

Handle

Air Inlet

Fuel Tank Flange

Axle

Wheel

Wheel support

Frame

Thermostat

Knob

Handle Installation NM-75K

Screw

Handle

-7-

Guard Assembly (For Canada Only)

Interception

Guard

Interception

Guard

-8-

OPERATION

KEROSENE (1-K) For optimal performance of this heater, it is strongly suggested that 1-K kerosene be used. 1-K

kerosene has been rened to virtually eliminate contaminants, such as sulfur, which can cause a rotten egg odor

during the operation of the heater. Be advised that these fuels do not burn as clean as 1-K kerosene, and care

should be taken to provide more fresh air ventilation to accommodate any added contaminants that may be

added to the heated space. NOTE: Kerosene should only be stored in a blue container that is clearly marked

“kerosene”. Never store kerosene in a red container. Red is associated with gasoline.

• NEVER store kerosene in the living space. Kerosene should be stored in a well ventilated area outside the

living area.

• NEVER use fuel such as gasoline, benzene, alcohol, white gas, camp stove fuel, paint thinners, or other oil

compounds in this heater (THESE ARE VOLATILE FUELS THAT CAN CAUSE A FIRE OR EXPLOSION).

• NEVER store kerosene in direct sunlight or near a source of heat.

• NEVER use kerosene that has been stored from one season to the next. Kerosene deteriorates over time. OLD

KEROSENE WILL NOT BURN PROPERLY IN THIS HEATER.

• Use 1-K kerosene in this heater. #1 fuel is a suitable substitute.

OVERVIEW OF HEATER DESIGN

Fuel System: This heater is equipped with an electric air pump that forces air through the air line connected to

the fuel intake, and then through a nozzle in the burner head. When air passes in front of the fuel intake, it causes

fuel to rise from the tank and into the burner nozzle. This fuel and air mixture is then sprayed into the combustion

chamber in a ne mist.

IGNITION

The electronic igniter sends voltage to a specially designed spark plug. The spark plug ignites the fuel and

air mixture described. The Air System: The heavy duty motor turns a fan that forces air into and around the

combustion chamber. Here, the air is heated and then forced out the front of the heater.

THE SAFETY SYSTEM

Temperature Limit Control: This heater is equipped with a Temperature Limit Control designed to turn the heater

off should the internal temperature rise to an unsafe level. If this device activates and turns your heater off, it may

require service. Once the temperature falls below the reset temperature, you will be able to start your heater.

ELECTRICAL SYSTEM PROTECTION

This heater’s electrical system is protected by a fuse mounted to the PCB Assembly that protects it and other

electrical components from damage. If your heater fails to operate, check this fuse rst and replace as needed.

Refer to specication chart.

FLAME-OUT SENSOR

Utilizes a photocell to monitor the ame in

burn chamber during normal operation. It

will cause the heater to shut off should the

burner ame extinguish.

FUELING YOUR HEATER

Never ll the heater fuel tank in the living

space: ll the tank outdoors. Do not overll

your heater and be sure heater is level.

IMPORTANT: REGARDING FIRST IGNITION

OF HEATER. The rst time you light the

heater, it should be done OUTDOORS.

This allows the oils, etc., used in

manufacturing heater to be burned

off outside.

Overview of Heater Design

WARNING:

Never rell fuel tank when heater

is operating or still hot.

MODELS

Internal Shut-Off Temp.

+/-10 Degrees

Reset Temp.

+/-10 Degrees

NM-75K, NM-125K,

NM-175K, NM-215K

176°F (80°C) 158°F (70°C)

Operation

-9-

VENTILATION

Provide a fresh air opening of at least three (3) square feet (2,800 sq. cm) for

each 120,000 btu/hr. rating. Provide extra fresh air if more heaters are being

used.

Example: A NM-175K heater requires one of the following:

1. A two-car garage door raised six inches (15.24 cm).

2. A single-car garage door raised nine inches (22.86 cm).

3. Two, thirty inch (76.20 cm) windows raised fteen inches (38.1 cm).

TO START HEATER

1. Fill fuel tank with kerosene or No. 1 fuel oil.

2. Attach fuel cap.

3. Plug power cord into three prong, grounded extension cord. Extension

cord must be at least six feet long.

Extension Cord Wire Size Requirements:

• 6 to 10 feet (1.8 to 3 meters) long, use 18 AWG conductor.

• 11 to 100 feet (3.4 to 30.53 meters) long, use 16 AWG conductor.

• 101 to 200 feet (30.8 to 61 meters) long, use 14 AWG conductor.

4. Turn THERMOSTAT CONTROL KNOB to desired setting and push power

switch to “ON” position. Power indicator lamp will light and heater will

start.

• If heater does not start, the thermostat setting may be too low.

• Turn THERMOSTAT CONTROL KNOB to higher position to start heater.

If heater still does not start, turn power switch to OFF and then to ON

position.

• NOTE: The major electrical components of this heater are protected by a

safety fuse mounted to the PCB board. If your heater fails to start, check

this fuse rst and replace as necessary. You should also check your power

source to insure that proper voltage and frequency are being supplied

to the heater.

TO SHUT DOWN HEATER

Turn power switch to “OFF” and unplug power cord.

TO RESTART HEATER

1. Wait 10 seconds after stopping heater.

2. Repeat steps under, “TO START HEATER.”

ELECTRICAL OUTLET

• Shock Hazard

• Never plug in an appliance with more than a

5amp rating into this outlet.

• Always keep outlet covered when not in use.

120V 30amp max(non fused).

IMPORTANT: Reinstall plug fully into hole in tank;

otherwise it will not seal completely.

• Make sure storage place is free of dust and

corrosive fumes.

• Store the heater in the original box with the

original packing material and keep USER’S

MANUAL with heater.

The room temperature display will indicate the following:

* When the temperature is less than 0° F, the display says “LO”

* When the temperature is more than 99° F, the display says “HI”

* Between 0° F and 99° F the display shows the actual room temperature

Power

Reset

Switch

Lamp

Thermostat

Control Knob

Room Temp.Display

Controls for All Models

Lint Filter

Air Out Put Filter

Intake Filter

End Filter Cover

Operation

CAUTION:

Risk of indoor air pollution. Use heater only in well ventilated areas.

Power Reset Switch

-10-

USE ORIGINAL EQUIPMENT REPLACEMENT PARTS. Use of

third party or other alternate components will void warranty

and may cause unsafe operating conditions.

FUEL TANK

Flush every 200 hours of operation or as needed. DO NOT

ush with water, use fresh 1-K kerosene only.

AIR INTAKE FILTER

Wash and dry with soap and water every 500 hours of

operation, or as needed.

• Remove screws along side of heater using medium

Phillips screwdriver.

• Lift off upper shell.

• Remove fan guard.

• Wash or replace air intake lter.

• Reinstall fan guard and upper shell.

AIR OUTPUT FILTER, LINT FILTER REPLACE EVERY 500

HOURS OF OPERATION OR ONCE A YEAR

• Remove upper shell and fan guard.

• Remove end lter cover screws using medium Phillips

screwdriver.

• Remove end lter cover.

• Replace air output and lint lter.

• Reinstall end lter cover.

• Reinstall fan guard and upper shell.

FAN BLADES

• CLEAN EVERY SEASON OR AS NEEDED

• Remove upper shell.

• Use M6 Allen wrench to loosen set screw which holds

fan blade to motor shaft.

• Slip fan blade off motor shaft.

• Clean fan blade using soft cloth moistened with

kerosene or solvent.

• Dry fan blade thoroughly.

• Reinstall fan blade to motor shaft.

• Place fan blade hub ush with

end of motor shaft.

• Place set screw on at of shaft.

• Tighten screw rmly (40-50 inch

pounds/ 4.5-5.6 N-m). Reinstall

upper shell.

NOZZLE

Clean nozzle as needed

• Open upper shell.

• Remove fan blade.

• Remove fuel and air line hoses

from burner head.

• Remove igniter wire from spark

plug.

• Remove spark plug from Nozzle

rod using medium Phillips

screwdriver.

Fan Assembly

Fan Blade

Flush

Moter Shaft

Set Screw

Fuel Hose

Ignitor

Wire

Burner Head

Air Hose

Nozzle

Rod

Spark Plug

Fuel Hose

Fitting

Air Hose Fitting

Lint Filter

Air Out Put Filter

Intake Filter

End Filter Cover

Maintenance

WARNING:

Never service heater while it is plugged in or while hot!

-11-

• Turn the Nozzle rod to anti clockwise and separate with Burner head.

• Carefully remove nozzle from Nozzle rod using 5/8” socket wrench.

• Blow compressed air through face of nozzle (This will remove any dirt).

• Reinstall nozzle into Nozzle rod and tighten rmly (80-100 inch-pounds).

• Reinstall spark plug into Nozzle rod.

• Turn the Nozzle rod to clockwise and Assemble with Burner Head.

• Attach igniter wire to spark plug.

• Attach fuel and air line hoses to Nozzle rod.

• Reinstall fan blade and upper shell.

• Remove upper shell.

• Remove fan.

• Remove igniter wire from spark plug.

• Remove spark plug from Nozzle head using medium Phillips screwdriver.

• Clean and regap spark plug electrodes to .140” (3.5 mm) gap.

• Reinstall spark plug into Nozzle head.

• Attach igniter wire to spark plug.

• Reinstall fan and upper shell.

PHOTOCELL

• CLEAN PHOTOCELL ANNUALLY OR AS NEEDED.

• Remove upper shell.

• Remove fan.

• Remove photocell from its mounting bracket.

• Clean photocell lens with cotton swab. TO REPLACE:

Remove side cover near power switch.

• Disconnect wires from circuit board and remove photocell.

• Install new photocell and attach wires to circuit board.

• Reinstall fan and upper shell.

• Remove upper shell.

• Remove fan.

• Remove photocell from its mounting bracket.

• Clean photocell lens with cotton swab. TO REPLACE:

Remove side cover near power switch.

• Disconnect wires from power switch and remove side

cover.

• Disconnect wires from circuit board and remove photocell.

• Install new photocell and attach wires to circuit board.

• Replace switch wires to power switch and side cover.

• Replace fan and upper shell.

Nozzle Face

Nozzle Rod

Nozzle

Spark Plug Replacement

Nozzle Rod

Spark Plug

Gap

PHOTO CELL

3VE49A Only

WIRE

CIRCUIT BOARD

Photocell Replacement for

Maintenance

-12-

FUEL FILTER

• Clean or replace twice per heating season or as needed.

• Remove side cover screws using medium Phillips screwdriver.

• Remove side cover.

• Pull fuel line off fuel lter neck.

• Turn fuel lter counterclockwise 90 degrees, pull, and remove.

• Wash fuel lter with clean fuel and replace in tank.

• Attach fuel line to fuel lter neck.

• Reinstall side cover.

• Open side cover screws using medium Phillips screwdriver.

• Disconnect switch wires from power switch and remove side

cover.

• Pull fuel line off fuel lter neck.

• Pull fuel line.

• Turn fuel lter clockwise 90 degrees and pull to remove.

• Wash fuel lter with clean fuel and replace in tank.

PUMP PRESSURE ADJUSTMENT

• If model is not equipped with a built in air pressure gauge, remove

pressure gauge plug from end of lter cover.

• If model is not equipped with a built in air pressure gauge, install

accessory pressure gauge.

• Start heater.

• Allow motor to reach full speed.

• Adjust pressure.

• Turn relief valve clockwise to increase pressure.

• Turn relief valve counterclockwise to decrease pressure.

• Set pump pressure to correct pressure for each model.

• Stop heater. If accessory pressure gauge is being used, remove

pressure gauge.

• Replace pressure gauge, and plug in end of lter cover. NOTE: USE

ONLY ORIGINAL EQUIPMENT REPLACEMENT PARTS. Use of alternate

or third party components will void warranty and may cause an

unsafe operating condition.

Pressure

Gauge

Plug

Relief

Valve

Adjusting Pump Pressure

NM-75K

Adjusting Pump Pressure

NM-125K, NM-175K, NM-215K

Maintenance

Photocell

Photocell

lens

Install Photocell

1) Incorrect

2) Correct

Photo Cell Wire

Circuit

Board

Side Cover

Power Switch

Power Switch Wire

Screw

Fuel Filter

Fuel Line

Model Pump Pressure

NM-75K 4.7PSI

NM-125K 4.9PSI

NM-175K 4.9PSI

NM-215K 5.5PSI

Switch Wires

Circuit Board

-13-

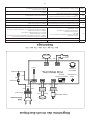

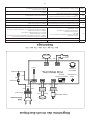

Power Plug

NM-75K, NM-125K, NM-175K, NM-215K

Circuit Diagram

Troubleshooting

Possible Cause Corrective Action

E1

Photocell (Flame Color Checking Sensor) Error

Oil Shortage

Bad Photocell (Flame Sensor)

Incomplete Combustion

Contamination of Fuel Filter

Ignition Failure

Charge Fuel (Fill the fuel if needed)

Check and clean or replace Photocell (Flame Sensor)

Using Designated Fuel

Clean or replace Fuel Filter

Check Wire Connection

Check Spark Plug For Normal Firing (clean or replace if

needed)

E2

Temperature sensor (Thermister) Error

Bad Connection or mis-operation of Sensor

Checking Wire Connection

Replace Sensor

LO Below 1°F Normal

HI Over 99°F Normal

OH It stops when the temperature reaches to 140°F Restart After Cooling

CN Continuously operating without set-temperature Normal

Blinking Error during operation

Check Error Code

Restart after resetting

-14-

1

3

2

4

8

9

23

24

10

5

6

7

12

11

13

14

19

17

16

18

15

20

21

22

25

Parts Diagram

In order to maintain warranty, components must be replaced using original manufacturers parts purchased

through your dealer or directly from NewmacPro by calling 1-800-750-2723.

Use of third party components will void the warranty.

-15-

Parts List

Key Description Model Part No

1 Fuel Gauge Assembly

NM-75k

892822

NM-125K, NM-175K, NM-215K

892823

2 Fuel Filter Assembly

NM-75k

892824

NM-125K, NM-175K, NM-215K

892825

3 Fuel Cap Assembly 892826

4 Power Switch 80718

5 Air Line

NM-75k

892813

NM-125K

892814

NM-175K, NM-215K

892815

6 Thermostat Limit Control 80719

7 Photocell 81274

8 Nozzle Assembly

NM-75k

892827

NM-125K

892828

NM-175K

892829

NM-215K

892830

9 Spark Plug 80729

10 Motor and Pump Assembly

NM-75k

80742

NM-125K

80743

NM-175K

80744

NM-215K

80745

11 Insert 83758

12 Rotor

NM-175K

80720

NM-215K

80721

NM-75K, NM-125K

80722

13 Blade (four)

NM-175K

80723

NM-215K

80724

NM-75K, NM-125K

80725

14 Filter Kit Assembly 892831

15 End Filter Cover 892816

16 Ball 83760

17 Spring 83761

18 Adjust Screw 83762

19 Plug/Pump Kit 83759

20 Fan Assembly

NM-75k

80746

NM-125K

80747

NM-175K

80748

NM-215K

80749

21 Igniter

NM-125K

80726

NM-75K, NM-175K, NM-215K

80727

22 Fan Guard (Plastic)

NM-75k

892817

NM-125K, NM-175K, NM-215K

892818

23 Main P.C.B Assembly 80728

24 Thermistor 81275

25 Handle

NM-75k

892819

NM-125K, NM-175K, NM-215K

N/A

26 Guard, Canada (not shown)

NM-75k

892844

NM-125K, NM-215K

892845

-16-

LIMITEDWARRANTY

UnitedSta te sStoveCompanywarrantsthisproduct,totheoriginalretailpurchaseronly,tobefreefrom

defectsinmaterialandworkmanshipforaperiodofone(1)yearfromthedateoftheinitialpurchaseas

evidenced on an invoice, cancelled check, sales receipt, etc. In the event of a defect, this Limited

Warrantyshallbelimitedtothe repairorreplacementofparts,whichprovedefectiveundernormaluse

and service within the limited warranty period, and which United States Stove Company deems at its

reasonable discretion. THE LIMITED WARRANTY SET FORTH HEREIN IS THE SOLE WARRANTY

PROVIDED TO PURCHASER AND IS IN LIEU OF ALL OTHER WARRANTIES AND REPRESENTATIONS,

EXPRESS OR IMPLIED. UNITED STATES STOVE COMPANY MAKES NO REPRESENTATIONS OR

WARRANTIESWHATSOEVER,EXPRESSORIMPLIED,WITHRESPECTTOTHEPRODUCT,OTHERTHAN(i)

THELIMITE D WARRANTY ABOVE, AND(ii)ANY IMPLIEDWARRANTIES IMPOSEDBYAPPLICABLELAW

WHICH CANNOT BEWAIVED OR DISCLAIMEDUNDERAPPLICABLE LAW.ALL OTHER WARRANTIESOF

ANY KIND, INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIME D AND EXCLUDED TO THE FULLEST

EXTENTNOTPROHIBITEDBYAPPLICABLELAW.ThisLimitedWarrantygivesthepurchaserspecificlegal

rights;

apurchasermayhaveotherrightsdependinguponwhereheorsheresides.Somestatesdonot

allowtheexclusionorlimitationofspecial,incidentalorconsequential damages,orstatelawmayaffect

thedurationoflimitations,sotheaboveexclusiona nd limitationsmaynotbeapplicable.

OTHERLIMITATIONS:UnitedStatesSt oveCompanydisclaimsall otherwarrantiesforproductsthatare

purchased from sellers other than aut horized retailers or distributors. This product must be properly

installed, maintained and operated in accordance with the instructions provided herein. Furthermore,

United States S to v e Company requires reasonable proof of the date of purchase from an authorized

retailerordistributor.ThisLimited Warrantydoesnotcover any operation a l failures or difficulties due

to normal use and wear and tear, accident, abuse, misuse, alteration, misapplication, improper

installationorimpropermaintenanceorservicebyyouoranythirdparty.Failuretoperformnormaland

routinemaintenanceontheproduct,shippingdamage,damagerelatedtoanimals,anddamagedueto

weatherarenotcoveredunderthisLimitedWarranty.Inaddition, thisLimitedWarrantydoesnotcover

damage to the finish on the product, such as scratches, den ts, discoloration, rust or other weather

damage. This warranty does not

apply to products purchased for rental use.United States Stove

Company assumes no responsibility for any defects caused by third parties. United States S tove

Companydoesnotauthorizeanypersonorcompanytoassumeforitanyo therobligationorliabilityin

connectionwiththesale,installation,use,removal,return,orreplacementofitsproducts,andnosuch

representationsarebindingonUnitedStatesStoveCompany.

CLAIMPROCEDURE:Alltransportationcostsforthereturnofthedamagedproductorpartswillbethe

responsibilityofthepurchaser.Uponreceiptoftheproduct, UnitedStatesStoveCompanywillexamine

it and determine if the product contains a defect. United States Stove Company will repair or replace

and return the item, freight pre‐paid. If United States Stove Company finds the item to be in normal

operating condition, or not defective, th e item will be returned freight co ll ect. Purchaser shall specify

themodelnumber(s)andserialnumber(s)ofanyproduct(s)whenmakinganyclaims withUnitedStates

StoveCompany.Pleaseusethefollowingtoidentifyyourproduct:

Model#:____________________

Serial#:_____________________

-16-

GARANTIE LIMITÉE

L’entreprise United States Stove Company garantit ce produit, seulement à l'acheteur commercial original,

d’être sans défaut matériel ou manutentionnaire pour une période d’un (1) an, à partir de la date d’achat

initiale, tel que convenu sur la facture, sur le chèque annulé sur le reçu de l’achat, etc. En cas de défaut, cette

garantie limitée est limitée à la réparation ou au remplacement des pièces qui se prouvées défectueuses selon

l’usage normal et le service normal, convenu à l’intérieur de la garantie limitée, et qui est jugé convenable à

la discrétion de l’United States Stove Company. LA GARANTIE LIMITÉE DÉNOTÉE CI-JOINT EST LA SEULE GARANTIE

FOURNIE À L'ACHETEUR ET EST EN LIEU DE TOUT AUTRE GARANTIE OU REPRÉSENTATION, EXPRESSE OU IMPLICITE.

L’UNITED STATES STOVE COMPANY NE FAIT AUCUNE REPRÉSENTATION OU GARANTIE QUE CE SOIT, QU’ELLE SOIT

IMPLICITE OU EXPRESSE, EN RESPECT AU PRODUIT, AUTRE QUE (i) LA GARANTIE LIMITÉE MENTIONNÉE CI-DESSUS, ET

(ii) TOUTE GARANTIE IMPLICITE IMPOSÉE PAR LA LOI APPLICATION QUI NE PEUT ÊTRE ANNULÉE OU DÉCLINÉES SELON

LA LOI APPLICABLE. TOUTE AUTRE GARANTIE, DE TOUT GENRE, INCLUANT MAIS SANS S’Y LIMITER AUX GARANTIES

IMPLICITES DE QUALITÉ MARCHANDE OU D’APTITUDE POUR UN BUT PARTICULIER, SONT DONC DÉCLINÉES ET

EXCLUSES AU PLUS HAUT POINT SELON LA LOI APPLICABLE. Cette garantie limitée donne à l'acheteur des droits

légaux spécifiques; un acheteur pourrait avoir des droits différents selon son lieu de résidence. Certains états

ne permettent pas l'exclusion ou la limitation de dommages spécifiques, accessoires ou consécutifs, ou des lois

d’état qui peuvent affecter la durée des limitations; l’exclusion et les limitations précédentes pourraient ne pas

s’appliquer.

AUTRES LIMITATIONS: L’United States Stove Company décline toutes autres garanties pour les produits qui sont

achetés auprès d’autres vendeurs que ceux autorisés. Ce produit doit être proprement installé, entretenu et

doit fonctionner selon les instructions ci-jointes. De plus, l’United States Stove Company requiert une preuve

raisonnable de la date d'achat effectuée auprès du fournisseur ou du distributeur autorisé. Cette garantie limitée

ne couvre pas les échecs ou les difficultés opérationnelles dus à un usage régulier et à l’usure, aux accidents, aux

abus, à l’abus, aux altérations, à l’installation ou à l’entretien incorrects effectués par vous ou par une troisième

partie. Un échec d’effectuer l’entretien normal et routinier de ce produit, les dommages d’expédition, les

dommages effectués par des animaux, et ceux faits par les événements météorologiques ne sont pas couverts

dans cette garantie limitée. Également, cette garantie limitée ne couvre pas le dommage fait au fini de ce

produit, comme les égratignures, les bosses, la discoloration du produit, la rouille ou tout autres dommages faits

par les événements météorologiques. Cette garantie ne s’applique pas aux produits achetés pour la location.

L’United Stated Stove Company n’assume aucune responsabilité envers les défauts effectués par des troisièmes

parties. L’United States Stove Company n’autorise aucune personne ou aucune entreprise d’assumer pour elle-

même toute obligation ou toute forme de responsabilité pour la vente, l’installation, l’utilisateur, l’enlèvement, le

retour ou le remplacement de ses produits, et aucune de ces représentations ne permette de lier l’United States

Stove Company.

PROCÉDURE DE RÉCLAMATION: Tous les coûts de transport pour le retour d’un produit ou de pièces endommagés

seront de la responsabilité de l'acheteur. Au moment de la réception du produit, l’United States Stove Company

examinera et déterminera si le produit est défectueux ou non. L’United States Stove Company réparera ou

remplacement et retournera le produit, par transport prépayé. Si United States Stove Company trouve que le

produit fonctionne selon les normes de fonctionnement normales, et qu’il n'est pas défectueux, le produit sera

retourné par port dû. Les acheteurs devront spécifier le numéro du mpdèle et le numéro de série de tout produit

lorsqu’ils feront les réclamations auprès d’United States Stove Company. Veuillez fournir les informations suivantes

afin d’identifier votre produit:

Modèle ____________________

No de série: _____________________

-15-

Liste des pièces

Clé Description Marquette Partie N°

1 Ensemble de jauge de carburant

NM-75k

892822

NM-125K, NM-175K, NM-215K

892823

2 Ensemble de filtre à carburant

NM-75k

892824

NM-125K, NM-175K, NM-215K

892825

3 Ensemble de bouchon de carburant 892826

4 Interrupteur 80718

5 Compagnie aérienne

NM-75k

892813

NM-125K

892814

NM-175K, NM-215K

892815

6 Contrôle de limite de thermostat 80719

7 Photocellule 81274

8 Ensemble de buse

NM-75k

892827

NM-125K

892828

NM-175K

892829

NM-215K

892830

9 Bougie d'allumage 80729

10 Ensemble moteur et pompe

NM-75k

80742

NM-125K

80743

NM-175K

80744

NM-215K

80745

11 Insérer 83758

12 Rotor

NM-175K

80720

NM-215K

80721

NM-75K, NM-125K

80722

13 Lame (quatre)

NM-175K

80723

NM-215K

80724

NM-75K, NM-125K

80725

14 Ensemble du kit de filtration 892831

15 Couvercle de filtre de fin 892816

16 Ballon 83760

17 Printemps 83761

18 Ajuster la vis 83762

19 Kit Plug / Pump 83759

20 Ensemble de ventilateur

NM-75k

80746

NM-125K

80747

NM-175K

80748

NM-215K

80749

21 Allumeur

NM-125K

80726

NM-75K, NM-175K, NM-215K

80727

22 Fan Guard (plastique)

NM-75k

892817

NM-125K, NM-175K, NM-215K

892818

23 Ensemble principal P.C.B 80728

24 Thermistance 81275

25 Manipuler

NM-75k

892819

NM-125K, NM-175K, NM-215K

N/A

26 Garde, Canada (non représenté)

NM-75k

892844

NM-125K, NM-215K

892845

-14-

1

3

2

4

8

9

23

24

10

5

6

7

12

11

13

14

19

17

16

18

15

20

21

22

25

Diagramme des pièces

Afin de maintenir la garantie, les composants doivent être remplacés à l’aide des pièces originales du

fabricant achetées via votre revendeur ou directement auprès de NewmacPro en composant le 1-800-750-

2723. L’utilisation de composants tiers annulera la garantie.

-13-

NM-75K, NM-125K, NM-175K, NM-215K

Bougie d’allumage

Noir

Noir

Amorceur

Brun

Brun

Température ambiante.

Achage

Lampe

de combustion

TEMP. Cadran

de contrôle

Condensateur

Rouge Jaune

Pompe du

moteur

Noir

Bleu

Brun Bleu

Alimentation

Câble

d'alimentation

Jaune

/vert

Bleu

Interrupteur

Bleu

Thermostat

Fusible

NoirNoirNoirNoir

Cellule

photoélectrique

Thermistor

PCB PRINCIPAL

Diagramme des circuits électriques

Dépannage

Cause possible Résolution de problème

E1

Erreur de cellule photoélectrique (détecteur de couleur de flamme)

Pénurie de pétrole

Mauvaise cellule photoélectrique (détecteur de

flamme)

Combustion incomplète

Contamination du filtre de carburant

Échec d’allumage

Changez le carburant (remplissez le radiateur si nécessaire)

Vérifiez et nettoyez la cellule photoélectrique (détecteur de flamme)

Utiliser le carburant désigné

Nettoyez ou remplacez le filtre à carburant

Vérifiez la connexion des câbles

Vérifiez la bougie d’allumage pour un allumage régulier (nettoyez-le

ou remplacez-le si nécessaire)

E2

Erreur de détecteur de la température (thermistor)

Mauvaise connexion ou mauvais fonctionnement du

détecteur.

Vérifiez la connexion des câbles

Remplacez le détecteur

LO Sous 1°F Normal

HI Au-dessus de 99 °F Normal

OH

Le radiateur s'arrête lorsque la température atteint

140 °F

Redémarrez après le refroidissement

CN

Opération continue sans température

préprogrammée.

Normal

Clignote Erreur durant le fonctionnement

Vérifiez le code d’erreur

Redémarrez après la réinitialisation

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

NewMac NM-175K Operating Instructions Manual

- Catégorie

- Cheminées

- Taper

- Operating Instructions Manual

dans d''autres langues

- English: NewMac NM-175K

Autres documents

-

Mi-T-M MH-0400-0M10 Manuel utilisateur

Mi-T-M MH-0400-0M10 Manuel utilisateur

-

Mi-T-M MH-0600-0M10 Kerosene Portable Heater Le manuel du propriétaire

Mi-T-M MH-0600-0M10 Kerosene Portable Heater Le manuel du propriétaire

-

Mi-T-M MH-0125-0M10 Manuel utilisateur

-

Mi-T-M MH-0400-0M10 Kerosene Portable Heater Le manuel du propriétaire

Mi-T-M MH-0400-0M10 Kerosene Portable Heater Le manuel du propriétaire

-

L.B. White CP170AK Owner's Manual And Instructions

L.B. White CP170AK Owner's Manual And Instructions

-

L.B. White CP400AK Owner's Manual And Instructions

L.B. White CP400AK Owner's Manual And Instructions

-

Heat Stream HS-215T-KFA Mode d'emploi

Heat Stream HS-215T-KFA Mode d'emploi

-

Mi-T-M Propane Directional Heater Le manuel du propriétaire

Mi-T-M Propane Directional Heater Le manuel du propriétaire

-

Warm Tech WTCAC30R-DU Le manuel du propriétaire

-

DeWalt DXH75KTHC Mode d'emploi