Cascade Instructions Document 1349A

H2384200A

WARNING

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler and heater installation and maintenance. Improper installation and/or operation

could create carbon monoxide gas in ue gases which could cause serious injury, property damage, or

death. Improper installation and/or operation will void the warranty.

AVERTISSEMENT

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ou ni

d’autres vapeurs ou liquides inammables dans

le à proximité de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous servir

des téléphones dans le bâtiment où vous vous

trovez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié

ou par le fournisseur de gaz.

Cascading the

Wall-Mounted, Modulating

Gas, Condensing,

Heating Only, Boiler

Model MFTHW

80,000 BTU/hr

100,000 BTU/hr

120,000 BTU/hr

140,000 BTU/hr

199,000 BTU/hr

• Natural Gas (NG)

Factory Conguration

• Propane Gas (LP)

Field-Convertible

FT

SERIES

Page 2

Table of Contents

SECTION 1

Piping

A. General Plumbing Connection Guidelines ... 3

B. Install a Backow Preventer ......................... 3

C. Piping Diagrams for Cascading Systems . . 3-7

SECTION 2

Electrical

A. Wiring Connections for Cascade ..................... 8

B. Terminal Blocks ............................................ 9

SECTION 3

The Control Display

A. The Control Display .................................... 10

B. The LCD ..................................................... 10

C. Start-Up Sequence ..................................... 11

SECTION 4

Cascade Programming

A. Programming a Cascade System .............. 12

B. The Cascade CH Function ....................13-14

C. Domestic Hot Water ‘Storage Mode’

for Cascade System ................................... 14

D. Cascade System Error Codes .................... 15

Page 3

Cascading the

FT Series ‘Heating Only’ Boiler

WARNING

WARNING

To control thermal expansion, a thermal expansion tank should be installed in systems with an

installed backflow preventer. DO NOT use a closed type expansion tank. Follow expansion tank

manufacturer’s specications to properly size an expansion tank to the installation. Failure to properly

accommodate thermal expansion could result in property damage, severe personal injury, or death.

Do not use FT Series units on common vents. Each unit must have its own supply and exhaust vents.

SECTION 1 Piping

A. General Plumbing Connection Guidelines

• Pipe material must be suitable to meet local codes and industry standards.

• The pipe must be cleaned and without blemish before any connections are made.

• Do not apply a torch within 12˝ of the bottom connections of the Heating Only Boiler. Doing so could

damage the Heating Only Boiler. Such damages ARE NOT covered by product warranty.

• The size of the CH supply pipe should be 1¼˝ diameter.

• Isolation (shutoff valves) should be used to ease future servicing.

• All piping should be insulated.

Multiple FT Series boilers can be connected via a cascade communication cable to create a

bank of boilers that work in tandem. Up to 20 boilers can be controlled by a “Leader” FT Series

boiler with the others acting as “Followers”.

B. Install a Backow Preventer

It may be recommended to use a back ow preventer – check local codes. If a back ow preventer or a

no return valve is used, a thermal expansion tank must be installed on the cold water supply between

the Heating Only Boiler and valve.

C. Piping Diagrams for Cascading Systems

Use at least the MINIMUM pipe size for all Heating Only Boiler loop piping. This is to avoid the

possibility of inadequate ow through the Heating Only Boiler. Using less than the required minimum

pipe size and piping could result in system problems, property damage, and premature Heating

Only Boiler failure. Such problems ARE NOT covered by product warranty.

CAUTION

Use both thread tape and pipe dope to connect to the 1¼˝ CH supply and return. Isolation valves

between the city water supply and inlet are recommended for ease of service.

Cascade Manifold Pipe Sizing (inches)

SIZE

Number of Cascaded Mascot FT Units

2

3

4

5

6

7

8

80

1 1/4

1 1/2

2

2

2

2 1/2

3

100

1 1/2

2

2

2 1/2

2 1/2

3

3

120

1 1/2

2

2 1/2

2 1/2

3

3

3

140

2

2

2 1/2

2 1/2

3

3

4

199

2

2 1/2

3

3

4

4

4

Note: Based on copper pipe and a 20°F Delta T with maximum water velocities of 4-1/2 ft per second

The next four pages give examples of typical cascading hydronic piping diagrams.

Number of cascaded FT units

Page 4

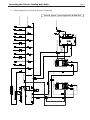

Do not exceed 12" apart

PRIMARY LOOP

SECONDARY LOOP (SPACE HEATING)

CH SUPPLY

(SPACE HEATING)

PRIMARY/SECONDARY

CONNECTION

Do not exceed 12" apart

PRIMARY LOOP

SECONDARY LOOP (SPACE HEATING)

CH SUPPLY

(SPACE HEATING)

PRIMARY/SECONDARY

CONNECTION

ZONE 1

ZONE 2

ZONE 3

FLOOR HEATING

CH RETURN

Circulation pump

Pressure relief valve

Expansion tank

Air separator

(Diaphragm type)

Isolation valve

Check valve

Gate valve

Circulation pump

Pressure relief valve

Expansion tank

Air separator

(Diaphragm type)

Isolation valve

Check valve

Gate valve

CH SUPPLY

CH RETURNCH RETURN

CH SUPPLY

CH RETURN

Cascade System - Diaphragm type Expansion tank

Piping Symbol Legend

Mixing Valve

Circulation pump

Pressure relief valve

Expansion tank

Air separator

(Closed type)

Expansion tank

(Diaphragm type)

Isolation valve

Check valve

Gate valve

2-way valve

Indirect DHW Tank

Air Separator

Pressure Reducing

Valve

NOTE: These drawings are meant to show system piping concept only. Installer is responsible for

all equipment and detailing required by local codes.

C. Piping Diagrams for Cascading Systems (continued)

Page 5

Cascading the

FT Series ‘Heating Only’ Boiler

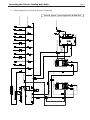

Cascade System - Zoning with circulation pump

Do not exceed 12" apart

PRIMARY LOOP

SECONDARY LOOP (SPACE HEATING)

CH SUPPLY

(SPACE HEATING)

PRIMARY/SECONDARY

CONNECTION

Do not exceed 12" apart

PRIMARY LOOP

SECONDARY LOOP (SPACE HEATING)

CH SUPPLY

(SPACE HEATING)

PRIMARY/SECONDARY

CONNECTION

ZONE 1

ZONE 2

ZONE 3

FLOOR HEATING

CH RETURN

Circulation pump

Pressure relief valve

Expansion tank

Air separator

(Diaphragm type)

Isolation valve

Check valve

Gate valve

Circulation pump

Pressure relief valve

Expansion tank

Air separator

(Diaphragm type)

Isolation valve

Check valve

Gate valve

CH SUPPLY

CH RETURNCH RETURN

CH SUPPLY

CH RETURN

Page 6

PRIMARY LOOP

CH SUPPLY

(SPACE HEATING)

ZONE 1

ZONE 2

ZONE 3

FLOOR HEATING

SECONDARY LOOP (SPACE HEATING)

Do not exceed 12" apart

CH RETURN

Circulation pump

Pressure relief valve

Expansion tank

Air separator

(Diaphragm type)

Isolation valve

Check valve

Gate valve

CH SUPPLY

CH RETURN

CH SUPPLY

CH RETURN

DHW Pump

Pressure relief valve

Indirect DHW Tank

Isolation Valve

2-way valve

Mixing Valve

DHW Pump

Indirect DHW Tank

CH SUPPLY

CH RETURN

PRIMARY LOOP

CH SUPPLY

(SPACE HEATING)

ZONE 1

ZONE 2

ZONE 3

FLOOR HEATING

SECONDARY LOOP (SPACE HEATING)

Do not exceed 12" apart

CH RETURN

Circulation pump

Pressure relief valve

Expansion tank

Air separator

(Diaphragm type)

Isolation valve

Check valve

Gate valve

CH SUPPLY

CH RETURN

CH SUPPLY

CH RETURN

DHW Pump

Pressure relief valve

Indirect DHW Tank

Isolation Valve

2-way valve

Mixing Valve

DHW Pump

Indirect DHW Tank

CH SUPPLY

CH RETURN

Cascade System - Indirect Water Heating

C. Piping Diagrams for Cascading Systems (continued)

Cascade System - Zoning with zone valve

Page 7

Cascading the

FT Series ‘Heating Only’ Boiler

Leader Follower

Cascade System

Closely spaced tees

Make up water

Indirect DHW Tank

CH System Pump

DHW System Pump

DHW TEMP

SENSOR

sensor

Space heating zone

circuit

Zone circulators

Purging valves

Cold water

Cascade System - System Application & DHW Tank

C. Piping Diagrams for Cascading Systems (continued)

Page 8

SECTION 2 Electrical

A. Wiring Connections for Cascade

(CN1 RS-485)

(CN1 RS-485)

Ending

Resistor

Last Male

Connector.

Wrap it up neatly and wire-tie it.

It does not need a cap or an end.

Primary

Connector.

Primary

Connector.

Last Female

Connector.

Plug the included

‘Ending Resistor’ into it.

Components Needed :

FT1868 : System Sensor (need only 1).

FT1861 : FT Series/ST Cascade Communication Cable (1 per unit) with Ending Resistor.

Example. If you are cascading 6 units, you will need 6 X FT1861’s and you will throw away

5 of the resistors.

A system sensor must be connected to the master boiler in order to provide feedback for set point

temperature reference and therefore properly control the bank of cascaded boilers.

In order for the system to work properly, the thermostat, 0-10V signal, and/or outdoor sensor must be

connected to the Leader boiler only. Following boilers will run based on the Leader boiler’s controls.

Reference the FT Series Heating Only Installation and Operation manual (1342-NH) to set the Leader

boiler’s temperature set point based on an outdoor sensor, 0-10V signal or a xed temperature set point.

1. Turn off the power.

2. Remove the front covers of the units (4 screws on each unit).

3. Connect the ‘Cascade Communication Cables’ to every unit (add the Resistor to the

end of the last follower. Use the wiring throughway at the bottom of each unit.

4. Plug the primary connector on the cable (as shown) to the receptacle inside the unit.

5. Replace the front covers.

6. Turn on the power.

Page 9

Cascading the

FT Series ‘Heating Only’ Boiler

DHW

PUMP

CH

PUMP

0-10V

Connection

Thermostat

Connection

Outdoor

Sensor

Connection

DHW

TEMP

SENSOR

CASCADE

SYSTEM

SENSOR

LOW

WATER

CUTOFF

B. Terminal Blocks

Page 10

SECTION 3 The Control Display

B. The LCD

The LCD features a backlit

lamp that will illuminate when

a user presses a button.

The display will time out after

approximately 2 minutes.

• Temperature Specications

Operating ambient Temperature Range : -10 to 60°C.

Operating Relative Humidity up to: 90% at 40°C.

Shipping & Storage Temperature Range of : -20 to 80°C.

Buttons

Functionality

PRESS (Tap) PRESS and HOLD (5 seconds)

A

Display Power

Turns Control Display ON / OFF

B Modes Tap to return to menu

(If Display Power was On ) Status Display Mode

(If Display Power was Off ) Installer Mode

C

Heating

Water

CH set-point change mode

(Maxium 82

°C(180°F))

D

Time / Date

Set

No Change To SET: Year/Month/Week/Day/Time/Min

E

Scroll / Select

Menu select or value

up(+)/down(-) or setting dial.

The Control Display has a Control Dial (E), 4 buttons (A, B, C, D), and a Liquid Crystal Display

(with 72 back-lit segments). Section 3 will show you only a few of the functions of the FT Series.

For all functions, please review the FT Series Install and Instruction Manual. Doc 1342.

Status Light

(constant green

when operating

normally)

E

Page 11

Cascading the

FT Series ‘Heating Only’ Boiler

C. Start-Up Sequence

After the appliance is powered ON, the LCD display shows a sequence of information. The icons will ash,

followed by various indicators that describe the appliance controller and software versions.

After start-up, the display appears as follows.

The Control Display can operate through user and service modes that have specific LCD outputs and

dedicated controls, including:

• Changing the Set-Point Temperature

• Error Mode

• Status Display Mode

• Installer Mode

Symbol Name Description

Service Reminder mode Service Reminder mode indication

Outside Temperature Mode Outside Temp setting indication

Anti-freeze mode Anti-freeze mode indication

Storage mode Storage mode indication

Information mode Information mode indication

Communication state Communication state indication

Time setting mode Time /Dispaly/Install mode indication

Fan operating mode Fan operating mode indication

Flame signal Flame Signal indication

CH pump mode CH pump mode indication

Storage pump mode Storage pump mode indication

Internal recirculation mode Internal recirculation mode indication

Celsius mode Indicated as Celsius temperature

Fahrenheit mode Indicated as Fahrenheit temperature

Heat demand mode Heat demand mode indication

DAY mode Current day mode indication

Cascade System connecting

mode

Cascade System connecting mode

indication

Cascade System operating mode

Cascade System operating mode

indication

B. The LCD (continued)

Page 12

SECTION 4 Cascade Programming

A. Programming a Cascade System

AUTODESK � � � � � � � � � �

AUTODESK � � � � � � � � � �

AUTODESK � � � � � � � � � �

AUTODESK � � � � � � � � � �

AUTODESK � � � � � � � � � �

AUTODESK � � � � � � � � � �

AUTODESK � � � � � � � � � �

AUTODESK � � � � � � � � � �

7. REPEAT steps 1 thru 6 with all following units in

sequence.

5. Then turn the dial to 27:Cn – Set the Number to

00. The Leader unit should always be addressed to

00. The Following units will then start at 01 and go

sequencially from there.

NOTE:

Do NOT change 29:Eh (Common Vent). This

Installer Parameter must always be set to 'Off'.

Once all of the 'Connection Wires' are made and all units are powered on, there are 2 items that need to

be programmed on all units. Start with the Lead Unit and then Repeat on all Following Units.

28: cP – (

PARAMETER)

The

TOTAL NUMBER

of units cascaded. Range: 01 - 20, The Default is 01 so

the Leader must be set to 01. Follower 1 set to 02, follower 2 set to 03, etc.

THEN

27: cn– (

NUMBER

) This is each units ASSIGNED NUMBER. Default 00. Range: 00 - 19 with 00 as the

Leader, 01 (follower 1), 02 (follower 2), etc.

6. Finish by pressing the button.

1.

START

by turning OFF the Power to the Display Control.

2. Then, with the power OFF, Press and HOLD (5 seconds) the

button to get into the Installer Mode.

3. Rotate the Dial until you get to 28cP. Tap Dial E to

enter into that Parameter.

4. Adjust to the Total Number of Units in the Cascaded

System. Range is Default at 01 and goes up to 20 units.

then press (tap) the Dial to save and to Exit.

Page 13

Cascading the

FT Series ‘Heating Only’ Boiler

B. The Cascade CH Function

1. The Leader unit controls all follower units' operation and combustion. All follower units follow what Leader

unit outputs. (Operating temperature and clock will only be controlled on Leader unit , but displayed on

Follower unit )

2. When Cascade is set for auto, the Leader boiler arranges which unit operates and for how long, when there

is a call for heat (CH), the Leader boiler controls the follower units either to increase or reduce ring rate.

* Installer mode 30: Cr -> Cr:at(Default)

3. When Cascade is set for cascade rotation time, the Leader boiler rotates the boilers based on a xed

operating time limit. Each boiler is run (when there is a call for heat) until it reaches the operating time

limit, at which point the Leader boiler turns that boiler off and replaces it in the ring sequence with a boiler

that has been off. In this way, the rst boiler on will be the rst boiler off, and that rst boiler will not turn on

again until the remaining boilers have each run for the operating time limit, as needed to meet demand.

*Installer mode 30: Cr -> Cr:Ct

4. Cascade mode operates via system sensor. Units shut off when system sensor reaches system target

temperature.

5. When each corresponding unit is operating the built in boiler pump operates. Also if a single unit is

operating the external CH pump operates

6. Only the Leader unit needs to be wired to the boiler pump.

Indicate Indicator

Current CH Temperature Set-Point

Celsius or Fahrenheit

or

If Communication state is activated

If ame is detected

Date and Time indicator

If CH pump is operating

If there currently a Demand for Central Heat (CH)

Default CH set-point is 180°F (82°C)

CH set-point range is 86°F ~180°F (30.0°C ~ 82.0°C)

Changing the CHW Set-Point,

press the C

button. The CH Icon and current

CH Setpoint will ash. Turn the E dial clockwise

to increase, and counterclockwise to decrease CH

setpoint, until desired temperature is reached.

Press E dial to save changes and to Exit.

B C

E

A D

NOTE: When you set the temperature set point

on the Leader Heating Only Boiler, it will

automatically be applied to the followers.

Page 14

Cascade Operation Sequence: The rst boiler in the rotation sequence will re to satisfy a call for heat. Once

this boiler reaches 80% of full re the rst boiler will modulate down and a second boiler will be brought on to

split the load between boilers. If the heat demand is not satised a third boiler will be brought on in the same

manner, splitting the heat between the three boilers. This mode of operation will continue until enough boilers

are brought on to satisfy the demand.

As the heating demand is met the boilers will be shut down in reverse order, shutting down each boiler as it

reaches 40% of re, until all boilers are shut down.

Index Numbers Parameter Description

30:Cr

Cr:at Automatic rotation (default)

The rst unit to operate when there is a T/T call is the unit

that ran the least amount of time during the prior heat calls

(burner ON time). Default auto

Cr:Ct Cascade Rotation time

Cascade Rotation time, Range: 0-240 Hours,

Default 48Hours

31: Ct Cascade System temperature

Cascade System temperature:

Range: 95°F – 180°F, Default 180°F

32: Cd

Cascade System Temperature

Differential (burner ON)

Cascade System Temperature Differential (burner ON)

Range: 5-30 °F, Default 10 °F

B. Cascade CH Function (continued)

C. Domestic Hot Water ‘Storage Mode’ for Cascade System.

The boiler cascade system can be set up for Domestic Hot Water by using either a DHW Sensor or DHW

Aquastats with a tank. Note that they are setup differently.

The default DHW priority time is 30 minutes and can be adjusted from 0 to 60 minutes using parameter 24: dP,

see below parameter table.

Using a DHW Sensor

If a DHW sensor is used, the DHW Sensor leads must be connected to the Leader Boiler on the terminal strip

labeled “DHW TEMP SENSOR” (page 9) and sensor installed in the tank.

In this mode the tank sensor will control demand and modulation based on the DHW setpoint (21:dh). In the

case of indirect heaters the boiler will also modulate on the outlet water temperature sensor (25:st).

The DHW System Pump must be connected to the Leader Boiler (same boiler that the DHW sensor is connected

to) on the terminal strip labeled “DHW Pump” (page 9).

Using Aquastats

If a DHW aquastat is used, the maximum DHW load needs to be calculated to determine the number of boilers

required to meet max DHW load. The aquastat must be installed in the tank and wired to each boilers’ terminal

strip “DHW TEMP SENSOR” connection (page 9). Wire the boilers in series with the aquastat: aquastat to rst

boiler and then from boiler to boiler.

The DHW System Pump must be connected to the rst boiler among those selected to handle the domestic

water load on the terminal strip labeled “DHW Pump” (page 9).

Page 15

Cascading the

FT Series ‘Heating Only’ Boiler

D. Cascade System Error Codes

For a complete list of error codes, reference the FT Series Installation and Operation Manual 1342.

Domestic Hot Water Parameters

For a complete list of parameters, reference the FT Series Installation and Operation Manual 1342.

If a DHW aquastat is used, the maximum DHW load needs to be calculated to determine the number of boilers

required to meet max DHW load. The aquastat must be installed in the tank and wired to each boilers’ terminal

strip “DHW TEMP SENSOR” connection (page 10). They can be wired either in parallel (straight from the

aquastat to each boiler) or in series (aquastat to first boiler and then from boiler to boiler).

The DHW System Pump must be connected to the first boiler among those selected to handle the domestic

water load on the terminal strip labeled “DHW Pump” (page 10).

Domestic Hot Water Parameters

For a complete list of error codes reference the Mascot FT Installation and Operation Manual 1342

Index

Numbers

Parameter Description

21: dH

Indirect Storage Tank

Temperature Set Point

Sets Maximum Indirect storage tank

Temperature Range: 95 - 180°F , Default 120 °F

22: dd

Indirect Storage Tank

Differential Set Point

DHW Differential Set Point Range: 5°F-30°F,

Default 7 °F

23: Pr

DHW Pump Post Run Time

DHW Pump Post Run Time Range: 0-10 Min,

Default 1 Min

24: dP

DHW Priority Timer

DHW Priority Timer Range: 0 – 60 Min , Default

30 Min

25: St

Boiler Supply Indirect Storage

Tank Temperature

Boiler Supply Indirect Tank Temperature Range:

120 °F– 180 °F , Default 180 °F

ADD NEW ERROR SECTION

D. Typical Cascade Error Codes

For a complete list of error codes reference the Mascot FT Installation and Operation Manual 1342

Er:30

System Sensor Short

NOTE: This error will only appear if the boiler is used in a cascaded system.

This Error Code will go away when system sensor is repaired or replaced.

1. Check system temperature sensor. Ensure connections are secure.

2. Check system sensor resistance. If resistance is zero, replace the sensor.

3. If the problem persists, replace the main control.

NOTE: During the error state the units will continue to operate. Boiler setpoint

will be the same as the system sensor setpoint until the issue is remedied.

During normal operation boiler setpoint is defaulted to 20°F higher than the

system setpoint to a maximum of 180°F setting

Er:78

Cascade

Communication Error

NOTE: This error will only appear in a cascaded system.

1. Turn power OFF and ON at the boiler display panel.

2. If error reappears, ensure all cascaded boilers are powered ON.

3. If error reappears, check Installer Mode parameter 28 at the Leader boiler.

Ensure the number of cascaded units chosen in this parameter matches the

number of cascaded units in the system.

4. If error reappears, check Installer Mode parameter 27 at all cascaded

boilers. Ensure the address number matches that of the connected boiler (00

for Leader, 01 for Follower 1, etc.) and that no numbers are skipped or

repeated.

5. Ensure every unit in the cascade system is connected properly. Inspect the

cascade cables and ensure all are connected without damage or defect.

Repair or replace any damaged cables.

6. If the problem persists, replace the main control.

Er:30

System Sensor

Short

NOTE: This error will only appear if the boiler is used in a cascaded

system.

This Error Code will go away when system sensor is repaired or

replaced.

1. Check system temperature sensor. Ensure connections are secure.

2. Check system sensor resistance. If resistance is zero, replace the

sensor.

3. If the problem persists, replace the main control.

NOTE: During the error state the units will continue to operate. Boiler

setpoint will be the same as the system sensor setpoint until the issue is

remedied. During normal operation boiler setpoint is defaulted to 20°F

higher than the system setpoint to a maximum of 180°F setting

Er:78

Cascade

Communication

Error

NOTE: This error will only appear in a cascaded system.

1. Turn power OFF and ON at the boiler display panel.

2. If error reappears, ensure all cascaded boilers are powered ON.

3. If error reappears, check Installer Mode parameter 28 at the Leader

boiler. Ensure the number of cascaded units chosen in this parameter

matches the number of cascaded units in the system.

4. If error reappears, check Installer Mode parameter 27 at all cascaded

boilers. Ensure the address number matches that of the connected

boiler (00 for Leader, 01 for Follower 1, etc.) and that no numbers are

skipped or repeated.

5. Ensure every unit in the cascade system is connected properly.

Inspect the cascade cables and ensure all are connected without

damage or defect.

Repair or replace any damaged cables.

6. If the problem persists, replace the main control.

C. Domestic Hot Water ‘Storage Mode’ for Cascade System (continued)

H2384200A

Notes:

Customer Service and Product Support: 800.900.9276 • Fax 800.559.1583

20 Industrial Way, Rochester, NH, USA 03867

1802 Document 1349A

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

Bradford White BMFTCW-199 Manuel utilisateur

- Taper

- Manuel utilisateur

- Ce manuel convient également à

dans d''autres langues

Documents connexes

-

Bradford White BMFTHW-199 Manuel utilisateur

-

Bradford White BMFTHW-199 Manuel utilisateur

-

Bradford White BMFTCF-199 Manuel utilisateur

-

Bradford White BMFTHW-199 Manuel utilisateur

-

Bradford White BMFTCW-140 Manuel utilisateur

-

Bradford White BMFTHW-199 Manuel utilisateur

-

Bradford White BMFTHW-199 Manuel utilisateur

-

Bradford White BFTHF-199 Manuel utilisateur

-

Bradford White BMFTCW-140 Manuel utilisateur

-

Bradford White FTHW301 Manuel utilisateur

Autres documents

-

FTHW Wall-Mounted Gas Condensing Heating Only Boiler Manuel utilisateur

-

Bryant BWH Le manuel du propriétaire

-

Raypak XVers L 406L-856L Type H Mode d'emploi

-

Laars MASCOT LX Manuel utilisateur

-

Laars LMH Manuel utilisateur

-

Daikin EBLQ036BA6VJU1 Guide d'installation

-

ACV Prestige 42, 50, 75, 100, 120 Solo (v14) Mode d'emploi

-

ACV HeatMaster C, TC Technical Manual

-

ACV Prestige 24 / 32 Solo / Excellence (v15) Mode d'emploi

-

HTP Mod Con Commercial Gas Boiler Installation Drawings