Empire Heating Systems Direct-Vent Wall Furnace (DV25/35) Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

Page 1

DIRECT VENT

WALL FURNACE

MODELS

DV-25-5SG

DV-35-4SG

This appliance may be installed in an after-

market, permanently located, manufactured

home (USA only), or mobile home, where not

prohibited by state or local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with other

WARNING

FIRE OR EXPLOSION HAZARD

If the information in these instructions is

result causing property damage, personal

injury or loss of life.

— Do not store or use gasoline or other

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

not use any phone in your building.

from a neighbor’s phone. Follow the

gas supplier’s instructions.

— Installation and service must be

service agency or the gas supplier.

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

WARNING

If not installed, operated and maintained in

accordance with the manufacturer's instruc-

tions, this product could expose you to sub-

stances in fuel or from fuel combustion which

can cause death or serious illness.

INSTALLATION INSTRUCTIONS

AND OWNER'S MANUAL

37408-5-0919Page 2

TABLE OF CONTENTS

Important Safety Information ..........................................................................................................3

Safety Information for Users of Propane Gas ................................................................................4

Requirements for Massachusetts ...................................................................................................5

Introduction..................................................................................................................................6-7

Specications .................................................................................................................................7

Gas Supply .....................................................................................................................................8

Clearances ..................................................................................................................................10

Installation Instructions ............................................................................................................10-12

Optional Thermostat Location ......................................................................................................13

Lighting Instructions ....................................................................................................................14

Pilot Flame Characteristics ..........................................................................................................15

Main Burner Flame Characteristics .............................................................................................15

Maintenance .................................................................................................................................16

Troubleshooting ............................................................................................................................16

Master Parts Distributor List .........................................................................................................17

How to Order Repair Parts ...........................................................................................................17

Parts List .....................................................................................................................................18

Parts View ....................................................................................................................................19

Optional Blower Installation Instructions ................................................................................20-21

Appliance Service History .......................................................................................................22-23

Warranty .......................................................................................................................................24

SECTION PAGE

37408-5-0919 Page 3

draperies.

of high surface temperatures and should stay away

to avoid burns or clothing ignition.

they are in the same room as the appliance.

placed on or near the appliance.

an appliance must be replaced prior to operating

the appliance.

Installation and repair should be done by a QUALI-

FIED SERVICE PERSON. The appliance should be

inspected before use and at least annually by a

-

ing, bedding materials, etc. It is imperative that

control compartments, burners and circulating air

passageways of the appliance be kept clean.

put anything around the furnace that will

keep the appliance area clear and free from

examine venting system periodically and replace

damaged parts.

make a periodic visual check of pilot and burner.

Clean and replace damaged parts.

closed during operation.

use this heater if any part has been under

-

cian to inspect the heater and to replace any part

of the control system and any gas control which

has been under water.

THIS IS A HEATING APPLIANCE

DO NOT OPERATE THIS APPLIANCE WITHOUT FRONT PANEL INSTALLED.

IMPORTANT SAFETY INFORMATION

37408-5-0919Page 4

SAFETY INFORMATION FOR USERS OF PROPANE GAS

-

sions. In its natural state, propane is odorless and colorless.

You may not know all the following safety precautions which

can protect both you and your family from an accident. Read

them carefully now, then review them point by point with the

members of your household. Someday when there may not

be a minute to lose, everyone's safety will depend on knowing

exactly what to do. If, after reading the following information,

you feel you still need more information, please contact your

gas supplier.

PROPANE GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas

because of the odorant put in the Propane Gas.

That's your signal to go into immediate action!

• Donotoperateelectricswitches,lightmatches,useyourphone.

Do not do anything that could ignite the gas.

• Geteveryoneoutofthebuilding,vehicle,trailer,orarea.Do

that IMMEDIATELY.

• Closeallgastankorcylindersupplyvalves.

• PropaneGasisheavierthanairandmaysettleinlowareas

such as basements. When you have reason to suspect a gas

leak,keepoutofbasementsandotherlowareas.Stayout

untilreghtersdeclarethemtobesafe.

• Useyourneighbor'sphoneandcallatrainedPropaneGas

servicepersonandtheredepartment.Eventhoughyoumay

notcontinuetosmellgas,donotturnonthegasagain.Donot

re-enterthebuilding,vehicle,trailer,orarea.

• Finally, lettheservicemanandreghterscheckforescaped

gas. Have them air out the area before you return. Properly

trainedPropaneGasservicepeopleshould repairtheleak,

thencheckandrelightthegasapplianceforyou.

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell the

odorofthechemicalputintothegas.Youmustndoutifyoucan

smelltheodorantinpropane.Smokingcandecreaseyourabilityto

smell. Being around an odor for a time can affect your sensitivity or

abilitytodetectthatodor.Sometimesotherodorsintheareamask

the gas odor. People may not smell the gas odor or their minds are

onsomethingelse.Thinkingaboutsmellingagasodorcanmake

it easier to smell.

TheodorantinPropaneGasiscolorless,anditcanfadeundersome

circumstances.Forexample,ifthereisanundergroundleak,the

movementofthegasthroughsoilcanltertheodorant.Odorants

in Propane Gas also are subject to oxidation. This fading can occur

ifthereisrustinsidethestoragetankorinirongaspipes.

The odorant in escaped gas can adsorb or absorb onto or into

walls,masonryandothermaterialsandfabricsinaroom.Thatwill

takesomeoftheodorantoutofthegas,reducingitsodorintensity.

PropaneGasmaystratifyinaclosedarea,andtheodorintensity

couldvaryatdifferentlevels.Sinceitisheavierthanair,theremay

be more odor at lower levels. Always be sensitive to the slightest gas

odor.Ifyoudetectanyodor,treatitasaseriousleak.Immediately

go into action as instructed earlier.

SOME POINTS TO REMEMBER

•

Learn to recognize the odor of Propane Gas. Your local Pro-

pane Gas Dealer can give you a "Scratch and Sniff" pamphlet.

Useittondoutwhatthepropaneodorsmellslike.Ifyou

suspectthatyourPropaneGashasaweakorabnormalodor,

call your Propane Gas Dealer.

• Ifyouarenotqualied,donotlightpilotlights,performservice,

ormakeadjustmentstoappliancesonthePropaneGassystem.

Ifyouarequalied,consciouslythinkabouttheodorofPropane

Gas prior to and while lighting pilot lights or performing service

ormakingadjustments.

• Sometimesa basement or aclosed-up house has a musty

smell that can cover up the Propane Gas odor. Do not try to

lightpilotlights,performservice,ormakeadjustmentsinan

area where the conditions are such that you may not detect

theodoriftherehasbeenaleakofPropaneGas.

• Odorfade,duetooxidationbyrustoradsorptiononwallsof

newcylindersandtanks,ispossible.Therefore,peopleshould

beparticularlyalertandcarefulwhennewtanksorcylinders

areplacedinservice.Odorfadecanoccurinnewtanks,or

reinstalledoldtanks,iftheyarelledandallowedtosettoo

longbeforerelling.Cylindersandtankswhichhavebeenout

of service for a time may develop internal rust which will cause

odorfade.Ifsuchconditionsaresuspectedtoexist,aperiodic

sniff test of the gas is advisable. If you have any question about

thegasodor,callyourPropane Gas dealer. A periodic sniff

test of the Propane Gas is a good safety measure under any

condition.

• If,atanytime,youdonotsmellthePropaneGasodorantand

youthinkyoushould,assumeyouhavealeak.Thentakethe

same immediate action recommended above for the occasion

when you do detect the odorized Propane Gas.

• Ifyouexperienceacomplete"gasout,"(thecontainerisunder

novaporpressure),turnthetankvalveoffimmediately.Ifthe

containervalveislefton,thecontainermaydrawinsomeair

throughopeningssuchaspilotlightorices.Ifthisoccurs,some

newinternalrustingcouldoccur.Ifthevalveisleftopen,then

treatthecontainerasanewtank.Alwaysbesureyourcon-

tainer is under vapor pressure by turning it off at the container

beforeitgoescompletelyemptyorhavingitrelledbeforeitis

completely empty.

37408-5-0919 Page 5

REQUIREMENTS FOR MASSACHUSETTS

For all side wall horizontally vented gas fueled equipment installed

ineverydwelling,buildingorstructureusedinwholeorinpartfor

residential purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent termination

islessthanseven(7)feetabovenishedgradeintheareaofthe

venting,includingbutnotlimitedtodecksandporches,thefollowing

requirementsshallbesatised:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS.

At the time of installation of the side wall horizontal vented

gasfueledequipment,theinstallingplumberorgasttershall

observe that a hard wired carbon monoxide detector with an

alarmandbatteryback-upisinstalledontheoorlevelwhere

thegasequipmentistobeinstalled.Inaddition,theinstalling

plumberorgasttershallobservethatabatteryoperatedor

hard wired carbon monoxide detector with an alarm is installed

oneachadditionallevelofthedwelling,buildingorstructure

served by the side wall horizontal vented gas fueled equipment.

It shall be the responsibility of the property owner to secure the

servicesofqualiedlicensedprofessionalsfortheinstallation

of hard wired carbon monoxide detectors

a. In the event that the side wall horizontally vented gas fu-

eledequipmentisinstalledinacrawlspaceoranattic,

the hard wired carbon monoxide detector with alarm and

batteryback-upmaybeinstalledonthenextadjacentoor

level.

b. In the event that the requirements of this subdivision can not

bemetatthetimeofcompletionofinstallation,theowner

shallhaveaperiodofthirty(30)daystocomplywiththe

aboverequirements;provided,however,thatduringsaid

thirty(30)dayperiod,abatteryoperatedcarbonmonoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each carbon

monoxide detector as required in accordance with the above

provisions shall comply with NFPA 720 and be ANSI/UL 2034

listedandIAScertied.

3. SIGNAGE.Ametalorplasticidenticationplateshallbeper-

manently mounted to the exterior of the building at a minimum

heightof eight (8) feetabove grade directly in linewith the

exhaust vent terminal for the horizontally vented gas fueled

heatingapplianceorequipment.Thesignshallread,inprintsize

nolessthanone-half(1/2)inchinsize, “GAS VENT DIRECTLY

4. INSPECTION. The state or local gas inspector of the side wall

horizontally vented gas fueled equipment shall not approve

theinstallationunless,uponinspection,theinspectorobserves

carbon monoxide detectors and signage installed in accordance

withtheprovisionsof248CMR5.08(2)(a)1through4.

(b) EXEMPTIONS:Thefollowingequipmentisexemptfrom

248CMR5.08(2)(a)1through4:

1. The equipment listed in Chapter 10 entitled “Equip-

ment Not Required To Be Vented” in the most current

edition of NFPA 54 as adopted by the Board; and

2. Product Approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separatefromthedwelling,buildingorstructureused

in whole or in part for residential purposes.

(c) MANUFACTURERREQUIREMENTS-GASEQUIPMENT

VENTING SYSTEM PROVIDED. When the manufacturer of

Product Approved side wall horizontally vented gas equip-

ment provides a venting system design or venting system

componentswiththeequipment,theinstructionsprovided

by the manufacturer for installation of the equipment and

theventingsystemshallinclude:

1. Detailed instructions for the installation of the venting

system design or the venting system components; and

2. A complete parts list for the venting system design or

venting system.

(e) AcopyofallinstallationinstructionsforallProductApproved

side wall horizontally vented gas fueled equipment, all

ventinginstructions,allpartslistsforventinginstructions,

and/or all venting design instructions shall remain with the

appliance or equipment at the completion of the installation.

37408-5-0919Page 6

Introduction

AlwaysconsultyourlocalBuildingDepartmentregardingregulations,

codes or ordinances which apply to the installation of a direct vent

wall furnace.

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installermusthaveownerlloutandmailwarrantycardsupplied

with furnace.

3. Installer should show owner how to start and operate furnace

and thermostat.

WARNING

Any change to this furnace or its control can be dangerous.

This is a heating appliance and any panel, door or guard

removed for servicing an appliance must be replaced prior

to operating the appliance.

To Conserve Gas: Turn off pilot when heater is not in use.

General Information

ThisfurnaceisdesigncertiedinaccordancewithAmericanNational

Standard/CSA Standard Z21.86 and CSA 2.32 by the Canadian

StandardAssociation,asaGravityDirectVentWallFurnacetobe

installed on an outside wall according to these instructions.

Anyalterationoftheoriginaldesign,installedotherthanasshown

in these instructions or use with a type of gas not shown on the

ratingplateistheresponsibilityofthepersonandcompanymaking

the change.

Important

AllcorrespondenceshouldrefertocompleteModelNo.,SerialNo.

and type of gas.

Notice:Duringinitialringofthisunit,itspaintwillbakeoutand

smokewilloccur.Topreventtriggeringofsmokealarms,ventilate

the room in which the unit is installed.

Installation in Residential Garages

Gas utilization equipment in residential garages shall be installed

so that all burners and burner ignition devices are located not less

than18"(457mm)abovetheoor.

Suchequipmentshallbelocated,orprotected,soitisnotsubject

to physical damage by a moving vehicle.

Installationandreplacementofgaspiping,gasutilizationequipment

or accessories and repair and servicing of equipment shall be

performedonlybyaqualiedagency.Theterm"qualiedagency"

meansanyindividual,rm,corporationorcompanywhicheitherin

person or through a representative is engaged in and is responsible for

(a)theinstallationorreplacementofgaspipingor(b)theconnection,

installation,repairorservicingofequipment,whoisexperiencedin

suchwork,familiarwithallprecautionsrequiredandhascomplied

with all the requirements of the authority having jurisdiction.

Commonwealth of Massachusetts: The installation must be

madebyalicensedplumberorgastterintheCommonwealth

of Massachusetts.

Theinstallationmustconformwithlocalcodesor,intheabsenceof

localcodes,withthe National Fuel Gas Code ANSI Z223.1/NFPA

54* Natural Gas and Propane Installation Code, CSA B149.1.

*Available from the American National Standards Institute, Inc., 11

West 42nd St., New York, NY 10036.

High Altitudes

For altitudes/elevations above 2,000 feet (610m), input ratings

shouldbereducedattherateof4percentforeach1,000(305m)

feet above sea level. Canadian High Altitudes for locations having

an elevation above mean sea level between 2,000 feet (610m)

and4,500feet(1370m),themanifoldpressureistobedecreased

from4.0"w.c.(.996kPa)to3.2"w.c.(.796kPa)forNaturalGasand

from9.0"w.c.(2.49kPa)to7.0"w.c.(1.992kPa)forPropaneGas.

INTRODUCTION

37408-5-0919 Page 7

SPECIFICATIONS

INTRODUCTION (CONT'D)

Model DV-25 DV-35

InputBTU/HR(KW/H)

25,000(7.3)

Natural

24,000(7.0)

Propane

35,000(10.3)

Height 28"(711mm) 28"(711mm)

Width 37"(940mm) 37"(940mm)

Depth 111/2"(292mm) 111/2"(292mm)

GasInlet(Pipe) 1/2"(13mm) 1/2"(13mm)

Accessories for the Above Furnaces

BlowerKit DRB-1 DRB-1

Description Model Number

VinylSidingVentKit DV-822 DV-822

VinylSidingVentKit VSK-2 VSK-2

Model Number Description Used On

DV984

VentExtensionKitForPropane

Units(13"-19"Walls)

DV35-4SGLPG

DV983

VentExtensionKitForPropane

Units(13"-19"Walls)

DV35-4SGNAT

Part Number Description Used On

17085 Propane to Natural DV25-5SGLPG

17084 Natural to Propane DV25-5SGNAT

17087 Propane to Natural DV35-4SGLPG

17086 Natural to Propane DV35-4SGNAT

WhenanexistingCategory1heaterisremovedorreplaced,the

original venting system may no longer be sized to properly vent the

attached appliances. Instructions shall also indicate effects of an

improperlysizedventingsystem(formationofcondensate,leakage,

spillage,etc.)andshallspecifythefollowingtestprocedure:

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance

connected to the venting system being placed into operation

could result in carbon monoxide poisoning or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system are

not in operation:

1. Seal any unused openings in the venting system.

2.

Z223.1/NFPA 54 or the Natural Gas and Propane Installation

Code, CSA B149.1 and these instructions. Determine that

there is no blockage or restriction, leakage, corrosion and

3. As far as practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building.

4.

5. Turn on clothes dryers and any appliance not connected

to the venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they are operating

at maximum speed. Do operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance

being inspected into operation. Adjust the thermostat so

appliance is operating continuously.

7.

at the draft hood relief opening after 5 minutes of main

8. If improper venting is observed during any of the above

tests, the venting system must be corrected in accordance

with National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

Natural Gas and Propane Installation Code, CSA B149.1.

9. After is has been determined that each appliance connected

to the venting system properly vents when tested as outlined

previous conditions of use.

37408-5-0919Page 8

GAS SUPPLY

Locating Gas Supply

Thegaslinecanentertheuniteitherthroughtheoororoutside

wall. The gas line opening should be made at this time. Location

oftheopeningwillbedeterminedbythepositionofoorjoistsand

the valve and union used for servicing.

Recommended Gas Pipe Diameter

Pipe

Length

Schedule 40 Pipe

Inside Diameter

Tubing, Type L

Outside Diameter

Natural Propane Natural Propane

0-10 feet

0-3 meters

1/2”

12.7 mm

3/8”

9.5mm

1/2”

12.7 mm

3/8”

9.5 mm

10-40 feet

4-12 meters

1/2”

12.7 mm

1/2”

12.7mm

5/8”

15.9 mm

1/2”

12.7 mm

40-100 feet

13-30 meters

1/2”

12.7 mm

1/2”

12.7mm

3/4”

19 mm

1/2”

12.7 mm

100-150 feet

31-46 meters

3/4”

19 mm

1/2”

12.7 mm

7/8”

22.2 mm

3/4”

19 mm

NOTE:Neveruseplasticpipe.Checktoconrmwhetheryourlocal

codes allow copper tubing or galvanized.

NOTE: Sincesomemunicipalitieshaveadditionallocalcodes,it

is always best to consult your local authority and installation code.

Theuseofthefollowinggasconnectorsisrecommended:

— ANS Z21.24 Appliance Connectors of Corrugated Metal Tubing

and Fittings

— ANS Z21.45 Assembled Flexible Appliance Connectors of Other

Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The Commonwealth of Massachusetts requires

thataexibleapplianceconnectorcannotexceedthreefeetinlength.

GAS SUPPLY

TEE HANDLE

FLEX TUBING

NPT NIPPLE

FLARE FITTING

FLARE SHUT OFF VALVE

CLOSE NIPPLE

TEE HANDLE

NPT NIPPLE

NPT UNION

SHUT OFF VALVE

NPT GAS SUPPLY

Figure 1

ConsultthecurrentNationalFuelGasCode,ANSIZ223.1CAN/

CGA-B149(.1or.2)installationcode.

Installing a New Main Gas Shut-Off

Each appliance should have its own manual gas shut-off.

A manual main gas shut-off should be located in the vicinity of the

unit.Wherenoneexists,orwhereitssizeorlocationisnotadequate,

contact your local authorized installer for installation or relocation.

Compounds used on threaded joints of gas piping shall be resistant

totheactionofliqueedpetroleumgases.Thegaslinesmustbe

checkedforleaksbytheinstaller.Thisshouldbedonewithasoap

solutionwatchingforbubblesonallexposedconnections,andif

unexposed,apressuretestshouldbemade.

Neveruseanexposedametocheckforleaks.Appliancemustbe

disconnected from piping at inlet of control valve and pipe capped

or plugged for pressure test. Never pressure test with appliance

connected; control valve will sustain damage!

A gas valve and ground joint union should be installed in the gas

line upstream of the gas control to aid in servicing. It is required by

the National Fuel Gas Code that a drip line be installed near the gas

inlet. This should consist of a vertical length of pipe tee connected

into the gas line that is capped on the bottom in which condensation

and foreign particles may collect.

Figure 2

Method of Installing a Tee Fitting Sediment Trap

Pressure Testing of the Gas Supply System

1. Tochecktheinletpressuretothegasvalve,a1/8"(3mm)N.P.T.

pluggedtapping,accessiblefortestgaugeconnection,mustbe

placed immediately upstream of the gas supply connection to

the appliance.

2. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2psig(3.5kPa).

3. The appliance must be isolated from the gas supply piping system

by closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal

toorlessthan1/2psig(3.5kPa).

Attention! If one of the above procedures results in pressures in

excessof1/2psig(14"w.c.)(3.5kPa)ontheappliancegasvalve,

it will result in a hazardous condition.

Checking Manifold Pressure

Both Propane and Natural Gas valves have a built-in pressure

regulator in the gas valve. Natural Gas models will have a manifold

pressureofapproximately4.0"w.c.(.996kPa)atthevalveoutlet

with the inlet pressure to the valve from a minimum of 5.0" w.c.

(1.245kPa)forthepurposeofinputadjustmenttoamaximumof

10.5"w.c. (2.61kPa).Propane Gasmodels willhave amanifold

pressureapproximately9"w.c.(2.49kPa)atthevalveoutletwiththe

inletpressuretothevalvefromaminimumof11.0"w.c.(2.739kPa)

for the purpose of input adjustment to a maximum of 13.0" w.c.

(3.237kPa).

A 1/8" (3mm) N.P.T.plugged tapping, accessiblefor test gauge

connection,islocatedontheoutletsideofthegascontrol.

37408-5-0919 Page 9

Thispageintentionallyleftblank.

37408-5-0919Page 10

1. Inselectingalocationforinstallation,itisnecessarytoprovide

adequate accessibility clearances for servicing and proper

installation.

2. Unitissupportedbyawallbracketsecuredtothewall.

3. The minimum clearances from casing to combustible construction

is48"(121cm)ontop,6"(152mm)oneachsideand4"(102mm)

fromtheoororfromthetopsurfaceofcarpeting,tileorother

oorcoveringand0"(0mm)torearwall.

4. The minimum distance from the center of the vent cap to the

nearestoutsidecornerorobstructionis24"(610mm).

5. TheDV-25andDV-35minimumwalldepthis41/2"(114mm)

(andthemaximumis13"(330mm).

*Themaximumwalldepthmaybeextendedto19"(483mm)by

usingthemodelDV983ventextensionkitfornaturalunitsandthe

DV984ventextension kitforpropane units.Thesekitsare only

available for DV35 models. The use of tubes not supplied by the

manufacturer results in unsatisfactory performance.

Theventterminalofadirectventappliance,withaninputof50,000

(14.6KW)BTUperhourorlessshallbelocatedatleast9"(229mm)

fromanyopeningthroughwhichuegasescouldenterabuilding.

Thebottomoftheventterminalandtheairintakeshallbelocated

atleast12"(305mm)abovegrade.

WARNING

The nearest point of the vent cap should be a minimum

regulator. In case of regulator malfunction, the six (6)

(1.83m) feet distance will reduce the chance of gas entering

the vent cap.

CLEARANCES

INSTALLATION INSTRUCTIONS

Location of Furnace

Pickalocationonanoutsidewallwithaclearspaceof28"(711mm)

highby49"(124cm)wideintheroom.

Locating Wall Opening

The furnace is to be located on an outside wall. Locate wall studs

so that wall opening will be located between wall studs. The wall

studscanbeusedforattachmentofwallmountingbracket.The

wall opening required as shown in Figure 3 is a diameter of 7 1/2

inches(191mm).

A template is provided in furnace carton for positioning furnace on

thewall.Also,refertoFigure3forpositioningthefurnaceonwall

and for locating gas line connection.

Figure 3willpositionthefurnacefourinches(102mm)offtheoor.

Ifitisdesiredtopositionthefurnacehigheronthewall,addthe

differencetothe"A,""B"and"C"dimensions.

NOTE: The vent opening is not in the center of the furnace.

WALL MOUNTING

BRACKET

14”

(356 MM)

11”

(279 MM)

2”x4” (51 Mmx102 MM) STUDS

16” (406 MM)ON CENTER

C

19 3/4”

(502 MM)

4” (102 MM) MIN.

OUTER CASING

OF UNIT

15 1/2”

(394 MM)

37”

(940 MM)

17 3/4”

(451 MM)

21 1/2”

(546 MM)

GAS INLET

TO VALVE

7 1/2” (191 MM) DIA.

WALL OPENING

B

27 3/16”

(691 MM)

A

28”

(711MM)

Figure 3

DV-25-2 SHOWN

UNIT

IS SUPPORTED

BY

WALL BRACKET

4 ½”(114mm)MIN. WALL DV-25, DV-35

13” (330mm) MAX. WALL DV-25, DV

-35

MOUNTING PLATE

(CAULK UNDER FLANGE)

VENT CAP

FLUE OUTLET TUBE EXTENDS

2 ½”(64mm) BEYOND WALL

AIR INLET TUBE EXTENDS

½”(13mm) BEYOND WALL

OUTSIDE WALL

UNIT FASTENED TO WALL

WITH (2) SCREWS

4”

102mm

4”

102m

m

Figure 4

Installing Wall Mounting Bracket

Locate and cut wall opening. If there is insulation above the wall

opening(airinlettube)abarriershouldbeinstalledabovethewall

opening(airinlettube)topreventinsulationfromcomingincontact

with the air inlet tube. The barrier must not penetrate into the

7-1/2"(191mm)diameterwallopening.Placetheatsurfaceofthe

wallmountingbrackettowardthewall.Inserthalfroundangeof

wallmountingbracketintoandatthetopofthewallopening.The

halfroundangeofthewallmountingbracketmustbeincontact

withthesheetrockorwoodatthetopofthewallopening.Level

thewallmountingbracketinthewallopening.

37408-5-0919 Page 11

INSTALLATION INSTRUCTIONS (CONT'D)

Onsolidwall,whenusingwallstudsforattachmentofwallmounting

bracket,fastenwallmountingbrackettowallstudswith(2)#10x

11/2"(38mm)screwsprovidedandfasten(2)additional#10x1

1/2"(38mm)screwsprovidedthroughthewallmountingbracket

and into the solid wall.

Onsheetrock,whenusingwallstudsforattachmentofwallmounting

bracket,fastenwall mounting brackettowall studswith(2) #10

x11/2"(38mm)screwsprovidedandbyusingwallopeningfor

access,fasten2additional#10x11/2"(38mm)screwsand(2)

Tinnermannutsprovidedthroughthewallmountingbracketand

intothesheetrock.

Attaching Furnace To Wall Mounting Bracket

Hangfurnaceonwallmountingbracketbyaligning(2)tabsonwall

mountingbracketwith(2)slotslocatedoninnercasingtop.

Theinnercasingbottomistobefastenedtothewall.Onsolidwall,

fasteninnercasingbottomwith(2)#10x11/2"(38mm)screws

provided.Onsheetrockwall,fasteninnercasingbottomwith(2)

toggle bolts provided.

Cutting Vent Tubes

This is the most important part of the installation. With the furnace

installedonwallthe6"(152mm)diameterairinlettubeandthe4"

(102mm)diameterueoutlettubearetobemarkedandcutusing

the following procedure.

1. Attach6"(152mm)diameterairinlettubeontothecollarofair

dropassembly.Besure6"(152mm)diameterairinlettubeis

placed as far as possible onto the collar of the air drop assembly.

Markthe6"(152mm)diameterairinlettube1/2"(13mm)beyond

theoutsidewall.Remove6"(152mm)diameterairinlettube

from collar of air drop assembly.

2. Attach4" (102mm) diameter ue outlet tube onto ue outlet

collaroncombustionchamber.Besure4"(102mm)diameter

ueoutlettubeisplacedasfaraspossibleontothecollarof

ueoutlet.Markthe4"(102mm)diameterueoutlettube21/2"

(64mm)beyondtheoutsidewall.Remove4"(102mm)diameter

ueoutlettubefromcollarofueoutletoncombustionchamber.

3. Markorwraptapecompletelyaroundthetubesatthemarked

pointstohelpinmakingatruecut.Donotcrimporenlarge

tubes.

Installing Vent Assembly

1. Placecaulking(notprovided)beneaththeedgeoftheoutside

mountingplate.Useadditionalcaulkingtocorrectunevenwall

surface,suchasclapboard.

2. Attach6"(152mm)diameterairinlettubeontothecollarofair

drop assembly. Attach caulked, outside mounting plate into

the6"(152mm)diameter airinlettube. Position theoutside

mountingplatesothat6"(152mm)diameterairinlettubehas

a slight downward slope to the outside. The downward slope

is necessary to prevent the entry of rainwater. Attach outside

mountingplateto exteriorwall with(4)#10 x1 1/2"(38mm)

screws provided.

3. Applyfurnacecementto4"(102mm)diameterueoutletcollar

oncombustionchamberandto4"(102mm)diametercollaron

ventcap.Attach4"(102mm)diameterueoutlettubeontoue

outlet collar on combustion chamber. Attach vent cap into the 4"

(102mm)diameterueoutlettube.Attachventcaptooutside

mountingplatewith(3)#10x1/2"(13mm)screwsprovided.

4. Installation is completed.

Reassembly And Resealing Vent-Air Intake System

Whenvent-airintakesystemisremovedforservicingthefurnace,

the following steps will assure proper reassembly and resealing of

thevent-airintakeassembly.

1. Removeoldfurnacecementfromueoutletcollaroncombustion

chamber and collar of vent cap. Remove old furnace cement

frombothendsof4"(102mm)diameterueoutlettube.

2. Removeoldcaulkingbeneaththeedgeoftheoutsidemounting

plate. Apply new caulking beneath the edge of the outside

mountingplate.Useadditionalcaulkingtocorrectunevenwall

surface,suchasclapboard.

3. Attach6"(152mm)diameterairinlettubeontothecollarofair

drop assembly. Attach caulked, outside mounting plate into

the6"(152mm)diameter airinlettube. Position theoutside

mountingplatesothat6"(152mm)diameterairinlettubehas

a slight downward slope to the outside. The downward slope

is necessary to prevent the entry of rainwater. Attach outside

mountingplateto exteriorwall with(4)#10 x1 1/2"(38mm)

screws provided.

4. Applyfurnacecementto4"(102mm)diameterueoutletcollar

oncombustionchamberandto4"(102mm)diametercollaron

ventcap.Attach4"(102mm)diameterueoutlettubeontoue

outlet collar on combustion chamber. Attach vent cap into the 4"

(102mm)diameterueoutlettube.Attachventcaptooutside

mountingplatewith(3)#10x1/2"(13mm)screwsprovided.

5. Reassemblyandresealingvent-airintakesystemiscompleted.

37408-5-0919Page 12

INSTALLATION INSTRUCTIONS (CONT'D)

Installing a Vent Near a Window Ledge, Other Type of Projection

or on Siding (vinyl, aluminum, etc.)

Direct vent furnaces are designed to be installed on a uniform

outsidewall.Whenthewindcomesfromanyangle(up,downor

fromeitherside),itmusthittheventcapequallyoverboththeair

inletandtheueoutletportionsofthevent.Anywallprojection,

suchasadoororwindowcasing,whichdisturbsthewindonone

sideoftheairinletsectionwillresultinbackpressureontheue

sectionsmotheringtheameandeventualpilotoutage.

When the vent cap is to be installed on siding or it appears that

aprojectionwithin6"(152mm)ofanysideoftheairinletsection

couldshieldtheairinletsection,theentireventshouldbesupported

away from the wall at least the distance of the projection. 2" x

4" (51mm x 102mm) framing whose outside dimensions match

the overall dimensions of the mounting plate is recommended.

The2"x4"(51mmx102mm)framingprotectssidingfrompossible

warpage or discoloration. All joints can then be sealed and painted.

Thewalldepthplustheadditionaldepthofthe2"x4"(51mmx

102mm)framingshouldnotexceedatotaldepthof13"(330mm)

forDV-25andDV-35.(SeeFigure5)

Vinylsidingvent kit,DV-822, isavailable fromEmpire Comfort

Systems,Inc.Thedepthis 3"(76mm),whichenables thevent

cap to be extended away from siding or projections. The wall

depthplustheadditional3"(76mm)depthofthevinylsidingvent

capextensionshouldnotexceedatotaldepthof13"(330mm)for

DV-25andDV-35.(SeeFigure5a)

WARNING

When vinyl siding vent kit, DV-822 or 2" x 4" (51mm x 102mm)

framing is added to an existing installation (furnace is

both tubes. Refer to Parts List, page 16 to order tubes.

Figure 5a

Figure 5

37408-5-0919 Page 13

OPTIONAL THERMOSTAT LOCATION

Millivolt wall thermostats are specially designed for use on self-

generating systems. They should never be used on line or low

voltage A.C. circuits.

Interior Wall - The thermostat can be installed on an inside wall.

Thermostat Bracket - The thermostat can also be attached to the

unitwiththeprovidedbracket.

1. Determine which side of the unit the thermostat will be secured

to.

2. Remove the front of the thermostat.

3. Attach thermostat to the bracket using the two (2) screws

provided. See Figure 6. Replace the front of the thermostat.

NOTE: Bracketinstallationisoptional.Donotuseifnotinstalling

an optional thermostat.

Figure 6

4. Ifinstallingthethermostatbracketaftertheunithasbeeninstalled,

drill a hole in the side of the unit as shown in Figure 7. and

attachthebracketwithascrew(notprovided).

Ifinstallingthethermostatbracketbeforetheunitisinstalled,

usetheexistingscrewonthebackoftheunittoattachthe

brackettotheunitasshowninFigure 7.

IF BRACKET IS INSTALLED

AFTER UNIT IS IN PLACE,

DRILL HOLE INTO CASING

SIDE AND ATTACH HERE.

USE

THIS EXISTING

SCREW

(ON EITHER SIDE

OF

THE HEATER) TO MOUNT

BRACKET

IF INSTALLING BEFORE

UNIT

IS AGAINST THE WALL.

PARTIAL VIEW OF

LEFT REAR

CORNER

Figure 7

Wire Gauges - It is important to use wire of a gauge proper for the

lengthofthewire:

RECOMMENDED WIRE GAUGES

Maximum Length Wire Gauge

1'to10' 18

10'to25' 16

25'to35' 14

Properoperationdependsonagoodpilotame.Theamemust

coverthetopofthethermopile.Cleaningofthepilotoriceand

burner may be required due to spiders.

System Check (Figure 8)

Amillivoltmeterisrequiredtocheckthesystem.Millivoltreadings

shouldbe:

• Acrossthethermopileterminals,400-450millivoltswiththermostat

OFF.

• Acrossthethermopileterminals,150-250millivoltswiththermostat

ON.

• Acrossthethermostatwiresatthevalve,lessthan30millivolts

with thermostat ON.

• Acrossthethermostatwiresatthethermostat,lessthan5millivolts

with thermostat ON.(Strongwinds,dirtypilotandlowpressure

will reduce readings.)

Depressingtheredbuttoncompletelycausesasparktooccurat

the pilot. This is a substitute for a match which requires opening

the pilot hole cover.

Tolightthepilot,itisimportantthattheelectrodebe1/8"(3mm)

fromthethermopile.Thesparkmustoccuratthepointtheburner

amehitsthethermopile.Theendoftheelectrodewillberedhot

with the pilot on.

Onanewinstallationwithairinthegasline,itissuggestedthata

match be used. The match will light the pilot faster than the piezo

under this condition.

Figure 8

NOTE:

TO OPTIONAL

THERMOSTAT

IS CONNECTED

WITH WIRE NUT

FROM FACTORY.

DISCONNECT

TO ATTACH

THERMOSTAT.

37408-5-0919Page 14

FOR YOUR SAFETY READ BEFORE LIGHTING

A. This appliance has a pilot which must be lighted by hand.

Whenlightingthepilot,followtheseinstructionsexactly.

B. BEFORE LIGHTING smell all around the appliance area

forgas.Besuretosmellnexttotheoorbecausesome

gasisheavierthanairandwillsettleontheoor.

WHAT TO DO IF YOU SMELL GAS

•Donottrytolightanyappliance.

•Donottouchanyelectricalswitch;

do not use any phone in your building.

•Immediatelycallyourgassupplierfromaneighbor's

phone.Followthegassupplier'sinstructions.

•Ifyoucannotreachyourgassupplier,callthere

department.

C. Use only your hand to push in or turn the gas control

knob.Neverusetools.Iftheknobwillnotpushinor

turnbyhand,don'ttrytorepairit;callaqualiedservice

technician. Force or attempted repair may result in a

reorexplosion.

D. Do not use this appliance if any part has been under

water.Immediatelycallaqualiedservicetechnician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

TO TURN OFF GAS TO APPLIANCE

1. Setthethermostattolowestsetting(ifapplicable).

2. Turn off all electric power to appliance if service is to

beperformed(ifapplicable).

3. Remove casing front assembly.

4. Pushingascontrolknobslightlyandturnclock-

wise to "OFF." Do not force.

5. Replace casing front assembly.

1. STOP! Read the safety information above.

2. Setthethermostattolowestsetting(ifapplicable).

3. Turnoffallelectricpowertotheappliance(ifappli-

cable).

4. Remove casing front assembly.

5. Pushingascontrolknobslightlyandturnclockwise

to "OFF".

NOTE:Knobcannotbeturnedfrom"PILOT"to"OFF"

unlessknobispushedinslightly.Donotforce.

6. Waitten(10)minutestoclearoutanygas.Thensmell

forgas, including neartheoor.If you smellgas,

STOP! Follow "B" in the safety information above. If

youdon'tsmellgas,gotothenextstep.

7. Remove the pilot access cover

located on the combustion

chamber.

8. Find pilot - follow metal tube

from gas control. The pilot is

behind the pilot access cover.

9. Turnknobongascontrolcounterclockwise

to "PILOT."

10.Pushincontrolknoballthewayandholdin.Im-

mediately light the pilot with the Piezo Pilot Ignitor

oramatch.Continuetoholdthecontrolknobinfor

aboutone(1)minuteafterthepilotislit.Release

knob,anditwillpopbackup.Pilotshouldremain

lit.Ifitgoesout,repeatsteps5through10.

•Ifknobdoesnotpopupwhenreleased,

stop and immediately call your service

technician or gas supplier.

•Ifthepilotwillnotstaylitafterseveraltries,

turnthegascontrolknobto"OFF"andcall

your service technician or gas supplier.

11. Replace pilot access cover.

12.Turngascontrolknobcounterclockwise to

"ON."

13. Replace casing front assembly.

14.Turnonallelectricpowertotheappliance(ifap-

plicable).

15.Setthermostattodesiredsetting(ifapplicable).

16.CAUTION:Pilotaccesscovermustbekepttightly

closed during operation.

LIGHTING INSTRUCTIONS

LIGHTING INSTRUCTIONS

GAS CONTROL KNOB SHOWN IN “OFF”

POSITION

WARNING

personal injury or loss of life.

37408-5-0919 Page 15

Thecorrectamewillbealmosthorizontal,blueandwillextendpast

thethermopile1/4"(6mm).Theamewillsurroundthethermopile

just below the tip.

OnPropaneGasslightyellowmightoccurwherethepilotame

andburneramemeet.

Natural Gas pilots require adjusting when the inlet pressure is above

5"w.c.(1.25kPa)Turnadjustmentscrewclockwisetoreduceame.

Propane will not require adjusting.

Figure 9

Therewillbeashortblueinneramewithamuchlargerlighterblue

secondaryame.Theburneramemayhaveayellowtipwhen

hot. See the burner drawing showing the approximate heights of

eachpartoftheame.Dustinthecombustionairwillproducean

orangeorredame.Donotmistaketheorangeorredamefor

animproperyellowame.Afteruse,cleaningmayberequiredfor

theproperame.

Figure 10

Primary Air Adjustment (Figure 11)

An air adjustment bolt is located on the chamber support bottom.

Thefourinch(102mm)clearancebetweenthefurnaceandtheoor

allows access to the air adjustment bolt. The air adjustment bolt is

above the rectangular opening on the inner casing bottom.

OnPropanegas,ifawhistlingnoise (resonation)occurs,screw

air adjustment bolt into the chamber support in order to reduce

theamountofprimaryair.Ifthewhistlingnoise(resonation)isnot

eliminated when the air adjustment bolt is screwed into the chamber

support this may indicate the air adjustment bolt is misaligned. Grasp

airadjustmentboltandpivot(push)airadjustmentboltawayfrom

yourself.Observethemainburnerameasyoupushairadjustment

boltandwhenthemainburneramebeginstodevelopayellow

ame,youshouldstoppushingontheairadjustmentbolt.Screw

airadjustmentboltoutofthechambersupportuntiltheyellowame

on the main burner is eliminated. The air adjustment bolt should

now be properly aligned. The reduction in primary air will soften the

mainburnerameandwilleliminatethewhistlingnoise(resonation).

OnPropane or NaturalGas, ifa yellowame occurs,screw air

adjustment bolt out of the chamber support but do not completely

remove air adjustment bolt from chamber support. The repositioning

of the air adjustment bolt will increase the amount of primary air.

Theincreaseinprimaryairwillsharpenthemainburnerameand

willeliminatetheyellowame.

Figure 11

PILOT FLAME CHARACTERISTICS

MAIN BURNER FLAME CHARACTERISTICS

37408-5-0919Page 16

Removing Main Burner

1. Disconnect the thermopile and pilot supply line at the pilot burner.

2. Remove the burner compartment cover.

3. Removeoriceshield.

4. Remove bolt on each side of burner and lift out.

Cleaning Main Burner

The main burner may be cleaned by forcing water into the ports

and the throat of the burner. The main burner should be blown dry

or heated to remove water from main burner.

1. Open the brass union located after the gas valve.

2. Loosenvalvebracket.

3. Removethe3/8"(10mm)manifoldpipethatisattachedtothe

union elbow until the manifold pipe is free.

4. Themainburneroriceisattheendofthemanifoldpipe.

1. Disconnect the pilot supply line at the pilot burner.

2. Removepilotoricefrompilotburner.Itmaybenecessaryto

taponpilotburnerinordertoremovethepilotorice.

Afteruse,cleaningofthepilotburnermayberequiredfortheproper

ame.Also,cleaningofthepilotburnermayberequireddueto

spiders(spiderwebs).Thepilotoricecanbecleanedwithhigh

pressureairorbyplacingunderrunningwater.Pilotoricemust

be dry before replacement. Use a pipe cleaner to clean inside the

pilotafterthepilotoricehasbeenremoved.

Cleaning Combustion Chamber

When the main burner and vent cap are removed, all internal

areas of the combustion chamber are accessible for cleaning with

a vacuum hose.

MAINTENANCE

1. Lit match goes out as it enters lighter port.

a.Certainwindconditionswillblowoutmatch.Ignitematch,

andasitares,thrustmatchthroughopening.

b. Open nearby door or window and relight pilot.

2.Pilotamesbutgoesoutwhenknobisreleased.

a. See Lighting Instructions. Relight Pilot.

b.Relightthepilotandholdknobdownlongerandharder.Close

lighterholecoverjustafterigniting.Checkforagoodpilot

ame.

c. Defective thermopile or defective magnet in safety section

of valve. Replace.

3.Yellowpilotame

a.Obstructionatpilotorice.

b.Cleanpilotorice.

4. Pilot and main burner go out during normal operation.

a.Checkmillivolts.

b.Checkforpropersizeofpilotame.

c. Checkfordefectiveorweakthermopile.

d. Checkinput,reduceasneeded.

e. Cover on pilot lighter hole must be air tight.

f. Checkfortighttofairanduetubesatbothendsofvent

assembly. No obstruction around vent that would prevent

the wind from hitting all of the vent equally.

5. Thermostat does not turn the main burner on.

a.Checkwiring.

b.Checkallmillivoltreadings.

c. Checkforspiderinmainburnerorice.

6.Yellowmainburneramesootontheventcap.

a. SeePage13,"PrimaryAirAdjustment".

b.Removemainburnertocheckforobstructionsinthroatand

ports.

c. Installnewmainburneroriceandpilotorice.RefertoParts

List,page16.

7. OnPropaneGas,ifawhistlingnoise(resonation)occurs.

a. SeePage13,"PrimaryAirAdjustment".

b. Reduce manifold pressure.

c. Sizemainburneroricewithadrillbit.ForDV-25use1.45mm

drillbit.ForDV-35use#50drillbit.

TROUBLESHOOTING

37408-5-0919 Page 17

ToOrderPartsUnderWarranty,pleasecontactyourlocalEmpiredealer.Seethedealerlocatoratwww.empirecomfort.

com.Toprovidewarrantyservice,yourdealerwillneedyournameandaddress,purchasedateandserialnumber,andthe

nature of the problem with the unit.

ToOrderPartsAftertheWarrantyPeriod,pleasecontactyourdealeroroneoftheMasterPartsDistributorslistedbelow.

Thislistchangesfromtimetotime.Forthecurrentlist,pleaseclickontheMasterPartsbuttonatwww.empirecomfort.com.

Pleasenote:MasterPartsDistributorsareindependentbusinessesthatstockthemostcommonlyorderedOriginalEquip-

mentrepairpartsforHeaters,Grills,andFireplacesmanufacturedbyEmpireComfortSystemsInc.

MASTER PARTS DISTRIBUTOR LIST

Parts Not Under Warranty

PartscanbeorderedthroughyourServicePerson,Dealer,oraMasterPartsDistributor.SeethispagefortheMasterPartsDistribu-

torslist.Forbestresults,theservice person or dealer should order parts through the distributor. Parts can be shipped directly to the

service person/dealer.

Warranty Parts

Warranty parts will need a proof of purchase and can be ordered by your Service Person or Dealer. Proof of purchase is for

warranty parts.

AllpartslistedinthePartsListhaveaPartNumber.Whenorderingparts,rstobtaintheModelNumberandSerialNumberfromthe

nameplateonyourequipment.ThendeterminethePartNumber(not the Index Number) and the Description of each part from the fol-

lowing illustration and part list. Be sure to give all this information . . .

Appliance Model Number Part Description

Appliance Serial Number Part Number

TypeofGas(PropaneorNatural)

Donotorderbolts,screws,washersornuts.Theyarestandardhardwareitemsandcanbepurchasedatanylocalhardwarestore.

Shipmentscontingentuponstrikes,resandallcausesbeyondourcontrol.

HOW TO ORDER REPAIR PARTS

Dey Distributing

1401WillowLakeBoulevard

VadnaisHeights,MN55101

Phone: 651-490-9191

Toll Free: 800-397-1339

Website: www.deydistributing.com

Parts: Heater, Hearth and Grills

F. W. Webb Company

200 Locust Street

Hartford,CT06114

Phone: 860-722-2433

Toll Free: 800-243-9360

Fax: 860-293-0479

Toll Free Fax: 800-274-2004

Websites: www.fwwebb.com & www.victormfg.com

Parts: Heater, Hearth and Grills

East Coast Energy Products

10 East Route 36

WestLongBranch,NJ07764

Phone: 732-870-8809

Toll Free: 800-755-8809

Fax: 732-870-8811

Website: www.eastcoastenergy.com

Parts: Heater, Hearth and Grills

37408-5-0919Page 18

PLEASENOTE:Whenorderingparts,itisveryimportantthatpartnumberanddescriptionofpartcoincide.

USEONLYMANUFACTURER'SREPLACEMENTPARTS.USEOFANYOTHERPARTSCOULDCAUSEINJURYORDEATH.

PARTS LIST

Index

No.

Part

No.

Description

1 DV769 Vent Cap

2 DV131 Outside Mounting Plate

3 DV548 Air Inlet Tube

4 DV524 Flue Outlet Tube

5 DV757 VentKit

6 DV899 WallMountingBracket

7 DV900 Inlet Air Drop Chute

8

DV762

& DV763

Gasket-AirDropChute

(2EachRequired)

9 DV951 Casing Top

10 DV901 Heat Shield

11 32143 Inner Casing

12 RH705 CasingSide(2Required)

13 M96 Gasket-FlueOutletSupport

14 DV903 CombustionChamber(DV25)

14 DV904 CombustionChamber(DV35)

15 M155 Gasket-LightingHole

16 DV781

Lighting Hole Cover Assembly

with Clear Mica

17 DV064 Cover Plate

18 DV988 Burner(DV25)

18 DV990 Burner(DV35)

19 R942 Thermopile

20 DV1004 Pilot Tubing w/Ferrells

21 RH238 Burner Door

22 DV778 Gasket-BurnerDoor

23 M151 Gasket-PilotBurner

24 DV994 Pilot Shield

25 R2224

PilotBurnerwithOrice(Natural)

25 R2223

PilotBurnerwithOrice(Propane)

26 DV772 Electrode and Wire

27 DV913 Casing Front

28 P8643 BurnerOrice,(DV25Natural)

28 P86145 BurnerOrice,(DV25Propane)

28 P8638 BurnerOrice,(DV35Natural)

28 P8650 BurnerOrice,(DV35Propane)

29 P190 Manifold

30 P191 Manifold Union Assembly

31 R5600

GasValve(Natural)7000MVRLC

31 R5601

GasValve(Porpane)7000MVRLC

32 DV1003 ValveBracket

33

DV764

& DV765

Gasket-ChamberSupport

(2EachRequired)

34 DV908 Valve Shield

35 R2708 Piezo Ignitor

Not Shown R1081 PilotOrice(Natural)

Not Shown R1089 PilotOrice(Propane)

Not Shown DV885 HardwarePackage

Index

No.

Part

No.

Description

37408-5-0919 Page 19

PARTS VIEW

37408-5-0919Page 20

OPTIONAL BLOWER DRB-1

Installing Optional DRB-1 Blower

1. ForRH-25andRH-35,removecasingfront.

1. ForDV-25-SGandDV-35-SG,removecasingfrontand

heat shield.

2. Whenfacingappliance,insertblowerassemblyintothe

left section of the casing (adjacent to the combustion

chamber).

3. ForRH-25andRH-35,routecordsetthroughopening

incasing back.Theopening in casingback islocated

adjacent to gas control.

3. For DV-25-SG and DV-35-SG, route cord set through

opening in casing bottom. The opening in casing bottom

is located beneath gas control.

4. Alignthe(2)screwholesontheinnersidepanelandthe

(2)screwholes on casing backwiththe(4) clearance

holes on the blower assembly. Attach blower assembly to

thecasingbackandinnersidepanelwith(4)#10x1/2"

(13mm)screwsprovided.Theblowerassemblymustbe

attachedrsttothecasingbackandthentothecasing

side panel.

5. ForRH-25andRH-35,replacecasingfront.

5. ForDV-25-SGandDV-35-SG,replaceheatshieldand

casing front.

ATTENTION:Wiringharnessonblowerisfactoryassembled

and installed. If wiring harness becomes disassembled use

the following steps to reassemble the wiring harness.

1. Attach (1) pin terminal from black (hot) wire, smooth

insulationoncordsetto(1)socketterminalonfancontrol

assembly.

2. Attach(1)pinterminalfromblack(neutral)wire,ribbed

insulationoncordsetto(1)socketterminalfromwhite

(neutral)wireonmotor.

3. Attach (1) pin terminal on fan control assembly to (1)

socketterminalfromblack(hot)wireonmotor.

4. Attachgreengroundwirebeneathoneofthe#10x1/2"

(13mm)screwsontheblowerhousing.

Fan Control

The automatic fan control is located in the switch box. The

switch box is attached to the front of the blower assembly.

The switch box is adjacent to the combustion chamber.

The fan control is a non-adjustable automatic type. The fan

control will require between 5 and 10 minutes of main burner

operation before the fan control "closes" and activates the

blower. The blower will continue to run between 5 and 10

minutesafterthemainburnershutsoff,beforethefancontrol

"opens" and deactivates the blower.

Wiring

Theappliance,wheninstalled,mustbeelectricallygrounded

inaccordancewithlocalcodesor,intheabsenceoflocal

codes, with the National Electrical Code, ANSI/NFPA 70

or Canadian Electrical Code, CSA C22.1, if an external

electrical source is utilized. This appliance is equipped with

a three-prong [grounding] plug for your protection against

shockhazardandshouldbepluggeddirectlyintoaproperly

grounded three-prong receptacle. Do not cut or remove the

groundingprongfromthisplug.Foranungroundedreceptacle,

anadapter,whichhastwoprongsandawireforgrounding,

canbepurchased,pluggedintotheungroundedreceptacle

and its wire connected to the receptacle mounting screws.

Withthiswirecompletingtheground,theappliancecordplug

can be plugged into the adapter and be electrically grounded.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

WARNING

Unplugging of blower accessory will not stop the heater

from cycling. To shut heater off: Turn temperature dial

or thermostat to lowest setting. Turn knob on gas

control to "OFF", depressing slightly. Do not force.

OPTIONAL BLOWER INSTALLATION INSTRUCTIONS

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

Empire Heating Systems Direct-Vent Wall Furnace (DV25/35) Le manuel du propriétaire

- Taper

- Le manuel du propriétaire

dans d''autres langues

Documents connexes

-

Empire Heating Systems Direct-Vent Wall Furnace (DV25/35) Le manuel du propriétaire

-

Empire Heating Systems DV-40E-5 Le manuel du propriétaire

-

Empire Heating Systems Direct-Vent Wall Furnace (DV210/215) Le manuel du propriétaire

-

Empire Heating Systems Vented Counterflow Wall Furnace (DVC55) Le manuel du propriétaire

-

Empire Heating Systems High-Efficiency Wall Furnace (DV20E, DV40E) Le manuel du propriétaire

-

Empire Heating Systems PVS35P-3 Le manuel du propriétaire

-

Empire Heating Systems DV210SGXNAT-1 Le manuel du propriétaire

-

Empire Heating Systems Gravity Wall Furnace (GWT25/35W) Le manuel du propriétaire

-

Empire Heating Systems Direct-Vent Wall Counterflow Le manuel du propriétaire

-

Empire Heating Systems 17083 Propane to Natural Gas (For DV215-(7,10)SG & DV215SGX-1,2) Le manuel du propriétaire

Autres documents

-

Empire DV-25-4SG Installation Instructions And Owner's Manual

-

Empire DV-55-1SPP Installation Instructions And Owner's Manual

-

Lambro FBA_361W Guide d'installation

-

Lambro L2676W Guide d'installation

-

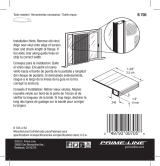

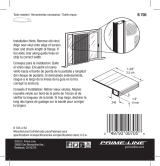

Prime-Line B 705 Mode d'emploi

Prime-Line B 705 Mode d'emploi

-

Empire DVC-35-2IP Le manuel du propriétaire

-

Legrand CCA6W Guide d'installation

-

Vita Springwood Arbor Mode d'emploi