4

USER NOTICES

Carefully read and follow all notices in this manual and on the equipment. All labels on the equipment should

be kept in good condition. Replace any unreadable or damaged labels.

#34072.0000 ITCB

#03408.7002

#03409.7002

Artwork for P/N: 00656.7000

Artwork Rev: F

Drawn: RN

Date: 06/27/08

Cet équipement doit être installé conformément au code

Canadien de plomberie et aux règlements de santé et de

sécurité qui s’ appliquent. Les modèles destinés à être

installés ailleurs qu’au Canada doivent respecter les codes de

plomberie et d’hygiène de la localité.

This equipment must be installed to comply with Canadian

Plumbing Codes and applicable health and safety regulations.

For models installed outside Canada, comply with the

applicable Plumbing /Sanitation Code.

#00986.7000 ITCB

#37881.7000

#00658.7000

#00656.7000

#39175.7000

36748.3 112912

#00831.0002 ITB

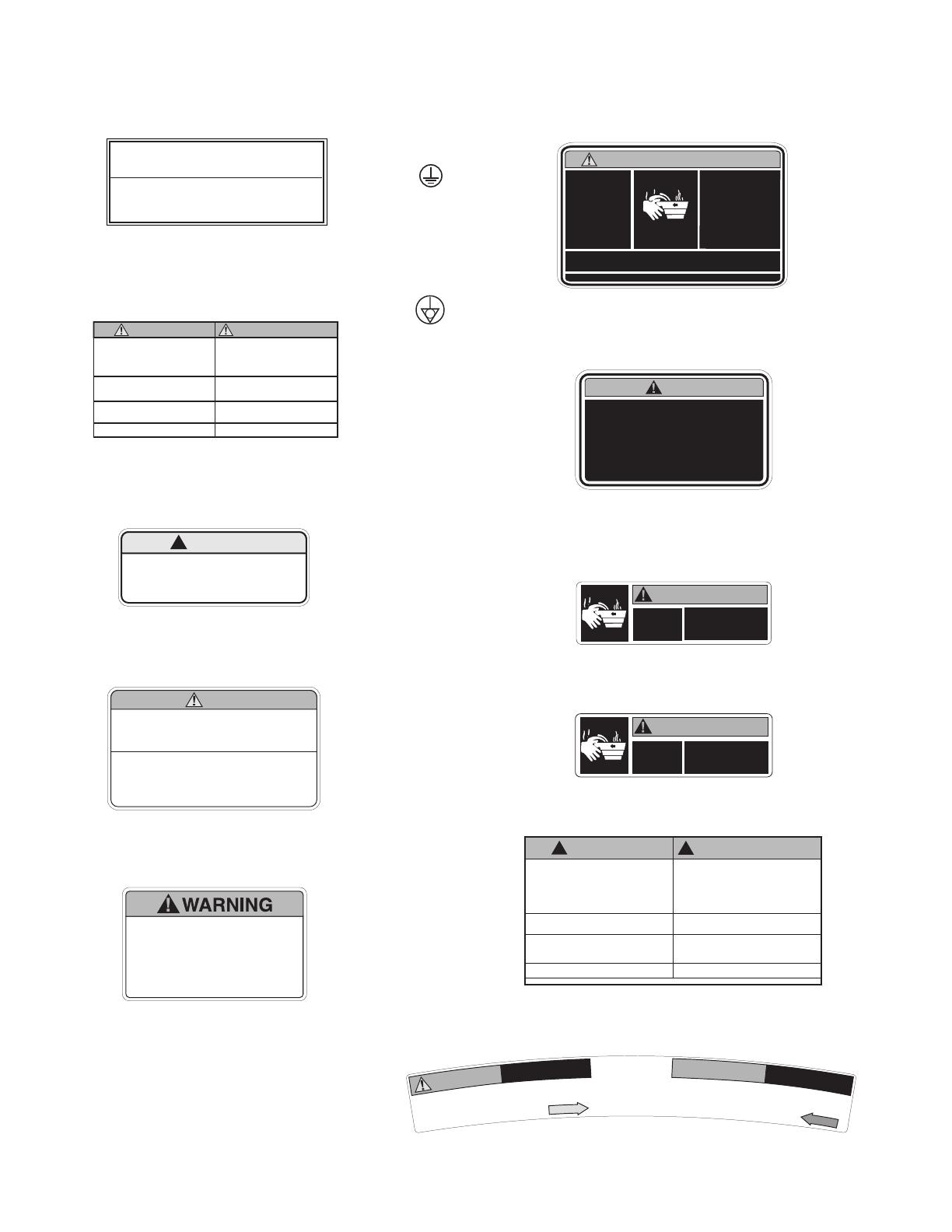

! AVERTISSEMENT

! WARNING

• FILL WATER TANK BEFORE PLUGGING IN UNIT OR

ENERGIZING THE THERMOSTAT.

• DO NOT OVERLOAD CIRCUIT.

• ALWAYS ELECTRICALLY GROUND THE CHASSIS.

• DO NOT DEFORM PLUG OR CORD.

• FOLLOW NATIONAL AND LOCAL ELECTRICAL CODES.

• KEEP COMBUSTIBLES AWAY.

FAILURE TO COMPLY RISKS EQUIPMENT DAMAGE, FIRE OR

SHOCK HAZARD.

READ THE ENTIRE OPERATING MANUAL INCLUDING

THE LIMIT OF WARRANTY AND LIABILITY BEFORE

BUYING OR USING THIS PRODUCT.

THIS EQUIPMENT IS ENERGIZED AT ALL TIMES UNLESS

ELECTRICALLY DISCONNECTED.

00831.0002K 17/11 © 1984 BUNN-O-MATIC CORPORATION

• REMPLIR LE RÉSERVOIR D'EAU AVANT DE BRANCHER

L'APPAREIL OU DE METTRE LE THERMOSTAT SOUS TENSION.

• NE PAS SURCHARGER LE CIRCUIT.

• TOUJOURS METTRE LE BOITIER À LA MASSE.

• NE PAS DÉFORMER LA FICHE OU LE CORDON.

• SE CONFORMER AUX CODES NATIONAL OU LOCAL

D'ÉLECTRICITÉ.

• GARDER LES PRODUITS COMBUSTIBLES À DISTANCE.

TOUT MANQUEMENT À SE CONFORMER À CES DIRECTIVES PEUT

ENTRAINER DES DOMMAGES À L'ÉQUIPEMENT OU PRODUIRE DES

DANGERS D'INCENDIE OU D'ÉLECTROCUTION.

VEUILLEZ LIRE LE MANUEL DE FONCTIONEMENT

EN ENTIER, Y COMPRIS LES LIMITES DE GARANTIES ET

RESPONSABILITÉS,AVANT D’ACHETER

OU D'UTILISER LE PRÉSENT PRODUIT.

L' ÉQUIPEMENT EST TOUJOURS SOUS TENSION

LORSQU'IL N'EST PAS DÉBRANCHÉ.

#00824.0001

(CE ONLY)

#00824.0002

#38125.0000 TWIN

WARNING

FAILURE TO COMPLY RISKS EQUIPMENT

DAMAGE, FIRE OR SHOCK HAZARD.

READ THE ENTIRE OPERATING MANUAL INCLUDING

THE LIMIT OF WARRANTY AND LIABILITY BEFORE

BUYING OR USING THIS PRODUCT.

00986.7000B 01/10 ©2007 Bunn-O-Matic Corporation

AVERTISSEMENT

• DO NOT OVERLOAD CIRCUIT.

• ALWAYS ELECTRICALLY GROUND THE CHASSIS.

• DO NOT DEFORM PLUG OR CORD.

• FOLLOW NATIONAL AND LOCAL

ELECTRICAL CODES.

• KEEP COMBUSTIBLES AWAY.

THIS EQUIPMENT IS ENERGIZED AT ALL TIMES UNLESS

ELECTRICALLY DISCONNECTED.

• NE PAS SURCHARGER LE CIRCUIT.

• TOUJOURS METTRE LE BOÎTIER À LA MASSE.

• NE PAS DÉFORMER LA FICHE OU LE CORDON.

• SE CONFORMER AUX CODES NATIONAL OU

LOCAL D'ÉLECTRICITÉ.

• GARDER LES PRODUITS COMBUSTIBLES À

DISTANCE.

TOUT MANQUEMENT À SE CONFORMER À CES

DIRECTIVES PEUT ENTRAINER DES DOMMAGES

À L'ÉQUIPEMENT OU PRODUIRE DES DANGERS

D'INCENDIE OU D'ÉLECTROCUTION.

VEUILLEZ LIRE LE MANUEL DE FONCTIONEMENT EN

ENTIER, Y COMPRIS LES LIMITES DE GARANTIES ET

RESPONSABILITÉS,AVANT D’ACHETER OU

D'UTILISER LE PRÉSENT PRODUIT.

L' ÉQUIPEMENT EST TOUJOURS SOUS TENSION LORSQU'IL

N'EST PAS DÉBRANCHÉ.

For 120/208V or 120/240 volt operation,

replace Power Supply Cord only with

Bunn-O-Matic part number 01699.0000.

! CAUTION

39175.7000A 05/06 ©2006 Bunn-O-Matic Corporation

Incorrect programming could result in accidental dispensing of HOT

LIQUID. Trained personnel are to follow instructions provided for

soft- ware programming. Use of additional graphic layer requires

disabling of appropriate switches. Read all instructions for additional

graphic layer prior to installing and programming.

WARNING AVERTISSEMENT

Une programmation incorrecte peut donner accidentellement une

distribution d'EAU CHAUDE. Personnel qualifié peut suivre les

instructions fournies pour la programmation du logiciel. Utilisation

d'un graphique additionnel supplémentaire requiert une mise hors

d'usage de certains interrupteurs appropriés.

Lire toutes les instructions concernant les graphiques

additionnels avant l'installation et la programmation.

Risk of Fire. Use a UL listed grounding

type attachment plug, rated 125/208

Vac, 30 A, 1 phase, 4 conductor. Plug

to be selected and installed only by

qualified service personnel.

38125.0001A 04/05 © 2005 Bunn-O-Matic Corporation

Artwork for P/N: 00658.7000

Artwork Rev: G

Updated by: RN

Date: 02/16/10

Colors:

PANTONE 1375 C

PANTONE 108 C

Funnel and hand to be white

PANTONE Process Black C

PN: 00658.7000G 02/10 © 1985 BUNN-O-MATIC CORPORATION OF CANADA

READ THE ENTIRE OPERATING MANUAL BEFORE USING THIS PRODUCT.

FAILURE TO COMPLY RISKS INJURY.

VEUILLEZ LIRE LE MANUEL D’EMPLOI AVANT D’UTILISER CE PRODUIT.

L’INOBSERVATION DE CES CONSEILS PEUT ENTRAÎNER DES RISQUES DE BLESSURE.

LE CONTENU

DE L’ENTONNOIR

EST CHAUD

FUNNEL CONTENTS

ARE HOT

DISCARD DECANTER

IF:

• CRACKED

• SCRATCHED

• BOILED DRY

• HEATED WHEN EMPTY

• USED ON HIGH FLAME

OR EXPOSED ELECTRIC

ELEMENTS

JETER LA CARAFE :

• SI ELLE EST FISSURÉE

• SI ELLE EST RAYÉE

• SI ON A LAISSÉ DE L’EAU

S’ÉVAPORER PAR

ÉBULLITION

• SI ELLE A ÉTÉ CHAUFFÉE À VIDE

• SI ELLE A ÉTÉ UTILISÉE SUR

UNE FLAMME VIVE OU SUR

DES ÉLÉMENTS ÉLECTRIQUES

DÉCOUVERTS

WARNING / AVERTISSEMENT

To reduce the risk of electric shock, do not remove or

open cover. No user-serviceable parts inside.

Authorized service personnel only. Disconnect power

before servicing.

Afin d’éviter un risque d’électrocution, ne pas ouvrir ou

enlever le panneau. Aucune pièce utile pour

l’opérateur à l’intérieur. Seulement le personnel

autorisé peut effectuer les réparations. Débrancher de la

source de courant avant d’effectuer une réparation.

WARNING AVERTISSEMENT

WARNING/AVERTISSEMENT

REMOVE

FUNNEL

SLOWLY

RETIRER

L’ENTONNOIR

LENTEMENT

LIQUIDE

CHAUD

WARNING/AVERTISSEMENT

HOT

LIQUID

M

a

k

e

s

u

r

e

F

u

n

n

e

l

i

s

r

o

t

a

t

e

d

a

n

d

a

l

i

g

n

e

d

w

i

t

h

M

a

k

e

s

u

r

e

F

u

n

n

e

l

i

s

r

o

t

a

t

e

d

a

n

d

a

l

i

g

n

e

d

w

i

t

h

T

e

a

D

i

s

p

e

n

s

e

r

o

n

t

h

e

R

I

G

H

T

s

i

d

e

t

o

a

v

o

i

d

T

e

a

D

i

s

p

e

n

s

e

r

o

n

t

h

e

L

E

F

T

s

i

d

e

t

o

a

v

o

i

d

p

o

t

e

n

t

i

a

l

b

u

r

n

s

a

n

d

w

a

t

e

r

s

p

i

l

l

s

.

R

I

G

H

T

p

o

t

e

n

t

i

a

l

b

u

r

n

s

a

n

d

w

a

t

e

r

s

p

i

l

l

s

.

L

E

F

T

W

A

R

N

I

N

G

H

O

T

L

I

Q

U

I

D

S

#41995.0000 ITB DD