Airwell PAC BT Series Guide d'installation

- Catégorie

- Climatiseurs split-system

- Taper

- Guide d'installation

Installation and operating manual

PAC BT

5 kW to 17 kW

M0GC6UN16-02

Nov.2016

English version

2

Dear Customer,

Congratulations on your purchase of the PAC BT, the air conditioning sy-

stem at annual cycle that offers the possibility in a sole system of meeting

all the heating, conditioning and domestic hot water needs.

Airwell is being working for years to offer systems able to assure the maxi-

mum comfort for long time with high reliability, efficiency , quality and safe-

ty. The target of the company is to offer advanced systems, that assure the

best comfort, reduce the energy consumption, the installation and mainte-

nance costs for all the life-cycle of the system.

With this manual, we want to give you information that are useful in all the

phases: from the reception, to the installation and use until the disposal so

that a system so advanced offers the best procedure of installation and use.

Best regards and have a nice reading !

AIRWELL RESIDENTIAL

3

Before any operation carefully read the GENERAL WARNINGS at the end of the manual

1

2

3

INDEX

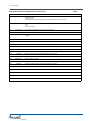

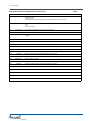

Installation quick guide

4

Reception

7

Installation

11

Water connections

15

Refrigerating connections

19

Electrical connections

22

Start - up

28

Control

34

Maintenace

67

Accessories

73

Technical data

74

General warnings

81

Residual risks / Disposal

83

Energy data sheets and labelling

85

4

5

6

7

8

9

10

11

12

13

DHW

pump

No recircu-

lation pump

Power supply 230 or 430

Separate power supply and signal

!

Thermostat

Elfocontrol

2

(option)

Segnals

Size 5kW 7kW 9kW 12kW 14kW 17kW

Liquid Ø Outdoor 3/8” 3/8” 3/8” 3/8” 1/2” 1/2”

Gas Ø Outdoor 3/8” 1/2” 1/2” 5/8” 5/8” 3/4”

Size 5kW 7kW 9kW 12kW 14kW 17kW

Min. content / Liters 17 20 25 33 40 50

System

pump

Anti-vibration joints

Cut-off valves

Vent

KPa = Useful pump discharge head

* Storage tank: this is present when the radiator circuit is excluded and there is not enough water

in the towel warmer circuit

*

Respect the functional clearances for maintenance

Size L2 W1

5 kW - 9 kW 200 250

12 kW -

14kW

250 300

17kW 300 350

Check that the pump head is adequate to the type of system

On the RS485

board is possible

to connect only

one con-

trol,RCW15

keypad

!

Avoid installations next to bedrooms

Install in a local or compartment where the

temperature can't drop below 0 ° C.

For details see the manual sections

Indoor unit

Place so that it doesn't disturb

Outdoor unit

Water minimum content always circulating

L

Pump head/pressure drops of the system

M

Functional clearances/access

B

Refrigerant piping: distance maximum height differences

G

Water connections

N

Electrical connections

F

Consider sound emissions

A

Rapid guide

PAC BT

BEFORE REQUESTING START-UP

Completed system

Refrigeration circuit emptying and charging

Water circuit loading and venting

Electrical connections

!

Reference document

M0GC6UN16

Provide a protection

< 15 °f. ?

If necessary, install water softener

To avoid the water freezing downstream of the

drain, lay the tube below the frost line (A).

Provide windbreaks or similar

1 Domestic Hot Water output

2 Water input

3 System water return

4 System water outlet

5 Pipe line( liquid )

6 Pipe line ( gas)

8 Solar system input (option)

9 Solar system output (option)

10 Domestic Hot Water recirculation

Litres ? °C ?

Tmax 95 °C

Charge OK ?

Carefully wash the system

Sizing expansion tanks according to the sy-

stem features

Condensate discharge

D

Strong winds

E

Snowdrifts

C

Water features

H

Domestic Hot Water Requirements

I

Indoor unit drains

O

Expansion tanks

P

System cleaning

Q

The requirements vary by the number of people living in the building

Estimated average daily per capita consumption of hot water

Requirements Liters - day - people (bathroom) Liters - day - people (kitchen)

Low Min.15 > max. 30 Min. 10 > max. 20

Medium Min.30 > max. 60 Min. 20 > max. 40

High Min.60 > max. 120 Min. 40 > max. 80

Example: average requirement for 4 people need about 230 litres/day

* Possibility of adding auxiliary cylinder in case of high hot water request

A System valve

I.A. Aqueduct input

C.C. Components provided by Customer

DEF Dirt separator

F Water filter

M Pressure gauge

P. A. Descaler protection

PS Solar pump

RID Pressure reducing valve

VEACS Domestic hot water expansion tank

VEI System expansion tank

VES Solar expansion tank

VR Check valve

VT Mixing valve thermostatic

MTGC40E16-01 26-05-16

6

GENERAL

Serie

Size

Serial number

Year of manufacture

Wiring diagram

UNIT INDENTIFICATION

Operate in compliance with safety regulations in force .

Use single protection devices.

PRELIMINARY INFORMATION

Before beginning the work, ensure you that have the final

project for installing the system and positioning the units.

Recommended instruments

Set of Philips and flathead screwdrivers;

Cutters;

Drill;

Scissors;

Set of open spanners or pipe wrenches;

Range;

Hydraulic material for the sealing of the threads;

Electrical equipment for the connections;

Cut prevention gloves;

Tester and amperometric pliers.

Serial number label

The serial number label is positioned on the unit and allows to

indentify all the unit features.

It has not to be removed for any reason.

It reports the regulations indications such as:

Machine type, exmple:

Series —> PAC BT

Size —> 5kW,7kW,…..17kW

Serial number

12 characters Axxxxxxxxxxx

Year of manufacture

Wiring diagram number

Electrical data

Supplier logo and address .

Serial number

It identifies uniquely each machine.

It identifies specific spare parts for the machine.

Assistance request

Note data from the serial number label and write them in the

chart on side, so you will find them easily when needed.

In case of intervention you have to provide data.

7

1 - ENERGY DATA SHEETS AND LABELLING

1.1 - DELIVERY CONTROL

1.2 - STORAGE

1.3 - HANDLING

?

A

A

Before handling verify that the unit keeps its balance.

B

Indoor unit

C

Fork input side the

D

Belt input side for lifting by crane

E

Maximum inclination

A identification label

A

Indoor unit

Outdoor unit

Before accepting the delivery you have to check:

that the unit hasn’t been damaged during transport.

Check that the materials delivered correspond with that

indicated on the transport document comparing the data

with the identification label ‘A’ positioned on the packaging.

In case of damage or anomaly:

Write down on the transport document the damage you

found and quote this sentence: "Conditional acceptance

clear evidence of deficiencies/damages during transport".

Contact supplier and the carrier by fax and registered mail

with advice of receipt.

Any disputes must be made within the 8 days following the

delivery. Complaints after this period are invalid.

Shelter from: direct sunlight, rain, sand and wind.

Stocking temperature:

maximum 50°C

minimum -10°C

The respect of the instructions on the exterior side of the

packaging assures the physical and functional integrity of the

unit for the final user’s advantage.

Verify unit weight and handling equipment lifting capacity .

The following examples are indications the choice of the

means and of the handling modes will depend on factors.

Use protection (A) to avoid the unit damaging

Identify critical points during handling (disconnected routes,

flights, steps, doors).

Stair climbing trolley.

8

1 - RECEPTION

1.4 - REMOVE WOODEN PLATFORMS

F

Outdoor unit

G

Fork input side the

H

Input side for lifting by crane

G H

F

Be careful not to damage the unit.

Keep packing material out of children's reach it may be

dangerous.

Recycle and dispose of packing material in conformity with

local regulations.

1.5 - PACKING REMOVING

Remove the screws

Remove planks and mural

Remove the screws by brackets

Remove the screws

9

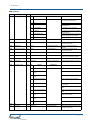

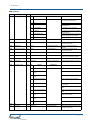

GENERAL

H. Vent

I. Solar system input (option)

J. Solar system output (option)

K. Aqueduct input

L. DHW output

M. Domestic hot water recirculation input (DHW )

CONNECTIONS

COMPONENTS

A

1

B

C

D

E

2

3

8

7

6

5

4

11

13

14

17

18

16

15

11. Electronic expansion valve

12. Solar probe (Provided by the customer)

13. System inlet temperature probe

14. Safety valve system DHW

15. System pump

16. DHW / System production valve

17. DHW pump

18. Electric panel

G

12

H I

J

K

F

L

M

9

1. Resistance (2kW)

2. System expansion vessel connection ø1/2” (Provided by the customer)

3. System exchanger

4. Differential pressure switch

5. System outlet temperature probe

6. Safety valve system side

7. DHW exchanger

8. Solar DHW exchanger (option)

9. Solar temperature probe

10. System expansion vessel connection ø1/2” (Provided by the customer)

10

A. Boiler return (option)

B. Boiler supply (option)

C. System return

D. System outlet

E. Gas line

F. Liquid line

G. Electronic Anode

10

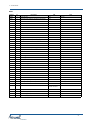

GENERAL

SCHEME CONNECTIONS

On the RS485 board is possible to connect only one control, RCW15 keypad

!

2

1

3

4

5

9

6

7.2

3.1

3.2

7.1

11

10

1

7

1

Supply line Pag.22

7.1

Power supply unit 12Vdc

(option)

System Pag.15

7.2

RS485

System outlet Ø 1”1/4M

DHW drain valve

Provided by the

customer

Pag.16

8

2

System return Ø 1”1/4M

System drain valve

Provided by the

customer

Pag.16

3

Solar panels (option) Ø 3/4”M Pag.18

9

Ethernet max 30 m UTP cat. 5 Pag.22

3.1

Solar panels unit (not provided)

10

Pipe liness

Provided by the

customer

Pag.19

3.2

Solar pump (not provided)

11

Unit drain

Provided by the

customer

Pag.13

4

Acqueduct Ø 1/2”M Pag.15

5

DHW Ø 1/2”M Pag.15

6

Room thermostat (not sup- Pag. 22

7

RCW15 control (option)

8

!

RCW15

11

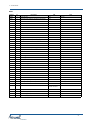

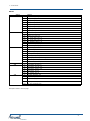

2 - INSTALLATION

Outdoor unit

2.1 - CLEARANCES

H1 H L1 L W1 W W2 L2

200 2040 800 800 30 600 100 10

Size H L L2 W1 W W2

5kW - 9kW 988 450 200 250 942 600

12 kW - 14kW 1234 460 250 300 1087 600

17kW 1137 720 350 350 1738 600

Install OUTDOOR

in fixed positions

If the unit is installed on a roof or terrace, check the load

capacity and the possibility for discharging the condensate.

Installation standards:

spaces for the air intake/exhaust

condensate water draining

install the unit raised from the ground

Prefer places where the unit doesn't disturb the neighbours.

Avoid installations in places subject to flooding

Avoid installations next to bedrooms or windows.

Avoid snow accumulating obstructing for air ejection and

suction

A correct circulation of the air is indispensible to guarantee the

good working order of the machine.

Avoid therefore:

obstacles to the airflow;

exchange difficulties;

leaves or other foreign bodies that can obstruct the

exchange batteries;

winds that hinder or favour the airflow;

heat or pollution sources close to the unit (chimneys,

extractors etc);

stratification (cold air that stagnates at the bottom);

recirculation (expelled air that is sucked in again);

positioning below the level of the threshold, close to very

high walls, attics or in angles that could give rise to

stratification or recirculation phenomenons.

Ignoring the previous indications could:

energy efficiency decrease;

blocks due to HIGH PRESSURE (in summer) or LOW

PRESSURE (in winter).

Choose the installation place according to the following

criteria:

customer approval

safe accessible position

carry out maintenance operations

technical spaces requested by the unit

water connections

max. distance allowed by the electrical connections

max. distance allowed by the refrigeranting connections

control points with capacity adequate to the unit weight

verify that all bearing points are aligned and leveled

sound levels (TECHNICAL INFORMATION section)

Indoor unit

installed inside

in a dry room/compartment where the temperature cannot

fall below 0 degrees

in fixed positions

Keep to the indicated safety spaces.

Prefer places where the unit doesn't disturb the neighbours.

Avoid installations in places subject to flooding

Avoid installations next to bedrooms or windows.

The spaces can be occupied by objects that must be easily

removeable in case of maintenance interventions.

12

2 - INSTALLATION

Avoid installations next to bedrooms or windows.

Consider sound emissions

2.2- MAXIMUM DISTANCE

Refrigerant pipes:

in vertical sections ensure the presence of siphons every six

metres of unevenness (on the supply/suction line only).

A max 25 m equivalent length of the pipe lines

B max 15 m height difference

C 6 m 6 m back up → siphon (gas line)

2.3 - OUTDOOR UNIT

Keep the min. distances from the podestrian areas.

Consider clearances and direction of expelled air.

Provide windbreaks (or similar) in locations with strong winds.

A Provide a protection.

B Avoid snow accumulations on batteries.

C Install the unit lifted from the ground.

13

2 - INSTALLATION

D Condensate discharge connection Ø 13

E Frost line

F

Layer of gravel or pebbles to help with condensate

drainage

To avoid freezing of the water downstream of the drain lay the

tube below the frost line (E).

Position the indoor unit on a flat, level surface.

Install the feet supplied (A)

2.4 - LEVELLING INDOOR UNIT

Condensate discharge via drainage

Use a spanner (36mm) to adjust the support feet and level the

position of the indoor unit.

When a heat pump is running it produces a considerable

amount of water due to the defrosting cycles of the outdoor

coil.

The condensation must be eliminated in a manner to avoid

wetting pedestrian areas.

With extensive very cold outdoor temperatures, condensation

could freeze outside the unit blocking the flow and causing a

slow build-up of ice; therefore special attention must be paid

to eliminating condensation, raising the unit off the ground and

evaluating whether antifreeze elements should be installed.

Condensate drain

A Condensate collection basin

B Unit support

C Condensate discharge connection

Customer care accessories

14

2 - INSTALLATION

2.5 - ACCESS TO THE INDOOR PARTS

A

A

A

A

A

INDOOR UNIT

B

B

Same sequence for the opposite side.

Unhook latch of the panel

Remove the panel

OUTDOOR UNIT

Remove the screws A

COMPONENTS SUPPLIED (indoor)

Refrigerating line connections: page 20

15

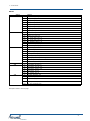

3 - WATER CONNECTIONS

3.1 - HYDRAULIC CONNECTION SCHEMA

In the tightening operations always use the wrench and backup wrench.

Indispensabile components system (not supplied)

A System valve

I.A. Aqueduct input

C.C. Components provided by Customer

DEF Dirt separator

F Water filter

M Pressure gauge

P. A. Descaler protection

PS Solar pump

RID Pressure reducing valve

VEACS Domestic hot water expansion tank

VEI System expansion tank

VES Solar expansion tank

VR Check valve

VT Mixing valve thermostatic

1 Domestic Hot Water output

2

Water input

3

System water return

4

System water outlet

5

Refrigerant line( liquid )

6

Refrigerant line ( gas)

8

Solar system input (option)

9

Solar system output (option)

10 Domestic Hot Water recirculation

Vent

Cut-off valves

Anti-vibration joints

PAC BT ODU

16

3 - WATER CONNECTIONS

A

system safety valve drain:

discharge in pressure (3 bar)

B

DHW safety valve drain:

discharge in pressure (6 bar)

drain accumulation / drain pit

C

H Boiler drain

A system safety valve

B

domestic hot water safety valve

D system draining tap

E domestic hot water draining tap

F system draining tap

G solar panel drain tap (domestic hot water)

Connecting the indoor unit drains

Any anti-freeze liquid contained in the system should not be

discharged freely as it is a pollutant.

It must be collected and reused.

An air bleed valve

Install the highest points of tubes in a way that the air can

escape form the circuit.

Inside the unit there are 2 water safety valves (the first one 6

bar on the Domestic Hot Water tank circuit, the second one 3

bar on the installation circuit) that must be connected to a

suitable drain, otherwise if valves intervened and flood the

rooms, the heat pump manufacturer will not be responsible.

The filter is extremely important: it helps to lockout any impuri-

ties in the water and avoid clogging the system and heat ex-

changer.

It must be installed immediately at the entrance to the water

mains, in a position that is easily accessible for cleaning.

The filter should never be re-moved.

Check for clogging from time to time

Installation

OK

Water filter (provided by the client)

A

D

B

F

E

For drain (see page 69)

G

Secure the pipes with hose clamps

17

3 - WATER CONNECTIONS

3.3 DOMESTIC HOT WATER TANK CHARGE

Maximum DWH system pressure 6 bar

DWH saftey valve setting 6 bar

1. Before charging, position the systems general switch in

the 'off' position .

2. Check that the draining taps of the system DWH are

closed ( C ).

3. Start the filling opening the water loading tap ( I.A. - see

hydraulic connection schema page 15)

4. Open taps (10-1-2)

5. Check the hydraulic seal of the joints.

3.4 SYSTEM CHARGE HEATING / COOLING

1. Check that the draining taps of the system are closed ( D-

F).

2. Start the filling opening the tap (A - see page 15)

3. Open taps (3 - 4)

4. Open all of the bleeding valves of the related terminals or

radiators

5. When water begins to exit from the bleeding valve, close

and continue the charging until the pressure intended for

the system (max.3 bar)

6. Check the hydraulic seal of the joints. Repeat the

operation after the unit has operated for a number of

hours and periodically control the system pressure.

Reintegration is carried out when the unit is off (pump

OFF).

3.2 - WATER FEATURES

C

D

F

Water features

confirming to local regulations

Water hardness (CaCo

3

) between 10°f and 25°f

Langelier (I

L

) index between 0 and +0.4

within the limits indicated by table

The water quality must be checked by qualified personnel.

Hardness

If the water hardness is high install a system suitable to

preserve the unit from harmful deposits and limestone

formations.

Cleaning

Before making the water connections to unit clean carefully

the system with specific and effective products for removing

residues or impurities that could affect the operation.

The existing systems must be free from sludgs, contaminants

and protected against foulings.

Exclusions

The warranty does not cover damages caused by limestone

formations, deposits and impurities from the water supply

and / or failure from failed system clearing to clean system.

Water component for corrosion limit on Copper

PH 7,5 ÷ 9,0

SO

4

--

< 100 ppm

HCO

3

-

/ SO

4

--

> 1

Total Hardness 4,5 ÷ 8,5 dH

Cl- < 50 ppm

PO

4

3-

< 2,0 ppm

NH3 < 0,5 ppm

Free Chlorine < 0,5 ppm

Fe

3

+

< 0,5 ppm

Mn

++

< 0,05 ppm

CO

2

< 50 ppm

H

2

S < 50 ppb

Temperature < 65 °C

Oxygen content < 0,1 ppm

Fill the Domestic Hot Water tank (DHW) only during the unit

start-up.

If the house is not immediately lived ,or the unit is turned off

for long periods, empty the storage tank to avoid the

stagnation of the water, or with temperatures close to 0°C the

risk of freeze.

See the Maintenance section for drain

18

3 - WATER CONNECTIONS

3.5 - SOLAR PREDISPOSITION - OPTION

Solar probe

The solar panels are equipped with:

a control panel (provided by costumer)

a temperature probe (provided by costumer)

For their operating with solar panels:

place the temperature probe on well ‘E’ positioned on the

storage tank

carried out the electrical connections

the solar system must be enabled (see page 38).

A Solar system water inlet Ø 3/4"

B Solar system water outlet Ø 3/4"

C Solar pump (provided by the client)

D

Solar expansion tank the Ø 3/4" (provided by the

client)

E

Solar probe well

F Solar draining tap

Any anti-freeze liquid contained in the solar system should not

be discharged freely as it is a pollutant. It must be collected

and reused.

The solar panel turns on whenever the machine's solar sensor

temperature reading is greater than that of the storage tank by

at least 8°C.

The solar panel turns off when the storage tank temperature

has reached 85°C of the machine's solar sensor temperature

reading is lower than that of the storage tank.

E

F

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

Airwell PAC BT Series Guide d'installation

- Catégorie

- Climatiseurs split-system

- Taper

- Guide d'installation

dans d''autres langues

Documents connexes

Autres documents

-

Panasonic WHADC1216H6E5C Mode d'emploi

-

Daikin EBLQ036BA6VJU1 Guide d'installation

-

Regency Fireplace Products E110 Le manuel du propriétaire

Regency Fireplace Products E110 Le manuel du propriétaire

-

ACV Glass HP 300 (C) Manuel utilisateur

-

Gorenje TC100ZNT Le manuel du propriétaire

-

Dometic MCS6 Mode d'emploi

-

Daikin EBLQ036BA6VJU1 Guide d'installation

-

Stovax Radiance Inset Edge User Instructions

-

Stovax Vision Electric Stoves Guide d'installation

-

Stovax eReflex 70W Guide d'installation