Bercomac 700259-4 700258-2 Manuel utilisateur

- Catégorie

- Tracteur

- Taper

- Manuel utilisateur

OWNER’S MANUAL

Model Number

700259-4 Subframe

700258-2 Drive Mechanism

Berco

Subframe & Drive Mechanism

for

HUSQVARNA, JONSERED, POULAN, RALLYE, WEEDEATER & YARD PRO

tractors

CAUTION:

READ & FOLLOW ALL SAFETY RULES & INSTRUCTIONS BEFORE

OPERATING YOUR EQUIPMENT

103738 E-05

* ASSEMBLY * REPAIR PARTS

* OPERATION * MAINTENANCE

WARRANTY

LIMITED ONE YEAR ON BERCO TRACTOR ATTACHMENTS

For one year from date of purchase, Bercomac Limitée will repair or replace free of charge at Bercomac's option, any

parts which are defective as a result of defective materials or faulty workmanship.

COMMERCIAL OR RENTAL USE:

Warranty on Berco attachments used for commercial or rental purposes is limited to 90 days.

This warranty does NOT cover:

* Wear items, such as shear pins and belts.

* Repairs due to customer abuse or neglect.

* Pre-delivery set-up.

* In home service.

Warranty service is available by returning the "Berco" attachment to the authorized dealers.

BERCOMAC Limitée

46 Fortin N, Adstock, Québec, Canada, G0N 1S0

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................................................... 2

SAFETY PRECAUTIONS ..................................................................................................................................... 3

ASSEMBLY

Step 1: Subframe Installation ................................................................................................................. 5

Step 2: Drive Mechanism Preparation ................................................................................................... 8

Step 3: Drive Mechanism Installation ..................................................................................................... 10

Step 4: Snowblower Installation ............................................................................................................. 11

Rotary Broom Installation .......................................................................................................... 13

Blade Installation ........................................................................................................................ 15

MAINTENANCE & DISMOUNTING

Maintenance ............................................................................................................................................. 16

Drive Mechanism Dismounting ............................................................................................................... 16

Belt Replacement ..................................................................................................................................... 16

End of Season Storage ........................................................................................................................... 16

TORQUE SPECIFICATION TABLE ..................................................................................................................... 17

PARTS BREAKDOWN AND LISTS

Subframe .................................................................................................................................................. 18

Drive Mechanism ..................................................................................................................................... 20

ATTACHMENTS .................................................................................................................................................... 22

TROUBLESHOOTING

See attachment owner’s manual for this section. (Snowblower, Blade, Rotary Broom)

PAGE

1

INTRODUCTION

2

INTRODUCTION

2

TO THE PURCHASER

This new attachment was carefully designed to give years of dependable service. This manual has been provided to

assist in the safe operation and servicing of your attachment.

NOTE: All photographs and illustrations in the manual may not necessarily depict the actual models or attachment, but

are intended for reference only and are based on the latest product information available at the time of publication.

Familiarize yourself fully with the safety recommendations and operating procedures before putting the machine to use.

Carefully read, understand and follow these recommendations and insist that they be followed by those who will use

this attachment.

THIS SAFETY ALERT SYMBOL IDENTIFIES AN IMPORTANT SAFETY MESSAGE IN THIS MANUAL

THAT HELPS YOU AND OTHERS AVOID PERSONAL INJURY OR EVEN DEATH. DANGER,

WARNING, AND CAUTION ARE SIGNAL WORDS USED TO IDENTIFY THE LEVEL OF HAZARD.

HOWEVER, REGARDLESS OF THE HAZARD, BE EXTREMELY CAREFUL.

DANGER: Signals an extreme hazard that will cause serious injury or death if recommended precautions are

not followed.

WARNING: Signals a hazard that may cause serious injury or death if the recommended precautions are not

followed.

CAUTION: Signals a hazard that may cause minor or moderate injury if the recommended precautions are not

followed.

Record your attachment serial number and purchase date in the section reserved below (there is no serial number on

the subframe). Your dealer requires this information to give you prompt, efficient service when ordering replacement

parts. Use only genuine parts when replacements are required.

If warranty repairs are required please present this registration booklet and original sales invoice to your selling dealer

for warranty service.

This manual should be kept for future reference.

7

SERIAL NUMBER : ___________________________

PURCHASE DATE : ___________________________

In this manual, right and left sides are determined by sitting on the tractor seat facing forward.

In this manual, "attachment" means accessories that you install on the tractor, such as, snowblower, rotary

broom, blade, rotary tiller, cab, subframe, etc...

SAFETY PRECAUTIONS

TRAINING

This symbol, "Safety Alert Symbol", is used

throughout this manual and on the attachment

safety labels to warn of the possibility of

personal injury. Please take special care in

reading and understanding the safety

precautions before operating the attachment

or the tractor.

1. Read this Owner's Manual carefully. Be thoroughly

familiar with the controls and proper use of the

attachment. Know how to stop the unit and

disengage the controls quickly.

2. Never allow children to operate attachment. Never

allow adults to operate attachment without proper

instructions.

3. No one should operate the unit while intoxicated or

while taking medication that impairs the senses or

reactions.

4. Keep the area of operation clear of all persons,

particularly small children and pets.

PREPARATION

1. Disengage all clutches and shift into neutral before

starting engine.

2. Handle fuel with care, it is highly flammable.

a) Use approved fuel container.

b) Never add fuel to a running engine or hot

engine

c) Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

d) Replace fuel cap securely and wipe up spilled

fuel.

3. Never attempt to make any adjustments while

engine is running (except where specifically

recommended by manufacturer).

4. Always wear safety glasses or eye shields during

operation or while performing an adjustment or

repairs to protect eyes from foreign objects that

may be thrown from the machine.

OPERATION

1. Do not run engine indoors except when starting

engine and transporting attachment, in or out of

building. Do not operate or let motor run in a

storage area without ventilation because gas

contains carbon monoxide which is odourless,

colourless and can cause death.

2. Do not carry passengers on attachment or tractor.

3. Take all possible precautions when leaving the

machine unattended. Lower the attachment, shift

into neutral, set the parking brake, stop the engine

and remove the key. Wait for all moving parts to

stop.

4. You must use manufacturer approved rear

counterweights, minimum 100 lbs., for better

traction and safety at all times when you have an

attachment installed in front.

5. Never operate the attachment without good visibility

or light.

3

Careful operation is your best insurance against an accident. Read this section carefully before operating the tractor

and attachment. All operators, no matter how experienced they may be, should read this and other manuals related to

the tractor and attachments before operating. It is the owner's legal obligation to instruct all operators in safe operation.

7

SAFETY PRECAUTIONS

MAINTENANCE AND STORAGE

1. Check shear bolts, mounting bolts, etc..., at frequent

intervals for proper tightness to be sure attachment is

in safe working condition.

2. Never store the machine with fuel in the tank inside a

building where ignition sources are present, such as

hot water tanks, space heaters, clothes dryers and

the like. Allow engine to cool before storing in any

enclosure.

3. Maintain or replace safety and instructions labels, as

necessary.

4

WHENEVER YOU SEE THIS SYMBOL

7

IT MEANS:

WARNING!

BECOME ALERT !

YOUR SAFETY IS INVOLVED!

7 WARNING 7

FOR YOUR SECURITY:

Read the attachment owner's manual for safety

precautions and rules.

Follow the assembly and operation instructions.

5

ASSEMBLY

IMPORTANT: TORQUE ALL BOLTS ACCORDING

TO TORQUE SPECIFICATION TABLE (SEE TABLE

OF CONTENTS) WHEN STATED: TIGHTEN

FIRMLY. REFER TO PARTS BREAKDOWN

SECTION FOR PARTS IDENTIFICATION.

NOTE: The subframe supplied with this kit may also

be used for different attachments (see attachments

page). Once installed it may remain permanently on

the tractor.

Open the tractor hood, disconnect the headlights and

remove the hood. Disconnect the wire from the spark

plug(s) and keep away from spark plug(s) to prevent

accidental starting.

Follow the instructions that are appropriate to

your particular tractor.

STEP 1

SUBFRAME INSTALLATION:

For 2000 and after model tractors

Remove the two bottom bolts (item 2) from each side.

Remove the heat shield (item 1).

For 1999 and before model tractors

Remove the heat shield (item 2), the mower brackets

(item 1) and the lower bolt (item 3) from each side.

Screw back in the top bolt (item 4) on each side.

Tractors with an electric clutch

To be able to install the subframe supports, you have to

remove the bolts and nuts (items 5 or 6 or 7) (depending

on the model of your tractor) which hold the anti-rotation

bracket for the electric clutch.

NOTE: Take note of the place and in which manner

the anti-rotation bracket was installed to be able to

reinstall it in the same manner.

Tractors with a manual clutch: remove the belt guide

(item 6).

Remove heat shield and bolts

Remove heat shield and mower brackets

Remove bolts and belt guide

2000 & after

1999 & before

6

ASSEMBLY

Install the left support (item 1)with three 3/8 x 1"

thread cutting bolts (items 2, 3 & 4), 5/16 x 1" carriage

bolts (items 5 & 6) and flange nuts. Do not tighten.

Install the right support in the same manner.

Install the new heat shield (item 7) as shown using

the tractor bolts.

Install the brace pin (item 1) inside the frame on the

left hand side and the handle support (item 2) as

shown. Use two 3/8 x 1" carriage bolts (item 3) and

flange nuts.

Do not tighten.

Insert the plastic grommet (item 4) as shown.

Slide the nylon bushing (item 3) flange first down the

lift arm (item 1) to the sleeve (item 5).

Slide the lift support (item 2) down the lift arm and

onto the nylon bushing. The slotted section (item 6) of

the lift support comes down over the fork (item 7).

Install the handgrip (item 4) as shown.

Install the new supports and heat shield

Install brace pin and handle support

Install lift support

7

ASSEMBLY

Tractors with a manual clutch:

Install the lift arm (item 1) on the tractor frame with

three 3/8 x 1" carriage bolts (item 3) heads inside the

frame.

Insert the lift arm assembly (item 1) on the brace pin

(item 2).

TIP: Insert bolts in holes then wrap a small elastic

band around the stems of the three bolts to hold

them in place. The elastic maybe cut off after

installation if so desired.

Tractors with an electric clutch:

Reinstall the electric clutch anti-rotation support over

the lift arm support (item 5). If it was installed with a

bolt in the hole (item 4), use a 3/8 x 1 1/4’’ carriage

bolt and original nut.

Secure the bolts with the flange nuts.

Do not tighten.

Install the pivot support (item 3) between the left and

right supports (items 4 & 5).

Insert the pivot pin (item 1) as shown.

Secure with two 3 mm hair pins (item 2).

Install the push bar (item 1) by sliding it into the tube

(item 2) welded on the pivot support.

Attach the other end in the fork (item 3) of the arm lift

(item 4) with the pin (item 5).

Secure in place with a 2.5 mm hair pin (item 6).

IMPORTANT: TIGHTEN ALL BOLTS FIRMLY.

NOTE:

For tractors with a 48" mower deck

When you reinstall the mower deck, you must remove

the push bar (item 1) and the pivot support (item 7).

If Utility blade (see Attachments & Options) is to

be used without removing the mower deck, an

attaching bracket is required. Sold as an option

#700317.

Install lift arm

Install push bar

Install pivot support

8

ASSEMBLY

For 1999 tractor models and before

Install the new mower brackets (item 1) inside the

right and left supports (items 2 & 3) with two 3/8 x

3/4" hex bolts (item 4) and flange nuts.

Tighten securely.

STEP 2

DRIVE MECHANISM PREPARATION:

NOTE: You must remove the mower deck to install

and use the drive mechanism.

To install the drive mechanism, you must install two

supports (item 1) (the big hole, item 5), towards the

front of the tractor as shown.

Fasten the supports (one on each side) with two 3/8 x

3/4" bolts (item 2) and flange nuts in the holes (item

3) of the supports.

To install the left support, you must remove the two

bolts from the tractor. Tighten firmly.

For tractors with a 48" mower deck

Fasten each of the supports with two 3/8 x 3/4" bolts

in the holes (item 4) of the supports.

To install the left support, you must remove the two

bolts from the tractor.

Tighten firmly.

For all size of mower decks

NOTE: When re-installing the mower deck, there may

be interference between the mower deck’s blade

spindle pulley and the subframe’s right hand side

support. If so, remove the support and store securely

to re-install next winter season.

Install mower brackets

Install supports

ASSEMBLY

NOTE: This drive mechanism may be mounted on

tractors with three different types of clutch

mechanisms. See the following instructions for those

that are appropriate for your tractor.

TRACTORS WITH AN ELECTRIC CLUTCH.

For tractors with a 48" mower deck only

You must remove the front support (item 5) and turn it

upside down (item 6).

All other size mowers:

No modifications.

Install the spring holder (item 1) on the drive

mechanism frame with two 1/4 x 3/4" hex bolts (item

2) and flange nuts in the rear set of holes of the drive

frame. Tighten firmly.

Hook the spring (item 3) by its shortest hook into the

top hole of the idler arm (item 4) and the other end

into the spring holder (item 1).

TIP: Use pliers to stretch the spring to facilitate

hooking it to the holder.

Go to drive mechanism installation step 3.

TRACTORS WITH A MANUAL CLUTCH

ACTIVATED BY A CABLE.

Install the belt guide (item 1) on the lift arm support

(item 2) with two 1/4 x 3/4 bolts and flange nuts.

Tighten firmly.

Cut the tie wrap that holds the cable to the frame.

NOTE: Depending on the mower deck model, there

are two different cable lengths. To determine where to

place the cable holder, hook the end of the cable

spring (item 3) into the top hole of the idler arm (item

4). Attach the cable shield (item 5) temporarily to the

holder (item 6). When the cable holder is well

positioned, the cable will have a slight tension. The

clutch arm must be in the OFF position.

Remove the cable shield and install the cable holder

(item 6) on the frame using two 1/4 x 3/4" hex bolts

(item 7) and flange nuts. Reinstall the cable shield

and secure with a 2 mm hair pin.

Go to drive mechanism installation step 3.

NOTE: After installation, attach the cable to the frame

with the new tie wrap supplied with this kit.

9

Install spring holder

Install cable holder

Electric clutch

Manual clutch

10

ASSEMBLY

TRACTORS WITH A MANUAL CLUTCH

ACTIVATED BY A ROD.

Install the belt guide (item 1) on the lift arm support

(item 2) with two 1/4 x 3/4 bolts and flange nuts.

Tighten firmly.

NOTE:

When you dismounted the mower deck, you

unhooked a round rod that was connected to the

clutch lever under the tractor. The spring (item 3)

must be hooked to this lever.

No modifications are needed on the drive mechanism.

Hook the spring (item 3) by its shortest hook into the

top hole of the idler arm (item 4) and the other end to

the clutch lever (item 5) underneath the tractor (the

same location where the round rod was connected).

STEP 3

DRIVE MECHANISM INSTALLATION:

Install the drive mechanism (item 1) by hooking the

front part of the drive frame to the brace pin (item 2).

Install the primary belt on the engine pulley (item 3)

and route inside the belt guide.

Lift and attach the rear portion of the drive frame

between the supports (items 4 & 5) using the pin

(item 6).

Secure with a 2.5 mm hair pin (item 7).

NOTE:Electric Clutch :

If your tractor is equipped with an electric clutch,

make sure the spring is well inserted in its place and

the belt does not touch the belt guides at any point.

NOTE: Manual Clutch:

If your tractor is equipped with a manual clutch, make

sure the belt guide does not touch the belt at any

point while the drive mechanism is engaged or

disengaged. This verification must be done when the

engine is stopped.

Install drive mechanism

7 WARNING 7

TO PREVENT INJURIES AND FOR MORE

TRACTION WHEN USING AN ATTACHMENT:

-Rear counterweight of 100 lbs. minimum is

required to counterbalance the attachment’s

weight.

-Tractor manufacturer approved tire chains are

required.

-Do not operate on a slope greater than 10°.

-When dismounting an attachment remove rear

counterweights.

Install spring

ASSEMBLY

Attach the snowblower to the subframe as shown.

Make sure the snowblower is pushed in until locked

into place by the springs (item 1).

Install the belt around the pulleys as shown.

Install the belt on the drive mechanism pulley (item 5)

under the tractor.

Apply tension on the belt by pulling up the belt tension

arm.

Reinstall the belt guard.

NOTE: See belt replacement instructions in the

maintenance section of the snowblower owner’s

manual.

11

Install-belt and belt guard

STEP 4

SNOWBLOWER INSTALLATION:

Refer to snowblower owner’s manual, parts breakdown

section for parts identification.

Install snowblower

Item 1: Snowblower pulley

Item 2: Tractor engine pulley

Item 3: Flat pulley L.H.

Item 4: Flat pulley R.H.

Item 5: Drive mechanism pulley

Item 6: Drive mechanism belt

Item 7: Snowblower belt

7 WARNING 7

FOR YOUR SECURITY:

Read the snowblower’s owner's manual for safety

precautions and rules.

Follow the assembly and operation instructions.

7 WARNING 7

TO PREVENT INJURIES:

Stop the motor.

Apply parking brake.

Remove the ignition key.

Disconnect the wire from the spark plug(s) and

keep away from spark plug(s) to prevent accidental

starting.

7 CAUTION 7

Never use the snowblower without the belt guard.

7 CAUTION 7

The belt tension arm is spring loaded & needs to be

held firmly while displacing to prevent injury.

ASSEMBLY

VERIFY BELT ROUTING:

-Lower the snowblower to the ground and let it run for

a few seconds under supervision.

-Disengage the snowblower and stop the engine.

-Remove the belt guard.

-Check the belts to make sure they are well inserted

on the pulleys and have not flipped on their sides in

the pulleys and that they do not touch the belt

guides.

- Reinstall the belt guard

Insert the handgrip (item 1) on the handle (item 2).

Insert the handle (item 2) through the support (item 3)

as shown.

Insert the handle (item 2) in the rotation worm (item 5)

and secure with a 2.5 mm. hair pin (item 4).

VERIFY SKID SHOE ADJUSTMENT:

LEVEL PAVED SURFACE: Adjust skid shoes to allow

3/16" to 1/4" clearance (A) between cutting edge and

surface.

UNEVEN OR GRAVEL SURFACE: Adjust skid shoes

to allow 1/2" to 5/8" clearance (A) between cutting

edge and surface.

VERIFY TIRE PRESSURE:

Attachments should raise 3" to 4" above ground (no

more, no less) if not, check and adjust tractor tire

pressure as follows:

Front tires: 14-15 psi

Back tires: 7-8 psi

Tire pressure must be even on both sides of tractor.

Install handle

12

Adjust skid shoe

ASSEMBLY

Attach the rotary broom to the subframe as shown.

Make sure the rotary broom is pushed in until locked

into place by the springs (item 1).

Install the belt on the drive mechanism pulley (item 1)

as shown.

NOTE: See belt replacement instructions in the

maintenance section of the rotary broom owner’s

manual.

13

Install belt

ROTARY BROOM INSTALLATION:

Refer to rotary broom owner’s manual, parts

breakdown section for parts identification.

VERIFY BELT ROUTING:

-Lower the rotary broom to the ground and let it run

for a few seconds under supervision.

-Disengage the rotary broom and stop the engine.

-Check the belts to make sure they are well inserted

on the pulleys and have not flipped on their sides in

the pulleys and that they do not touch the belt

guides.

Attach rotary broom to subframe

Item 1: Drive mechanism pulley

Item 2: Rotary broom pulley

7 WARNING 7

FOR YOUR SECURITY:

Read the Rotary Broom owner's manual for

safety precautions and rules.

Follow the assembly and operation instructions.

7 WARNING 7

TO PREVENT INJURIES:

Stop the motor.

Apply parking brake.

Remove the ignition key.

Disconnect the wire from the spark plug(s) and

keep away from spark plug(s) to prevent accidental

starting.

7 CAUTION 7

Never use the Rotary Broom without the belt

guard.

ASSEMBLY

Insert handgrip on the handle.

Insert the handle (item 1) through the support (item 2)

as shown.

Install the handle on the control rod (item 3) as shown

and secure with a 2.5 mm. hair pin (item 4.

VERIFY TIRE PRESSURE:

Attachments should raise 3" to 4" above the ground

(no more, no less) if not, check and adjust tractor tire

pressure as follows:

Front tires: 14-15 psi

Back tires: 7-8 psi

Tire pressure must be even on both sides of the

tractor.

14

Install handle

ASSEMBLY

Attach the blade to the subframe as shown.

Make sure the blade is pushed in until locked into

place by the springs (item 1).

Insert the handgrip on the handle.

Insert the handle (item 1) through the support (item 2)

as shown.

Install the handle on the control rod (item 3) as shown

and secure with a 2.5 mm hair pin (item 4).

VERIFY TIRE PRESSURE:

Attachments should raise 3" to 4" above the ground

(no more, no less) if not, check and adjust tractor tire

pressure as follows:

Front tires: 14-15 psi

Back tires: 7-8 psi

Tire pressure must be even on both sides of the

tractor.

Attach blade to subframe

15

BLADE INSTALLATION:

Refer to blade owner’s manual, parts breakdown

section for parts identification.

Install handle

7 WARNING 7

FOR YOUR SECURITY:

Read the Blade owner's manual for safety

precautions and rules.

Follow the assembly and operation instructions.

MAINTENANCE & DISMOUNTING

MAINTENANCE

a) Check mounting bolts at frequent intervals for

proper tightness to be sure equipment is in safe

working condition.

b) Apply oil at all pivot points.

DRIVE MECHANISM DISMOUNTING

SEE ATTACHMENT OWNER'S MANUAL

(SNOWBLOWER, BROOM AND BLADE) FOR

DISMOUNTING INSTRUCTIONS.

a) Dismount the attachment.

b) Remove the rear counterweight when you remove

the front attachment.

c) Dismount the drive mechanism by supporting it in

hand and removing the 1/2" pin. Carefully lower to

the ground. Remove the V-belt from engine pulley.

Manual clutch activated by rod:

Unhook the spring. Pull out drive mechanism from

underneath tractor.

Manual clutch activated by cable:

Unhook cable shield by removing the hair pin.

Unhook spring. Pull out drive mechanism from

underneath tractor.

d) You may leave the subframe on tractor all year long

or remove it if preferred.

NOTE:

For tractors with a 48" mower deck

When you reinstall the mower deck, you must

remove the push bar and the pivot support.

If Utility blade (see Attachments & Options) is to

be used without removing the mower deck, an

attaching bracket is required. Sold as an option

#700317.

e) Reinstall mower if needed.

For all size mower decks:

NOTE: When re-installing the mower deck, there may

be interference between the deck’s blade spindle

pulley and the subframe’s right hand side support. If

so, remove the support and store securely to re-install

next winter season.

16

BELT REPLACEMENT

Drive Mechanism Belt:

Before proceeding with this step, notice carefully how

the belt guide is installed to avoid damage to the belt.

When re-installing, remove the bolt which retains the

tension pulley and the belt guide. Replace the belt

and re-install the tension pulley and belt guide. Before

tightening make sure the belt guide does not touch

the belt at any time. Re-install the drive mechanism.

Manual Clutch:

With the engine stopped, engaged and disengage the

clutch and make sure the belt does not come into

contact with the belt guide.

Electric Clutch:

Make sure the belt does not come into contact with

the belt guide.

END OF SEASON STORAGE

a) Clean and paint all parts from which paint has worn.

b) Apply oil at all pivot points.

c) Inspect and replace all defective parts before using

again.

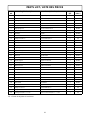

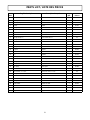

GENERAL TORQUE SPECIFICATION TABLE

USE THE FOLLOWING TORQUES WHEN SPECIAL TORQUES ARE NOT GIVEN

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal oil. They do not apply if

special graphited or moly disulphide greases or other extreme pressure lubricants are used. This applies to both UNF and UNC

threads.

17

TORQUE SPECIFICATION TABLE

SEE Grade No. 2 5 8 *

BOLT HEAD

IDENTIFICATION

MARKS AS PER GRADE

NOTE MANUFACTURING

MARKS WILL VARY

TORQUE TORQUE TORQUE

BOLT SIZE POUNDS FEET NEWTON-METERS POUNDS FEET NEWTON-METERS POUNDS FEET NEWTON-METERS

Inches Millimetre Min. Max. Min. Max. Min. Max. Min. Max. Min. Max. Max. Min. Max. Max.

1/4" 6.35 5 6 6.8 8.13 9 11 12.2 14.9 12 15 16.3 30.3

5/16" 7.94 10 12 13.6 16.3 17 20.5 23.1 27.8 24 29 32.5 39.3

3/8" 9.53 20 23 27.1 31.2 35 42 47.5 57 45 54 61 73.2

7/16" 11.11 30 35 40.7 47.4 54 64 73.2 86.8 70 84 94.9 113.9

1/2" 12.7 45 52 61 70.5 80 96 108.5 130.2 110 132 149.2 179

9/16" 14.29 65 75 88.1 101.6 110 132 149.2 179 160 192 217 260.4

5/8" 15.88 95 105 128.7 142.3 150 180 203.4 244.1 220 264 298.3 358

3/4" 19.05 150 185 203.3 250.7 270 324 366.1 439.3 380 456 515.3 618.3

7/8" 22.23 160 200 216.8 271 400 480 542.4 650.9 600 720 813.6 976.3

1" 25.4 250 300 338.8 406.5 580 696 786.5 943.8 900 1080 1220.4 1464.5

*Thick nuts must be used with grade 8 bolts

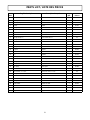

METRIC BOLT TORQUE SPECIFICATIONS

COARSE THREAD

Size Screw Grade No. Pitch (mm) Pounds Feet Newton-Meters Pitch (mm) Pounds Feet Newton-Meters

M6 4T 1.00 3.6 - 5.8 4.9 - 7.9 - - -

7T 5.8 - 9.4 7.9 - 12.7 - -

8T 7.2 - 10 9.8 - 13.6 - -

M8 4T 1.25 7.2 - 14 9.8 - 19 1.00 12 - 17 16.3 - 23

7T 17 - 22 23 - 29.8 19 - 27 25.7 - 36.6

8T 20 - 26 27.1 - 35.2 22 - 31 29.8 - 42

M10 4T 1.50 20 - 25 27.1 - 33.9 1.25 20 - 29 27.1 - 39.3

7T 34 - 40 46.1 - 54.2 35 - 47 47.4 - 63.7

8T 38 - 46 51.5 - 62.3 40 - 52 54.2 - 70.5

M12 4T 1.75 28 - 34 37.9 - 46.1 1.25 31 - 41 42 - 55.6

7T 51 - 59 69.1 - 79.9 56 - 68 75.9 - 92.1

8T 57 - 66 77.2 - 89.4 62 - 75 84 - 101.6

M14 4T 2.00 49 - 56 66.4 - 75.9 1.50 52 - 64 70.5 - 86.7

7T 81 - 93 109.8 - 126 90 - 106 122 - 143.6

8T 96 - 109 130.1 - 147.7 107 - 124 145 - 168

M16 4T 2.00 67 - 77 90.8 - 104.3 1.50 69 - 83 93.5 - 112.5

7T 116 - 130 157.2 - 176.2 120 - 138 162.6 - 187

8T 129 - 145 174.8 - 196.5 140 - 158 189.7 - 214.1

M18 4T 2.00 88 - 100 119.2 - 136 1.50 100 - 117 136 - 158.5

7T 150 - 168 203.3 - 227.6 177 - 199 239.8 - 269.6

8T 175 - 194 237.1 - 262.9 202 - 231 273.7 - 313

M20 4T 2.50 108 - 130 146.3 - 176.2 1.50 132 - 150 178.9 - 203.3

7T 186 - 205 252 - 277.8 206 - 242 279.1 - 327.9

8T 213 - 249 288.6 - 337.4 246 - 289 333.3 - 391.6

FINE THREAD

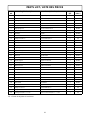

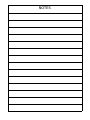

PARTS BREAKDOWN / NOMENCLATURE DES PIÈCES

SUBFRAME / SOUS-CHÂSSIS

18

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

Bercomac 700259-4 700258-2 Manuel utilisateur

- Catégorie

- Tracteur

- Taper

- Manuel utilisateur

dans d''autres langues

Documents connexes

-

Bercomac 700413-2 Le manuel du propriétaire

-

Bercomac 700413-2 Le manuel du propriétaire

-

Bercomac 700279-4 700280-1 Manuel utilisateur

-

Bercomac 700413-5 700459-1 700459-2 Manuel utilisateur

-

Bercomac 700279-3 Le manuel du propriétaire

-

Bercomac C151 61576 0 _ C151 61577 0 Manuel utilisateur

-

Bercomac C151 61676 3 _ C151 61677 3 Manuel utilisateur

-

Bercomac C151 61580 0 Manuel utilisateur

-

Bercomac 700457 700459 Manuel utilisateur

-

Bercomac 700565 Manuel utilisateur