1

"

For

READ & FOLLOW ALL SAFETY RULES & INSTRUCTIONS BEFORE

OPERATING YOUR EQUIPMENT

J-02

* ASSEMBLY * REPAIR PARTS

* OPERATION * MAINTENANCE

*105122_EN*

105122_EN

2

LIMITED WARRANTY

Bercomac Limitée

92, Fortin North, Adstock, Quebec, Canada, G0N 1S0

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

.

1

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................................................... 2

SAFETY PRECAUTIONS ...................................................................................................................................... 3

SAFETY DECALS .................................................................................................................................................. 5

ASSEMBLY

Tools Required ............................................................................................................................ 6

Step 1: Vehicle Preparation ..................................................................................................................... 7

Step 2: Rotary Broom Preparation .......................................................................................................... 7

Step 3: Subframe Preparation ................................................................................................................. 9

Installing the Winch Hook ........................................................................................................... 12

Step 4: Installation of the Control Box ..................................................................................................... 12

Step 5: Installation of the Wires for the Electric Starter .......................................................................... 13

OPERATION

Familiarization of the Controls .................................................................................................................. 14

Raising and Lowering the Rotary Broom ................................................................................................. 14

Angle Adjustment ...................................................................................................................................... 14

Pressure on the Brush Adjustment .......................................................................................................... 14

General Sweeping .................................................................................................................................... 15

Snow Sweeping ........................................................................................................................................ 15

Lawn Dethatching and Leaf Raking ......................................................................................................... 15

MAINTENANCE & DISMOUNTING

Maintenance .............................................................................................................................................. 16

Brush Replacement .................................................................................................................................. 16

Belt Replacement ...................................................................................................................................... 16

Dismounting .............................................................................................................................................. 17

End of Season Storage ............................................................................................................................ 17

TROUBLESHOOTING ........................................................................................................................................... 18

TORQUE SPECIFICATION TABLE ...................................................................................................................... 19

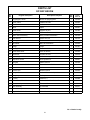

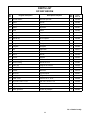

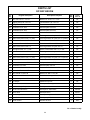

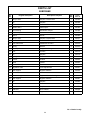

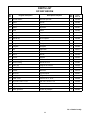

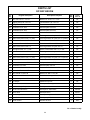

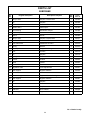

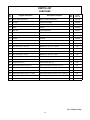

PARTS BREAKDOWN AND PARTS LIST

Rotary Broom ............................................................................................................................................ 20

Subframe ................................................................................................................................................... 25

ATTACHMENTS ..................................................................................................................................................... 28

PAGE

2

INTRODUCTION

TO THE PURCHASER

This new accessory was carefully designed to give years of dependable service. This manual has been provided to

assist in the safe operation and servicing of your attachment.

NOTE: All photographs and illustrations in the manual may not necessarily depict the actual models or attachment, but

are intended for reference only and are based on the latest product information available at the time of publication.

Familiarize yourself fully with the safety recommendations and operating procedures before putting the machine to

use. Carefully read, understand and follow these recommendations and insist that they be followed by those who will

use this attachment.

THIS SAFETY ALERT SYMBOL IDENTIFIES AN IMPORTANT SAFETY MESSAGE IN THIS

MANUAL THAT HELPS YOU AND OTHERS AVOID PERSONAL INJURY OR EVEN DEATH.

DANGER, WARNING, AND CAUTION ARE SIGNAL WORDS USED TO IDENTIFY THE LEVEL OF

HAZARD. HOWEVER, REGARDLESS OF THE HAZARD, BE EXTREMELY CAREFUL.

DANGER: Signals an extreme hazard that will cause serious injury or death if recommended precautions

are not followed.

WARNING: Signals a hazard that may cause serious injury or death if the recommended precautions are

not followed.

CAUTION: Signals a hazard that may cause minor or moderate injury if the recommended precautions are

not followed.

Record your attachment serial number and purchase date in the section reserved below (there is no serial number on

the subframe). Your dealer requires this information to give you prompt, efficient service when ordering replacement

parts. Use only genuine parts when replacements are required.

If warranty repairs are required please present this registration booklet and original sales invoice to your selling dealer

for warranty service.

This manual should be kept for future reference.

Please check if you have received all the parts for your kit with the list of the

bag and the list of the box.

SERIAL NUMBER : ___________________________

(IF APPLICABLE)

MODEL NUMBER: ___________________________

PURCHASE DATE : ___________________________

3

SAFETY PRECAUTIONS

Careful operation is your best insurance against an accident. Read this section carefully before operating the vehicle

and accessory. This accessory is capable of amputating hands and feet and throwing objects. Failure to observe the

following safety instructions could result in serious injury. All operators, no matter how experienced they may be,

should read this and other manuals related to the vehicle and accessory before operating. It is the owner's legal

obligation to instruct all operators in safe operation of the accessory.

GLOSSARY:

In this manual, right and left sides are determined by

sitting on the seat of the vehicle facing forward.

In this manual, "accessories" means attachments

(snowblower, rotary broom, blade etc.) that you install

on the vehicle (lawn tractors, A.T.V. s etc).

TRAINING:

This symbol, "Safety Alert Symbol", is used

throughout this manual and on the

accessory’s safety labels to warn of the

possibility of serious injury. Please take

special care in reading and understanding

the safety precautions before operating the

vehicle and accessory.

1. Read this owner's manual carefully. Be thoroughly

familiar with the controls and proper use of the

vehicle and accessory. Know how to stop the unit

and disengage the controls quickly.

2. Never allow children to operate the vehicle nor the

accessory. Never allow adults to operate the vehicle

nor the accessory without proper instructions.

3. No one should operate the vehicle nor the

accessory while intoxicated or while taking

medication that impairs the senses or reactions.

4. Keep the area of operation clear of all people,

particularly small children and pets.

PREPARATION:

1. Thoroughly inspect the area where the accessory

is to be used and remove door mats, all foreign

objects and the like.

2. For motorized accessories, disengage all clutches

and shift into neutral before starting engine.

3. Do not operate the accessory without wearing

adequate winter outer garments. Avoid loose fitting

clothing that can get caught in moving parts. Wear

footwear that will improve footing on slippery

surfaces.

4. Handle fuel with care, it is highly flammable.

a) Use approved fuel container.

b) Never add fuel to a running engine or hot engine.

c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

d) Never fill containers inside a vehicle, or on a

truck or a trailer bed with a plastic liner. Always

place containers on the ground, away from your

vehicle, before filling.

e) When practical, remove gas-powered

equipment from the truck or trailer and refuel it

on the ground. If this is not possible, then refuel

such equipment on a trailer with a portable

container, rather than from a gasoline

dispenser nozzle.

f) Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times, until

refueling is complete. Do not use a nozzle lock-

open device.

g) Replace fuel cap securely and wipe up spilled

fuel.

h) If fuel is spilled on clothing, change clothing

immediately.

5. Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by manufacturer).

6. Let the vehicle and accessory adjust to outdoor

temperatures before starting to clear snow.

7. Never use an accessory without proper guards,

plates, or other safety protective devices in place

8. Always make sure to wear the appropriate safety

equipment required (glasses, muffs, mask…) for

each type of product. See operation section.

9. Always make sure of having safe traction on the

vehicle by using the recommended accessories

(chains, A.T.V. tracks, counterweights…). See

operation section.

10. Never modify the accessory or any part without

the written consent from the manufacturer.

4

OPERATION:

1. Do not put hands or feet near, under or inside rotating

parts.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks or roads. Stay alert for

hidden hazards or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine (motor),

disconnect the wire from the spark plug(s) and keep

wire away to prevent accidental starting. Thoroughly

inspect the accessory for any damage and repair

damage before restarting and using the accessory.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the

cause. Vibration is generally a warning of trouble.

5. Take all possible precautions when leaving the

vehicle unattended. Disengage the power take-off,

lower the attachment, place the transmission into

neutral, set the parking brake, stop the engine and

remove the contact key.

6. Do not run the engine indoors, except when starting

the engine and for transporting in or out of the

building. Do not operate or let motor run in a storage

area without ventilation because gas contains

carbon monoxide which is odorless, colorless and

can cause death.

7. Never clean across the face of slopes, go from top

to bottom. Exercise extreme caution when using

equipment on slopes. Do not attempt to clear a

steep slope.

8. Never tolerate bystanders in the working zone.

Never use an accessory in the direction of

bystanders, it might throw gravel or debris that can

hurt people or damage property.

9. Never operate the accessory at high transport

speeds on slippery surfaces. Use care when

backing up.

10. Do not carry passengers.

11. Disengage power to the accessory when it is

transported or not in use.

12. Never operate the accessory without good visibility

or light.

14. Keep the accessory away from heat sources or

flames.

MAINTENANCE AND STORAGE

1. When cleaning, repairing or inspecting the vehicle

and accessory, make certain that all moving parts

have stopped. Disconnect wire from the spark

plug(s) and keep wire away to prevent accidental

starting.

2. Check all the bolts and components at frequent

intervals to make sure that they are properly

tightened.

3. Never store a motorized accessory with fuel in the

fuel tank inside a building where ignition sources are

present such as hot water and space heaters,

clothes dryers, and the like. Allow the engine to cool

before storing in any enclosure.

4. Always refer to the owner’s manual when you store

the accessory and vehicle for a prolonged or an

unspecified length of time.

5. Maintain or replace safety and instruction labels, as

necessary.

6 For winter accessories, (if applicable), let the engine

run for a few minutes after clean snow in order to

prevent the rotary parts from freezing.

7. Inspect the vehicle’s and accessory’s air filter every

day. Clean it or replace it as necessary. Change the

oil more often when working in dusty conditions.

See the vehicle’s and accessory's owner’s manual.

THIS SYMBOL MEANS

DANGER !

BECOME ALERT !

YOUR SAFETY IS INVOLVED !

SAFETY PRECAUTIONS

5

REPLACE IF DECALS ARE DAMAGED

SEE PARTS BREAKDOWN FOR DECAL LOCATION

SAFETY DECALS

To avoid injury from drive belt:

Keep hands, feet & clothing away.

Do not attempt to install or remove drive belt without

reading owner’s manual.

DECAL #105128

Before installing or using:

Locate, read and make sure to understand all of the

owner’s manual.

DECAL #105131

Refer to owner’s manual about wearing safety

glasses, ear muffs and mask.

Refer to owner’s manual for use of counter weights,

cat tracks and tire chains.

DECAL #105130

1-Do not drive faster than 3 KM/H when the rotary

broom is in operation.

2-Do not drive faster than 10 KM/H when the rotary

broom is in the raised position.

3-The sound pressure level (dBA) is measured at 1

meter from the engine (full charge at 3600 RPM).

1

2

3

6

ASSEMBLY

IMPORTANT: TORQUE ALL BOLTS ACCORDING

TO TORQUE SPECIFICATION TABLE (SEE TABLE

OF CONTENTS) WHEN STATED: TIGHTEN

FIRMLY. REFER TO PARTS BREAKDOWN

SECTION FOR PART IDENTIFICATION.

Overall view

TOOLS REQUIRED

Wrenches: 9/16’’, 10mm, 1 1/16’’, 7/16’’, 1/2’’, 3/4’’

Ratchet

Sockets 9/16’’, 1 1/16’’, 7/16’’, 1/2’’, 3/4’’

Drill

1/4’’ bit

Cutting pliers

Wrench (for the nuts on the vehicle’s battery posts)

7

ASSEMBLY

STEP 2

ROTARY BROOM PREPARATION:

STEP 1

VEHICLE PREPARATION:

NOTE: A 1 7/8” or 50 mm tow hitch ball is required.

A) Install the lift strap (item 1) by looping it around the

suspension arm (as shown) on the vehicle.

Tighten the loop firmly.

# Item Description Action

B) Install the brackets (item 3) on both sides of

vehicle.

Bolt and nut from

suspension arm

Remove.

2-3 Flat washer and

bracket

Install and lightly

secure with the

original bolt and nut.

C) Install the brackets (item 4) on both sides of

vehicle.

Nut from

suspension arm

Remove.

4 Bracket Install and lightly

secure with the

original nut.

Choose among the three different options to prepare

your vehicle (A, B, C).

Install the lift strap or the brackets.

Install parking stands

Install a parking stand on each side of broom.

# Item Description Action

1 Parking stand

(qty 2)

Insert in stand holder.

2 Cotter pin 5/32 x 1’’

(qty 2)

Secure in top hole as

shown.

3 Hair pin 2.5mm

(Qty 2)

Secure in bottom

hole as shown.

This will allow the broom to rest on the parking

stands.

8

ASSEMBLY

CAUTION

Never use the Rotary Broom without the belt

guard.

DANGER

NEVER OPERATE THE ROTARY BROOM

WITHOUT:

Brush hood

Belt guard

Gear box guard

Extension guard and any other safety protection

devices in place.

Install the push frame

Install the link

Install the push frame (item 1).

# Item Description Action

1 Push frame Insert under the

motor frame.

2 Cone bearing

(qty 2)

Insert as shown.

3 Seal washer Secure with hollow

portion towards the

top.

Tighten loosely enough to permit the push frame to

move freely.

Fill the space between the bearings with grease.

4 Nylon insert lock nut Secure from the

bottom as shown.

Install the link (item 3)

# Item Description Action

1 Hex bolt

1/4 X 1’’ (qty 2)

Insert under the lever

as shown.

2 Flat washer

(qty 2)

Install on lever as

shown.

3 Link Install one end of link

on the bolt as shown.

Tighten loosely enough to permit the parts to move

freely.

Install the other end of the link on the pivot following

the same steps as shown.

4 Nylon insert lock nut

(qty 2)

Secure link as

shown.

9

ASSEMBLY

Install the wheel support

Install the assembled turnbuckles

Install broom to subframe

STEP 3

SUBFRAME PREPARATION:

NOTE: Determine according to the height of the

vehicle which set of holes to use to assemble the

wheel support (item 1) to the subframe* (See below).

Install the wheel support (item 1).

# Item Description Action

1 Wheel support Install to the

subframe.

2 Hex bolt

3/8" x 1"(qty 4)

Insert as shown.

3 Flange nut 3/8"

(qty 4)

Tighten firmly.

*The subframe must be parallel with the ground when

the subframe is installed under the vehicle.

Install the assembled turnbuckles (item 1).

# Item Description Action

1 Assembled

turnbuckle (qty 2)

Install on subframe as

shown.

2 Flat washer 3/8"

(qty 2)

Install on the

assembled

turnbuckles as shown.

3 Hex bolt

5/16" x 1"(qty 2)

Insert as shown.

4 Nylon insert lock nut

5/16" (qty 2)

Install and tighten

firmly.

NOTE: Position the chains as shown and tighten

firmly.

Install the broom to the subframe.

# Item Description Action

1 Hair pin

4mm

Remove from pin

(item 2).

2 Pin Remove as shown.

Install the broom’s push frame to the subframe.

Secure with the pin and hair pin previously removed.

NOTE: The hooked end of the pin must be inserted

into the hole to lock it in place.

10

ASSEMBLY

Choose between the three positions (see figure), the

height of the hitch support.

There must be a maximum of ground clearance

according to your vehicle.

Figure A does not have the hitch support (item 1).

Assemble the hitch supports (item 1) and the hitch

(item 3).

# Item Description Action

1 Hitch support

(qty 2)

Install the supports on

the hitch support.

2 Hex bolt

3/8’’ x 3/4’’

(qty 4)

Insert in chosen holes

(two on each side) and

secure with the flange

nuts 3/8’’.

Tighten firmly.

3 Hitch Insert on the two hitch

supports (if applicable).

4 Hex bolt

3/8’’ x 3’’

Insert in hole as shown

and secure with nylon

insert lock nut 3/8’’.

Assemble the hitch support

You have seven different positions on the adjustment

tube (item 1) (the the adjustment tube can be

inverted) to adjust the length of the subframe.

To choose the right adjustment, insert the adjustment

tube (item 1) into the subframe (item 2) and insert the

hitch support (item 3) on the adjustment tube. Do not

secure.

Turn the hitch support to the side to facilitate

installation.

Drive the vehicle over the subframe, make sure the

caster wheels do not touch the front wheels of the

vehicle.

Identify the right length and secure in place with a pin

(item 4) and 3mm hair pin (item 5).

IMPORTANT: Make sure the adjustment tube is

inserted to its maximum in the subframe in order to

prevent premature damage to the subfame.

Adjust length of subframe

11

ASSEMBLY

Install the assembled hitch support (item1) on the

vehicle’s tow hitch ball.

# Item Description Action

1 Assembled hitch

support

Insert onto the

adjustment tube.

2-3 Pin and 3mm hair

pin

Secure in place.

NOTE: The hitch support has two sets of holes to

increase the length of the subframe if necessary.

1 Assembled hitch

support

Attach on the

vehicle’s tow hitch

ball.

4-5 Pin and 3mm hair

pin

Secure.

Make sure the subframe does not come into contact

with vehicle at any time.

NOTE: You can turn the hitch assembly (item 1) by

removing the pin (item 2) to facilitate driving the

vehicle over the subframe.

WARNING : Always check that ball is completely

inserted into hitch coupler socket and that the

underjaw is securely closed around the bottom of ball.

Always check tightness before using the tow hitch. If

necessary, tighten locknut against tension spring.

Be sure hitch coupler handle is in locked position.

Secure the hitch support on the tow hitch ball

Install the turnbuckles (item 1) into the brackets or

into the lift straps.

# Item Description Action

1 Turnbuckle

(qty 2)

Adjust them so that the

subframe is centered

under the vehicle.*

*Tighten the turnbuckles firmly in order to tighten the

vehicle's suspension.

IMPORTANT: After adjusting the turnbuckles, tighten

the nuts on the vehicle’s suspension arms firmly.

Make sure to lock the nuts with the original locks.

Install the turnbuckles

12

Attach the vehicle’s winch’s hook on the bracket.

# Item Description Action

If the vehicle's winch is

higher than 20" (510mm) from the ground.

1 Sleeve Install in the top hole

of the lever.

If the vehicle's winch is

lower than 20" (510mm) from the ground.

1 Sleeve Install in the bottom

hole of the lever.

2 Hex bolt 1/2" x 2

1/4" and nylon

insert lock nut

Tigten firmly.

Vehicle’s winch’s

hook

Install on bracket as

shown.

Tip: Thread the winch’s hook behind the lever as

shown and then thread the cable over the sleeve.

ASSEMBLY

Install the winch hook

STEP 4

INSTALLATION OF THE CONTROL BOX

As shown, choose from the three different ways to

secure the control box support (item 1).

Use two hex bolts 1/4” x 1 1/2” (item 2), the support

brackets (item 4), spacers (item 3) and the flange

nuts.

Insert the control box (item 5) into the support.

Install the control box

13

ASSEMBLY

Wires for the control box:

Connect the red wire (item 1) to the positive post and

the black wire (item 2) to the negative post on the

vehicle's battery.

NOTE: Secure the wires to the vehicle with the nylon

tie wraps. These wires will stay on the vehicle.

IMPORTANT: The control box is equipped with a red

emergency kill switch (item 3) in case you need to

stop the engine quickly.

NOTE: The emergency kill switch must be pulled out

to start the engine for the broom.

Install the wires of the control box

STEP 5

INSTALLATION OF THE WIRES FOR THE

ELECTRIC STARTER:

Wires for the electric starter:

C o n n e c t t h e w i r e a s s e m b l y ( i t e m

1) on the ATV’s battery, the longest red wire (positive)

(item 1) on the positive post as shown.

Connect the black wire (negative) (item 3) on a bolt

that is on the A.T.V’s. frame (scrape away any paint

to make sure the contact is good) and retighten the

bolt.

Connect the electric starter wire assembly to the wire

assembly on the battery.

NOTE: Attach the wires to the vehicle with the nylon

tie wraps. These wires will stay on the vehicle.

Install the wires for the electric starter

14

OPERATION

WARNING

Read the vehicle owner’s manual carefully. Be

thoroughly familiar with the controls & proper

use of the attachment. Know how to stop the

accessory quickly.

PRESSURE ON THE BRUSH ADJUSTMENT

By turning the adjustment screw (item 1) counter

clockwise, the gauge (item 2) moves higher and the

pressure of the brush on the ground increases. By

turning the adjusting screw clockwise, the gauge

(item 2) moves lower on the gear box frame and the

pressure of the brush on the ground decreases.

IMPORTANT: Adjust frequently to compensate for

brush wear. Remember to sweep with the tips of the

bristles like a broom and not with the sides of the

bristles like a mop. Too much pressure can decrease

the brush life up to 95%.

Adjust the pressure on the brush

FAMILIARISATION OF THE CONTROLS:

Familiarize yourself with the controls before using.

a) Raise the broom.

b) Start the engine (full throttle).

c) Engage the broom (item 3).

d) Lower to the ground.

e) Adjust the pressure on the brush (item 1).

ANGLE ADJUSTMENT:

In order to be able to change the angle of the broom

follow these instructions.

a) Raise the broom to its maximum (the lock

mechanism will disengage).

b) Activate the control to turn the broom to the angle

desired.

c) Lower the broom to the ground (the locking

mechanism will reengage).

NOTE: It is not necessary to perfectly align the latch

with the slots. When the broom will be lowered to the

ground the springs will allow the latch to engage itself

into the slot.

WARNING

TO PREVENT INJURIES AND FOR MORE

TRACTION WITH ROTARY BROOM:

-Do not drive faster than 3 km/hr (2 m/hr) with

rotary broom on the ground.

-Do not drive faster than 10 km/hr (6 m/hr) with

the rotary broom in raised position.

-Do not operate on a slope greater than 10°.

-A.T.V. manufacturer approved tire chains are

required.

RAISING AND LOWERING THE ROTARY BROOM:

Use the winch switch control to raise and lower the

rotary broom.

IMPORTANT: To prolong the subframe’s life, release

the switch immediately when the attachment hits the

stopper in the highest position.

IMPORTANT:

Always keep the winch cable taut when the broom is

in operation to keep the wheel support on the ground.

15

GENERAL SWEEPING

Minimize dust by reducing brush speed and by

sweeping after rain or on a day with high moisture.

SNOW SWEEPING

Adjust the gauge (item 2) to be even with the top of

gear box frame. The broom works well for light snow

removal.

Sweep with the wind blowing in the direction of broom

discharge (wind in your back).

NOTE: Foreign objects in the snow may be thrown

faster than the snow itself.

Frequently clean the snow and ice accumulation from

the top and bottom of the broom hood.

LAWN DETHATCHING AND LEAF RAKING:

Lower the broom on a hard surface and lift the brush

1" from the ground by turning the adjusting screw

clockwise. The brush is supported by dolly wheels.

This adjustment is normally satisfactory but you may

raise or lower depending upon grass height.

Low brush speed and ground speed is best for lawn

dethatching and leaf raking.

OPERATION

16

MAINTENANCE & DISMOUNTING

MAINTENANCE

a) Check oil level in gear box every fifty hours and fill to

plug level with SAE-90-EP oil when necessary.

b) Grease the wheel axles after every eight hours of

use.

c) Chain: do not lubricate when used in dusty

conditions. After use, wash clean and lubricate.

d) Adjust the chain frequently by moving the idler

sprocket to give 1/2" deflection.

e) Frequently clean the interior and exterior of hood,

dirt, mud, ice, etc, accumulation adds weight on the

brush and could result in premature wear of brush.

f) Check mounting bolts at frequent intervals for proper

tightness to be sure equipment is in safe working

conditions.

g) Apply oil at all pivot points.

h) Inspect the air filter on the vehicle and accessory

every day. Clean it or replace it when necessary.

Change the oil more often when working in dusty

conditions. See the owner's manual for the vehicle

or for the accessory.

BRUSH REPLACEMENT:

See parts breakdown section for parts identification.

a) Remove the hood.

b) Loosen the chain idler sprocket.

c) Remove the bolts from both flangettes that holds the

brush hollow shaft.

d) Remove the brush hollow shaft from the broom

frame.

e) Loosen the set screw and remove the right bearing

from the brush hollow shaft

f) Remove the bolt which retains the brush to the brush

hollow shaft.

g) Remove the brush tube from axle.

h) Install the new brush by reversing the procedure.

i) Adjust the tension on the chain by moving the idler

sprocket to give a 1/2" deflection on the length of the

chain.

BEFORE DOING ANY MAINTENANCE OR

DISMOUNTING AN ACCESSORY, REFER TO THE

SAFETY PRECAUTIONS.

CAUTION

Never use the Rotary Broom without the belt

guard.

BELT REPLACEMENT:

For belt part numbers, refer to parts breakdown

section for parts identification.

a) Remove the belt guard (item 1).

b) Replace the belt (item 2).

c) Engage the accessory.

d) Make sure the pulleys are well aligned.

e) Engage and reinstall the belt guard.

17

END OF SEASON STORAGE

a) Clean the broom and inside of the hood and paint

all the parts where the paint has worn off.

b) Take note of the replacement parts needed for

next season.

c) Lubricate all grease fittings and all moving parts.

d) Store broom on parking stands. Make sure the

brush bristles never touch the ground.

e) If brush bristles are exposed to direct sunlight,

protect the bristles with a tarp.

f) Store the broom in a dry place.

DISMOUNTING

a) Select a level surface, set parking brake, stop the

engine, and remove the ignition key to prevent

accidental starting.

b) Straighten the broom perpendicular with the

vehicle.

c) Set the parking stands in their most extended

position Make sure the brush bristles never touch

the ground.

d) Lower the broom to the ground.

e) Unhook the turnbuckles from the front of the

vehicle, the hook from the winch and the hitch

from the rear of the vehicle.

f) Remove the control box (item 1) from the support

(item 2). Disconnect the wires (item 3) and place

the box on the accessory.

g) Remove the vehicle.

MAINTENANCE & DISMOUNTING

18

TROUBLESHOOTING

* Please refer to parts breakdown section for parts identification

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTION

Brush wears out prematurely or

does not wear out evenly.

The brush turns jerkily.

The pressure on the brush is not

well adjusted.

Too much pressure on the brush, it

will wear out up to 5 times faster.

Reduce the pressure on the brush

when on the ground.

Adjust when needed to compensate

for the wearing out of the brush.

Always sweep with the tips of the

bristles like a broom and not with

the sides of the bristles like a mop.

Maintain the gauge even with the

top of the gear box frame or lower

when sweeping hard surfaces.

The brush does not sweep well. Debris accumulation. Clean the inside and outside of the

hood frequently during operation.

Dirt, mud, ice, etc.. accumulation

adds weight on the brush and could

result in premature wear of the

brush.

The brush is too aggressive when

lawn dethatching or leaf raking.

The brush does not turn on the

grass.

Too much pressure on the brush. Lower the broom on a hard surface

and lift brush 1" from the ground by

turning the adjusting screw

clockwise.

Adjust from time to time if

necessary.

The chain wears out prematurely.

Inappropriate lubrication. Do not lubricate the chain during

operation. Wait until the job is

finished.

Wash the rotary broom and

lubricate the chain.

Let the broom turn a few moments

so the oil penetrates in the chain.

Th e s p r o c ke t w e a r s o u t

prematurely.

Chain is not adjusted. Check the chain adjustment

frequently (too tight, too loose).

Loss of steering. Too much pressure on the brush. Reduce pressure on the brush. If

problem persists, contact your

dealer for more information.

The bristles take a bad form or

shape.

The broom was not stored on the

parking stands.

Wash the broom with warm water or

warm steam. Leave in raised

position and let it turn a few turns.

The brush should take its original

shape.

Electric motor does not work Motor overheating. These motors are equipped with an

internal protector.

Wait 10 minutes before using.

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

dans d''autres langues

- English: Bercomac 700448-2 User manual

Documents connexes

-

Bercomac 700448-1 Manuel utilisateur

-

Bercomac 700516-2 Manuel utilisateur

-

Bercomac 700316-2 Manuel utilisateur

-

Bercomac 700360-6 Manuel utilisateur

-

Bercomac 700480-1 Manuel utilisateur

-

Bercomac 700490-1 700491-1 700492-1 Manuel utilisateur

-

Bercomac 700457 700458 Manuel utilisateur

-

Bercomac 700457-1 700459 Manuel utilisateur

-

Bercomac 700527-2 700529-1 Manuel utilisateur

-

Bercomac 700316-3 Manuel utilisateur