Nilfisk SC4000 28C HP ECO 234AH OBC Le manuel du propriétaire

- Catégorie

- Machine à plancher

- Taper

- Le manuel du propriétaire

Ce manuel convient également à

Model No:

56120070 (28C), 56120071 (28D), 56120072 (28 REV), 56120073 (32C), 56120074 (34D),

56120405 (28C HP), 56120406 (28D HP), 56120407 (28 REV HP),

56120408 (32C HP), 56120409 (34D HP)

SC4000

Instructions for Use Instructions for Use

Original Instructions

Instrucciones de uso

Mode d’ emploi

9/2022 revised 1/2023 REV B

Form no. 56091272

A-English

B-Español

C-Français

A - 2 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

TABLE OF CONTENTS

Introduction .................................................................................3

Parts and Service ......................................................................3

Modications .............................................................................3

Name Plate ................................................................................3

Uncrate the Machine ................................................................. 4

Transporting the Machine .......................................................... 4

Cautions and Warnings.............................................................. 5

Regulatory ...................................................................................7

Know Your Machine....................................................................8

Control Panel ...........................................................................10

Information Menu Display ........................................................13

Magnetic SmartKey™ .............................................................15

Prepare the Machine for Use ...................................................15

Lead-Acid Batteries .................................................................15

Lead-Acid Battery Installation ..................................................15

Install the Brushes (disc system) .............................................17

Install the Brushes (cylindrical system) ................................... 18

Install the Pads (REV™ system) .............................................19

Filling the Solution Tank ..........................................................20

Solution Tank Indicator ............................................................ 20

Squeegee Installation ..............................................................21

Detergent System Preparation (with Ecoex) .........................22

Fill the Detergent Cartridge .................................................. 22

Detergent System Purge (with EcoFlex) .............................. 23

Detergent System Use (Ecoex) .............................................24

Operating the Machine .............................................................27

Starting the Machine ...............................................................27

Stopping the Machine ..............................................................27

Operating the Machine (Disc & Cylindrical) .............................28

Wet Vacuuming ....................................................................... 29

Operating the Machine (REV) ................................................. 30

Wet Vacuuming ....................................................................... 31

After Use .................................................................................32

Maintenance ..............................................................................33

Maintenance Schedule ............................................................33

Cleaning Recovery Tank ......................................................... 34

Cleaning Solution Filter ........................................................... 34

Lubricating the Machine .......................................................... 35

Electromagnetic Brake ............................................................ 35

Charging Wet Lead-Acid Batteries .......................................... 36

Charging GEL/AGM (VRLA) Batteries ....................................37

Charging Other Types of Batteries .......................................... 37

Squeegee Maintenance ..........................................................38

Squeegee Adjustment ............................................................. 38

Side Blade Maintenance .........................................................40

Side Blade Height Adjustment ................................................. 40

Side Blade Pressure Adjustment - Cylindrical Adjustable Only 42

Side Blade - Double Scrub Position ........................................ 42

Troubleshooting ....................................................................... 43

General Machine Troubleshooting ..........................................43

Fault Code Display ..................................................................44

Fault Code History ...................................................................45

Specications ........................................................................... 46

Accessories / Options ..............................................................46

Solution Flow Rates ................................................................46

Technical Specications .......................................................... 47

9/2022 A - 3 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

INTRODUCTION

This manual will help you get the most from your Advance Scrubber. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages 8 – 12.

This machine is intended for commercial use, for example in hotels, schools, factories, shops, ofces and rental businesses. The Advance

SC4000 is a battery powered oor cleaning machine.

WARNING:

The operation of this machine is strictly reserved to trained and qualied operators.

CAUTION!

• Use extreme CAUTION when operating this machine. Be certain that you are thoroughly familiar with all operating

instructions before using this machine. If you have any questions, contact your supervisor or your local Advance Dealer.

• If the machine malfunctions, do not try to correct the problem unless your supervisor directs you to do so. Have a

qualied company mechanic or an authorized Advance Dealer service person make any necessary corrections to the

equipment.

• Use extreme care when working on this machine. Loose clothing, long hair, and jewelry can get caught in moving parts.

Turn the Power Switch OFF and remove the magnetic key before servicing the machine. Use good common sense,

practice good safety habits and pay attention to the yellow decals on this machine.

• Drive the machine slowly on inclines.

• The maximum rated incline for scrubbing is 9% (5°). The maximum rated incline during transport is 16% (9°).

PARTS AND SERVICE

Repairs, when required, should be performed by Nilsk, Inc., who employs factory trained service personnel, and maintains an inventory of

Advance original replacement parts and accessories.

Call Nilsk, Inc. for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

MODIFICATIONS

Modications and additions to the cleaning machine which affect capacity and safe operation shall not be performed by the customer or user

without prior written approval from Nilsk, Inc. Unapproved modications will void the machine warranty and make the customer liable for any

resulting accidents.

NAME PLATE

The Model Number (also known as Part Number) and Serial Number of your machine are shown on the Nameplate, located on the rear of the

steering column.

Date of Manufacture “Date Code” is marked on the nameplate. Date Code: A21, means January 2021.

This information is needed when ordering repair parts for the machine. Use the space below to note the Model Number and Serial Number of your

machine for future reference.

MODEL NO. ___________________________________________________________

SERIAL NO. ___________________________________________________________

A - 4 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

UNCRATE THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping

carton (if applicable) so that it can be inspected. Contact the Nilsk Customer Service Department immediately to le a freight damage claim.

Refer to the unpacking instruction sheet included with the machine to remove the machine from the pallet.

TRANSPORTING THE MACHINE

CAUTION!

Before transporting the machine in an open truck or trailer, make sure that . . .

• All tanks are empty.

• All access doors are latched securely.

• Lower scrub deck and squeegee then press Emergency Stop (A) or disconnect batteries to prevent them from raising when the machine is

powered off.

• The machine is tied down securely - see Tie Down Locations (21) in “Know Your Machine”. Only use locations designated as “Tie Down

Locations” to secure the machine during transport. Using any other location of the machine to tie down the machine may cause damage or

injury.

• The machine’s electromagnetic brake is engaged (not manually overridden), see “Electromagnetic Brake” section if necessary.

• The machine is turned off and the magnetic SmartKey™ is removed.

9/2022 A - 5 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

CAUTIONS AND WARNINGS

SYMBOLS

Nilsk uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take

the necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specic Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

This machine is intended for commercial use, for example in hotels, schools, factories, shops, ofces and rental

businesses.

WARNING!

• This machine shall be used only by properly trained and authorized persons.

• This machine is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the machine by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the appliance.

• Close attention is necessary when used near children.

• While on ramps or inclines, avoid sudden stops. Avoid abrupt sharp turns. Use low speed down ramps.

• Keep sparks, ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

• Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away

from open ame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the power switch off, remove the magnetic key and disconnect the batteries before servicing electrical

components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense ammable cleaning agents, operate the machine on or near these agents, or operate in areas where

ammable liquids exist.

• Do not pressure wash operator control panel, circuit breaker panel or batteries.

• Only use the brushes provided with the appliance or those specied in the instruction manual. The use of other

brushes may impair safety.

• Observe the Gross Vehicle Weight, GVW, of the machine when loading, driving, lifting or supporting the machine.

• Do not leave the machine unattended without being sure that it cannot move independently.

A - 6 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

CAUTIONS AND WARNINGS - CONTINUED

CAUTION!

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that service task.

• Do not leave the machine unattended without rst turning the power switch off and removing the magnetic key.

• Turn the power switch off and remove the magnetic key, before changing the brushes, and before opening any access

panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery

or detergent tanks or in the hose lines could freeze, causing damage to valves and ttings. Flush with windshield

washer uid.

• The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries

should be safely done in accordance with your local environmental regulations.

• CAUTION - This machine is for indoor use only.

• CAUTION - This machine shall be stored indoors only.

• Do not use on surfaces having a gradient exceeding that marked on the machine.

• All doors and covers are to be positioned as indicated in the instruction manual before using the machine.

• Only use locations designated as “Tie Down Locations” to secure the machine during transport. Using any other

location of the machine to tie down the machine may cause damage or injury.

• Do not operate the machine on a grade outside that which is written on the nameplate.

• Do not carry passengers on any part of the machine.

• In order to prevent unauthorized use of the machine, the power source shall be switched off or locked, and key

removed.

• Machines left unattended shall be secured against unintentional movement.

SAVE THESE INSTRUCTIONS

9/2022 A - 7 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

REGULATORY

SC4000 with TC-1 IoT module

FCC:

FCC-ID: 2AVNE-TC1

This device and its antenna must not be co-located or operating in conjunction with any other antenna or transmitter. Non

body-worn devices must be placed at least 8” (20cm) away from the body.

IC:

IC-ID: 25476-TC1

This device complies with Industry Canada license-exempt RSS standards RSS-210 and/or RSS-247. The term “IC” before

the equipment certication number only signies the Industry Canada technical specications were met. It does not imply

that Industry Canada approved the equipment. The radio transmitter has been approved by Industry Canada to operate only

with the antenna supplied. Use of any other antenna is strictly prohibited for use with this product. This device complies with

the ICES RF radiation exposure limits set forth for an uncontrolled environment. This equipment should be installed and

operated with a minimum distance of 20cm between the radiator and any part of the human body.

A - 8 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

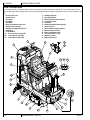

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item

shown on these pages unless otherwise noted. Refer back to these pages whenever necessary to pinpoint the location of an item mentioned in the

text.

1 Recovery Tank Cover

2 Operator’s Seat

3 Drive Pedal

4 Drive Wheel

5 Rear Wheel

6 Battery Compartment (under seat)

7 Warning Beacon (optional)

8 Detergent Cartridge (with EcoFlex™)

9 Storage Box

10 Circuit Breakers

10a Drive Controller 70 Amp (CB2)

10b Control Board 5 Amp (CB1)

10c Control Board 5 Amp (CB3)

11 Headlights (optional)

12 Blue Light (optional)

13 Solution Tank Drain Hose (optional)

14 Front Roller Bumper

15 Scrub Deck

16 Side Blade Assembly Removal Knobs

17 Solution Tank Fill

18 Onboard Battery Charger (optional)

19 Machine Battery Connector

20 Battery Compartment Latch

21 Tie-Down Location (1 front)

22 SmartKey™ Reader

39 Magnetic SmartKey™

1

2

34

5

6

8

89

10

12

13

15

14

10a 10c

10b

12

11

16

11

13

6

7

17

18

14

21

22

9

39

19

20

9/2022 A - 9 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

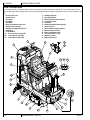

KNOW YOUR MACHINE

21 Tie Down Location (2 rear)

23 Control Panel

24 Recovery Tank Cover

25 Recovery Tank Shutoff Float

26 Vacuum Motor Filter Housing

27 Debris Catch Tray

28 Recovery Tank Drain Hose

29 Recovery Hose

30 Squeegee Tilt Adjust Knob

31 Squeegee Mount Thumb Nuts

32 Squeegee Caster Lock Knob

33 Squeegee Assembly

34 Hopper (Cylindrical only)

35 Scrub Deck

36 Solution Filter

37 Solution Shutoff Valve

38 Solution Solenoid Valve (on scrub deck)

23

25

28

31

32

33

21

34

35

37

36

29

30

24

26

27

38

A - 10 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

CONTROL PANEL

A Emergency Stop

B Information Switch & Navigation Switches

C Display (see Control Panel-Continued)

D Reverse Paddle

E Horn Paddle

F Solution Switch

F+ Solution Flow Increase Switch

F- Solution Flow Decrease Switch

G Vacuum Switch

H Power Switch

J Detergent Switch

K Brush Install Switch (optional functionality)

L Speed Limiter Switch

M One-Touch™ Scrub ON/OFF Switch

M+ Scrub Pressure Increase Switch

M- Scrub Pressure Decrease Switch

N Burst of Power Paddle

O Timed Solution Off Paddle

F+

CB

O

N

M

M-

LKJH

M+

F

G

A

D

E

F-

9/2022 A - 11 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

CONTROL PANEL - CONTINUED

C1 Hour Meter (Drive Hours)

C2 Active Fault Codes

C3 Battery Indicator

C4 Solution Tank Level Indicator

C5 Speed (MPH or KPH)

C6 Detergent Indicator (with EcoFlex)

C7 Detergent Percentage Indicator

C8 Detergent Indicator Bar Graph

FIRST = Minimum Concentration Detergent Mode

SECOND = Maximum Concentration Detergent Mode

NONE = Off

C9 Solution Flow Indicator

C10 Solution Flow Rate Bar Graph

FIRST = Low

SECOND = Medium

THIRD = High

FOURTH = Extreme

NONE = Off

C11 Scrub Pressure Indicator

C12 Scrub Brush Pressure Bar Graph

FIRST = Regular

SECOND = Heavy

THIRD = Extreme

NONE = Off

C28 Floor Finish Removal Prompt Screen

C29 5 Second Timer

C30 Floor Finish Removal Mode Indicator

C31 Scrub Brush Pressure Bar Graph

FIRST = Regular

SECOND = Heavy

THIRD = Extreme

NONE = Off

C32 Floor Finish Removal Speed Indicator (Low)

C33 Floor Finish Removal Speed Indicator (High)

C1

C2

C3

C4

C5

C8C7

C6

C10

C12

C11

C9

C29

C28

C32

C31

C30

C33

A - 12 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

CONTROL PANEL - CONTINUED

C14 Battery Low Voltage Indicator

C15 Burst of Power Indicator (with EcoFlex)

C16 Vacuum Indicator

C17 Wand Indicator

C18 Brush Install Indicator

C19 Purge Indicator (with EcoFlex)

C20 Emergency Stop Activated Indicator

C21 No Key Indicator

C22 Key Read Error Indicator (see Troubleshooting)

C23 Restricted User Key Indicator (see Troubleshooting)

C24 Critical Fault Indicator

C25 Fault Code (Critical)

C26 Impact Lockout Indicator (see page 13)

C27 Reverse Indicator

C26

C25

C14 C15 C21

C22

C23

C16 C17 C18 C19 C20

C24

C27

9/2022 A - 13 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

INFORMATION MENU DISPLAY

Menu Display

Pressing the Information Switch (B) will bring up the menu shown

below which allows the operator to change machine settings and

gather machine information. Use the four Navigation Arrows (B1)

(up, down, left & right) to move through the menu and the information

switch to exit the menu.

B

Menu

Hours

Faults

Keys

Options

i Exit Select B1

B1

Menu visible with either blue (User) or yellow (Supervisor) SmartKey.

Menu Level Notes

1 2

Hours Displays various system hours

On Time Displays Power ON hours

Drive Time Displays drive(non-neutral) hours

Scrub Time Displays scrub/brush ON hours

Recovery Time Displays recovery/vacuum ON hours

Faults**

Active Faults Displays list of active faults w/timestamp and description

Fault History Displays list of fault history w/timestamp and description

Keys

Read Key Read the key serial number, family and type for key inserted into holder

- if user key, allows supervisor to add to key list

Key List Display the current approved user key list

supervisor can also remove selected key from list

**See Fault Code Display

Menu visible only with yellow (Supervisor) SmartKey.

Menu Level Notes

1 2 3

Options User selectable options

Language

English*

Italiano

Deutsch

Portuguese

Français

Español

Menu display language

Floor

Standard*

Smooth

Polisher**

Floor type

**polisher only available for 34D machines

Scrub Startup

Light

Heavy

Extreme

Last Used*

Scrub level at start

Scrub Max

Light

Heavy

Extreme*

Maximum scrub level allowed

*Default setting

A - 14 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

INFORMATION MENU DISPLAY - CONTINUED

Options Menu visible only with yellow (Supervisor) SmartKey.

System Menu visible with either blue (User) or yellow (Supervisor) SmartKey

Menu Level Notes

1 2 3

Options User selectable options

Solution

Proportional*

Fixed

UK

Solution mode; Proportional – solution ow

increases with speed of machine. Fixed – Solution

ow stays the same despite machine speed. UK

(United Kingdom) – solution ow is reduced to

conserve water.

Solution In Rev No*

Yes Leave solution on in reverse?

Lock Detergent No*

Yes Lockout detergent percentage adjustment for user?

Beacon On*

Off Beacon light on/off

Burst Of Power (s)

min = 60*

max = 300

step = 60

Burst-of-power (BOP) time span (seconds) EcoFlex

Fwd Speed Max (%)

min = 50

max = 100*

step = 10

Maximum forward speed as percentage of maximum

available speed

Lock Speed Limit No*

Yes Lockout scrub speed limit for user?

Inactivity Time (min)

min = 1

max = 30

step = 1

default = 15

Inactivity time before putting machine in sleep mode

(minutes)

Impact Detect

Off*

Log

Lockout

Impact detection status

Log – Impact is recorded

Lockout – Impact is recorded and User is locked

out of scrub functions (Display shows (C26)) until

machine is reset with a Supervisor key.

Impact Level High*

Low

Impact detection sensitivity level. If nuisance

tripping occurs (i.e. driving over a oor transition),

adjust setting to low.

System

MMC Firmware Main controller (mmc) rmware revision

UI Firmware User interface panel (ui) rmware revision

CSP190-Comm F/W Drive controller comm rmware revision

CSP190-Motor F/W Drive controller main/motor control rmware revision

MMC S/N Main controller (mmc) pcb serial number

UI S/N User interface panel (ui) pcb serial number

Impact Log

Display list of impact events with max value,

timestamp and user id (only if enabled)

- single item view will show max values for each axis

(x,y,z)

*Default setting

SERVICE NOTE: Additional menus (Service and Conguration) are accessible only through service/technician mode. The service menu

allows observing operational and user parameters. The conguration menu allows adjusting machine settings. See Service Manual

for more details.

9/2022 A - 15 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

MAGNETIC SmartKey™

The use of a Magnetic SmartKey (39) is required to operate this machine. Pressing the power switch without a key in place on the SmartKey

Reader (22) will cause the machine to momentarily turn on and display No Key Indicator (C21) before turning off.

There are two different Magnetic SmartKeys (39).

1. The “User” (blue) key allows a basic level of access to the information menu (press Information Switch (B)).

2. The “Supervisor” (yellow) key allows an additional level of access to see Options Menu.

FIGURE 1-1

PREPARE THE MACHINE FOR USE

LEAD-ACID BATTERIES

If your machine shipped with batteries installed do the following:

• Check that the batteries are connected to the machine.

• Turn ON the Power Switch (H) and check the Battery Indicator (C3). If the gauge is completely lled the batteries are ready for use. If the

gauge is less than full the batteries should be charged before use. See “Charging The Batteries” section.

• IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR

INSTRUCTIONS REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

If your machine shipped without batteries installed do the following:

• Consult your Authorized Advance dealer for recommended batteries.

• Install the batteries by following the instructions below.

• IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE OEM PRODUCT MANUAL FOR

INSTRUCTIONS REGARDING SETTING THE CHARGER FOR BATTERY TYPE.

LEAD-ACID BATTERY INSTALLATION

WARNING!

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact

the skin or eyes. Explosive hydrogen gas is vented from the batteries through openings in the battery caps. This gas

can be ignited by any electrical arc, spark or ame. Do not install any lead-acid battery in a sealed container or enclosure.

Hydrogen gas from overcharging must be allowed to escape.

When Servicing Batteries...

• Remove all jewelry

• Do not smoke

• Wear safety glasses, rubber gloves and a rubber apron

• Work in a well-ventilated area

• Do not allow tools to touch more than one battery terminal at a time

• ALWAYS disconnect the negative (ground) cable rst when replacing batteries to prevent sparks.

• ALWAYS connect the negative cable last when installing batteries.

22

39

A - 16 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

LEAD-ACID BATTERIES - CONTINUED

CAUTION!

Electrical components in this machine can be severely damaged if the batteries are not installed and connected properly.

Batteries should be installed by Nilsk or by a qualied electrician.

1 Remove the batteries from their shipping crate and carefully inspect them for cracks or other damage. If damage is evident, contact the

carrier that delivered them or the battery manufacturer to le a damage claim.

2 Turn the Power Switch (H) OFF and remove the Magnetic SmartKey (39).

3 Rotate the Battery Compartment Latch (20) to unlock then tip the seat forward (the gas spring holds the seat open).

4 For additional access the recovery tank can be removed from the machine. NOTE: Disconnect the recovery hose, vacuum motor wiring and

warning beacon wiring then lift the tank straight up and off the machine, using two people or an overhead hoist.

5 Your machine comes from the factory with enough battery cables to install three 12 volt batteries. Using at least (2) people and an

appropriate lifting strap, carefully lift the batteries into the battery compartment and arrange them exactly as shown in FIGURE 2-1. Secure

the batteries as close to the rear and right side of the machine as possible. Use battery spacer to keep batteries from moving. If installing a

mono-block battery use an overhead hoist.

6 Install the battery cables as shown. Position the cables so the battery caps can be easily removed for battery service.

IMPORTANT!: The protective caps supplied with the batteries need to be left on or re-used to completely cover the portion of the

battery terminals that are not being protected by the battery cable terminal cover boots supplied with the battery cables. This also

applies to the in-line fuse holder boot.

7 Carefully tighten the nut in each battery terminal until the terminal will not turn. Do not over-tighten the terminals, or they will be very difcult

to remove for future service.

8 Coat the terminals with spray-on battery terminal coating (available at most auto parts stores).

9 Put one of the black rubber boots over each of the terminals and connect the Machine Battery Connector (19).

10 Make sure the fuse holder boot is covering the fuse holder, the cable end of the Machine Battery Connector (19), and as much of the battery

terminal as possible. Leave the protective caps supplied with the batteries in place or re-use to cover the terminal areas not protected by the

terminal cover boots.

When changing batteries or the charger, please contact your local authorized service center for correct battery, charger and machine

settings to prevent battery damage.

FIGURE 2-1

-NOTES-

6ADHESIVE LINER TO BE BACKSPLIT VERTICALLY

5ALL DIMENSIONS ARE CONTROLLED BY PRODUCTION ARTWORK

4NON PRINTING MAGENTA INDICATES CUT OUT

3

COLOR: 56E00158-56975034 (BLACK)

2

COLOR: 56E00158-56975004 (WHITE)

1) MATERIAL: 56E05002-03 OR ORACAL 1640.

5 FULL SCALE PRODUCTION ARTWORK

2 3

6

6.5 ±0.03

3.50 ±0.03

4 X R 0.25 ±0.03

4

B

REV

DWG NO

TITLE

C

SHEETS: 1 OF 1

SCALE: 1.000

FUO:

NOTES UNLESS

OTHERWISE SPECIFIED

1. ALL DIMENSIONS IN INCH, [ ] IN MM.

2. DO NOT SCALE DRAWING.

3. ALL DIMENSIONS APPLY AFTER

PLATING AND HEAT TREATING, BUT

BEFORE PAINTING.

4. REMOVE ALL BURRS AND

SHARP EDGES.

5. SEE 56E00713 FOR TORQUE INFO.

6. APPEARANCE AND FINSH SHALL

COMPLY WITH NILFISK OPERATIONAL

PROCEEDURE 1-720050.

7. WELD SYMBOLS PER AWS A2.4.

DRAWING STATUS: RELEASED

ASSY:

SIZE

CC: NO

NILFISK INC.

BROOKLYN PARK, MN 55445

Compliance with: NACS 2020

PRJ ENG

18-OCT-2021DRAWN

CANVAS

MATERIAL: SEE NOTES

FINISH: SEE NOTES

56120182 B

56120E12-1

SC4000

MLB

DECAL-BATTERY

3D Model: MODEL NAME

Drawing: SAMPLE-DECAL

SHEET

DWG NO REVISIONS

APPDDFTMDATEECOREV

1

CPGMLB18-OCT-2021A-15247

ARELEASE

56120182

F

F

12

3

4

5

6

CONFIDENTIAL

THIS DRAWING AND THE DESIGN REPRESENTED HEREON IS THE PROPERTY OF NILFISK INC.,

BROOKLYN PARK, MINNESOTA AND IT HAS BEEN ISSUED WITH THE UNDERSTANDING THAT IT WILL NOT BE REPRO-

DUCED NOR COPIED NOR USED FOR ANY PURPOSE OTHER THAN FOR WHICH IT WAS ISSUED AND RECIPIENT

AGREES TO RETURN IT UPON REQUEST.

A

B

C

D

E

B

C

D

E

12

3

4

5

6

CPG

CPGMLB15-NOV-2021A-15452

BUPDATE: ARTWORK

9/2022 A - 17 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

INSTALL THE BRUSHES (DISC SYSTEM)

CAUTION!

Turn the machine OFF at the power switch, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck is in the RAISED position. Make sure the Power Switch (H) is off.

2 See Figure 2-2. Remove both Side Blade Assemblies (AA). NOTE: The blade assemblies are held in place by two large Knobs (BB).

Loosen these knobs and slide the Blade Assemblies (AA) forward slightly and then off of the Scrub Deck.

3a To manually install the brushes:

Lift the Brushes (DD) (or pad holders) and align the lugs on the brush with the holes on the mounting plate then turn to lock in place (turn the

outside edge of brush towards the front of machine as shown by arrow (EE)).

3b To use the automatic Brush Install feature (optional kit must be installed):

i. Press the Guide Bar (CC) forward while sliding the brush under the deck and stop when the brush is contacting both legs of the guide bar.

Repeat this step for the brush on the other side of the deck. NOTE: Do not push the rst brush out of position with the second brush.

ii. Turn the machine ON at the Power Switch (H). (SCRUB SYSTEM MUST BE OFF and MACHINE MOTIONLESS)

CAUTION!

Keep hands and feed out from underneath the deck. Take precautions to prevent hair, jewelry, or loose clothing from

becoming caught in moving parts.

iii. Press the Brush Install Switch (K) the display will show Brush Install Indicator (C18) then wait for the brush install sequence to nish.

4 Reinstall the side blade assemblies. NOTE: While scrubbing the brushes rotate as shown by arrows (FF).

FIGURE 2-2

CC

CC

EE

EE

FF

FF

AA

BB

BB

DD

K

C18

A - 18 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

INSTALL THE BRUSHES (CYLINDRICAL SYSTEM)

CAUTION!

Turn the machine OFF at the power switch, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck is in the RAISED position. Make sure the Power Switch (H) is off.

2a Fixed Side Skirts: See Figure 2-3a. Remove both side blade assemblies. NOTE: The side blade assemblies are held in place by two large

Knobs (BA). Loosen these knobs and then slide the Blade Assemblies (BB) forward and off of the Scrub Deck.

2b Adjustable Side Skirts: See Figure 2-3b. Unlatch and swing open both Side Blade Assemblies (AA).

3 Unhook the Latch (AB) on top of the Idler Assemblies (AC) and remove.

4 Slide the brush into the housing, lift slightly, push and turn until the tabs on the drive hub seat into the notches in the brush. NOTE: The idler

is designed with a snug t into the brush to reduce vibration. Re-install the Idler Assemblies (AC) make sure the tabs on the idler are inside of

the weldment (as shown in inset of Figure 2-3). Secure with Latch (AB).

5 Reinstall Blade Assemblies (BB) or close and latch both the Blade Assemblies (AA).

FIGURE 2-3

AA

AB

AC

AC

AC

2-3a 2-3b

BA

BB

AB

9/2022 A - 19 56091272 - Advance SC4000

ENGLISH - AINSTRUCTIONS FOR USE

INSTALL THE PADS (REV™ SYSTEM)

CAUTION!

Turn the machine OFF at the power switch, before changing the pads, and before opening any access panels.

1 Make sure the Scrub Deck is in the RAISED position. Make sure the Power Switch (H) is off.

2 See Figure 2-4. Remove both Side Blade Assemblies (AA). NOTE: The blade assemblies are held in place by two large Knobs (BB).

Loosen these knobs and slide the Blade Assemblies (AA) forward slightly and then off of the Scrub Deck.

3 Daily Scrubbing: Slide a daily scrubbing pad (AE) or Microber Pad (AB) under each pad driver, center it on the xed pad driver (AC) and

lift it upwards and press it onto the harpoon face of the pad driver.

4 Floor Finish Removal: Install a new red pad (AE) to each pad driver (AC) as described in step 3 above. If using the optional double sided

Velcro (AF), attach it to the center of maroon SPP pad (AD) and slide this assembly under the red pad and center it and then press upwards

to attach this assembly to the red pad. If the optional double sided Velcro is not used, install a new red as described in step 3 above and

place a new maroon SPP pad on the oor centered on the red pad. Lower the deck to the oor on top of the maroon SPP pad and check that

it is centered.

NOTE: Never attach a maroon SPP pad directly to the pad driver, damage to the pad driver will result requiring replacement.

NOTE: Do not use the Automatic Brush Install Feature (Brush Install Switch (K)) in an attempt to install pads.

FIGURE 2-4

AF

AD

AB

AE

AC

BB

AA

BB

A - 20 Advance SC4000 - 56091272 9/2022

INSTRUCTIONS FOR USEA - ENGLISH

FILLING THE SOLUTION TANK

See Figure 2-5. Fill the solution tank with a maximum of 33 gallons (125 Liters) of cleaning solution. The solution tank can be lled to the bottom

of the Solution Fill (17). The solution should be a mixture of water and the proper cleaning detergent for the job. Always follow the dilution

instructions on the detergent container label. NOTE: EcoFlex machines can either be used conventionally with detergent mixed in the tank or the

detergent dispensing system can be used. When using the detergent dispensing do not mix detergent in the tank, plain water should be used.

CAUTION!

Use only low-foaming, non-ammable liquid detergents intended for machine application. Water temperature should not

exceed 130 degrees Fahrenheit (54.4 degrees Celsius)

FIGURE 2-5

3"

(7.5cm)

17

C4 C26

SOLUTION TANK INDICATOR

See Figure 2-6. The solution tank has three level sensors that correspond with three measurement points. The Solution Level Indicator (C4)

displays the level (1-3) of the solution in the tank. Once the tank is empty the Solution Empty Indicator (C26) will ash on the display.

FIGURE 2-6

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

Nilfisk SC4000 28C HP ECO 234AH OBC Le manuel du propriétaire

- Catégorie

- Machine à plancher

- Taper

- Le manuel du propriétaire

- Ce manuel convient également à

dans d''autres langues

Documents connexes

Autres documents

-

Nilfisk-Advance 56212260 Manuel utilisateur

-

Nilfisk-Advance America UHR 70-1700 Manuel utilisateur

-

Nilfisk-Advance Hydro-Retriever 3800 Instructions For Use Manual

-

Nilfisk-Advance Warrior AXP Instructions For Use Manual

-

Windsor Chariot 2 iScrub 20 Deluxe Le manuel du propriétaire

-

Nilfisk-Advance America BRX 700 Series Manuel utilisateur

-

Clarke Focus II Mid-Size Autoscrubber Boost 28 Manuel utilisateur

-

Windsor Chariot 3 iScrub 26 Le manuel du propriétaire