LiftMaster LA250EVK Guide d'installation

- Catégorie

- Ouvre-porte

- Taper

- Guide d'installation

LA250EVK / LA300EVK

en Swing Gate Operator Installation Manual*

fr Manuel d‘installation de l‘opérateur de porte battante

nl Installatiehandleiding draaihekaandrijving

* For GB (UK, NI) specic information on national regulations and requirements

see English part of the manual.

1

TABLE OF CONTENTS

NOTE:The original installation and operating instructions were compiled in English. Any other available language is a translation of the original English version.

1. SAFETY INSTRUCTIONS AND INTENDED USE......................................................................................................................................................................................2

2. DELIVERY SCOPE......................................................................................................................................................................................................................................4

3. TOOLS NEEDED.........................................................................................................................................................................................................................................4

4. OVERVIEW OF GATE OPERATOR............................................................................................................................................................................................................4

5. MECHANICAL INSTALLATION....................................................................................................................................................................................................................5

5.1 Dimensions of Gate and Operator.........................................................................................................................................................................................................5

5.2 Post Bracket Position and A&B Dimensions........................................................................................................................................................................................5

5.3 Post Bracket Installation........................................................................................................................................................................................................................6

5.4 Operator Mounting and Travel Distance Adjustment...........................................................................................................................................................................6

5.5 Hardstop Installation..............................................................................................................................................................................................................................7

5.6 Emergency Release Mechanism..........................................................................................................................................................................................................8

5.7 Control Box Installation.........................................................................................................................................................................................................................8

5.8 Power Wiring.........................................................................................................................................................................................................................................8

6. WIRING DIAGRAM......................................................................................................................................................................................................................................9

7. PROGRAMMING..............................................................................................................................................................................................................................................10

7.1 Display, Programming Buttons and Function Setting.........................................................................................................................................................................10

7.2 General Programming Overview..........................................................................................................................................................................................................10

7.3 Wing Movement Direction...................................................................................................................................................................................................................11

7.4 Basic Settings......................................................................................................................................................................................................................................11

7.4.1 Application Settings..................................................................................................................................................................................................................11

7.4.2 Direction Motor 1 Settings.........................................................................................................................................................................................................11

7.4.3 Direction Motor 2 Settings.........................................................................................................................................................................................................11

7.4.4 Limit Learning...........................................................................................................................................................................................................................11

7.5 Stand-by Mode....................................................................................................................................................................................................................................12

7.6 Programming and Erasing of Remote Controls, Radio Accessories and myQ Devices.......................................................................................................................13

7.7 Advanced Settings..............................................................................................................................................................................................................................14

7.7.1 Overview Advanced Settings....................................................................................................................................................................................................14

7.7.2 Transmitter Settings.................................................................................................................................................................................................................14

7.7.3 Infrared Photocells Settings......................................................................................................................................................................................................14

7.7.4 Input Settings...........................................................................................................................................................................................................................14

7.7.5 Partial Opening Motor 1.............................................................................................................................................................................................................15

7.7.6 Delay Motor 2 in Open Direction..............................................................................................................................................................................................15

7.7.7 Delay Motor 1 in Close Direction..............................................................................................................................................................................................15

7.7.8 Timer to Close..........................................................................................................................................................................................................................15

7.7.9 Reversal Time after Impact.......................................................................................................................................................................................................15

7.7.10 E-Lock / Mag-Lock Settings.....................................................................................................................................................................................................15

7.7.10a Relief Motor 1 for E-Lock.......................................................................................................................................................................................................16

7.7.11 Flashing Light Settings...........................................................................................................................................................................................................16

7.7.11a Pre-Flashing................................................................................................................................................................................................................................16

7.7.12 Special Contact Settings.........................................................................................................................................................................................................16

7.7.13 Start Speed in Open and Close Directions.............................................................................................................................................................................16

7.7.14 Maintenance Counter...............................................................................................................................................................................................................16

7.7.15 Password Protected Functions and Setup.............................................................................................................................................................................16

7.7.15a Password Setup....................................................................................................................................................................................................................16

7.7.15b Password Use.......................................................................................................................................................................................................................17

7.7.15c Password Change.................................................................................................................................................................................................................17

7.7.15d Force Motors 1 and 2 in Open and Close Directions............................................................................................................................................................17

7.7.15e Speed Motors 1 and 2 in Open and Close Directions............................................................................................................................................................17

7.7.15f Soft-Stop Speed....................................................................................................................................................................................................................18

7.8 Factory Default Settings....................................................................................................................................................................................................................18

7.9 Finish and Exit..................................................................................................................................................................................................................................18

8. BATTERY BACKUP....................................................................................................................................................................................................................................18

9. ERROR CODES........................................................................................................................................................................................................................................19

10. TECHNICAL DATA....................................................................................................................................................................................................................................20

11. MAINTENANCE.......................................................................................................................................................................................................................................21

12. DISPOSAL........................................................................................................................................................................................................................................21

13. WARRANTY........................................................................................................................................................................................................................................21

14. DECLARATION OF CONFORMITY..........................................................................................................................................................................................................21

2

1. SAFETY INSTRUCTIONS AND INTENDED USE

About this Manual – Original Manual

These instructions are the original operating instructions according the machinery directive 2006/42 EC. The instruction manual must be read carefully to understand

important product information. Pay attention to the safety and warning notices. Keep the manual in safe place for future reference and to make it available to all persons

for inspection, service, maintenance and repair. After installation pass the complete documentation to the responsible person/owner.

Qualication of a competent installer

Only correct installation and maintenance by a competent installer (specialist) / competent company, in accordance with the instructions, must understand and ensure the

safe and intended function of the installation. Specialist is, who on the basis of their technical training and experience, has sufcient knowledge in the eld of powered

gates and moreover is familiar with relevant state occupational safety regulations and generally accepted rules of technology in such an extent that he is also able to

assess the safe working condition of powered gates according to EN 13241, 12604, 12453 (EN12635)

The installer must understand the following:

Before installing the drive, check that the driven part is in good mechanical condition, opens and closes properly and correctly balanced where applicable

Before rst use and at least annually a specialist must inspect powered gate regarding their safe condition. After installation, the installer must ensure that the

mechanism is properly adjusted and that the protection system and any manual release function correctly (EU: EN 13241, EN12604, EN 12453, EN 12635; GB (UK, NI)

BS EN 13241, BS EN12604, BS EN 12453, BS EN12635). A regular maintenance, inspection must be carried out according to the standards. The installer must

instruct other users on the safe operation of the drive system.

After successful installation of the drive system, the responsible installer, in accordance with the EU: Machinery Directive 2006/42/EC; GB (UK, NI): Supply of Machinery

(Safety) Regulations 2008 SI 2008 No. 1597, must issue the EU: CE / GB (UK,NI): UK declaration of conformity for the gate system. The EU: CE / GB (UK,NI): UKCA

mark label must be attached to the gate system. This is also obligatory in the process of retrotting on a manually operated gate. Further, a handover pack and an inspec-

tion book must be completed.

After successful installation of the drive system, the responsible installer, in accordance with the EU: Machinery Directive 2006/42/EC; GB (UK, NI): Supply of Machinery

(Safety) Regulations 2008 SI 2008 No. 1597, must issue the EU: CE / GB (UK,NI): UK declaration of conformity for the gate system. The EU: CE / GB (UK,NI): UKCA

mark label must be attached to the gate system. This is also obligatory in the process of retrotting on a manually operated gate. Further, a handover pack and an inspec-

tion book must be completed.

Please read the operating instructions and especially the precautions. The following symbols are placed in front of instructions to avoid personal injury or damage to

property. Read these instructions carefully.

Warnings Symbols

The general warning symbol indicates a danger that can lead to injuries or death. In the text section, the general warning symbols are used as described below.

Intended use

The swing gate operator is exclusively designed and tested for the operation of smooth-running swing gates in the residential, non-commercial sector.

Specication for gates are dened under mechanical requirements according EU: EN12604 / GB (UK, NI): BS EN 12604.

The maximum permissible gate size and the maximum weight must not be exceeded. The gate must open and close smoothly by hand. Use the operator on gates which

comply with the applicable standards and guidelines. Regional conditions of wind loads must be taken into account when using door or gate panels EU: EN13241 / GB

(UK, NI): BS EN 13241. Observe the manufacturer‘s specications regarding the combination of door and operator. Possible hazards within the meaning of EU: EN13241

/ GB (UK, NI): BS EN 13241 are to be avoided by designing and installing the door/gate according to the relevant instructions. This gate mechanism must be installed and

operated in accordance with the appropriate safety rules.

Improper use

It is not intended for continuous operation and use in a commercial application.

The construction of the drive system is not designed for the operation of gates outside of manufacturers specication.

It is not permitted on gates that travel with incline/decline.

Any improper use of the drive system could increase the risk of accidents. The manufacturer assumes no liability for such usage. With this drive, automated gates must

comply with the current, valid international and country-specic/local standards, guidelines and regulations (EU: EN 13241, EN12604, EN 12453; GB (UK, NI) BS EN

13241, BS EN12604, BS EN 12453).

Only LiftMaster and approved accessories may be connected to the drive. Incorrect installation and/or failure to comply with the following instructions may result in serious

personal injury or damage to property.

Gate systems located in public areas and have only force limitation, can only be operated under full supervision.

Additional safety devises should be considered in accordance with EU: EN 12453; GB (UK, NI) BS EN 12453.

DANGER Symbol WARNING Symbol CAUTION Symbol ATTENTION Symbol

DANGER WARNING CAUTION ATTENTION

Indicates a danger that leads directly

to death or serious injuries.

Indicates a danger that can lead to

death or serious injuries.

Indicates a danger that can lead to

damage or destruction of the product.

Indicates a danger that can lead to

damage or destruction of the product.

3

During operation, the gate should not under any circumstances obstruct public path ways and roads (public area).

When using tools and small parts to install or carry out repair work on a gate exercise caution and do not wear rings, watches or loose clothing.

To avoid serious personal injury due to entrapments, remove any locking device tted to the gate in order to prevent damage to the gate.

Installation and wiring must be in compliance with your local building and electrical installation regulations. Power cables must only be connected to a properly earthed

supply.

Disconnect electric power to the system before installation, maintenance, repairs or removing covers. A disconnecting device must be provided to the mains power supply

(permanently-wired installation) to guarantee all-pole disconnection (isolating switch or by a separate fuse). The repairs and electrical installations may be performed only

by an authorised electrician. Emergency Stop Button must be installed for emergency case based on the risk assessment.

Ensure that entrapment between the driven part and the surrounding xed parts due to the opening movement of the driven part is avoided by respecting the given safety

distances in accordance with the EU: EN 13241, EN12604, EN 12453, EN 12635; GB (UK, NI) BS EN 13241, BS EN12604, BS EN 12453, BS EN12635 and/or with

safety devices (e.g. safety edge).

Testing of the safety function of the drive system is recommended to be carried out at least once a month. Refer also to manufacturers instruction of the gate system

components.

After the installation a nal test of the full function of the system and the of the safety devices must be made and all users must be instructed in the function and operation

of the swing gate operator.

Gate systems must meet the force limitation according EU: EN 12453, EN 60335-2-103; GB (UK, NI) BS EN 12453, BS EN 60335-2-103.

Additional safety device (safety edge,.) must be considered in accordance to the standard by changes to the system.

It is important to make sure that the gate always runs smoothly. Gates which stick or jam must be repaired immediately. Employ a qualied technician to repair the

gate, never attempt to repair it yourself. This device is not intended for use by persons (including children) with restricted physical, sensory or mental abilities or lack of

experience or knowledge, unless they are supervised by a person responsible for their safety or have received instruction in how to use the device. If necessary, control

equipment MUST be mounted within sight of the gate and out of reach of children. Children should be supervised to ensure that they do not play with the device. Do not

allow children to operate push button(s) or remote(s). Misuse of the gate operator system can result in serious injury.

The warning signs should be placed in clearly visible locations.

The gate opener should ONLY be used if the user can see the entire gate area and is assured that it is free of obstacles and the gate operator is set correctly. No one may

pass through the gate area while it is moving. Children must not be allowed to play in the vicinity of the gate.

The full protection against potential crushing or entrapment must work immediately when the drive arms are installed.

There may be existing hazards on mechanical, electrical installation or the closing edges of the gate by crushing, impact points:

• Structural failure, leaf, hinges, xings, travel stops, wind load

• Crush, hinge area, under the gate, safety distance on xed object

• Electrical failure (Control – faults in safety systems)

• Impact, swept area, hold to run, force limitation, presence detection

Appropriate measures must be taken to ensure safe operation of the gate system according the standards.

Never start up a damaged drive.

Use the manual release only to disengage the drive and – if possible – ONLY when is gate closed. Operation of the emergency manual release can lead to uncontrolled

movements of the gate. The Timer-to-Close (TTC) feature, the myQ Smartphone Control app, are examples of unattended operation of the gate.

Any device or feature that allows the gate to close without being in the line of sight of the gate is considered as unattended open/close.

The Timer-to-Close (TTC) feature, the myQ Smartphone Control, and any other myQ devices can ONLY be activated when Liftmasters photo cells are installed (TTC

works only in close direction). The gate shall only be operated in the direct sight line to the gate.

IMPORTANT INFORMATION!

• This procedure is also required on private installations (new or retrotted to a manually operated gate).

This installation and operating manual must be retained by the user.

• The manufacturer accepts no liability/warranty claims resulting from use other than intended use and after the warranty expires.

• The legal remedy is the sole responsibility for all associated rights.

NOTE: Observe the installation and operating manual.

• Always monitor the function of the system and rectify the cause immediately in the event of a malfunction.

• Carry out an annual inspection of the system. Call a specialist.

• Safety distances must be respected between the gate leaf and the environment in accordance with related standards.

• The operator can be installed Only on stable and rigid gate leaves. Gate leaves must not bend or twist when opening and closing.

• Assure that the hinges of the gate leaf are installed and working correctly and not creating any obstacles.

• Installation of two operators on same door leaf is strictly prohibited.

• Observe the corresponding requirements of the local, national regulations for compliance with the measures to protect human health, which must be observed when

contacting other people, including employees, suppliers and customers (e.g. safety distance, mask requirement, etc).

• Precise information can be requested from the local authorities.

1. SAFETY INSTRUCTIONS AND INTENDED USE

4

2. DELIVERY SCOPE

3. TOOLS NEEDED

4. OVERVIEW OF GATE OPERATOR

LA250EVK (2 x motor units) LA300EVK (2 x motor units)

Post Mounting

Bracket (2x)

Fix Post

Bracket (2x)

Adjustable Post

Bracket (2x)

Control Box Remote

Control (2x)

Release Key (4x)

Release Key (4x)

Installation

Manual

Installation

Manual

Remote

Control (2x)

Control Box

M10x30 Screws

(4x)

Gate Mounting

Bracket (2x)

Gate Mounting

Bracket (2x)

Circlip (4x) Circlip (2x)Circlip pin (4x)

Circlip pin (2x) Washer and Bolt

(2x)

LA250EVK / LA300EVK

LA250EVK / LA300EVK

1. Motor 1

2. Motor 2

3. Control board

4. Post bracket

5. Gate bracket

6. Infrared photocells

7. Flashing lamp

1 2

6

4 45

3

5

6

7

13, 14 mm 5 mm

5

5. MECHANICAL INSTALLATION

5.2 Post Bracket Position and A&B Dimensions

Determine the A and B dimension based on the opening angle provided in Table 1 to conrm the position where the post bracket will be mounted.

1. To ensure that the motor does not touch the pillar, please dene your C dimension using B-60 mm formula.

2. For optimal mechanical advantage A and B dimension shall be equal or not differ by more than 40 mm.

NOTE: Smaller A and B dimensions determine higher peripheral speed of the leaf. Higher differences between A and B dimensions cause greater speed and force variati-

ons during the gate opening and closing movement. It is always good practice to use all available travel of the operator.

All crushing points must be secured by an entrapment protection according to EU: EN 12453, EN 60335-2-103; GB (UK, NI): BS EN 12453, BS EN 60335-2-103.

5.1 Dimensions of Gate and Operator

LA250EVK with external hardstop,

using max 300 mm travel

LA300EVK with internal hardstop,

using max travel 300 mm

LA300EVK without internal hardstop,

using max travel 350 mm

830 (max.1150)

LA250EVK

Example installation

Herewith you start mechanical installation of the gate operator.

LA300EVK

LA250EVK

1.5 m 250 kg

2.0 m 200 kg

2.5 m 150 kg

LA300EVK

2.0 m 300 kg

2.5 m 250 kg

3.0 m 200 kg

mm A

100 120 140 160 180

B

100 n.a. 110° 105° 105° 100°

120 110° 110° 100° 95° 95°

140 100° 100° 100° 90° 80°

160 95° 95° 90° 85° 75°

180 90° 90° 80° 75° 70°

mm A

100 120 140 160 180

B

100 n.a. 110° 105° 105° 100°

120 110° 110° 100° 95° 95°

140 100° 100° 100° 90° 80°

160 95° 95° 90° 85° 75°

180 90° 90° 80° 75° 70°

mm A

100 120 140 160 180

B

100 n.a. 120° 120° 120° 120°

120 115° 115° 115° 110° 100°

140 105° 110° 110° 105° 100°

160 100° 100° 100° 95° 90°

180 95° 95° 95° 90° 85°

60

80

22

Ø 8.5

100

60

20

7

125

92

133

835

35055 Max. 350 mm (w/o hardstops)

Max. 300 mm with hardstops

110

92

40

7

Ø8.5

60

85

95

137

Ø10

10020

Ø10

Ø10

66

30

20 22 15 85

85

52

Extension bracket

(not included)

B

A

Gate

Gate Bracket

Gate Operator

Post Bracket

C

B

A

Gate

Gate Bracket

Gate OperatorPost Bracket

Gate Post

Gate Post

Example installation

C

Extension bracket

(not included)

Gate

B

B

A

A

Gate Bracket

Gate Bracket

Gate Operator

Gate Operator

Post Bracket

Post Bracket

Gate Post

Gate Post

Gate

Table 1: Table 1:

Gate leaf bracket extension shall be coside-

red in case the pivoting point of the gate is not

centered with the gate leaf.

Gate leaf bracket extension shall be coside-

red in case the pivoting point of the gate is not

centered with the gate leaf.

85

33

24

70

50

90

110

Ø10

6

1. Using the post bracket as a reference, mark and drill the holes for the post

bracket.

2. Attach the post bracket using the correct fastening material based on

existing installation (building / material substance). Please consult the gate

manufacturer.

3. The slots on the post bracket allow for alignment. When the post bracket is

level tighten the nuts.

1. Using the post bracket as a reference, mark and drill the holes for the post

bracket.

2. Attach the post bracket using the correct fastening material based on

existing installation (building / material substance). Please consult the gate

manufacturer.

3. The slots on the post bracket allow for alignment. When the post bracket is

level tighten the nuts.

5.4 Operator Mounting and Travel Distance Adjustment

Level

1. Align the holes on the operator to the post bracket holes and connect using the circlip pin and circlip.

2. Release the operator clutch with the release key (see page 8).

3. Bring gate leaf to the CLOSED position.

NOTE: The system must operate with:

LA250EVK only with external gate hard stops in both directions.

LA300EVK with external gate or internal operator hard stops in both directions.

4.1 Installation with external gate hard stops: (gate hard stops already installed):

a. For LA250EVK: pull out the tube completely and make 1 complete turn of the tube in clockwise direction see (picture 4.1.a).

For LA300EVK (with internal operator hard stops removed): pull the operator trolley to the max. closed position leaving 25 mm free space from absolute end position.

(see picture 4.1.a).

b. Connect the operator arm with the gate leaf bracket (see picture 4.1.b or 4.1.c).

c. Preliminary x the gate bracket on the gate leaf. Ensure that the gate touches the external hard stop. Consider the dimensions A and B from Table 1.

d. Manually open and close the gate to the required positions. Ensure the operator arm does not bind and gate is moving smoothly.

For LA300EVK please ensure that in the OPEN position the trolley is having min. 25 mm free space.

e. Make permanent connection of the gate bracket at chosen correct position.

4.2 Installation with internal operator hard stops, LA300EVK only: (no gate hard stops installed):

a. Release the CLOSE position hard stop and bring it to the required position within available range. Fix it.

b. Manually move the trolley to the hard stop.

c. Connect the gate leaf bracket to the trolley of the operator (see picture 4.1.c).

d. Make a preliminary connection of the gate bracket to the gate leaf. Ensure the gate leaf does not change its position.

e. Manually move the gate leaf to the OPEN position and if no obstruction release the OPEN position hard stop and move it until it hits the trolley and x it.

If there is an obstruction during manual movement, please check the A, B and C dimensions from the Table 1 and make required corrections.

f. Once the required positions are dened make permanent connection of the gate bracket at chosen correct position.

4.3 A combination of operator and gate hard stops is allowed for LA300EVK. Please use the respective set up procedures as described above.

5. Repeat the procedure for the unit on the opposite side.

Level

5.3 Post Bracket Installation

NOTE: For brick or concrete posts please use correct dowels and screws. Please maintain correct distance to the post edges. For metal posts please consider the post thickness and weld or

bolt the bracket directly to post. For timber posts please use correct screws and if required use reinforcement plates.

Caution: The fastened brackets must not loosen after installation and during operation.

1 1

LA250EVK LA300EVK

LA250EVK LA300EVK

5. MECHANICAL INSTALLATION

7

5.5 Hardstops Installation

Hardstop

Hardstop

90°

Example for 90° opening, please see

table on page 5 for other settings!

1 and 2 are operator internal hardstops

12

5 mm

1115 mm

Spirit level

61 mm

730 mm with hardstops

750 mm w/o hardstops

Spirit level

1

2

31 x 360°

4.1.a 25 mm min.

25 mm min.

4.1.a

4.1.b 4.1.c

LA250EVK LA300EVK

LA250EVK LA300EVK

5. MECHANICAL INSTALLATION

8

The control box must be installed at a safe location that enables the installer to

have access at all times to the logic board without the risk of the gates crushing

or trapping.

It is advised that you must have full view of the gates when programming the

logic board.

Install the control box in an appropriate and accessible position. The installation

has to be done in accordance with local electrical regulation.

Motor 1 Connection

NOTE: The operator wired to the MOTOR 1 terminal will always open rst and

close last. Consider this for Basic and Advanced Settings (see Programming

section).

1. Feed the motor1 cable through a cable gland.

2. Connect motor cables to the MOTOR 1 terminals as follows:

red cable to RED terminal, green cable to GRN terminal , white cable to WHT

terminal on control board.

5.8 Power Wiring

Power wiring must be done by a certied electrician specialist.

Congratulations! Herewith the mechanical installation of your gate ope-

rator is nished. Please proceed with Programming and Basic Settings

to be able to start operation.

Motor 2 Connection

NOTE: The operator wired to the MOTOR 2 terminal will always open last and

close rst. Consider this for Basic and Advanced Settings (see Programming

section).

1. Feed the motor 2 cable through a cable gland.

2. Connect motor cables to the MOTOR 2 terminals as follows:

red cable to RED terminal, green cable to GRN terminal , white cable to WHT

terminal on control board.

0

-.0

-.

225 mm 110 mm

280 mm

310 mm

5.7 Control Box Installation

Not included with LA250EVK

Ø 6 mm drilling holes

5.6 Emergency Release Mechanism

To disengage the release mechanism turn protection cap to the side, enter the key and turn it 90°. Pull the clutch up. To re-engage the release meachanism, push the

clutch down and turn the key 90°.

NOTE: Same procedure applies for left and right hand units.

5. MECHANICAL INSTALLATION

9

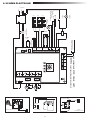

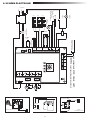

6. WIRING DIAGRAM

MOTOR 2

WHT GRN RED

MOTOR 1

+

M

+

M

BAT+

BAT-

24V

BATTERY

POW

24V

SPEC

24VDC SYNC STBY UART LIMIT-SW

+

+

+

+

+

E-LK

FLA

COMMANDIR SENSOREDGE24V BAT

8.2K

SAFETY EDGE

+

+

+

+

+

+

NC

NO

NO

Stop

Total Open

Partial Open

E-LOCK / MAG LOCK

LAMP 1

FLASH LAMP

SE SE GND GNDIR3 IN3 IN2 IN1IR2 IR1

L L

NN

PE

AC 230V IN

CTRL GND 12V - TX RX 5V OP - CL

+

24V external accessories

Examples: outdoor receiver

+

PE

220-240V/50/60Hz

28V AC

EXAMPLE

WHT GRN RED

S P

+

-

EXAMPLE

Fuse

IR 1IR 2IR 3

SYNC, STBY, UART, LIMIT-SW

connectors are not used for LA units

E-LOCK: 600024

24 V CC

15W

2

1

E-LK

JP1

4321

Power

Signal

4

3

FLA

+

+

FLASH-LAMP: FLA1-LED 24V BAT: 490EV

1 1

BAT+

BAT-

24V BAT

+

10

P +S

P +S

P +S

P +S

P +S

P +S

I

I

I

I

I

I

I

I

I

I

I

I

5 sec.

5 sec.

EXIT

Go to stand by

mode

or

or

P +S

7. PROGRAMMING

7.1 Display, Programming Buttons and Function Setting

Function setting - programming mode

7.2 General Programming Overview

Programming Procedure Overview

Button Function

Sprogram / delete remote controls and specic functions

Penter programming mode, select function and save

+/- Navigate through the menu and change the value on display

Function and programmed values are shown on LED display.

LED display shows following values after control board is powered:

The programming is divided in 2 sections:

1. Basic Settings (Page 11)

2. Advanced Settings (Page 14)

After Basic Settings are done, following parameters will be learned automatically

during Learning phase:

1. Travel length from FULL CLOSED to FULL OPEN position.

2. Opening and closing force for each motor.

NOTE:

• Basic Settings and Learning phase must be completed to enable operation.

• After the Learning phase and Programming are nished the operator will work

as per default settings.

• Advanced Settings cannot be accessed if Basic Settings and Learning phase

are not completed.

• Before making the programming ensure that the relevant safety devices

are connected.

1. Press and hold “P” button for 5 seconds to enter the menu. “AP” on the display

indicates the rst available function in menu.

2. Use “+“ and “–” buttons to navigate between the functions.

3. Press “P” button to select the required function.

4. The default setting or previously programmed value will appear. This will be

indicated by ashing of value on display.

5. Use “+” or “–“ buttons to select the required value. Press “P” button to conrm

selection.

6. The programmed function is shown on display.

7. To change the setting of another function, repeat the sequence from the points

#2 to #6

8. To exit to the Function menu, press “P” button for 5 seconds, then the board will

go in Stand-by mode.

If “P” button is not pressed to conrm new value setting, new settings will be saved

after 3 minutes and programming will exit menu and return into Stand-by mode.

NOTE: To operate the gate or execute any command, setting menu must be

nished by pressing the “P” button for 5 seconds, or by selecting FE Function, or

waiting 3 minutes for automatic exit and return into Stand-by mode.

Control board is pre-programmed to relevant application (see

below under “Application” and “Stand-by Mode” for status

description).

“E0”, in case the control board has not been programmed yet

or reset by function “Factory Default”. From this status, an

Input or transmitter command will be always ignored.

Example only

2 digit LED display

LED spot

Herewith you start programming of your gate operator.

Programming buttons function (4 buttons):

11

7.3 Wing Movement Direction

7.4 Basic Settings

Before programming, move the gate manually in the middle position and re-engage

release mechanism (see page 8).

Press and hold the “–“ button on the control board and ensure that the motors are

moving in CLOSE direction. If correct, immediately let go of the “-“ button and gate

stops.

If motors are moving in OPEN direction, go to the functions “d1“ and “d2” and

change the direction settings.

Once CLOSE direction is set correctly, leave the gate in the middle position. The

operator is ready for the Learning phase.

Note: gate can be moved with „ + “ and „ - „ buttons prior to nal settings if required.

Press and hold the “+“ button on the control board to move the gate into OPEN

position. When button is released operator stops.

Press and hold the “–“ button on the control board to move the gate into CLOSE

position. When button is released operator stops.

Application function shown on display.

This function is already pre-set at factory at value 07.

More settings available on demand:

LED Function

Basic Settings (mandatory)

AP Application

d1 Direction Motor 1

d2 Direction Motor 2

LL Limit Learning Phase

Basic Settings Overview

7.4.1 Application Settings

No application selected

Swing gate, one motor for LA250/LA300 application

Swing gate, two motors for LA250/LA300 application (defauft)

Direction Motor 1 function shown on display

Denes movement direction of the Motor 1.

7.4.2 Direction Motor 1 Settings

Motor 1 is moving in closing direction

Motor 1 is moving in opening direction

Direction Motor 2 function shown on display. Denes movement direction

of the Motor 2. Not available for “one motor” application.

7.4.3 Direction Motor 2 Settings

Motor 2 is moving in closing direction

Motor 2 is moving in opening direction

Available Learning methods:

Before starting a Learning phase ensure that:

1. Other Basic Settings are completed

2. Internal / external hard stops are installed (for swing gates)

3. First movement will be in CLOSE direction.

1. Press and hold “+ and –“ buttons for 2 seconds.

2. Automatic learning process starts. LL will ash on the display during complete

process.

3. Wing 2 moves in CLOSE direction until the hard stop is reached, and stops.

4. Wing 1 moves in CLOSE direction until the hard stop is reached, and stops for

2 seconds. Then Wing 1 starts in OPEN direction until the hard stop is reached.

5. Wing 2 moves in OPEN direction until hard stop is reached, stops for 2 seconds

and then moves in CLOSE direction until hard stop is reached, and stops.

6. Wing 1 moves in CLOSE direction until hard stop is reached, and stops.

7. Standard Learning phase is nished. LL will appear on display and board will

return in stand-by mode after 3 seconds.

Standard Learning Mode (Automatic)

7.4.4 Limit Learning

P +S

2 sec.

I

I

I

I

I

I

3 sec.

P +S

Values 01-05 are not suitable for LA250/LA300 application and shall not be chosen. NOTE: In single motor application, “Wing 2” actions are not used.

Following settings are done during Standard Learning Mode:

1. Travel length from FULL CLOSED to FULL OPEN position.

2. Opening and closing force for each motor.

3. 15% of total travel in both directions is assigned for Soft Stop.

4. Wing delay in opening and closing position is 2 seconds. Shall you need to

change the delay please go to Advanced Settings: Delay Motor 2 (d0) and

Delay Motor 1 (dC).

7. PROGRAMMING

12

Advanced Learning Mode (manual setting of Soft Stop position)

1. Press and hold “+ and –“ buttons for 2 seconds.

2. Automatic learning starts. LL will ash on the display during complete process.

3. Wing 2 moves in CLOSE direction until hard stop is reached, and stops.

4. Wing 1 moves in CLOSE direction until hard stop is reached, and stops for 2

seconds.

5. Wing 1 starts in OPEN direction at default speed. To dene start of the Soft

Stop for Wing 1 in OPEN direction press “P” button at required start point. Wing

1 will continue opening until hard stop is reached, and stops.

6. Wing 2 moves in OPEN direction at default speed.

7. To dene start of the Soft Stop for Wing 2 in OPEN direction press “P” button

at required start point. Wing 2 will continue opening until hard stop is reached,

stops for 2 seconds and then moves in CLOSE direction at default speed.

8. To dene start of the Soft Stop for Wing 2 in CLOSE direction press “P” button

at required start point. Wing 2 will continue closing until hard stop is reached,

and stops.

9. Wing 1 moves in CLOSE direction at default speed.

10. To dene start of the Soft Stop for Wing 1 in CLOSE direction press “P” button

at required start point. Wing 1 will continue closing until hard stop is reached,

and stops.

11. Advanced Learning phase is nished. LL will appear on display and board will

return in stand-by mode after 3 seconds.

NOTE: In single motor application, “Wing 2” actions are not used.

Following settings are programmed during Advanced Learning mode:

1. Travel length from FULL CLOSED to FULL OPEN position.

2. Opening and closing force for each motor.

3. Starting positions of the Soft Stops.

4. Wing delay in opening and closing position is 2 seconds. Shall you need to

change the delay please go to Advanced Settings: Delay Motor 2 (d0) and

Delay Motor 1 (dC).

NOTE: To stop Learning phase press “S” button. The Learning process will be

interrupted, “LE” will ash on LED display. After 5 seconds “LL” will appear on

display indicating readiness to start Learning phase again.

If Learning process was not completed, it needs to be re-done.

ATTENTION: Learning phase must be completed to enable operation.

P +S

2 sec.

P +S Soft Stop OPEN

Wing 1

P +S Soft Stop OPEN

Wing 2

P +S Soft Stop CLOSE

Wing 2

I

I

I

I

I

I

P +S Soft Stop CLOSE

Wing 1

3 sec.

P +S

I

I

I

I

I

I

5 sec.

7.5 Stand-by Mode

After the control board is powered on and programming is nished, the LED display

lights completely for 2 seconds and goes into the stand-by mode. During Stand-by

mode the LED display shows current gate status.

Two motors

(default) One motor

Motor is opening, upper section of the display

ashes.

I

I

I

I

I

I

Motor stops at the opening position, upper

section of the display is on.

Motor is closing, lower section of the display

ashes.

I

I

I

I

I

I

Motor stops at the closed position, lower

section of the display is on.

Motor stops in the middle, middle of the

display is on.

Herewith the Basic Settings are completed. You can leave Programming

and operate your gate or proceed with Advanced Settings.

7. PROGRAMMING

13

7.6 Programming and Erasing of Remote Controls, Radio Accessories and myQ Devices

Program remote control devices (transmitters and wireless wall controls):

NOTE: the remote controls delivered with the operator are already factory pre-

learned to the operator (top button near the LED) and do not require extra pro-

gramming.

1. Press and release “S” button. An LED spot turns ON in the display. The ope-

rator will stay in Radio programming mode for 3 minutes. Any radio accessory

device can be learned within rst 30 seconds. During the remaining 2.5 minutes

only myQ devices can be learned.

2. Chose the required button on your transmitter and hold it until the dot in the

display turns off.

To program a new remote control repeat the sequence.

To program a wireless keypad, please follow the respective manual of the acces-

sory.

Programming Transmitter in Partial opening

Press and hold “S“ and “+“ buttons at the same time, until the LED spot starts as-

hing. Press and hold the desired free button on transmitter to program the Partial

Opening Mode.

The LED spot turns off when the programming is nished. If there is a light connec-

ted to SPEC contact it will ash once.

Program myQ gateway (828EV):

1. Connect

Connect ethernet cable (1) provided with gateway to router (2).Use the plug valid

for your country ( not all models). Connect power (3) to the internet gateway (4).

When the internet gateway connects to the internet, the green light (5) will stop

blinking and will light solid. A connected set of IRs is mandatory for myQ operation.

2. Create an account

Download the free myQ App from App Store or Google Play Store and create an

account. If you already have an account, use your username and password.

3. Register the internet gateway

Enter the Serial Number located on the bottom of the internet gateway when

prompted.

4. Add myQ devices

To add your gate operator to the registered gateway follow the instructions on the

app. When adding a new myQ capable gate operator press and release “S” button

on operator control board. An LED spot turns ON in the control board display.

Note: After you add a device, the blue light on the internet gateway will appear and

stay on. Press “S” button on the operator control board to exit the radio programm-

ing mode.

5. Test

After having installed and registered correctly you may now test the following

features: open or close the gate, request status GATE OPEN or GATE CLOSED.

For more functions see www.liftmaster.eu

Erase radio control devices (transmitters, wireless wall controls, wireless

keypads):

Press and hold “S” button for > 6 seconds. All radio control devices (transmitters,

wall controls, keypads) are erased. The LED spot in the display turns OFF. Note: It

is not possible to erase radio control devices individually.

Erase myQ devices:

1. Erase remote control devices rst as indicated above.

2. Within next 6 seconds press and hold “S” button. An LED spot turns ON in the

display.

3. Press and hold “S” button for > 6 seconds. All myQ devices are erased. The

LED spot in the display turns OFF.

NOTE: It is not possible to erase myQ devices individually. It is not possible to

erase myQ devices only.

1

2

3

4

5

P +S

I

I

I

EXIT

6 sec.

P +S

I

I

I

EXIT

7. PROGRAMMING

14

LED Function

tr Transmitter

r1 IR1 photocell

r2 IR2 photocell

r3 IR3 photocell

i1 Input 1 command

i2 Input 2 command

i3 Input 3 command

Pd Partial Opening Motor 1 only

d0 Delay Motor 2 in OPEN

dC Delay Motor 1 in CLOSE

tC Timer To Close (TTC)

rt Reversal time after impact

EL E-lock

rb Relief Motor 1 for E-lock

LED Function

FL Flashing Light

PF Pre-Flashing

SP Special contact

St START Speed in OPEN and CLOSE

Cn Maintenance counter

PS Password

F1 Force Motor 1 in Open (protected by PS)

F2 Force Motor 1 in Close (protected by PS)

F3 Force Motor 2 in Open (protected by PS)

F4 Force Motor 2 in Close (protected by PS)

S1 Speed Motors in OPEN (protected by PS)

S2 Speed Motors in CLOSE (protected by PS)

SF SOFT-STOP Speed in OPEN and CLOSE

(protected by PS)

Fd Factory default

FE Finish and Exit

7.7.1 Overview Advanced Settings

7.7 Advanced Settings

Herewith you start with Advanced Settings.

7.7.2 Transmitter Settings

Transmitter function denes how Transmitter commands are working.

Note: Under settings “01”, “02” and “03”, TTC timer will be overridden

by a transmitter command and will CLOSE the gate.

Under setting “04”, active TTC timer countdown will be re-set to start

again by Transmitter command.

Residential Mode: Open – Close – Open

Standard Mode: Open – Stop – Close – Stop – Open (Default)

Automatic with Stop Mode: Open – Stop – Close – Open

Car Park Mode: Open, to complete Open position. Additional com-

mand during the opening will be ignored 7.7.4 Input Settings

Inputs function denes the way Input commands from external accessories are

executed. Each of the 3 Inputs can be programmed individually.

NOTE: Under settings “01”, “02” and “03”, TTC timer will be overridden by an Input

command and will CLOSE the gate. Under setting “06”, active TTC timer count-

down will be re-set to start again by an Input command

IR active on CLOSE movement. If IR beam is obstructed, gate re-

verses in complete OPEN position (Default).

IR active on OPEN movement. If IR beam is obstructed gate stops.

When obstruction disappears the gate continues to OPEN.

IR is active on OPEN and CLOSE movement. If IR beam is obst-

ructed on CLOSE movement, gate stops and after the obstruction

disappears gate reverses in complete OPEN position. If IR beam

is obstructed on OPEN movement, gate stops. When obstruction

disappears the gate continues to OPEN.

IR active on CLOSE movement. If IR beam is obstructed, gate re-

verses in complete OPEN position. The activated TTC function will

be overridden 2 seconds after the beam obstruction is eliminated

and will start CLOSE movement not waiting till the end of TTC time

end.

7.7.3 Infrared Photocells Settings

IR functions dene functioning mode of Infrared Photocells (IR).

IRs will be auto-learned when installed. Each of the 3 IR sets can be

programmed individually.

NOTE: Depending on the chosen settings the Partial Opening inputs or Remote

Controls commands will not be executed in both OPEN or CLOSE direction if the

IR beam is obstructed.

If IRs are removed, the control board power must be turned OFF/ON for two times

to unlearn.

For check and maintenance of the photocells see the manual of the photocells.

7. PROGRAMMING

15

Open – Close – Open

Open – Stop – Close – Stop – Open (Default)

Open – Stop – Close – Open

Partial opening Motor 1 only

STOP (NC contact)

Open, to complete OPEN position. Additional Open command during

the opening will be ignored

Close, to complete CLOSE position. Additional Close command

during the closing will be ignored

Open – Stop – Open - Stop

Close – Stop – Close - Stop

Open, hold to run

Close, hold to run

no delay (both wings start in the same time)

1 second

2 seconds (Default)

... ... seconds

20 seconds

7.7.7 Delay Motor 1 in Close Direction

Delay Motor 1 in CLOSE direction function denes time delay for Motor 1 in

CLOSE direction. Not available for the single motor application.

Not executed during reversal or after IR beam interruption in both directions.

1. Press and hold „S“ and „+“ buttons on the control board at the same time, until

the LED spot starts ashing.

2. Press and hold the desired free button on transmitter to program the Partial

Opening Mode.

3. The LED spot turns off when the programming is nished. If there is a light

connected to SPEC contact it will ash once.

TTC not active (Default)

10 seconds

20 seconds

30 seconds

45 seconds

1 minute

1.5 minutes

2 minutes

3 minutes

5 minutes

7.7.8 Timer To Close

Timer to close (TTC) function enables automatic closing of the gate from a com-

plete OPEN position after a pre-set period of time. Minimum one pair of LiftMaster

Infrared Photocells (IR) has to be installed to monitor closing movement to enable

TTC operation. TTC will not work if IR are protecting opening movement only.

TTC will also work with activated partial opening. If TTC function is active, timer is

counting down, and the IR beams are interrupted, the TTC timer shall re-start.

2 seconds reversal and Stop

Reversal back up to the end limit position (Default)

During Closing movement, upon impact gate reverses up to Open

position. During Opening movement, upon impact gate reverses for

2 seconds and stops

7.7.9 Reversal Time after Impact

Reversal time after impact function denes reversal behavior after obstacle obst-

ruction during closing or opening movement. This reversal behavior is valid both for

motor force detection and safety edge application.

50% opening travel

75% opening travel (default)

100% opening travel

7.7.5 Partial Opening Motor 1

Partial opening Motor 1 only gives you the ability to open active leaf to a pre-set

value only.

NOTE: Pd command will work starting from Close limit position and during closing

movement. If a Pd command is executed from a complete OPEN position, the gate

will close.

An Open or transmitter command will always override the Pd command.

no delay (both wings start opening at the same time)

1 second

2 seconds (Default)

3 seconds

4 seconds

7.7.6 Delay Motor 2 in Open Direction

Delay Motor 2 in OPEN direction function denes time delay for Motor 2 in OPEN

direction. Not available for single motor application.

Not executed during reversal or after IR beam interruption in both directions.

7. PROGRAMMING

e-lock/mag-lock not installed (Default)

e-lock active for 1 second prior to Motor 1 start in Open direction

e-lock active for 2 seconds prior to Motor 1 start in Open direction

Magnetic lock, constantly active at gate CLOSED, constantly

inactive during OPEN and CLOSE movement, gate OPEN or STOP

position. Magnetic lock will be deactivated in Battery Back-up mode.

7.7.10 E-Lock / Mag-Lock Settings

E-Lock function denes e-lock/mag-lock behavior.

24VDC – 500mA e-lock or mag-lock can be connected.

16

7.7.13 Start Speed in Open and Close Directions

Start Speed function allows switching the Soft-Start in OPEN and CLOSE directi-

ons ON and OFF.

deactivated (Default)

Soft Start active: motors will accelerate gradually until they reach

standard speed.

Hard Start active, motors will start at the regular Speed and for the

rst second the force sensor will not be considered.

no ashing lamp installed (Default)

continuous 24V supply - for ashing lamp with own control board

(FLA1-LED)

interrupted 24V supply - for ashing lamp without own control board

7.7.11 Flashing Light Settings

Flashing Light function allows to select which type of Flashing Lamp is connected.

24VDC- max 500 mA Flashing lamp (FLA1-LED) can be connected.

7.7.11a Pre-Flashing

Pre-Flashing function denes time interval of pre-ashing of the ashing lamp prior

to gate movement. Function not active if Flashing Lamp (FL) Function is set to “00”.

no pre-ashing (Default)

1 second

2 seconds

7.7.12 Special Contact Settings

Special Contact function denes relay activation time.

A 24V max 500mA relay can be connected to manage other devices, e.g. courtesy

light. The time set here will also control countdown for myQ remote light.

no activation (Default)

15 seconds

30 seconds

45 seconds

1 minute

1.5 minutes

2 minutes

3 minutes

4 minutes

5 minutes

7.7.14 Maintenance Counter

Maintenance Counter function allows to set maintenance interval in cycles.

4 seconds pre-ashing of the Flashing Lamp will be a signal the interval is reached.

If PF Function (Pre-Flashing) is active then 4 second pre-ashing will be added

to the set time. To reset counter after maintenance is done, it will be enough to

program the cycles one more time.

deactivated (Default)

1 second activated

2 seconds activated

7.7.10a Relief Motor 1 for E-Lock

Relief Motor 1 for E-Lock function enables to briey push Motor 1 in CLOSE direc-

tion before engaging e-lock to relieve excess pressure on e-lock. Not available if EL

Function is set to “00” or “03” (e-lock not connected / mag-lock connected).

3 seconds

4 seconds

5 seconds

7. PROGRAMMING

7.7.15a Password Setup

7.7.15 Password Protected Functions and Setup

Learning Phase must be completed and Password must be set before

doing changes for Password protected functions, like Force and Speed.

Chose the “PS” function to program password.

No password selected (Default)

Selection available

ATTENTION

Any changes done to the Password protected functions (Force and Speed)

require verication of speed and force according to EU: EN 12453, EN 60335-

2-103; GB (UK, NI) BS EN 12453, BS EN 60335-2-103.

no counter (Default)

1000 cycles

2000 cycles

... ... cycles

20000 cycles

Password Setup Procedure

NOTE: “00” cannot be used as password. It is only used as a default setting.

Functions protected by password can’t be accessed if the new password is not set.

Password will be required to change protected Functions after the setup.

1. Choose “PS” function and press “P” button.

2. “00” ashes on display.

3. Use “+” and “–” buttons to set the new password.

4. Press “P“ button.

5. New set password value remains on display for 2 seconds. Then display

changes to “PS“.

Please note your password where it can be found later.

P +S

P +S

P +S

I

I

I

I

I

I

I

I

I

I

I

I

2 sec.

17

7.7.15b Password Use

1. Choose “PS” function and press “P” button.

2. “00” ashes on display.

3. Use “+” and “–” buttons to enter the correct password and press “P” button to

conrm.

4. If correct password is entered, the display shows the value for 2 seconds and

changes to “PS”.

5. Choose the protected function to set.

NOTE: If entered password is not correct, “00” will ash for 5 seconds, then

change to “PS”. Use correct password to access protected functions.

Attention: The password protected Advanced Settings can only be executed by a

trained professional. The requirements of the EU: EN 12453, EN 13241; GB (UK,

NI) BS EN 12453, BS EN 13241 must be fullled.

P +S

P +S

P +S

I

I

I

I

I

I

I

I

I

I

I

I

2 sec.

7.7.15c Password Change

1. Choose “PS” function and press “P” button.

2. “00” ashes in display.

3. Use “+” or “–” buttons to enter current password and press “S” button. Value

starts ashing.

4. Use “+” or “–” buttons to enter NEW password and press “P” button.

5. Changed password value remains on display for 2 seconds. Then display

changes to “PS“.

NOTE: If wrong (current) password was entered, “00” will ash for 5 seconds and

change to “PS”. Password is not changed.

If password is lost, use Factory Default function (Fd) to go back to default settings.

All settings (apart from Radio Memory) will be deleted. See page 18.

P +S

P +S

P +S

P +S

I

I

I

I

I

I

I

I

I

I

I

I

2 sec.

I

I

I

I

I

I

or

or

7. PROGRAMMING

7.7.15d Force Motors 1 and 2 in Open and Close Directions

Force Motor 2 in OPEN Direction

Force Motor 1 in OPEN direction allows force adjustment on top of force set during

the Learning phase. Password must be entered to access this function.

Force Motor 2 in OPEN direction allows force adjustment on top of force set during

the Learning phase. Password must be entered to access this function.

Standard force (Default)

+15%

Standard force (Default)

+15%

+30%

+50%

Force Motor 1 in CLOSE Direction

Force Motor 1 in OPEN Direction

Force Motor 2 in CLOSE Direction

Force Motor 1 in CLOSE direction allows force adjustment on top of force set

during the Learning phase. Password must be entered to access this function.

Force Motor 2 in CLOSE direction allows force adjustment on top of force set

during the Learning phase.Password must be entered to access this function.

Standard force(Default)

+15%

+30%

+50%

Standard force (Default)

+15%

+30%

+50%

+30%

+50% 7.7.15e Speed Motors 1 and 2 in Open and Close Directions

Speed Motors 1 and 2 in OPEN Direction

Speed Motor 1 and 2 in OPEN direction allows opening speed adjustment compa-

red to the speed set during Learning phase. Password must be entered to access

this function.

Standard speed (Default)

+10%

+20%

+30%

+50%

-10%

-20%

18

Speed Motors 1 & 2 in CLOSE Direction

Speed Motor 1 and 2 in CLOSE direction allows closing speed adjustment compa-

red to the speed set during Learning phase. Password must be entered to access

this function.

Standard speed (Default)

+10%

+20%

+30%

+50%

-10%

-20%

7.7.15f Soft-Stop Speed

Soft-Stop Speed function allows adjustment of the Soft-Stop speed compared to

default values set during Learning phase. Soft-Stop speed is 50% of the standard

speed as per default setting. Standard speed change impacts the Soft-Stop speed.

Password must be entered to access this function.

Standard speed (Default)

-10%

-20%

-30%

-50%

+10%

+20%

7.8 Factory Default

7.9 Finish and Exit

Factory default function resets control board to the original factory set-ups. All set-

tings, including limit settings, will be erased. LED display will show “E0”. Program-

med remote controls will remain learned. If Remote control accessories need to be

erased refer to the respective Radio Controls Programming section of this manual.

To exit the programming phase and save all changes,

move to FE function and press “P” button. The control board will go into Stand-by

mode and is ready to work.

There are also other ways to exit the programming and save settings:

• Press and hold “P” button for 5 seconds

• Wait 3 minutes after the last changes in the programming for automatic exit

no reset (Default)

reset to the factory default settings

7. PROGRAMMING

8. BATTERY BACKUP

Battery Back-Up Mode

2 Optional 12V, 2.2Ah lead batteries SKU 490EV (optional, not included) can be mounted inside the E-Box. Follow the manual of SKU 490EV for exact installation proce-

dure. A Flashing lamp (if mounted) will ash 2 seconds every 10 minutes indicating BBU mode and power loss. Control board will switch into stand-by mode with active

radio receiver accepting radio control device commands only. All other accessories and peripheral devices will not be functioning.

When in Battery Back-up mode, myQ Smartphone Control and wireless myQ devices will be disabled. Full charged battery capacity shall support up to ~20 cycles at a

rate of 2 per hour. After 24 hours of BBU mode the battery shall provide power for 1 complete opening and closing cycle. Please note that only the specied battery can

be use. Use of any other battery leads to loss of warranty and loss of liability of LiftMaster for any related damages resulting from use of unspecied batteries.

19

9. ERROR CODES

LED Error

code Issue Possible reason Solution

E0 Press transmitter, but no gate

movement AP is set to 00 Check if AP is set to 00. If yes, change to correct application setting.

E1 Gate do not close, but can

open.

1) IR1 is not connected, or wire is cut. 1) Check if IR1 is not connected, or wire is cut.

2) IR1 wire is shorted out or reverse connected. 2) Check IR1 connection, change wires if needed.

3) IR1 is not aligned or blocked for a moment. 3) Align IR transmitter and receiver to make sure both LED is on,

instead of blinking. Make sure there is nothing hanging on gate that

may cause IR blocking.

E2 Gate can close when it is at

open limit, but cannot open

when it‘s at close limit.

1) IR2 is not connected, or wire is cut. 1) Check if IR2 is not connected, or wire is cut.

2) IR2 wire is shorted out or reverse connected. 2) Check IR2 connection, change wires if needed.

3) IR2 is not aligned or blocked for a moment. 3) Align IR transmitter and receiver to make sure both LED is on,

instead of blinking. Make sure there is nothing blocking the IR.

E3 Press transmitter, but no gate

movement.

1) IR3 is not connected, or wire is cut. 1) Check if IR3 is not connected, or wire is cut.

2) IR3 wire is shorted out or reverse connected. 2) Check IR3 connection, change wires if needed.

3) IR3 is not aligned or blocked for a moment. 3) Align IR transmitter and receiver to make sure both LED is on,

instead of blinking. Make sure there is nothing hanging on gate that

may cause IR blocking in short time.

E4 Press transmitter, but no gate

movement.

1) Safety edge is not connected with 8.2kohm

resistor. 1) Check if the 8.2 kOhm safety edge is properly connected or if the

8.2 kOhm resistor is installed.

2) Safety edge wire is shorted out. 2) Check safety edge wires and replace wire if needed.

3) Safety edge is pressed. 3) Check if safety edge is pressed.

E5 Press transmitter, but no gate

movement.

1) STOP swtich is open. 1) Check if STOP switch is open or damaged.

2) STOP switch is not connected. 2) Check if STOP switch is disconnected. If yes, then reconnect

STOP switch or change the respective Input setting to other value.

E7 Press transmitter, but no gate

movement. Control board amplier for Motor 1 fail. Switch off power for 20 seconds and reset to check if control board

recovers. If not, change control board.

E8 Press transmitter, but no gate

movement. Control board amplier for Motor 2 fail. Switch off power for 20 seconds and reset to check if control board

recovers. If not, change Control board.

E9 Press transmitter, but no gate

movement. Control board memory mistake. Switch off power for 20 seconds and reset to check if control board

recovers. If not, change control board.

F1 Motor 1 stop and reverse

during open or close. Motor 1 is blocked. Check and remove obstruction. Clean gate.

F2 Motor 2 stop and reverse

during open or close. Motor 2 is blocked. Check and remove obstruction. Clean gate.

F3 Motor 1 stop and reverse

during open or close. Motor 1 stall or speed sensor is damaged. Check if motor 1 stalled or speed sensor is damaged.

F4 Motor 2 stop and reverse

during open or close. Motor 2 stall or speed sensor is damaged. Check if motor 2 stalled or speed sensor is damaged.

F5 Press transmitter, but motor

has no action. Radio module fail. Switch off power for 20 seconds and reset to check if control board

recovers. If not, change control board.

F6 Gate reverse during closing. Low battery power. Charge battery.

F7 Press transmitter, but no gate

movement. Control board damaged. Switch off power for 20 seconds and reset to check if control board

recovers. If not, change control board.

F9 Press transmitter or push

button, but motor has no

action. AP menu is reset to factory default. Relearn limits.

LE Motor stops suddenly. Press C button during limit learning. Relearn limits.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

LiftMaster LA250EVK Guide d'installation

- Catégorie

- Ouvre-porte

- Taper

- Guide d'installation