TWECO

®

FUSION

™

250

Safety and

Operating

Instructions

AIR-COOLED MIG GUN 250 AMP

Tweco.com

English

Canadien Français

Americas Español

Revision: B Issue Date: August 2, 2013 Manual No.: 89200015

IMPORTANT: Included inside - special

instructions for liner replacement.

WE APPRECIATE YOUR BUSINESS!

Congratulations on receiving your new Tweco product. We are proud to

have you as our customer and will strive to provide you with the best

service and support in the industry. This product is backed by our extensive

warranty and world-wide service network.

We know you take pride in your work and we feel privileged to provide you

with this high performance product that will help you get the job done.

For more than 75 years Tweco has provided quality products you can trust,

when your reputation is on the line.

YOU ARE IN GOOD COMPANY!

Tweco is a Global Brand of Arc Welding Products for Victor Technologies

Inc. We distinguish ourselves from our competition through market-

leading innovation and truly dependable products that will stand the test of

time.

We strive to enhance your productivity, efficiency and welding performance

enabling you to excel in your craft. We design products with the welder in

mind delivering- advanced features, durability, ease of use and ergonomic

comfort.

Above all, we are committed to a safer working environment within the

welding industry. Your satisfaction with this product and its safe operation

is our ultimate concern. Please take the time to read the entire manual,

especially the Safety Precautions.

If you have any questions or concerns regarding your new Tweco product,

please contact our friendly and knowledgeable Customer Service Team at:

1-800-462-2782 (USA) and 1-905-827-4515 (Canada),

or visit us on the web at www.Tweco.com

i

WARNINGS

Read and understand this entire Manual and your employer’s safety practices

before installing, operating, or servicing the equipment. While the information

contained in this Manual represents the Manufacturer’s judgment, the Manufacturer

assumes no liability for its use.

Tweco

®

Fusion 250 AMP MIG Gun

Safety and Operating Instructions

Instruction Guide Number 89200015

Published by:

Victor Technologies, Inc.

2800 Airport Rd.

Denton, TX. 76208

(940) 566-2000

www.tweco.com

U.S. Customer Care: (800) 426-1888

Canada Customer Care: 905-827-4515

International Customer Care: (940) 381-1212

Copyright © 2012, 2013 Victor Technologies, Inc. All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher is

prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss

or damage caused by any error or omission in this Manual, whether such error results from

negligence, accident, or any other cause.

Publication Date: December 17, 2012

Revision Date: August 2, 2013

Record the following information for Warranty purposes:

Where Purchased:

Purchase Date:

Equipment Serial #:

ii

Table of Contents

SECTION 1: SAFETY PRECAUTIONS .........................................................................3

1.01 Safety Precautions .......................................................................... 3

SECTION 2: INTRODUCTION ......................................................................................5

2.01 How to Use this Manual ................................................................... 5

2.02 Receipt of Equipment ....................................................................... 5

2.03 Description ....................................................................................... 5

SECTION 3: MIG GUN SPECIFICATIONS.....................................................................6

3.01 MIG Gun Classification ..................................................................... 6

3.02 Duty Cycles ..................................................................................... 6

3.03 Tweco

®

fusion 250A MIG Gun Selection guide ................................ 7

3.04 Tweco

®

Fusion 250A MIG Gun Part Number Identification .............. 7

3.05 Velocity Contact Tip Nozzle Identification ......................................... 8

3.06 Velocity 250 Amp Conductor Tube Identification ............................. 8

SECTION 4: MIG GUN INSTALLATION ........................................................................9

4.01 Direct Plug MIG Gun Installation ...................................................... 9

4.02 Tweco

®

MIG-Kwik Connection and Adapter Kit Installation ........... 10

SECTION 5: REPLACEMENT INSTRUCTIONS ...........................................................11

5.01 Replacing Velocity Contact Tip ...................................................... 11

5.02 Replace Conductor Tube ............................................................... 11

5.03 Conduit Identification and Replacement ......................................... 12

5.04 Replacing Handle, trigger .............................................................. 13

SECTION 6: CABLEHOZ

®

REPAIR ............................................................................14

6.01 Tools Required ...............................................................................14

6.02 Repair of Cablehoz

®

...................................................................... 14

SECTION 7: MAINTENANCE AND TROUBLESHOOTING............................................19

SECTION 8: 250 AMP REPLACEMENT PARTS .........................................................20

8.02 Tweco

®

Fusion 250 A MIG Gun Parts ............................................ 20

8.02 Tweco

®

Fusion MIG Gun Consumables ......................................... 22

SECTION 9: STATEMENT OF WARRANTY ................................................................24

9.01 Warranty Schedule .........................................................................24

Global Contact Information ...............................................Rear Cover

SAFETY AND OPERATING INSTRUCTIONS

389200015

SECTION 1:

SAFETY PRECAUTIONS

1.01 SAFETY PRECAUTIONS

WARNING

SERIOUS INJURY OR DEATH may result if welding and cutting equipment is not

properly installed, used, and maintained. Misuse of this equipment and other

unsafe practices can be hazardous. The operator, supervisor, and helper must read

and understand the following safety warnings and instructions before installing

or using any welding or cutting equipment, and be aware of the dangers of the

welding or cutting process. Training and proper supervision are important for a

safe work place. Keep these instructions for future use. Additional recommended

safety and operating information is referenced in each section.

WARNING

WARNING: This product contains chemicals, including lead, known to the State

of California to cause birth defects and other reproductive harm. Wash hands

after handling.

ELECTRIC SHOCK CAN CAUSE INJURY OR DEATH

Install and maintain equipment in accordance with the National Electrical Code

(NFPA 70) and local codes. Do not service or repair equipment with power on.

Do not operate equipment with protective insulators or covers removed. Service

or repair to equipment must be done by qualified and/or trained personnel only.

Do not contact electrically live parts. Always wear dry welding gloves that are in

good condition. Aluminized, protective clothing can become part of the electrical

path. Keep oxygen cylinders, chains, wires, ropes, cranes, and hoists away from any part of the

electrical path. All ground connections must be checked periodically to determine if they are

mechanically strong, and electrically adequate for the required current. When engaged in AC

welding/cutting under wet conditions or where perspiration is a factor, the use of automatic

controls for reducing the no load voltage is recommended to reduce shock hazards. Accidental

contact must be prevented when using open circuit voltage exceeding 80 volts AC, or 100 volts

DC by adequate insulation or other means. When welding is to be suspended for any length of

time, such as during lunch or overnight, all electrode holders and electrodes should be removed

from the electrode holder and the power supply should be turned off to prevent accidental

contact. Keep MIG Guns, electrode holders, Tig torches, Plasma torches, and electrodes away

from moisture and water. See safety and operating references 1, 2, and 8.

SMOKE, FUMES, AND GASES CAN BE DANGEROUS TO YOUR HEALTH

Ventilation must be adequate to remove smoke, fumes, and gases during

operation to protect operators and others in the area. Vapors of chlorinated

solvents can form the toxic gas “Phosgene” when exposed to ultraviolet radiation

from an electric arc. All solvents, degreasers, and potential sources of these

vapors must be removed from the operating area. Use air-supplied respirators

if ventilation is not adequate to remove all fumes and gases. Oxygen supports, and vigorously

accelerates fire and should never be used for ventilation. See safety and operating references

1, 2, 3, and 4.

4

SAFETY AND OPERATING INSTRUCTIONS

89200015

ARC RAYS, HOT SLAG, AND SPARKS CAN INJURE EYES AND BURN SKIN

Welding and cutting processes produce extreme localized heat and strong

ultraviolet rays. Never attempt to weld/cut without a federally compliant welding

helmet with the proper lens. A number 12 to 14 shade filter lens provides the

best protection against arc radiation. When in a confined area, prevent the

reflected arc rays from entering around the helmet. Approved shielding curtains

and appropriate goggles should be used to provide protection to others in the surrounding area.

Skin should be protected from arc rays, heat, and molten metal. Always wear protective gloves

and clothing. All pockets should be closed and cuffs sewn shut. Leather aprons, sleeves, leggings,

etc. should be worn for out-of-position welding and cutting, or for heavy operations using large

electrodes. Hightop work shoes provide adequate protection from foot burns. For added protection,

use leather spats. Flammable hair preparations should not be used when welding/cutting. Wear

ear plugs to protect ears from sparks. Where work permits, the operator should be enclosed in

an individual booth painted with a low reflective material such as zinc oxide.

See safety and operating references 1, 2, and 3.

WELDING SPARKS CAN CAUSE FIRES AND EXPLOSIONS

Combustibles reached by the arc, flame, flying sparks, hot slag, and heated

materials can cause fire and explosions. Remove combustibles from the work

area and/or provide a fire watch. Avoid oily or greasy clothing as a spark may

ignite them. Have a fire extinguisher nearby, and know how to use it. If welding/

cutting is to be done on a metal wall, partition, ceiling, or roof, precautions must

be taken to prevent ignition of nearby combustibles on the other side. Do not

weld/cut containers that have held combustibles. All hollow spaces, cavities, and containers

should be vented prior to welding/cutting to permit the escape of air or gases. Purging with inert

gas is recommended. Never use oxygen in a welding torch. Use only inert gases or inert gas

mixes as required by the process. Use of combustible compressed gases can cause explosions

resulting in personal injury or death. Arcing against any compressed gas cylinder can cause

cylinder damage or explosion. See safety and operating references 1, 2, 5, 7, and 8.

NOISE CAN DAMAGE HEARING

Noise from the air carbon-arc process can damage your hearing. Wear protective

hearing devices to ensure protection when noise levels exceed OHSA standards.

Adequate hearing protection devices must be worn by operators and surrounding

personnel to ensure personal protection against noise. See safety and operating

references 1, 2, and 6.

SAFETY AND OPERATING REFERENCES

1. Code of Federal Regulations (OSHA) Section 29, Part 1910.95, 132, 133, 134, 139,

251, 252, 253, 254 and 1000. U.S. Government Printing Office, Washington, DC 20402.

2. ANSI Z49.1 “Safety in Welding and Cutting”.

3. ANSI Z87.1 “Practice for Occupational and Educational Eye and Face Protection”.

4. ANSI Z88.2. “Standard Practice for Respiratory Protection”. American National

Standards Institute, 1430 Broadway, New York, NY 10018.

5. AWS F4.1. “Recommended Safe Practices for Welding and Cutting Containers”.

6. AWS C5.3. “Recommended Practices for Air Carbon-Arc Gouging and Cutting”. The

American Welding Society, 550 NW Lejeune Rd., P.O. Box 351040, Miami, FL 33135.

7. NFPA 51B. “Fire Prevention in Cutting and Welding Processes”.

8. NFPA-7. “National Electrical Code”. National Fire Protection Association, Battery Park,

Quincy, MA 02269.

9. CSA W117.2. “Safety in Welding, Cutting and Allied Processes”. Canadian Standards

Association, 178 Rexdale Blvd., Rexdale, Ontario, Canada M9W 1R3.

SAFETY AND OPERATING INSTRUCTIONS

589200015

SECTION 2:

INTRODUCTION

2.01 HOW TO USE THIS MANUAL

To ensure safe operation, read the entire manual, including the chapters on safety instructions

and warnings.

Throughout this manual, the words WARNING, CAUTION, and NOTE may appear. Pay particular

attention to the information provided under these headings. These special annotations are

easily recognized as follows:

NOTE

NOTE conveys installation, operation, or maintenance information which is

important but not hazard-related.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

2.02 RECEIPT OF EQUIPMENT

When you receive the equipment, check it against the invoice to make sure it is complete and

inspect the equipment for possible damage due to shipping. If there is any damage, notify the

carrier immediately to file a claim. Furnish complete information concerning damage claims

or shipping errors to the location in your area, listed on the back cover of this manual. Include

a full description of the parts in error.

If you want additional or replacement copies of this manual, please contact Tweco

®

at the

address and phone number in your area listed on the back cover of this manual. Include the

Manual number (from page i).

2.03 DESCRIPTION

Tweco MIG Guns are furnished with rear connections to fit directly into most Miller

®

, Lincoln

®

,

and Euro connection wire feeders. These guns are referred to as Direct Plug MIG Guns. Tweco

MIG guns are also furnished with the time-proven MIG-Kwik connection. The MIG-Kwik

connection, when utilized with a Tweco adapter kit, allows a Tweco MIG gun to be installed on

almost any wire feed system. For a listing of available adapter kits, see the Tweco Adapter Kit

Listing, Form No. TAKL-97, or call Tweco Customer Care.

MILLER is a registered trademark of Miller Electric Mfg. Co.; ESAB is a registered trademark of ESAB AB; LINCOLN is

a registered trademark of LINCOLN Electric Co.; The aforementioned registered trademarks are no way affiliated with

Tweco Products, Inc. or Victor Technologies, Inc. Tweco is a registered trademark of Victor Technologies, Inc.

6

SAFETY AND OPERATING INSTRUCTIONS

89200015

SECTION 3:

MIG GUN SPECIFICATIONS

3.01 MIG GUN CLASSIFICATION

Process MIG/MAG welding

Method of Guidance Manually guided

Voltage Class for Welding and Control Circuits L (up to 113 V peak)

Type of Cooling Air or cooling gas

Type of Shielding Gas All types

3.02 DUTY CYCLES

Duty Cycle

MIG Gun

250 AMP

10% 320

35% 290

80% 250

100% 195

The above duty cycles were established by testing under the following parameters:

Parameter MIG (metal inert gas) MAG (metal active gas)

Type of Voltage D.C.

Shielding Gas Argon Argon/CO

2

Mixed Gas (80/20, 75/25)

Gas Flow Rate 30-35 CFH (14,2- 16,5 l/m)

Gun Cable Length

10 ft. (3 m)

12 ft. (3,7 m)

15 ft. (4,6 m)

20 ft. (6 m)

25 ft. (7,6 m)

Electrode Polarity Positive

Wire Diameter

Wire (Continuous Electrode) Size

250 amp

.023" (0,6 mm)

.030" (0,8 mm)

.035" (0,9 mm)

.040" (1,0 mm)

.045" (1,2 mm)

.052" (1,3 mm)

3/64” (1,2 mm)

1/16” (1,6 mm)

5/64” (2,0 mm)

3/32” (2,4 mm)

7/64” (2,8 mm)

1/8” (3,2 mm)

SAFETY AND OPERATING INSTRUCTIONS

789200015

3.03 TWECO

®

FUSION 250A MIG GUN SELECTION GUIDE

Rear

Connection

250 AMP MIG Gun*

Rear Connector

(Replacement)

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

Part Number

Stock Number

10 ft cable 12 ft cable 15 ft cable 20 ft cable 25 ft cable

Tweco

®

FV210-3545

1023-1059

FV212-3545

1023-1060

FV215-3545

1023-1061

FV220-3545

1023-1062

FV225-3545

1023-1063

350-174H

2035-2110

Miller

®

FV210M-3545

1023-1067

FV212M-3545

1023-1068

FV215M-3545

1023-1069

FV220M-3545

1023-1070

FV225M-3545

1023-1071

350-174MH

2035-2111

Lincoln

®

----

FV212L-3545

1023-1084

FV215L-3545

1023-1085

---- ----

350-174LH

2035-2112

Euro-Kwik

FV210X-3545

1023-1089

FV212X-3545

1023-1090

FV215X-3545

1023-1091

----

FV225X-3545

1023-1092

174EX-1

2040-2276

252i

ThermalArc

---- ----

FV215TA3545

1023-1097

---- ----

350-174H

2035-2110

*Rear connector supplied as standard

3.04 TWECO FUSION 250A MIG GUN PART NUMBER

IDENTIFICATION

NOTE

Tweco Fusion MIG guns, as a general rule, have a specific nomenclature

incorporated within each part number to help determine the wire size of each

MIG gun.

Example Part Number:

FV215TA3545

T=Tweco

TA=Tweco (Bundle)

L=Lincoln

M=Miller

X, XE=Euro-Kwik

Fusion Velocity

15 foot (5 M) cable

.035"-.045" Wire Capacity

(0,9 mm - 1,2 mm)

So a part number "FV215TA3545" would identify the MIG gun as a: Tweco Fusion 250A MIG

Gun bundle pack with a 8-pin rear connector, 15 foot long cable and having a 0.035" to 0.045"

diameter wire capacity.

So a part number"FV2253545" would identify the MIG gun as a: Tweco Fusion 250A MIG Gun

with a 4-pin Tweco rear connector, 25 foot long cable and having a 0.035" to 0.045" diameter

wire capacity.

MILLER is a registered trademark of Miller Electric Mfg. Co.; ESAB is a registered trademark of ESAB AB; LINCOLN is

a registered trademark of LINCOLN Electric Co.; The aforementioned registered trademarks are no way affiliated with

Tweco Products, Inc. or Victor Technologies, Inc. Tweco is a registered trademark of Victor Technologies, Inc.

8

SAFETY AND OPERATING INSTRUCTIONS

89200015

3.04 VELOCITY CONTACT TIP IDENTIFICATION

Velocity Contact Tips may be identified by the tip type and the part number marking for each tip.

Example Part Number:

VTSARZT30

Velocity

Tip

Blank=CU,

RZ=CHROM ZIRC,

RS=SILVER ZIRC

T=Tapered,

Blank=None

S=Small,

M=Medium,

L=Large

A=Aluminum,

Blank=Other

Wire Size: 23=0.023” 116=1/16”

30=0.030” 564=5/64”

35=0.035” 332=3/32”

40=0.040” 764=7/64”

45=0.045” 18=1/8”

52=0.052” 364=3/64”

So a part number "VTSARZT30" would be: Velocity Tip Type, Small Size, Aluminum, RZ Alloy,

Tapered for wire size 0.030" diameter.

A part number "VTM40" would be: Velocity Tip Type, Medium Size, CU, wire size 0.040" diameter.

3.05 VELOCITY CONTACT TIP NOZZLE IDENTIFICATION

Nozzles for the Velocity contact tip Tweco Fusion MIG Guns may be identified by their type and part

number marking on each nozzle.

Example Part Number:

Blank=Standard,

H=Heavy Duty

VNSH50FS

Velocity

Nozzle

Blank=Std Recess,

F=Flush,

P=Protrude,

R= Recess ¼” (6.35mm)

FAS=Spot Weld

FC=Flux Core

S=Small Nozzle,

M=Medium Nozzle,

L=Large Nozzle

Orifice Opening Size: 37=3/8” 62=5/8”

50=1/2” 75=3/4”

Blank=Threaded,

S=Slip

So a part number "VNSH50FS" would be: Velocity Nozzle Type, Small Nozzle Size, Heavy Duty,

orifice opening size of 0.50 inch, Flush end, Slip fit.

A part number "VNS50" would be: Velocity Nozzle Type, Small Nozzle Size, Standard Duty,

orifice opening size of 0.50 inch, Standard Recess end, Threaded fit.

3.06 VELOCITY 250 AMP CONDUCTOR TUBE IDENTIFICATION

Conductor tubes for the Velocity Contact Tip on the Tweco Fusion MIG Guns may be identified by their

type and part number marking on each tube.

Example Part Number:

FVCTS45

Fusion

Velocity

Conductor Tube

Bend Angle: 45˚, 60˚, or 180˚

S=Small Tip,

M=Medium Tip,

L=Large Tip

So a part number "FVCTS45" would be: Tweco Fusion Gun Type, Velocity 250 Amp Conductor

Tube, Small Tip Size, 45 degree bend.

A part number "FVCTM60" would be: Tweco Fusion Gun Type, Velocity 250 Amp Conductor

Tube, Medium Tip Size, 60 degree bend.

SAFETY AND OPERATING INSTRUCTIONS

989200015

SECTION 4:

MIG GUN INSTALLATION

NOTE

Be certain that the end user (welder, operator, or helper) reads and understands

these instructions. Be certain that the welder also reads Section 1 “Safety

Precautions.”

WARNING

Electric shock can cause injury or death.

POWER

SOURCE

WIRE FEEDER

GROUND

WORK PIECE

GUN

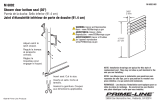

Figure 1: Standard MIG Gun Installation

4.01 DIRECT PLUG MIG GUN INSTALLATION

Direct plug MIG guns install by directly inserting the rear connector plug into the feeder wire

guide outlet (see figure 2) and tightening the plug retaining screw. All models of MIG guns,

except the Euro-Kwik guns, require a control wire assembly to attach the MIG gun trigger

leads to the feeder. The control wire assemblies plug into the rear connector case of the MIG

gun, and into the control wire receptacle on the feeder. Euro-Kwik connections are installed by

inserting the gun connection into the feeder receptacle, aligning the conduit plug first, then the

gas plug. Push until all fittings are seated, then tighten the nut hand tight as shown in figure 3.

Figure 2

Figure 3

10

SAFETY AND OPERATING INSTRUCTIONS

89200015

4.02 TWECO

®

MIG-KWIK CONNECTION AND ADAPTER KIT

INSTALLATION

Installation of a Tweco MIG gun with a Tweco connector plug, may require an adapter kit. Choose

the correct adapter kit for your wire feeder from the Adapter Kit Listing Form No. TLAK-97 for

more detail. To install, follow the instructions furnished with the adapter kit. Figure 4 shows

the general adapter kit installation.

Receptacle

(TLAK-1 or 6TLAK-1)

Receptacle

(TAK-1 or 6TAK-1)

ADAPTER PLUG

WIRE FEEDER

GAS HOSE

GAS HOSE

POWER CABLE

CONTROL WIRE

MIG GUN

Figure 4

1. Screw adapter plug into the receptacle and tighten.

2. Insert the adapter plug and receptacle into the wire feeder wire guideout. Tighten the

wire guide attachment screw.

3. If needed, attach a proper sized welding cable from the welding power source to the

receptacle power connection.

4. Attach a gas hose to the receptacle and to the feeder gas solenoid.

NOTE

When using an adapter kit, the gas must be attached to the receptacle to provide

gas to the MIG gun. If the feeder gas supply is attached to the feeder wire guideout

block, it must be rerouted to the receptacle.

5. Insert the MIG gun rear connection plug into the receptacle and tighten the attachment

screw.

6. Attach the control wire plug assembly to the wire feeder MIG gun control circuit. Then

plug the flat double female plug into the MIG gun.

The gun should now be installed and ready to feed wire as recommended by the feeder

manufacturer.

SAFETY AND OPERATING INSTRUCTIONS

1189200015

SECTION 5: REPLACEMENT INSTRUCTIONS

5.01 REPLACING VELOCITY CONTACT TIP

CAUTION

While nozzle and contact tip are removed, maintain an adequate distance of the

wire from metal objects to avoid burnbacks to conduit or conductor tube.

1. Remove worn nozzle and tip. (Clean nozzle if reusing.)

2. Slide new contact tip over

the conduit end and into the

conductor tube end.

3. Replace the nozzle. Hand tighten

(Nozzle secures tip).

NOTE

For proper operation the

nozzle MUST be tight.

4. Trim wire to desired stick out.

The MIG gun is now ready operation.

5.02 REPLACE CONDUCTOR TUBE

The conductor tube is attached to the Tweco

®

Fusion handle by two set screws on the side of

the handle. To remove:

1. Remove the front end consumables from the conductor tube.

2. Loosen the conduit liner set screw with a 5/64" Allen wrench (supplied) and then

loosen the socket head cap screw securing the conductor tube in place inside the

handle with a 5/32" Allen wrench.

3. Remove conductor tube.

4. Slide the new tube over the liner and insert into the brass connection within the handle.

Confirm the tube is correctly aligned with the MIG Gun handle and wrench tighten the

socket head cap screw.

5. Tighten the conduit set screw down against the liner. Do not overtighten to avoid

damaging the liner.

6. Re-assemble the front end consumables.

The MIG gun is now ready for operation.

12

SAFETY AND OPERATING INSTRUCTIONS

89200015

Conduit liner set screw

Socket head cap screw

5.03 CONDUIT IDENTIFICATION AND REPLACEMENT

The procedure for removal and installation of a wire conduit is similar for all Tweco MIG guns. Conduits

may be identified by the type of conduit stop and the part number marking on each conduit stop.

Example Part Number:

44-116-15

44 Series

1/16" (1,6mm) Wire Capacity

Liner length in feet

Conduit Removal

1. Lay the MIG gun out on a table or on the floor in a straight line. Make sure the gun is

fully extended and all twists in the cable are removed.

2. Remove the nozzle and tip.

NOTE

On Miller

®

Direct Plug MIG guns, remove the nipple on the end of the connector

plug. On Euro-Kwik connections, remove the conduit retaining cap.

3. Loosen the conduit set screw in the front of the gun. This is usually located at the

front of the handle. Then loosen the conduit set screw in the rear connector plug.

4. Grip the conduit stop and remove the conduit with a twisting motion. On Miller

®

Direct

Plug MIG guns, twisting the rear of the gun approximately one revolution clockwise

will raise the conduit stop out of the connector plug recess.

Conduit Installation - Velocity Contact Tip Style

WARNING

Failure to follow Conduit Installation Instructions will cause wire feed issues.

1. Uncoil the conduit and lay it in a straight line. Insert the conduit into the rear connector plug.

Push the conduit into the gun with short strokes.

NOTE

If the conduit hangs up gently whip the cable while applying pressure to the

conduit. New liners must be cut to the correct length.

2. When the conduit is completely in the gun, tighten the rear conduit set screw. On Miller

®

guns, reinstall the nipple. On Euro-Kwik guns, reinstall the conduit retaining cap.

SAFETY AND OPERATING INSTRUCTIONS

1389200015

IMPORTANT!

3. The new conduit liner will need to be cut to length.

This can be done by trimming the conduit to the

appropriate length.

1/8” (3,2 mm)

Velocity

Conductor Tube

4. File the cut conduit end to remove burrs.

5. Replace the contact tip.

6. Replace the nozzle. Hand tighten

(Nozzle secures tip).

NOTE

For proper operation the nozzle MUST

be tight.

The MIG gun is now ready to be reinstalled on the

feeder.

5.04 REPLACING HANDLE, TRIGGER

Remove the MIG gun from the feeder prior to beginning these steps.

Handle screws Back Cap

Gun Hanger

1. Lay MIG gun on side, screw side up and remove both handle screws at the front of the

gun handle.

2. Remove the small screw from the other side of the gun hanger clip and remove the

gun hanger clip being careful to keep all internal components in place.

3. Lay the gun back down on its side and untwist the handle back cap.

4. Remove the top handle half being careful to keep all components in place in the lower

handle half.

5. (Follow this step ONLY if the trigger is to be replaced.) Lift out the molded trigger, the

trigger mechanism, and disconnect the lead wires. Connect the wires to the new trigger

mechanism then place the molded trigger and new trigger in the lower handle half.

6. Place the new top handle half on the old lower handle half and gently flip the gun over.

Replace the old lower handle half with the new lower handle half. Molded trigger should

move within the handle.

7. Flip the gun back to the screw side up and press the handle halves together until they

bottom. Be careful not to pinch the trigger lead wires.

8. Put the gun hanger in place and install the two handle screws. Rotate the gun handle

to the other side and install the small gun hanger clip screw.

9. Slide the Back Cap into place and twist onto the handle end.

The MIG gun is now ready to be reinstalled on the feeder.

14

SAFETY AND OPERATING INSTRUCTIONS

89200015

SECTION 6:

CABLEHOZ

®

REPAIR

6.01 TOOLS REQUIRED

6.02 REPAIR OF CABLEHOZ

®

A. Back-End Repair

1. Disassemble the rear case to expose the rear connector assembly and pull the assembly

away from the rear case.

2. Cut the Cablehoz

®

to remove the damaged area.

3. Use replacement connector assembly,

Part No. MS172-RK (Stock No. 2060-

2134) on 250 Amp Tweco

®

Fusion MIG

Guns.

4. Measure back 2-1/2" (63,5 mm) from the end of the Cablehoz and cut away the outer

jacket of the cable, being careful not to cut the copper strands and or lead wires.

5. Pull the copper strands and lead

wires away from the inner core tube

that is exposed and cut away leaving

approximately ¼" (6,35 mm) past the

end of the end of the Cablehoz.

SAFETY AND OPERATING INSTRUCTIONS

1589200015

6. Cut the copper strands to a length of ¾"

(19,05 mm) while leaving the wire leads

intact.

7. Thread the pressure nut onto the

replacement rear connector until it

bottoms out and then slide the sleeve

over the connector.

Note: Make sure the bevel is facing the

right direction.

Bevel

8. Insert the replacement connector nipple

into the inner core tube of the Cablehoz.

It is recommended to use a small amount

of non-petroleum based lubricant* to help

the connector to slide into the tube. The

core tube should bottom out against the

shoulder, approximately 15/16" (23,8

mm) onto the connector.

*A small amount of white glue works well.

9. Push the copper strands underneath the sleeve. It is recommended that a 1/8” glass

filament tape be wrapped around the exposed copper to keep the copper strands together

when tightening the pressure nut.

10. Begin to turn the pressure nut counter-

clockwise which will force the copper

strands & sleeve against and then under

the machined taper on the connector.

Use Torque Wrench and wrench to

perform this task.

11. Torque the pressure nut to 250 inch

pounds, +/-50 inch pounds, (28,2 newton

meters, +/- 5,6 newton meters).

16

SAFETY AND OPERATING INSTRUCTIONS

89200015

12. Apply clamp over outside cable and

tighten. Trim excess clamp.

13. Connect lead wires accordingly.

14. Re-assemble the rear case.

Approx.

0.2” (5mm)

B. Front-End Repair

1. Disassemble the front handle halves to expose the front connector assembly and pull

the assembly from the front handle case.

2. Cut the Cablehoz

®

to remove the damaged area.

3. Use replacement connector assembly,

Part No. MS102-RK (Stock No. 2060-

2132) on 250 Amp Tweco

®

Fusion MIG

Guns.

4. Measure back 2-1/2” (63,5 mm) from the end of the Cablehoz and cut away the outer

jacket of the cable, being careful not to cut the copper strands and or lead wires.

5. Pull the copper strands and lead

wires away from the inner core tube

that is exposed and cut away leaving

approximately ¼” (6,35 mm) past the

end of the end of the Cablehoz.

6. Cut the copper strands to a length of ¾”

(19,05 mm) while leaving the wire leads

intact.

SAFETY AND OPERATING INSTRUCTIONS

1789200015

7. Thread the pressure nut onto the

replacement front connector until it

bottoms out and then slide the sleeve

over the connector.

Note: Make sure the bevel is facing the

right direction.

Bevel

8. Insert the replacement connector nipple

into the inner core tube of the Cablehoz.

It is recommended to use a small amount

of non-petroleum based lubricant* to help

the connector to slide into the tube. The

core tube should bottom out against the

shoulder, approximately 15/16” (23,8

mm) onto the connector.

*A small amount of white glue works well.

9. Push the copper strands underneath the

sleeve. It is recommended that a 1/8”

glass filament tape be wrapped around

the exposed copper to keep the copper

strands together when tightening the

pressure nut.

10. Begin to turn the pressure nut counter-

clockwise which will force the copper

strands & sleeve against and then under

the machined taper on the connector.

Use Torque Wrench and wrench to

perform this task.

11. Torque the pressure nut to 250 inch

pounds, +/-50 inch pounds, (28,2 newton

meters, +/- 5,6 newton meters).

12. Apply clamp over outside cable and

tighten. Trim excess clamp.

13. Connect lead wires accordingly.

14. Re-assemble the front end.

Approx.

2” (5mm)

18

SAFETY AND OPERATING INSTRUCTIONS

89200015

This page intentionally blank.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

Tweco TWECO® FUSION™250 Air-Cooled Mig Gun 250 AMP Manuel utilisateur

- Taper

- Manuel utilisateur

- Ce manuel convient également à

dans d''autres langues

Documents connexes

-

Tweco Classic No. Series Mig Guns with Velocity Consumables Manuel utilisateur

Tweco Classic No. Series Mig Guns with Velocity Consumables Manuel utilisateur

-

Tweco Classic Serial No. Mig Guns Manuel utilisateur

Tweco Classic Serial No. Mig Guns Manuel utilisateur

-

Tweco Classic No. Series Mig Guns Manuel utilisateur

Tweco Classic No. Series Mig Guns Manuel utilisateur

-

Tweco Tweco Spool Gun Manuel utilisateur

Tweco Tweco Spool Gun Manuel utilisateur

-

Tweco Classic No. Series Mig Guns Manuel utilisateur

Tweco Classic No. Series Mig Guns Manuel utilisateur

-

Tweco Classic No. Series Mig Guns Manuel utilisateur

Tweco Classic No. Series Mig Guns Manuel utilisateur

-

Tweco Air-Cooled 350 AMP 450 AMP Water-Cooled 400 AMP 500 AMP PulseMaster™ Mig Gun Manuel utilisateur

Tweco Air-Cooled 350 AMP 450 AMP Water-Cooled 400 AMP 500 AMP PulseMaster™ Mig Gun Manuel utilisateur

-

Tweco Tweco Spray Master MIG Guns with VELOCITY2 Manuel utilisateur

-

Tweco Tweco Spray Master MIG Guns with VELOCITY2 Manuel utilisateur

-

Tweco Tweco Spray Master MIG Guns with VELOCITY2 Manuel utilisateur

Autres documents

-

ESAB 220 AMP Manuel utilisateur

-

ESAB Firepower Air Cooled Mig Gun 180 AMP and 220 AMP Manuel utilisateur

-

Tweco Robotics Light Weight Quick Robotics Torch Guide d'installation

-

Prime-Line M 6092 Mode d'emploi

Prime-Line M 6092 Mode d'emploi

-

ESAB FABRICATOR252i Manuel utilisateur

-

ESAB ESAB Fabricator® 252i 3-IN-1 Multi Process Welding Systems Manuel utilisateur

-

ESAB ESAB Fabricator® 252i 3-IN-1 Multi Process Welding Systems Manuel utilisateur

-

Thermal Arc 400SP 500SP Powermaster Automation Manuel utilisateur

Thermal Arc 400SP 500SP Powermaster Automation Manuel utilisateur

-

Ryobi P307 Le manuel du propriétaire

-

Prime-Line M 6092 Guide d'installation

Prime-Line M 6092 Guide d'installation