Mr. Steam AromaFlo Installation & Operation Manual

- Taper

- Installation & Operation Manual

RISK OF ELECTRIC SHOCK - This pump

is supplied with a grounding conductor and grounding-type

attachment plug. To reduce the risk of electric shock, be

certain that it is connected only to a properly grounded,

grounding-type receptacle.

RISQUE DE CHOC ÉLECTRIQUE - Cette

pompe est fournie avec un conducteur de mise à la terre

et une fiche de branchement de type mise à la terre. Pour

réduire le risque de choc électrique, assurez vous qu’il est

connecté uniquement à une mise à la terre, à la terre prise.

mr

.steam® AROMAFLO Operation & Installation

____________________________________________________________________

2

containing emulsifiers or aldehydes. AromaFlo

system damage may result. MrSteam oils are

approved for operation with this system.

introduce excessive concentration of oil into the

steam room, resulting in a health hazard.

out of the reach of children. In case of contact with

eyes, rinse immediately with plenty of water and

seek medical advice. If swallowed, rinse mouth with

water (only if the person is conscious), seek medical

advice immediately and show this container or label.

ignition–No smoking. Keep container tightly closed

& in a well-ventilated place. This material & its

container must be disposed of as hazardous waste.

Safety Data Sheet (MSDS) available upon request

IMPORTANT NOTE:

As you follow these instruc-

tions, you will notice warning and caution symbols. This

blocked information is important for the safe and efficient

installation and operation of this generator. These are

types of potential hazards that may occur during installa-

tion and operation:

states a hazard may cause serious

injury or death if precautions are not followed.

signals a situation where minor injury

or product damage may occur if you do not follow

instructions.

IMPORTANT NOTE:

This highlights information that

is especially relevant to a problem-free installation.

TABLE OF CONTENTS

Box Contents 3

Assembly and Installation

General 3

Pump Assembly 4

Installation of Hoses 4

System Schematic 5

Electrical Wiring 5

Assembly Diagram 6

Start-up

Initial Priming of Metering Pump 7

Filling the Pressure Hose 7

Operation 7

Powering Up Pump 7

Adjusting oil Delivery Pump 7

Troubleshooting 8

Technical Information 8

Warranty 8

PUR 100193 1.17

Fragrance Metering Pump

for Commercial Steam Rooms

mr.steam®

Sussman-Automatic Corp®

www.mrsteam.com

43-20 34th Street

Long Island City, NY 11101

tel: 1 800 76 STEAM

fax: 718 472 3256

9410 S. La Cienega Blvd.

Inglewood CA 90301

tel: 1 800 72 STEAM

fax: 310 216 2944

NOTE: It is strongly recommended that this warning sign (supplied)

be posted in a conspicuous location near the steam room.

AVERTISSEMENT

!

This room is equipped with an aromatic

oil dispensing system. Leave room

immediately if you have any adverse or

allergic reactions, including difficulty

breathing or eye, nasal, throat.

Sussman-Automatic Corp.

3-20 34th Street, Long Island City NY 11101

1-800-76 STEAM

WARNING!

PUR 100381 3/02

CAUTION

!

WARNING

!

WARNINGS

!

WARNING

!

3

Warning Sign

Injector

1/4 x 1/2 NPT

Atomizing Nozzle

mr

.steam® AROMAFLO Operation & Installation

____________________________________________________________________

BOX CONTENTS

This room is equipped with an aromatic oil dispens-

ing system.

Leave the room immediately if you have any

adverse or

allergic reactions, including difficulty breathing or

eye, nasal, throat, or skin irritation and seek medi-

cal attention.

mr.steam

®

Commercial Steam Generators

Sussman-Automatic Corp. 43-20 34th Street , Long Island City NY 11101

WARNING

!

Do Not alter or modify any

MrSteam product. Doing so may result in an

inoperable or hazardous installation and will

void the warranty.

The AromaFlo pump is quali-

fied for use with MrSteam commercial steam

generators. The use with other brand equip-

ment must be qualified by installation owner/

installer. For use with commercial steam rooms

only. Not for use in residential installations.

1. MrSteam AromaFlo Pumps are designed and

intended for indoor use only and are to be

located indoors in a dry clean location and

not subject to moisture, condensation or similar

high humidity environments.

2. Do not install AromaFlo Pumps outdoors.

3. Do not install AromaFlo Pumps in a location

where water could freeze.

4. Do not install AromaFlo Pumps near flammable

or corrosive materials and chemicals. Installation

in areas having high concentrations of

chlorine (such as pool equipment room)

should be avoided.

5. Install AromaFlo Pump on a solid and level

surface.

6. Provide access to AromaFlo Pump for servicing.

7. The unit should not be installed in areas

accessible to the general public (ie: utility

room). A LOCKED UTILITY ROOM

IS STRONGLY RECOMMENDED.

8. Height difference between metering pump and

90 degree T is to be held to a maximum 6 feet

(see page 5).

9. Place scent container below metering pump.

Height difference between metering pump and

scent container is to be no greater than a

maximum of 3 feet (see page 5).

Clearance to heat sources

• Do not install the metering pump

directly below or above the steam

generator where it is subject to heat.

• Distance between metering pump and

heat source (e.g. steam

generator, heating system) minimum

3 ft. If this

distance of minimum 3 ft cannot be

maintained, install a radiation plate

or heat insulation between the heat

source and metering pump.

• Ambient temperature at pump should

not exceed 90˚ F.

Tubing Connections

1. Completely unscrew tightening nut

from pump head (or fitting) and

remove components

2. Assemble tubing components as

shown in figure 1.

IMPORTANT NOTE: To prevent

connection from coming undone, insert

tubing holder completely into tubing

until it reaches the bottom. Lubricate the

ID of the tubing as required with soap to

facilitate insertion.

To prevent damage do

not use tools to tighten the nut.

8 ft.

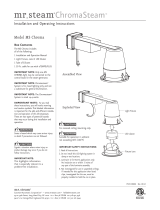

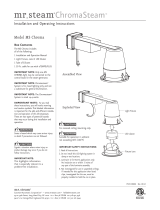

Metering Pump Pressure Hose

Receptacle and

Face Plate Installation &

Operation Manual

–––––––––––––––––––––––––––––––––––––––––––––––

Additional Items Included but Not Shown:

–––––––––––––––––––––––––––––––––––––––––––––––

CAUTION

!

CAUTION

!

WARNING

!

____________________________________________________________________

GENERAL INSTALLATION

Tubing

Tightening

Nut

Collar

Tube Holder

Figure 1

90˚ T

Steam line

Container Height

12 inches

Container Cap

Suction Hose

Foot Valve

Open End to Pump

mr

.steam® AROMAFLO Operation & Installation

____________________________________________________________________

4

PUMP ASSEMBLY

Installing the 90 degree T and Atomizing Nozzle

1. For optimal results locate a brass 90 degree T (not provided) and

atomizing nozzle in the steam supply line within 10 feet of the steam

head. If using copper tubing for steam lines, install a female 1/2

NPT or 1/4 NPT reducing Tee in the steam line facing downward.

2. T must face downward as shown (in figure 2).

3. If a 1/2 NPT tee is used, cut off the 1/4 NPT portion of the

injector with a hacksaw.

4. Screw the atomizing nozzle into 90° T fitting using teflon tape

on the threads.

IMPORTANT NOTE: Follow the installation instructions

for the steam pipeline in the MrSteam Steam Bath Installation

and Operation Manual.

Visit www.mrsteam.com to download this document.

Installation of Pressure Hose to

AromaFlo System

1. Insert the pressure hose through the hole of the pressure end nut

and firmly push the pressure hose onto the pressure valve.

2. Screw the pressure end nut onto the pressure valve and tighten

the nut by HAND only.

Installation of Suction Hose in Scent Container

1. Locate the “container cap” included with the bottle of oil.

2. Unscrew the cap from the MrSteam scent container

and discard.

3. Insert the suction hose with the open end from below

through the hole in the container cap (see Fig. 3).

4. Insert the foot valve into the scent container so that the

foot valve rests on the bottom.

5. Screw the cap onto the scent container.

Installation of Suction Hose to

AromaFlo System

1. Unscrew the suction end nut from the pump head.

2. Assemble the tubing connection as shown in

Figure 1 on page 3.

3. Screw the suction tube tightening nut to the

suction side of the pump.

IMPORTANT NOTE: HAND-TIGHTEN ONLY.

Figure 3

Figure 4

Figure 2

Cut 1/4 NPT extension

off atomizing nozzle

to use 1/2 NPT threads

Thread atomizing

nozzle into Tee

Pressure Tube

Pressure Tube

Priming Port Valve

Priming Port

Suction Tube

Tightening Nut

Suction Tube

Pressure Hose

Repeat the suction hose installation steps on the pressure side of the pump.

MrSteam recommends installing the AromaFlo lower than the Atomizing

nozzle. If the pump must be installed higher that the atomizing nozzle a loop

should be placed in the pressure tubing to prevent siphoning as required.

An air bubble should be trapped at the top of the loop.

5

Max height

6 ft.

Max.

height 3 ft.

Steam

head

Utility

Room

Steam

Room

Steam Line

Pump line cord 120V

90˚ T

Atomizer

Nozzle

Pressure hose

AromaFlo Pump

Suction hose

Scent Container

Steam Solenoid

with Electrical Box

Typical MrSteam Commercial SteamGenerator

Electrical connection to

Digital 1 Temperature Control

(see wiring diagram)

Max distance 10ft.

TYPICAL AROMAFLO

INSTALLATION

__________________________________

(see full disclaimer)

__________________________________

CU Steam Generator Digital 1 Control

CU AROMAFLO

PROBE

Steam Solenoid Valve

Digitl One Control

_____________________________________________________________________

ELECTRICAL CONNECTION OF METERING PUMP

This meter-

ing pump is factory wired and

power supply. Refer to name-

plate on AromaFlo pump. If

the power cord of the meter-

ing pump is damaged it must

be replaced by the Sussman-

Automatic service department

or similarly qualified personnel

in order to avoid risks. All elec-

trical connections to be made

by a licensed, qualified electri-

cian. Disconnect all power to

the steam generator before

making power connections.

CAUTION

!

mr

.steam® AROMAFLO Operation & Installation

____________________________________________________________________

Digital 1 Control and CU-AromaFlo Wiring Schematic

mr

.steam® AROMAFLO Operation & Installation

____________________________________________________________________

6

ELECTRICAL BOX ASSEMBLY

To avoid possible electric

shock, the AromaFlo pump must be suitably

grounded according to National Electric and

local Codes. Disconnect all power supplies

before proceeding. Such wiring should be

done by a licensed electrician.

NOTE: Refer to the wiring diagram

on pg. 5 for all wiring connections

Fully Assembled

The electrical

outlet shown is for AromaFlo

Pump connection only. Make

no other connections to this

outlet. Other connections may

result in circuit overload.

Receptacle Faceplate

(supplied with AromaFlo)

Single Receptacle

(supplied with AromaFlo)

(2x4) NEMA Electrical Box

(supplied by others)

Electric Box with

Steam Solenoid

3 Conductor,

Grounding-type

Line Cord

AromaFlo

Metering Pump

MrSteam Commercial

Steam Solenoid.

MrSteam Commercial

Steam Solenoid.

CAUTION

!

CAUTION

!

mr

.steam® AROMAFLO Operation & Installation

____________________________________________________________________

7

START-UP

Initial Priming of the Pump

1. Insure MrSteam scent container is full.

2. Insert a short piece of soft injector hose onto the tip of

the injector (see Fig. 5).

3. Insert the open end of the injector hose onto the pressure

valve (see Fig. 5).

4. Open the priming valve by turning the knob counter

clockwise 1 full revolution.

5. Draw liquid from the injector slowly and evenly.

Continue until the injector is full of liquid.

6. If you have drawn up the injector completely and no liquid is in

the injector, remove the injector hose from the pressure valve.

7. Drain injector. Repeat steps until the injector is filled.

8. Save the oil injector as it will be needed when new oils are used.

9. Close the priming valve completely by turning the knob clockwise.

Failing to close the valve will result in oil leaking from

the priming port.

Filling the Pressure Hose

1. Insure the AromaFlo System is primed and the scent

container is full.

2. Insert the open end of the injector into the pressure hose.

3. Draw liquid from the injector slowly and evenly.

Continue until the pressure hose if full of liquid.

OPERATION

Powering Up the Pump

IMPORTANT NOTE: This step only needs to be performed

during installation.

1. The pump needs to be turned on before it can be used

2. Press and hold the power button for 2 seconds.

The LED will turn on solid green.

PUMP LED LIGHT:

Green Blinking Pump is ON

No Light Pump is OFF

Adjusting the Amount of Oil Delivery

The AromaFlo system has been factory set to deliver a suitable amount of

aromatic oil into a typical sized steam room. Please contact the MrSteam

Technical Service Department before changing this setting.

Contact the MrSteam Technical Service Dept. at (800) 76-STEAM (East coast)

or (800) 72-STEAM (West Coast) for assistance or additional information.

Increasing the settings may introduce excessive

concentration of oil into the steam room, resulting in a health hazard.

CAUTION

!

WARNING

!

AROMAFLO®

VOLUME

RECOMMENDED

SETTING

For Commercial Installations Only

L2210-2 Rev B

AromaFlo Aromatic Setting Knob

Priming Valve Knob

Soft Injector Tubing

Injector

Figure 5

8

mr

.steam® AROMAFLO Operation & Installation

____________________________________________________________________

TROUBLESHOOTING

Metering pump does not prime

1. Check if voltage is available.

2. Check liquid level in scent container.

Replenish liquid, if necessary.

3. Check for air bubbles in the suction hose or the pump

head. To eliminate air bubbles see: Priming Pump.

4. Check valves for contamination. Clean valves, if necessary.

5. Check foot valve in container for contamination.

Rinse foot valve under clean water.

Metering pump does not inject oil into

steam room

1. Check if voltage is available.

2. Check liquid level in scent container.

Replenish liquid, if necessary.

3. Check for air bubbles in the suction hose or the pump

head. To eliminate air bubbles see: Priming Pump.

4. Check valves for contamination. Clean valves, if necessary.

5. Check foot valve in container for contamination.

Rinse foot valve under clean water.

6. Check the pressure hose for kinking or jamming.

Straighten or replace.

7. Check if liquid is freely flowing through the atomizing

nozzle when the metering pump is energized.

Apply compressed air through the atomizing nozzle.

Attach the compressed air at the point of connection

of the pressure hose.

8. Ensure the pump has been powered up. See page 7.

Metering pump oil delivery too much

or too little

The AromaFlo system has been factory set

to deliver a suitable amount of aromatic oil into a typical

sized steam room.

Please contact the MrSteam Technical Service Department

before changing this setting. See page 7 for instructions on

adjusting the amount of oil delivery.

Contact the MrSteam Technical Service Dept. at (800)

76-STEAM (East coast) or (800) 72-STEAM (West Coast)

for assistance or additional information.

TECHNICAL SPECIFICATIONS

List of Spare Parts

Description Part No.

Pump Head 104239

Pressure/Suction Hose 104255

(ordered by the foot)

Eucalyptus Oil, 1 gallon CU-EUCALYPTUS

Atomizing Nozzle 104240

Fitting (Fig. 1) 104250

_____________________________________________________

Dimensions: 7.5”W x 4.5”H x 4.5”D

Weight: 5 pounds

Current Draw 0.5 Amps

_____________________________________________________

WARNING

!

WARNING

!

4.5”

7.5”

WARRANTY:

To view or download the

MrSteam Warranty and register your product

go to:

blog.mrsteam.com/wr

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

Mr. Steam AromaFlo Installation & Operation Manual

- Taper

- Installation & Operation Manual

dans d''autres langues

- English: Mr. Steam AromaFlo

Documents connexes

Autres documents

-

MrSteam AromaFlo System Installation & Operation Manual

-

MrSteam xButler Package Installation & Operation Manual

-

MrSteam Basic Butler Installation & Operation Manual

-

Mr.Steam AromaSteam Fragrance Metering Pump System Manuel utilisateur

Mr.Steam AromaSteam Fragrance Metering Pump System Manuel utilisateur

-

Mr.Steam MS400EB1 Manuel utilisateur

-

MrSteam AirTempo™ Installation & Operation Manual

-

Mr.Steam MS-CHROMA 72 ChromaSteam System Manuel utilisateur

Mr.Steam MS-CHROMA 72 ChromaSteam System Manuel utilisateur

-

Prochem blazer gt Le manuel du propriétaire