HeatStar ERXL150-LP Le manuel du propriétaire

- Catégorie

- Chauffe-eau

- Taper

- Le manuel du propriétaire

· WHAT TO DO IF YOU SMELL GAS

• Open Windows

•DO NOT try to light any appliance.

•DO NOT use electrical switches.

•DO NOT use any telephone in your house. Immediately call your local gas supplier from a neighborÊs telephone.

Follow the gas supplierÊs instructions.

•Do not touch any electrical switch; do not use any phone in your building.

• Installation and service must be performed by a qualified installer, service agency or the gas supplier.

• If you cannot reach your gas supplier, call the Fire Department.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

18677XL 2015 CB

HEAT STAR, Inc., 4560 W. 160TH ST., CLEVELAND, OHIO 44135 • 866-447-2194

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury, or death. Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

OPERATING INSTRUCTIONS

AND OWNER’S MANUAL

READ INSTRUCTIONS CAREFULLY: Read and follow all instructions.

Place instructions in a safe place for future reference. Do not allow anyone who has

not read these instructions to assemble, light, adjust or operate the heater.

Model #

LANGUAGES INCLUDED

•ENGLISH

•FRENCH

•SPANISH

EnerRADIANT®

Gas-Fired Low-Intensity Infrared Heaters Approved

For Residential Garage/Commercial Applications

ERXL-40 ERXL-60

ERXL-80 ERXL-80S

ERXL-100 ERXL-100S

ERXL-125 ERXL-125S

ERXL-150 ERXL-150L

ERXL-175 ERXL-175L

2

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

SECTION 1:Introduction

Ener-Radiant ERXL models are low-cost, field assembled

infrared heaters that are easy to install and require only minimal

maintenance. They are designed to provide years of economical

operation and trouble-free service.

Checking Shipment

Check the shipment against the Bill of Lading for shortages.

Also, check for external damage to cartons. Note any

shortages, and/or external damage to cartons on the Bill of

Lading in the presence of the delivery trucker. The delivery

trucker should acknowledge any shortages or damage by

initializing this „noted‰ Bill of Lading. Immediately report

any claims for damaged material, or shortages that were not

evident at the time of shipment, to the carrier and your ENERCO

Factory Representative.

Installer Responsibility

All heaters and associated gas piping should be installed in

accordance with applicable specifications and this installation

made only by firms (or individuals) well qualified in this type of

work. Consult local building inspectors, Fire Marshals or your

local ENERCO Factory Representative for guidance.

Ener-Radiant ERXL heaters are installed on the basis of

information given in a layout drawing, which together with the

cited codes and regulations, comprise the basic information

needed to complete the installation. The installer must furnish

all needed material that is not furnished as standard equipment,

and it is his responsibility to see that such materials, as well

as the installation methods he uses result in a job that is

workmanlike and in compliance with all applicable codes.

ENERCO Factory Representatives have had training and

experience in the application of this equipment and can be

called on for suggestions about installation which can save

material and money.

WARNING:

FIRE, BURN, INHALATION, AND EXPLOSION HAZARD.

KEEP SOLID COMBUSTIBLES, SUCH AS BUILDING

MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE

AWAY FROM THE HEATER AS RECOMMENDED BY THE

INSTRUCTIONS NEVER USE THE HEATER IN SPACES

WHICH DO OR MAY CONTAIN VOLATILE OR AIRBORNE

COMBUSTIBLES, OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNER, DUST PARTICLES OR

UNKNOWN CHEMICALS.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND

INSTRUCTIONS PROVIDED WITH THIS HEATER, CAN

RESULT IN DEATH, SERIOUS BODILY INJURY AND

PROPERTY LOSS OR DAMAGE FROM HAZARDS OF

FIRE, EXPLOSION, BURN, ASPHYXIATION, CARBON

MONOXIDE POISONING, AND/OR ELECTRICAL SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW

THE INSTRUCTIONS SHOULD USE OR SERVICE THIS

HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION

SUCH AS AN INSTRUCTIONS MANUAL, LABELS, ETC.

CONTACT THE MANUFACTURER.

WARNING:

YOUR SAFETY IS IMPORTANT TO YOU AND TO OTHERS,

SO PLEASE READ THESE INSTRUCTIONS BEFORE YOU

OPERATE THIS HEATER.

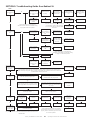

CONTENTS

Section 1 INTRODUCTION.........................................................2

Section 2 PLANNING.................................................................3

Section 3 INSTALLATION & ASSEMBLY.......................................6

Section 4 Engineering Specifications .......................................13

Section 5 VENTING/DUCTING⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄⁄ 14

Section 6 GAS PIPING..............................................................17

Section 7 WIRING....................................................................18

Section 8 OPERATION MAINTENANCE.....................................19

Section 8 TROUBLESHOOTING.................................................21

Section 9 REPLACEMENT PARTS..............................................22

WARRANTY INFORMATION.....................................................28

WARNING:

The State of California requires the following warning:

COMBUSTION BY-PRODUCTS PRODUCED WHEN USING

THIS PRODUCT CONTAIN CARBON MONOXIDE, A

CHEMICAL KNOWN TO THE STATE OF CALIFORNIA

TO CAUSE CANCER AND BIRTH DEFECTS (OR OTHER

REPRODUCTIVE HARM).

3Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

SECTION 2: Planning

The following codes and instructions should be followed when

planning the installation of the Ener-Radiant ERXL heater. In

addition to these instructions, the warnings in (Section 1) must

be carefully adhered to since improper installation may lead to

property damage, injury, or death.

National Standards and Applicable

Codes

Gas Codes:

The type of gas appearing on the nameplate must be

the type of gas used. Installation must comply with local

codes and recommendations of the local gas company,

and the National Fuel Gas Code, ANSI Z223.1 – latest

revision, (same as NFPA Bulletin 54) or the Natural Gas

and Propane Installation Code, CSA B149.1.

• Clearance between the heater and its vent and adjacent

combustible material (which is part of the building or its

contents) shall be maintained to conform with the Stan-

dard for Installation of Gas Appliances and Gas Piping,

NFPA-54 / ANSI Z223.1 – latest revision, National Fuel

Gas Code or the Natural Gas and Propane Installation

Code, CSA B149.1.

Aircraft Hangers:

Installation in aircraft hangers must be in accordance

with the Standard for Aircraft Hangers, ANSI / NFPA-409

– latest revision.

• Heaters in aircraft storage or service areas shall be

installed at a height of 10 feet above the upper surface

of wings or engine enclosures of the highest aircraft

which may be housed in the hanger. (This should be

measured from the bottom of the heater to the wing or

engine enclosure, whichever is highest from the floor.)

• In other sections of aircraft hangers, such as shops or

offices, heaters must not be installed less than 8 feet

above the floor.

• Heaters installed in aircraft hangers shall be located

so as not to be subject to damage by aircraft, cranes,

moveable scaffolding or other objects.

Public Garages:

Installations in garages must be made in accordance

with the Standard for Parking Structures, NFPA-88A –

latest revision or the Standard for Repair Garages, NFPA-

88B – latest revision.

• Heaters must not be installed less than 8 feet above

the floor. Minimum clearances to combustibles must be

maintained from vehicles parked below the heater.

• When installed over hoists, minimum clearances to com-

bustibles must be maintained from the uppermost point

on the hoist.

Venting:

The venting must be installed in accordance with NFPA-

54 / ANSI Z223.1 or CSA 149.1– latest revision, National

Fuel Gas Code. Partial information with regard to this

code is provided in (Section 5) of this installation manual

with regard to size and configurations for venting

arrangements.

• Any portion of flue pipe passing through a combustible

wall must be dual insulated or have an approved thim-

ble. Refer to ANSI-Z223.1 or CSA149.1– latest revision.

Hazardous Locations:

Where there is the possibility of exposure to combustible

airborne material or vapor, consult the local Fire Marshal,

the fire insurance carrier or other authorities for approval

of the proposed installation.

Critical Considerations

Ener-Radiant ERXL is a suspended heater. Therefore, its

stability, flexibility, and safety are very important. Before

starting installation, be sure the system can meet the

following requirements.

• Maintain specified clearances to combustibles, and safe

distance from the heat-sensitive material, equipment and

work stations.

• The stated clearances to combustibles represent

a surface temperature of 90°F (30°C) above room

temperature. Building materials with low heat tolerance

(such as plastic, vinyl siding, canvas, etc.) may be subject

to degradation at lower temperatures. It is the installers

responsibility to assure that adjacent materials are

protected from degradation.

• Provide a suspension with vertical length of chain or

swinging rod which has at least 2 inches of horizontal

travel for each burner in a straight run. Be sure the

suspension system is sufficiently flexible to accommodate

thermal expansion which occurs as the system heats up

(see Figure 6 on page 12).

• Provide access to burners for servicing, preferable on

both sides, above and behind the burner for removal.

• Provide a minimum of 18 inches of clearance between

burners and building walls. (Always observe minimum

clearances to combustibles.)

• Be sure the heater has a downward pitch of one-half

inch per 20 feet away from the burner.

• Provide signs in storage areas to specify maximum

stacking height to maintain required clearances to

combustibles.

• Plan location supports (see Figure 2A-F starting on page

8). Locate a support near all elbows.

• The installation must conform with local building codes

or in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 or the Natural Gas

and Propane Installation Code, CSA B149.1.

• If an external electrical source is utilized, the heater,

when installed, must be electrically grounded in

accordance with the National Electical Code, ANSI/

NFPA 70 or current Canadian Electrical Code, CSA

C22.1.

4

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

Clearances To Combustibles

TABLE 1: Minimum Clearances to Combustibles (Use Figure 1 on page 5 as a Guide)

Reflector Type Position ERXL-40 ERXL-60 ERXL-80 ERXL-100 ERXL-125 ERXL-150 ERXL-175

Standard

Reflector

(Horizontal)

A

B

C

D

6‰

30‰

55‰

30‰

6‰

30‰

55‰

30‰

6‰

36‰

55‰

36‰

6‰

36‰

74‰

36‰

6‰

36‰

87‰

36‰

6‰

36‰

87‰

36‰

8‰

36‰

87‰

36‰

45° Reflector Tilt

A

B

C

E

F

12 ‰

30‰

55‰

36‰

60‰

12 ‰

30‰

55‰

36‰

60‰

18‰

36‰

55‰

36‰

60‰

18‰

36‰

74‰

36‰

60‰

18‰

36‰

87‰

36‰

60‰

18‰

36‰

87‰

36‰

60‰

18‰

36‰

87‰

36‰

60‰

U-Tube Standard

(Horizontal)

A

B

C

D

6‰

30‰

55‰

30‰

6‰

30‰

55‰

30‰

6‰

36‰

55‰

36‰

6‰

36‰

74‰

36‰

6‰

36‰

87‰

36‰

6‰

36‰

87‰

36‰

8‰

36‰

87‰

36‰

U-Tube Opposite

45°

A

B

C

F

12 ‰

30‰

55‰

60‰

12 ‰

30‰

55‰

60‰

18‰

36‰

55‰

60‰

18‰

36‰

74‰

60‰

18‰

36‰

87‰

60‰

18‰

36‰

87‰

60‰

18‰

36‰

87‰

60‰

U-Tube Full 45°

A

B

C

E

F

12 ‰

30‰

55‰

36‰

60‰

12 ‰

30‰

55‰

36‰

60‰

18‰

36‰

55‰

36‰

60‰

18‰

36‰

74‰

36‰

60‰

18‰

36‰

87‰

36‰

60‰

18‰

36‰

87‰

36‰

60‰

18‰

36‰

87‰

36‰

60‰

Unvented Above A 36‰ 36‰ 36‰ 36‰ 36‰ 36‰ 36‰

WARNING:

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE INJURY OR DEATH.

In all situations, clearances to combustibles must be maintained. Failure to observe clearances to combustibles may result in property

damage, severe injury, or death.

Minimum clearances must be maintained from vehicles parked below the heater. Signs should be posted in storage areas to specify

maximum stacking height to maintain required clearances to combustibles.

Caution should be used when running the system near combustible materials such as wood, paper, rubber, etc. Consideration should be

given to partitions, storage racks, hoists, building construction, etc.

TABLE 1 gives minimum acceptable clearances to combustibles. Clearances as shown in TABLE 1 are not for use in four-sided enclosures.

5Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

Clearances To Combustibles

Figure 1: Clearances To Combustibles (Refer to TABLE 1 on page 4)

A

C

EF

STANDARD REFLECTOR

D

A

C

A

C

D

„U‰-Tube, Standard

A

C

D

F

„U‰-Tube, Opposite 45°

F

C C

AA

E

A

F

„U‰-Tube, Full 45°

C

AC

B

B

Front and Back Clearance

6

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

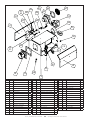

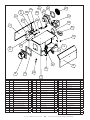

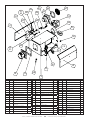

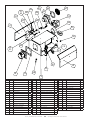

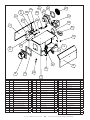

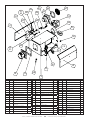

SECTION 3: Installation & Assembly

TUBE COUPLING(19021)

KEY FOR TUBE COUPLING

(14616)

TUBE HANGER

(14585P)

HEAT EXCHANGER TUBE 10'

(06413)

TURBULATOR BAFFLE 10' (03445)

TURBULATOR BAFFLE 5' (03447)

**NOT INCLUDED WITH ALL MODELS**

**ONLY HEATERS 30' LENGTH AND UNDER**

REFLECTOR 10'

(00418A)

VENT ADAPTER

(19021)

BURNER BOX

7Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

Installation Procedure

Take maximum advantage of the building upper

structure, beams, joists, purlins, etc., from which to

suspend the heater. There is no unique sequence for

installation of the tubing. On-site observation will usually

reveal a logical sequence. Begin the installation at the

most critical dimension. This could save time. Watch for

swinging doors, overhead cranes, car lifts etc. Reflectors

and tubing can be installed as you move along. Carefully

adjust system pitch at each position to level the heater.

Pitch down one-half inch in 20 feet (away from burner).

DON’T Pressure test the gas line using high pressure (greater

than ½ PSIG) without closing the high-pressure shutoff

cocks. Failure to do so will result in damage to the

burners.

Burner Housing

Must always be

installed horizontally.

Tube and Reflector Hanger

Install immediately after first

coupling.

Turbulator Assembly

Enerco normally ships Ener-Radiant heaters with

turbulators assembled into appropriate tubes.

Tube and Reflector Hanger

Suspend system from these hangers.

Minimum two (2) required per tube.

Reflectors

Alternate overlap as shown

on overview. Length of

reflector and amount of

overlap is indicated.

10' 2-1/2" ALUMINIZED

Heat Exchange Tubes

Supplied in 10 ft. lengths.

Tube Coupling Assembly

Coupling should be oriented with

slide bar on top, and all couplings

should „point‰ in the same direction.

Where Field Changes Occur

Turbulator Sections and Adapter are available in

sections and must be assembled before installation

(See Figure 3 for details). The number of sections

required is indicated.

Assemble the heater components as shown in Figures 2A, 2B, 2C, 2D, 2E, 2F and 2G. Optional reflector configurations are shown in (Figure

1). Install appropriated suspension hardware, beam clamps, chain or rod at predetermined locations. Adjustment of chain length will provide

uniform pitch.

DO Familiarize yourself with local and national

codes.

Develop a planned procedure which will conserve material

and labor on the job.

Check to see that all material and equipment is on the job

before starting installation.

Allow for thermal expansion of the hot tube.

Install the gas connector only as shown in instructions (see

Figure 14 on page 17).

Have slip joints where required between reflectors to keep

them from buckling or coming apart.

Provide 1 sq. inch of free air opening to each 1,000 BTU/hr.

of heater input (but not less than 100 sq. inches) in enclosed

spaces. One opening should be within 12 inches of the top

and one within 12 inches of the bottom of the enclosure.

FIGURE 2: Ener-Radiant XL Overview

Vent Adapter

Used to attach the heat

exchanger tubing to vent pipe.

8

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

HANGER HANGER

18” 18”

10’ 2-1/2” ALUMINIZED

ALUMINIZED

FIGURE 2B: Ener-Radiant XL Model ERXL-60, ERXL-80S, Assembly Overview

20 ft. Exchanger length. 21 ft. - 4 in. Total Heater length. 4 Suspensin points indicated.

FIGURE 2A: Ener-Radiant XL Model ERXL-40

10 ft. Exchanger length. 11 ft. - 4 in. Total Heater length. 2 Suspension points as indicated.

HANGER HANGER HANGER HANGER

18” 18” 18” 18”

10’ 2-1/2” 10’ 2-1/2”

ALUMINIZED

2-1/2” OVERLAY TYP

(1) Turbulator Sections

ALUMINIZED

FIGURE 2D: Ener-Radiant XL Model ERXL-100S Assembly Overview

30 ft. Exchanger length. 31 ft. - 4 in. Total Heater length. 6 Suspension points as indicated.

FIGURE 2C: Ener-Radiant XL Model ERXL-80, Assembly Overview

30 ft. Exchanger length. 31 ft. - 4 in. Total Heater length. 6 Suspension points as indicated

18” 18” 18” 18” 18” 18”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

(1) Turbulator Sections

HANGER HANGER HANGER

Typ.

HANGER

ALUMINIZED ALUMINIZED

9' Long Turbulator Section

10' Long Turbulator Section

5' Long Turbulator Section

10' Long Turbulator Section

9Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

FIGURE 2E: Ener-Radiant XL Model ERXL-100, ERXL-125S

40 ft. Exchanger length. 41 ft. - 4 in. Total Heater length. 8 Suspension points as indicated.

FIGURE 2F: Ener-Radiant XL Model ERXL-125, ERXL-150, ERXL-175

50 ft. Exchanger length. 51 ft. - 4 in. Total Heater length. 10 Suspension points as indicated.

FIGURE 2G: Ener-Radiant XL Model ERXL-150L, ERXL-175L

60 ft. Exchanger length. 61 ft. - 4 in. Total Heater length. 12 Suspension points as indicated.

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

10’ 2-1/2”

10’ 2-1/2”

18”

Typ.

ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED

18” 18” 18” 18” 18” 18” 18” 18” 18”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

18”

Typ.

ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZEDALUMINIZED

18” 18” 18” 18” 18” 18” 18” 18” 18” 18” 18”

ALUMINIZED ALUMINIZED ALUMINIZED ALUMINIZED

18”

Typ. 18” 18” 18”

10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2” 10’ 2-1/2”

18" 18" 18" 18" 18" 18" 18"

10

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

FIGURE 3: Ener-Radiant XL Dimensions & Suggested Mounting Heights

(some Models)

Turbulator

Heat Exchanger Tubing (some Models)

Turbulator

Heat Exchanger Tubing

Minimum Total Length (see chart below)

Burner Side View

Burner Ratings and Heat Exchanger Lengths: (NG and LP) Suggested Mounting Heights

Model # Rate (BTU/Hr.) Heat Exchanger

Length Turbulator Minimum

Total Length

Suggested

Min. Space

Typical

Mounting

Height Spot

ERXL-40 40,000 10 ft. 9 ft. 10' - 4' 8' - 10' 10Ê - 14'

ERXL-60 60,000 20 ft. 10 ft. 21' - 4' 10Ê - 12Ê 10Ê - 14Ê

ERXL-80S 80,000 20 ft. 10 ft. 21' - 4' 12Ê - 15Ê 12Ê - 15Ê

ERXL-80 80,000 30 ft. 10 ft. 31' - 4' 12Ê - 15Ê 12Ê - 15Ê

ERXL-100S 100,000 30 ft. 5 ft. 31' - 4' 12Ê - 15Ê 12Ê - 15Ê

ERXL-100 100,000 40 ft. None 41' - 4' 15Ê - 18Ê 12" - 15'

ERXL-125S 125,000 40 ft. None 41' - 4' 15Ê - 20Ê 14Ê - 19'

ERXL-125 125,000 50 ft. None 51' - 4' 15Ê - 18Ê 14Ê - 19'

ERXL-150 150,000 50 ft. None 51' - 4' 20Ê - 23Ê 15Ê - 25'

ERXL-150L 150,000 60 ft. None 61' - 4' 20Ê - 25Ê 15Ê - 25'

ERXL-175 175,000 50 ft. None 51' - 4' 20Ê - 23Ê 15Ê - 25'

ERXL-175L 175,000 60 ft. None 61' - 4' 20Ê - 25Ê 15Ê - 25'

Burner Rear View

9.25"(23.49cm)

9.25"(23.49cm)

17.75"(45.08)

11 Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

Couplings: Tube and tube fittings are connected by wrap-

around couplings which clamp by means of

a tapered, hammer-driven lock member. The

starting ends of the coupling and lock member

are identified by 1/4‰ holes which are put

together when starting assembly. Be sure the

tube ends are in line and tube ends butt against

stop pin(s) inside coupling. The slide bar is to be

hammer-driven to a point of securing the coupling

snugly to the tubes. Over-driving will result in

distortion of the coupling or slide bar lip to a

point decreasing the holding the capability of the

coupling. (See Figure 4)

90° Elbow

Elbow Fitting Dimensions

FIGURE 5: Installation of Elbow & Coupling

Elbow Package: Stk. # F106415 Elbow Package includes:

(1) elbow, (1) coupling and (1) refelctor.

Install elbow into radiant tube sequence

where plans indicate a 90° bend

(see Figure 4).

U-Tube Fitting Dimensions 180° U-Tube

Stk. # i ncludes:

F106414 U-Tube Package

(1)U -tube, (1) coupling and (2)

radiant tube sequence where plans

indicate a 180° bend

(see Figure 4).

COUPLING ASSEMBLY

Plain Coupling - 14612

Key for Coupling - 14616

Tighten

Loosen

Hole 1

Coupling

Assembly

Impact

Block

Hole 2

When assembling coupling note

the location of Hole 1 and Hole 2

Orient coupling so that

the impact block is above

tube centerline.

TUBE COUPLING

KEY for COUPLING

FIGURE 4:

(38.73 CM)

(15.24 CM)

18" (45cm)

10"

(25cm)

(10cm)

(43cm)

9" (22cm) Radius

12

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

A

Chain kit - Stk. #17370

One chain kit will suspend one 10 ft. section of tube and one 10 ft.

section of reflector.

FIGURE 7: Tube and Reflector Hanger

FIGURE 7: Mounting Flange / Tube Detail

1) Insert tube 06413 into front casting to point (A).

2) Tighter all set screws marked (B) until snug.

3) After both set screws are snug, turn each

additional 1/4 turn to secure tube in place.

FIGURE 8: Burner Box / Transition Tube Detail

FIGURE 6: Typical Suspension Details

Locknut

Washer

Wood Beam

Washer

Screw Hook

min. 3/8" (10 mm)

I-Beam

Beam

Clamp

As Req'd

S-Hook

Bar Joist

Clip

Truss

Concrete

Beam

Anchor

Mounting Flange

Cap Screw

Stk. 98012

Split Lock Washer

Stk. #98527

Gasket

Stk. #12397

Burner Box

(flame observation

window facing down)

HORIZONTAL REFLECTOR POSITION (STANDARD)

ANGLE MOUNTING RING

RADIANT TUBE

HORIZONTAL MOUNTING RING

HANGER

REFLECTOR

TOP

SIDE 45° REFLECTOR POSITION (OPTIONAL)

BELOW

FIGURE 9: Reflector End Cap

Parts list

1 00419 Reflector End Cap (Qty 1)

2 09369 Spring Clip (Qty 4)

Flange Kit #06428XL

Kit Includes: Flange,Screws(4), Lock Washers(4), Gasket(1)

B

B

13 Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

SECTION 4

Engineering Specifications

The total heating system supplied shall be design certified by CSA

under ANSI Z83.20a latest revision and CGA 2.34a latest revision.

A. Burner & Burner Controls

1. Burners shall be capable of firing with one of the fuel options as

specified on the purchase documents: Natural Gas or LP.

2. Burners shall be supplied to fire at any one of the input rates as

specified.

ERXL-40 40,000 BTU/Hr. ERXL-125 125,000 BTU/Hr.

ERXL-60 60,000 BTU/Hr. ERXL-150 150,000 BTU/Hr.

ERXL-80 80,000 BTU/Hr. ERXL-175 175,000 BTU/Hr.

ERXL-100 100,000 BTU/Hr.

3. Burner shall be equipped with a direct sense silicon-carbide hot

surface ignition control system with 100% shut-off ignition device.

Power supplied to each heater shall be 120V, 60Hz, single phase.

Burners shall be rated for 1.0 Amp (run) and 5.0 Amp (start.)

4. Burner shall be equipped with thermal overload motor

protection, balanced air rotor, combustion air proving safety

pressure switch, and viewing window for flame observation.

5. When specified, in contaminated environments, the burner shall

be capable of supplying outside air to each burner for the sup-

port of combustion.

6. All burners shall be pre-wired with a grounded electrical

cord and plug.

7. At customerÊs choice, burners may be controlled with either

an optional line voltage thermostat or by optional low voltage

thermostats with an appropriate low voltage transformer relay.

8. Gas supply to the burners shall conform to the following:

1/2‰ NPT gas connector size

Natural Gas: 4.6‰ W.C. MIN, 7.0‰ W.C. MAX

LP Gas: 11‰ W.C. MIN, 14.0: W.C. MAX

B. Heat Exchanger

1. Radiant tubing shall be 4‰ diameter aluminized steel supplied in

10 ft. sections. Sections shall be joined with stainless steel wrap-

around couplings.

2. Reflector to be of aluminum material and designed to direct all

radiant output below horizontal center line of radiant tube.

3. Heaters shall be vented according to manufacturerÊs

recommendations.

Gas pressure at MANIFOLD:

Natural Gas: 3.5” W.C.

LP Gas: 10.5” W.C.

1/2‰ NPT Gas Connector Size

Gas INLET pressure:

Natural Gas: 4.6” W.C. Min

11.0” W.C. Max

LP Gas: 11.0” W.C. Min

14.0” W.C. Max

1/2‰ NPT Gas Connector Size

Electrical Rating: (All Models)

120V - 60Hz

1.0 AMP (Run) 5.0 AMP (Start)

Dimensions:

Flue Connection Size…………………4”

Outside Air Connection Size………4”

14

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

COMMON VENTING - (2) Heaters (Horizontal and Vertical)

Model # H = 6 ft. H = 8 ft. H = 15 ft.

ERXL-40 D = 7" D = 6" D = 6"

ERXL-60 D = 7" D = 6" D = 6"

ERXL-80 D = 8: D = 7" D = 6"

ERXL-100 D = 8" D = 8" D = 7"

ERXL-125 D = 10" D = 10" D = 8"

ERXL-150 D = 10" D = 10" D = 8"

ERXL-175 D = 10" D = 10" D = 8"

SECTION 5

Venting / Ducting

General Requirements

This heater must be vented in accordance with the specifications

contained in this manual and with the following national codes

and any state, provincial or local codes which may apply:

• Refer to National Fuel Gas Code NFPA 54/ANSI Z223.1- latest

revision.

• CANADA: Refer to Natural Gas and Propane Installation Code

CSA B149.1- latest revision.

The heater may be vented to the outdoors either vertically or

horizontally.

Optional outside air supply may be directed to the heater

horizontally or vertically.

Be sure that the method selected for venting heater complies

with all codes as required for each particular location

The use of single-wall vent pipe (26 gauge) is recommended. A

section of double-wall vent pipe is recommended when passing

through the roof or wall.

Exhaust end of heater will accept a 4'(10 cm) vent pipe using

the vent adapter. Install the vent adapter with the seam on top,

secure all vent joints with a minimum of 3 #8 x 3/8" sheet metal

screws and seal all joints using a high temperature silicone

sealant.

If condensation in the flue is a problem, the flue length should

be shortened or insulated.

Vent pipe must be sloped downward away from the burner

1/4"(.6 cm) for ever 10'(3m).

VENT LENGTHS:

• Maximum total vent length allowed in thirty (30Ê) feet.

• Maximum outside air supply duct allowed thirty (30Ê) feet.

• Maximum total vent length plus outside air supply length

shall not exceed fifty (50Ê) feet.

NOTE:

A total of two (2) elbows are allowed for vent and

outside air supply combination. Subtract 5' feet per additional

elbow from maximum length allowed if 3 or more elbows are

used.

Install a minimum 18" (30 cm) straight length of duct for air

intake or vent before any Tee or elbow.

Alternative Arrangements / Optional Equipment for Venting

Unvented Operation

a) Sufficient ventilation must be provided in the amount of 4

CFM per 1,000 BTU/hr. firing rate.

b) Refer to ANSI Z223.1 - latest revision, NFPA-54 and local

codes for additional information.

c) Use of optional outside combustion air is not recommended

with unvented heaters due to pressure considerations. Refer

to page 16

Horizontal Venting

a) Four (4‰) inch O.D. flue pipe is required. Thirty (30Ê) feet

maximum length is recommended.

b) All flue joints should be sealed using suitable product such

as General Electric RTV106 or Permatex Form-A-Gasket Red

High Temperature Silicone Adhesive Sealant.

c) Do not install any elbow or 45 fitting to bring vent lower

than the horizontal tube system.

d) Vent terminal should be installed at a height sufficient to

prevent blockage by snow.

1) Vent must exit building not less than seven (7Ê) feet

above grade when located adjacent to public walkways.

2) Vent must terminate at least three (3Ê) feet above any

forced air inlet located within ten feet (10Ê).

3) Vent must terminate at least four (4Ê) feet below, four

(4Ê) feet horizontally from, or one (1Ê) foot above any

door, window, or gravity inlet into any building.

4) Vent terminal shall be located at least twelve (12‰) inches

from any opening through which vent gases could enter

the building.

5) Vent terminal must be beyond any combustible over

hang

Vertical Venting

a) Four (4‰) inch O.D. flue pipe, maximum thirty (30Ê) feet

in length may be used as shown with approved vent cap.

(See General Requirements on this page for additional

information.)

b) An insulated thimble may be required to pass through

combustible structures (check local codes).

c) All flue joints should be sealed using suitable products (see

recommendation for horizontal venting.)

Common Venting

a) Horizontal run to vent must never exceed 75% of the vertical

height of the vent. Refer to ANSI Z223.1 - latest revision,

NFA-54 for proper vent sizes and installation.

b) Open area of common vent must equal the sum of the open

area of individual vents connected to it. (See chart below

and diagrams - page 14.)

c) Use double wall vent as required (check codes.)

d) All joints must be sealed using suitable products.

e) Connections to common stack must be positioned to avoid

direct opposition between streams of combustion gases.

15 Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

FIGURE 12: Common Roof Venting

HORIZONTAL COMMON VENTING

VERTICAL COMMON VENTING

SIDE VIEW

Type "B" Vent required outdoors.

Vent Adapter Stk. #19021

Roof

Secure all joints with 3 (minimum) #8 x 3/8"

sheet metal screws and seal all joints.

H

Approved Vent Cap

Flashing

D

Burner Box Burner Box

Type "B" Vent required outdoors.

Vent Adapter Stk. #19021

Outside Wall

Secure all joints with 3 (minimum) #8 x 3/8"

sheet metal screws and seal all joints.

H

Vent Cap

Wall Thimble

(If Applicable)

Burner Box

Burner Box

D

D

16

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

FIGURE 10: Unvented Operation

36”

36”

A

1. Ventilation equal to 4 CFM per 1,000 BTU/HR firing rate must

be provided in unvented heater installations

2. For dimensions A "unvented" refer to ( Figure 1- Minimum

Clearances to Combustibles.)

FIGURE 10A: Single Wall

Single wall vent run

Single wall terminal end

FIGURE 10b: Double Wall

Double wall vent run

Double wall terminal end

FIGURE 11: Vertical Venting

18"(45cm)

18" (45cm) Min. 3'-0" (91cm) Min.

8"(20cm) to 10"(25cm) Max.

6' (182cm) Min.

18" (45cm) Min. 3'-0" (91cm) Min.

6' (182cm) Min.

2"(5cm) Clearance thimble

2"(5cm) Clearance thimble

required when fl u pipe

extends through

combustible materials

(91cm)

(91cm)

17 Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

Outside Combustion Air Supply

The Ener-Radiant XL heater is approved for installation with

an outside air supply system. Some compounds such as

halogenated hydrocarbons or other corrosive chemicals in the

air can be drawn into the equipment and cause an accelerated

rate of corrosion of some of the heater components. The use

of such chemical compounds near the enclosure should be

avoided.

IMPORTANT: If the building has a slight negative

pressure or contaminants are present in the air, an

outside combustion air supply to the heaters is strongly

recommended.

For an outside air supply, a four (4‰) inch O.D. single wall pipe

may be attached to the heater. The duct may be up to forty-five

(30Ê) ft. maximum length or two (2Ê) ft. minimum length with

no more than two (2) elbows. (See General Requirements on

page 15 for additional information.)

The air supply duct may have to be insulated to prevent

condensation on the outer surface. The outside air terminal

should be securely fastened to the outside wall by drilling four

(4) 1/4‰ diameter holes in the outside flange; wood screws or

bolts and expansion sleeves may be used to fasten terminal.

FIGURE 13: Non-Pressurized Outside Air Supply Duct

PVC Pipe, „Dryer Hose‰, or equivalent may be used instead of

standard vent pipe.

SECTION 6

Gas Piping

Read applicable warnings in (Section 1) before proceeding with

Gas Pipe installation. Improper installation may result in property

damage, severe injury, or death.

Meter and service must be large enough to handle all the burners

being installed plus any other connected load. The gas line which

feed the system must be large enough to supply the required gas

with a maximum pressure drop of 1/2‰ water column. When gas

piping is not included in the layout drawing, the local gas supplier

will usually help in planning the gas piping.

A 1/2‰ tapping at each burner location must be located and oriented

as shown in (Figure 14). To check system pressure, put a plugged

1/8‰ NPT tapping in the gas line at the connection to the burner

farthest from the supply. Before connecting the burners to the

supply system, verify that all high pressure testing of the gas piping

has been completed. Do not high pressure test the gas piping with

the burners connected.

Follow these instructions to ensure a professional gas supply

installation:

• Support all gas piping with suitable pipe hanging

materials.

• Use wrought iron or wrought steel pipe and malleable

iron fitting. All pipe fittings should be new and free

from defects. Carefully ream the pipe and tubing ends

to remove obstructions and burrs.

• Use L.P. gas-resistant joint compound on all pipe

threads.

• Check the pipe and tubing ends for leaks before

placing heating equipment into service. When

checking for gas leaks, use soap and water solution:

NEVER USE AN OPEN FLAME.

Install the flex gas connector as shown. The flex gas connector

accommodates expansion of the heating system and allows for easy

installation and service of the burner.

FIGURE 14: Gas Line Connection with Stainless Steel Flex Gas

Connector

Shut-Off Valve must be parallel

to burner gas inlet. The 2‰

displacement shown is for the cold

condition. This displacement may

reduce when the system is fired.

Shut – off Valve

12 "

2"

1/2" Stainless Steel Flex Gas Connector

Stk. #16401

90°

45°

0°

45°

4" (10 cm)

Seal All Joints

4"

Heater Movement

Heater Movement

Heater Movement

Heater Movement

Outside Air

Terminal

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

Flex Pipe

6" (15 cm) to

12" (30 cm) Long

Outside Air

Terminal

NOTE:

Flue pipe requires additional

support. Flex pipe will not

support riser and outside

air terminal

Vertical Outside Air

Horizontal Outside Air

FIGURE 14A: Incorrect Gas Line Connection with Stainless

Steel Flex Gas Connector

18

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

SECTION 7

Wiring

Heaters are normally controlled by thermostats. Line voltage

thermostats are wired directly (see Figure 15), 24V thermostats are

wired directly using the terminals on burner box(see Figure 16).

Heaters must be grounded in accordance with the National Electric

Code ANSI/NFPA- 70 or current Canadian Electrical Code, CSA

C22.1. Heaters may also be controlled with a manual line voltage

switch or timer switch in place of the thermostat.

FIGURE 15: Line Voltage Thermostat Wiring

T

H

N

120v – 60 Hz

White

Green

Supply Circuit

Burners

(Maximum – 2 per Thermostat)

Black

FIGURE 16: Low Voltage Thermostat Wiring

White

Green

120v – 60 Hz

Supply Circuit

Burners

(Maximum – 1 per Thermostat)

Black

H

N

T

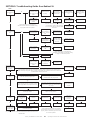

FIGURE 17: Ener-Radiant XL Burner Internal Wiring

• If any of the original wire as supplied with the

appliance must be replaced, it must be replace with

wiring material having a temperature rating of at least

105°C and 600 volts.

• Each burner must be electrically grounded in

accordance with the National Electric Code ANSI/NFPA

- 70 or current Canadian Electrical Code, CSA C22.1.

FIGURE 18: Ener-Radiant XL Burner Internal Wiring Ladder

Diagram

VAC

120

120V 24V

Black

Black

Purple

Yellow

Yellow

Black

Black

Black

Green

Green

Orange

Transformer

White

White

White

THERMOSTAT

White

Blue

Gas Valve

Air Switch

Ignitor

Sensor

Motor / Blower Door Switch

Terminal

Bushing

120V

L2

(NEUTRAL)

White

White

White

White

White

White

Gray

Orange

Transfomer

Thermostat

Air Switch

Gas Valve

Door Switch Motor / Blower

Ignitor

Sensor

Blue

Yellow

Yellow

Purple

Black

Black

Black

Black

L2 (HOT)

24V

19 Operating Instructions and OwnerÊs ManualEnerco | enerRadiant® XL Series Heater

9. A qualified service agency should be contacted for service

other than routine maintenance.

10. Check vent terminal and fresh air inlet to see that they have

not been blocked during the non-heating season. If either

pipe is restricted, the air switch wonÊt close, resulting in a

no-heat situation.

Troubleshooting

CAUTION: Before opening the Ener-Radiant XL

burner door for any type of service, be sure

the gas supply has been shut off at the heater

and the electrical cord from the burner box

has been unplugged.

Blower Motor 1. Is the thermostat calling for heat? Is there

Fails to Run: 115V at the burner receptacle?

2. Check blower side door for seal. Check door

switch. Replace if necessary/

3. Check blower for obstructions. Replace

blower if necessary.

Igniter 1. Check igniter for damage. Replace if

Does Not Glow: necessary.

2. Check voltage and resistance at igniter.

(Voltage should be 115V. Resistance should

be 40-75 ohms.)

3. Check for obstructions to the air inlet and

outlet.

4. Check wiring and hose connections to the

air switch. Replace if necessary.

5. Check voltages at transformer primary and

secondary. Replace transformer or module if

necessary.

Valve Does Not Gas pressure downstream of gas control can

Come On: be measure by using a manometer and

connecting to pressure tap on control/

1. Check to see if manual valve heater is ON.

2. Check to see if manual valve knob on heater

gas control in ON.

3. Supply gas pressure can be checked at 1/8‰

NPT pressure tapping on heater external

manual valve.

4. Check to see if gas control is opening: no

manifold pressure indicates valve is closed.

If the valve is closed, either the gas valve or

the ignition module is faulty.

WARNING: Do not disconnect ground leads

inside heater. Do not interchange grounded

and ungrounded leads on transformer or

ignition module.

Burner Does Not 1. Check to see if gas lines were properly

Light: purged of air.

2. Check inlet and outlet gas pressure during

ignition period.

Natural inlet pressure should be 4.6‰

Natural outlet pressure should be 3.5‰

LP inlet pressure should be 11.0‰

LP outlet pressure should be 10.25‰

3. Check for proper orifice and air plate.

SECTION 8

Operation & Maintenance

Sequence of Operation

1. Turn the thermostat up. When the thermostat calls for heat,

blower motor will energize.

2. When the motor approaches nominal running RPM, the air

proving switch closes and activates the ignition module.

3. The ignition module then energizes the hot surface igniter for

a timed warm-up period (approximately 45 to 60 seconds.)

4. After the warm-up period, the gas valve is energized.

5. During the last part of the sequence, the igniter is de-

energized and is converted to a flame sensing rod.

6. If a flame is detected, the gas valve remains open. When the

call for heat is satisfied, and the system control mechanism

de-energizes the burner line voltage supply, the gas valves are

turned off.

7. If no flame is detected on a single-try module, the gas valve

is closed, and the module will lockout until it is reset. Reset

is accomplished by removing power from the module for at

least five (5) seconds (thermostat cycle required.)

8. If no flame is detected on a three-trial module, the gas

valve is closed, and a purge period begins. After the purge,

the module acts to power the igniter for a second warm-

up period, and a second trial for ignition period. If flame is

still not established, a third and final purge, warm-up, and

trial cycle begins. After three trials, the module will lockout

until reset. Reset is accomplished by removing power from

the module for at least five (5) seconds (thermostat cycle

required.)

9. On a three-trial module, if flame is established and lost

on the first or second trial, the gas valve is turned off, a

purge, warm-up, and trial for ignition will occur on a three-

trial module, only three trials for ignition are allowed per

thermostat cycle.

Maintenance

For best performance, the following maintenance procedures should

be performed before each heating season:

1. Be sure gas and electrical supply to heater are off before

performing any service or maintenance.

2. Check condition of blower scroll and motor. Dirt and dust

may be blown out with compressed air, or a vacuum cleaner

may be used. When using compressed air do not exceed 30

psi in order to not damage fragile hot surface igniter.

3. Check condition of burner. Carefully remove any dust or

debris from inside the burner box or burner cup.

4. Inspect the igniter. Replace igniter if there is excessive carbon

residue, erosion, breakage or other defects.

5. Check the inside of the firing tube with a flashlight. If carbon

or scale are present, scrape out the deposits with a wire

brush or rod, or metal plate attached to a wooden pole.

6. Check to see that the burner observation window is clean

and free of cracks or holes. Clean or replace as necessary.

7. Check the flue pipe for soot or dirt. After cleaning as

necessary, re-attach the flue pipe to the heater.

8. Outside surfaces of heater may be cleaned by wiping with a

damp cloth.

20

Enerco | enerRadiant® XL Series Heater Operating Instructions and OwnerÊs Manual

Burner Does Not 1. Check ground wire continuity.

Stay Lit: 2. Check burner internal wiring for reversed

leads.

3. Check insulation on the igniter leads.

4. Replace module if necessary.

Honeywell Valve LED Status

The Ener-Radiant XL series Tube Heater is equipped with a honeywell

Smart Valve. This valve has a built-in diagnostic program, which will

assist in troubleshooting in the event of a valve-related problem. The

LED or (Light Emitting Diode) is located on the top of the valve as

shown in diagram below. The LED status indications are listed below

to help with the troubleshooting.

FIGURE 19:

OFF INDICATED

Off No power to the control

Bright-Dim Normal operation.

This indication shows whenever the system is

powered, unless some abnormal event has occurred.

2-Flashes Airflow providing switch remains closed longer than

30 seconds after call for heat begins (air providing

switch stuck closed.)

3-Flashes Airflow providing switch remains open longer than 30

seconds after combustion air blower is energized - or

blower does not energize.

4-Flashes White jumper wire is loose.

5-Flashes Flame signal sensed out of proper sequence.

6-Flashes System Lockout.

LED

Honeywell Smart Valve

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

HeatStar ERXL150-LP Le manuel du propriétaire

- Catégorie

- Chauffe-eau

- Taper

- Le manuel du propriétaire

dans d''autres langues

Documents connexes

-

HeatStar ERXL-40 Le manuel du propriétaire

-

HeatStar ERXL125-N Le manuel du propriétaire

-

HeatStar ERXL125-N Le manuel du propriétaire

-

HeatStar ER2STG175-LP Le manuel du propriétaire

-

HeatStar HS45GSP Le manuel du propriétaire

-

HeatStar ERXL125-N Le manuel du propriétaire

-

HeatStar ER2STG175-LP Le manuel du propriétaire

-

HeatStar HS115TC Le manuel du propriétaire

-

HeatStar ERSP175-LP Le manuel du propriétaire

-

HeatStar HEATSTAR HS9120 Mode d'emploi