USER INSTRUCTION MANUAL

TALON™ SELF RETRACTING LIFELINES

This manual is intended to meet the Manufacturer’s Instructions as

required by ANSI Z359.14 and should be used as part of an employee

training program as required by OSHA.

© Copyright 2007, DB Industries, Inc.

Talon SRLs

Instruction Manual 5911858 Rev. J

(See back page for model numbers)

2

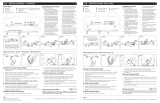

Figure 1 - Talon Self Retracting Lifeline - 8 ft. (2.4 m) Series

Locking Pin

ID Label

Order Picker

Attachment

Handle

Quick Connect

Attachment Handle

Impact

Indicator

Fold

Inspection

and

Warning

Label

i-Safe

RFID Tag

Self Locking

Snap Hook

Locking Lever

3

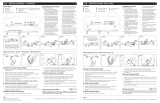

Figure 2 - Talon Self Retracting Lifeline - 16 ft. (4.9 m) Series

Swivel Eye

ID Label

i-Safe

RFID Tag

Self Locking

Snap Hook

Impact

Indicator

Fold

Inspection

and

Warning

Label

4

SAFETY INFORMATION

Please read, understand, and follow all safety information contained in these

instructions prior to the use of this Self-Retracting Device (SRD). FAILURE TO DO

SO COULD RESULT IN SERIOUS INJURY OR DEATH.

These instructions must be provided to the user of this equipment. Retain these

instructions for future reference.

INTENDED USE:

This Self-Retracting Device is intended for use as part of a complete personal fall protection

system.

Use in any other application including, but not limited to, material handling, recreational

or sports related activities, or other activities not described in the User Instructions, is not

approved by 3M and could result in serious injury or death.

This device is only to be used by trained users in workplace applications.

! WARNING

This Self-Retracting Device is part of a personal fall protection system. It is expected that all

users be fully trained in the safe installation and operation of their personal fall protection

system. Misuse of this device could result in serious injury or death. For proper

selection, operation, installation, maintenance, and service, refer to these User Instructions

including all manufacturer recommendations, see your supervisor, or contact 3M Technical

Services.

• To reduce the risks associated with working with an SRD which, if not avoided,

could result in serious injury or death:

- Before each use, inspect the SRD and check for proper locking and retraction.

- If inspection reveals an unsafe or defective condition, remove the device from

service and repair or replace according to the User Instructions.

- If the SRD has been subjected to fall arrest or impact force, immediately remove the

SRD from service and label the device ‘UNUSABLE’.

- Ensure the lifeline is kept free from any and all obstructions including, but not limited

to; entanglement with moving machinery or equipment (e.g., the top drive of oil

rigs), other workers, yourself, surrounding objects, or impact from overhead objects

that could fall onto the lifeline or the worker.

- Never allow slack in the lifeline. Do not tie or knot the lifeline.

- Attach the unused leg(s) of the Harness Mounted SRD to the parking attachment(s)

of the harness if equipped.

- Do not use in applications that have an obstructed fall path. Working on slowly

shifting material, such as sand or grain, or within conned or cramped spaces, may

not allow the worker to reach sufcient speed to cause the SRD to lock. A clear path

is required to assure positive locking of the SRD.

- Avoid sudden or quick movements during normal work operation. This may cause

the device to lock up.

- Ensure that fall protection systems/subsystems assembled from components made

by different manufacturers are compatible and meet the requirements of applicable

standards, including the ANSI Z359 or other applicable fall protection codes,

standards, or requirements. Always consult a Competent and/or Qualied Person

before using these systems.

• To reduce the risks associated with working at height which, if not avoided,

could result in serious injury or death:

- Ensure your health and physical condition allow you to safely withstand all of the

forces associated with working at height. Consult with your doctor if you have any

questions regarding your ability to use this equipment.

- Never exceed allowable capacity of your fall protection equipment.

- Never exceed maximum free fall distance of your fall protection equipment.

- Do not use any fall protection equipment that fails pre-use or other scheduled

SIT 5908239 Rev. C

5

inspections, or if you have concerns about the use or suitability of the equipment for

your application. Contact 3M Technical Services with any questions.

- Some subsystem and component combinations may interfere with the operation

of this equipment. Only use compatible connections. Consult 3M prior to using

this equipment in combination with components or subsystems other than those

described in the User Instructions.

- Use extra precautions when working around moving machinery (e.g. top drive of oil

rigs) electrical hazards, extreme temperatures, chemical hazards, explosive or toxic

gases, sharp edges, or below overhead materials that could fall onto you or your fall

protection equipment.

- Use Arc Flash or Hot Works devices when working in high heat environments.

- Avoid surfaces and objects that can damage the user or equipment.

- Ensure there is adequate fall clearance when working at height.

- Never modify or alter your fall protection equipment. Only 3M or parties authorized

in writing by 3M may make repairs to the equipment.

- Prior to use of fall protection equipment, ensure a rescue plan is in place which

allows for prompt rescue if a fall incident occurs.

- If a fall incident occurs, immediately seek medical attention for the worker who has

fallen.

- Do not use a body belt for fall arrest applications. Use only a Full Body Harness.

- Minimize swing falls by working as directly below the anchorage point as possible.

- If training with this device, a secondary fall protection system must be utilized in a

manner that does not expose the trainee to an unintended fall hazard.

- Always wear appropriate personal protective equipment when installing, using, or

inspecting the device/system.

6

WARNING: This product is part of a personal fall arrest system. These

instructions must be provided to the user and rescuer (see section 8

Terminology). The user must read and follow the manufacturer’s

instructions for each component of the system. The user must

read and understand these instructions before using this product.

Manufacturer’s instructions must be followed for proper use and

maintenance of this product. Alteration or misuse of this product, or

failure to follow instructions may result in serious injury or death.

IMPORTANT: If you have questions about the use, care, or suitability

of this equipment for your application contact DBI‑SALA.

IMPORTANT: Before using this equipment record the product

identication information from the ID label in the inspection and

maintenance log in section 10.0 of this manual.

DESCRIPTIONS

TALON 8 FT (2.4 M) SERIES SELF RETRACTING LIFELINE: See

Figure 1. Includes quick connect anchorage attachment handle

and 8 foot (2.4 m) nylon web lifeline or order picker anchorage

attachment handle and 8 foot nylon web lifeline.

TALON 16 FT (4.9 M)SERIES SELF RETRACTING LIFELINE: See

Figure 2. Includes swivel eye anchorage attachment and 16 foot

(4.9 m) nylon web lifeline.

1.0 APPLICATIONS

1.1 PURPOSE: DBI-SALA self retracting lifelines (SRL’s) are

components of a personal fall arrest system (PFAS). These

SRL’s may be used where worker mobility and fall protection are

required.

FALL PROTECTION: The SLR is used as part of a complete

personal fall arrest system. Personal fall arrest systems typically

include a full body harness, anchorage connector, and SRL.

1.2 LIMITATIONS

D. CAPACITY:

The SRL is designed for use by persons with a

combined weight (clothing, tools) of no more than 310 lbs.

(141 kg). No more than one person may be connected to the

SRL at any time.

E. LOCKING SPEED: Use of the SRL in confined spaces, on

slowly shifting material (sand or grain), or on a low pitched

roof may not allow sufficient lock-up speed to arrest a fall. A

clear fall path is required to safely arrest a fall.

F. NORMAL OPERATION: Normal operation will allow the full

length of the lifeline to extend and retract without hesitation or

creating a slack line condition as the worker moves at normal

7

speeds. If a fall occurs, a speed sensing brake system will

activate, stopping the fall and absorbing much of the energy

created. If a fall has been arrested, the SRL must be removed

from service and inspected. See section 5.0. Sudden or quick

movements should be avoided during normal work operation

as this may cause the SRL to lock-up.

G. ENVIRONMENTAL HAZARDS: Use of the SRL in hazardous

environments may require additional precautions to reduce

the possibility of injury to the user or damage to the personal

fall arrest system. Hazards may include, but are not limited

to; heat, extreme cold, caustic or corrosive chemicals,

high voltage power lines, explosive or toxic gases, moving

machinery, sharp edges.

H. TRAINING: The SRL is intended to be installed and used by

persons trained in its application and use.

1.3 Refer to national standards, including the ANSI Z359 (.1,

.2, .3, and .4) family of standards on fall protection, ANSI

A10.32 and applicable local, state, and federal (OSHA)

requirements governing occupational safety for more

information about fall arrest.

2.0 SYSTEM REQUIREMENTS

2.1 COMPATIBILITY OF COMPONENTS: DBI-SALA equipment

is designed for use with DBI-SALA approved components and

subsystems only. Substitutions or replacements made with non-

approved components or subsystems may jeopardize compatibility

of equipment and may effect the safety and reliability of the

complete system. Personal fall arrest systems must meet

applicable local, state, and federal (OSHA) requirements. A full

body harness must be used with the Talon SRL.

2.2 COMPATIBILITY OF CONNECTORS: Connectors are considered

to be compatible with connecting elements when they have been

designed to work together in such a way that their sizes and

shapes do not cause their gate mechanisms to inadvertently open

regardless of how they become oriented. Contact DBI-SALA if you

have any questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capable

of supporting at least 5,000 lbs. (22.2 kN). Connectors must be

compatible with the anchorage or other system components.

Do not use equipment that is not compatible. Non-compatible

connectors may unintentionally disengage. See Figure 3.

Connectors must be compatible in size, shape, and strength. Self

locking snap hooks and carabiners are required by ANSI Z359.14

,OSHA 1926.502, and OSHA 1910.104.

2.3 MAKING CONNECTIONS: Only use self-locking snap hooks and

carabiners with this equipment. Only use connectors that are

8

suitable to each application. Ensure all connections are compatible

in size, shape and strength. Do not use equipment that is not

compatible. Ensure all connectors are fully closed and locked.

DBI-SALA connectors (snap hooks and carabiners) are designed to

be used only as specied in each product’s user’s instructions. See

Figure 4 for inappropriate connections. DBI-SALA snap hooks and

carabiners should not be connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

NOTE: Large throat opening snap hooks should not be connected

to standard size D‑rings or similar objects which will result in a load

on the gate if the hook or D‑ring twists or rotates. Large throat snap

hooks are designed for use on xed structural elements such as rebar

or cross members that are not shaped in a way that can capture the

gate of the hook.

C. In a false engagement, where features that protrude from the

snap hook or carabiner catch on the anchor and without visual

confirmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the

manufacturer’s instructions for both the lanyard and connector

specifically allow such a connection).

F. To any object which is shaped or dimensioned such that the

snap hook or carabiner will not close and lock, or that roll-out

Figure 3 - Unintentional Disengagement (Roll-out)

If the connecting element that a snap hook (shown) or carabiner attaches to is undersized

or irregular in shape, a situation could occur where the connecting

element applies a

force to the gate of the snap hook or carabiner. This force may cause the gate (of either a

self-locking or a non-locking snap hook) to open, allowing the snap hook or carabiner to

disengage from the connecting point.

1. Force is applied to

the snap hook.

2. The gate presses against

the connecting ring.

3. The gate opens

allowing the snap hook

to slip off.

Small ring or other

non-compatibly

shaped element

9

could occur.

2.4 ANCHORAGE STRENGTH: In accordance with ANSI Z359.14,

anchorages selected for a fall arrest systems shall have a strength

capable of sustaining static loads applied in the directions

permitted by the system of at least: A) 5,000 pounds (22.2 kN) for

non-certied anchorages or B) Two times the maximum arresting

force for certied anchorages (see section 8 Terminology).

When more than one personal fall arrest system is attached to an

anchorage, the strengths previously set forth in (A) and (B) shall

be multiplied by the number of systems attached to the anchorage.

• From OSHA 1910.104 and 1926.502:

Anchorages

used for attachment of a personal fall arrest system shall

be independent of any anchorage being used to support or

suspend platforms, and must support at least 5,000 lbs.

(22.2 kN) per user attached, or be designed, installed, and

used as part of a complete personal fall arrest system which

maintains a safety factor of at least two, and is supervised by a

qualied person.

2.5 USING THE SRL WITH A HORIZONTAL SYSTEM: The SRL and

horizontal system components must be compatible. Horizontal

systems must be designed and installed under the supervision of a

qualied person (see section 8 Terminology).

3.0 INSTALLATION AND USE

WARNING: Do not alter or intentionally misuse this equipment.

Consult DBI‑SALA when using this equipment in combination with

components or subsystems other than those described in this manual.

Some subsystem and component combinations may interfere with the

operation of this equipment. Use caution when using this equipment

Figure 4 - Inappropriate Connections

10

around moving machinery, electrical hazards, chemical hazards, and

sharp edges.

WARNING: Consult your doctor if there is reason to doubt your

tness to safely absorb the shock from a fall arrest. Age and tness

can seriously affect your ability to withstand a fall. Pregnant women

and minors must not use this equipment.

3.1 BEFORE EACH USE: Inspect the SRL according to section 5.0.

3.2 PLAN your personal fall arrest system before installing and using

this equipment. Consider all factors affecting your safety during

use of this equipment.

A. ANCHORAGE: Select a rigid anchorage point capable of

supporting at least 5,000 lbs. (22.2 kN) See section 2.4. Select

an anchorage location that will avoid free fall and swing fall

hazards. To prevent an increased free fall distance do not work

above the anchorage.

B. FREE FALL: Your personal fall arrest system must be rigged

such that the SRL is

above your harness

attachment element

(dorsal D-ring) when

in use. Avoid working

where your lifeline may

cross or tangle with that

of another worker. Do

not allow the lifeline to

pass under your arms or

between your feet. Never

clamp, knot, or otherwise

prevent the lifeline from

retracting. Do not allow

slack in your lifeline. Do

not lengthen the SRL by

connecting a lanyard or

other component.

C. SWING FALLS: Swing

falls occur when the

anchorage point is not

directly above the point

where a fall occurs.

The force of striking an

object in a swing fall may

cause serious injury. In

a swing fall, the total

vertical fall distance will

be greater than if the

user had fallen directly

Figure 5 - Swing Falls

NOTE: The 6 ft. minimum assumes the fall

occurs from a standing position and the SRL

is located overhead. If the worker is kneeling

or crouching near an edge when a fall occurs,

and additional 3 ft. clearance is needed. If

the worker is not directly below the SRL,

additional clearance is needed.

11

below the anchorage point, thus increasing the total free fall

distance and the area required to safely arrest the user. The

SRL will activate regardless of its orientation relative to the

user. The recommended work zone represents the typical

acceptable work area for most applications. Review your

specific application to determine what the appropriate work

zone should be. See Chart 1. Minimize swing falls by working

as directly below the anchorage point as possible. Never

permit a swing fall if injury could occur. If a swing fall situation

exists in your application contact DBI-SALA before proceeding.

See Figure 5.

D. FALL CLEARANCE: Ensure adequate clearance exists in your

fall path to prevent striking an object. A minimum of 6 feet

from the working level to the lower level or nearest obstruction

is recommended. See Figure 5.

E. SHARP EDGES: Avoid working where the lifeline will be in

contact with or abrade against unprotected sharp edges.

Provide protection for the lifeline when possible. An energy

absorbing component can sometimes be added in-line to

further protect the worker. Compatibility and total fall distance

must be considered if this is done. Contact DBI-SALA before

using an in-line energy absorbing component or lanyard with

an SRL.

F. AFTER A FALL: Equipment which has been subjected to fall

arrest forces must be removed from service for inspection. See

section 5.

G. RESCUE: If a fall occurs, the employer must have a rescue

plan and the ability to implement a rescue.

3.3 BODY SUPPORT: A full body harness must be used with the SRL.

Chart 1

Working Distance From Anchorage

D=Distance person can move (horizontally)

Example: If the worker is 15 feet directly below the SRL.

The recommended work zone is 12 feet in any direction

H=Height of Talon

(Overhead)

0 ft.

0 ft.

5 ft.

10 ft.

15 ft.

20 ft.

25 ft.

5 ft.

10 ft.

15 ft. 20 ft.

12

For fall arrest applications connect to the dorsal D-ring on your

harness.

3.4 CONNECTING TO THE ANCHORAGE: When using a hook or

carabiner to attach to the anchorage, ensure roll-out cannot occur.

See section 2.3. Do not use a hook or carabiner that will not

completely close over the anchorage or anchorage connector. See

Figure 6. Follow the manufacturer’s instructions supplied with each

system component.

A. QUICK-CONNECT ATTACHMENT HANDLE: See Figure 7. To

open the quick-connect attachment handle, depress the locking

lever on top of the SRL. Pull the locking pin out to release the

handle. Swing the handle up to open. Place the handle around

the anchorage or anchorage connector. Swing the handle down

and realign the holes. Push the locking pin through the holes.

Figure 6 - Connecting to the Anchorage

13

Figure 7 - Using the Attachment Handles and Swivel Eye

WARNING: Ensure the locking pin fully engages the handle and the

locking lever is in the locked position.

B. ORDER PICKER ATTACHMENT HANDLE: See Figure 7.

Open the order picker attachment handle by removing the

14

bolt and lock nut. Place the handle around the anchorage or

anchorage connector. Reinstall the bolt and lock nut. Do not

over tighten.

C. SWIVEL EYE: See Figure 7. Attach the SRL to the anchorage

or anchorage

connector by

inserting a

carabiner through

the swivel eye

and around

the anchorage

or anchorage

connector [16 ft.

(4.9 m) series

only].

3.5 ATTACHING THE

SRL TO A FULL

BODY HARNESS:

For models including

a quick-connect attachment handle only, and to be used with

DBI-SALA full body harnesses only. See Figure 8. To attach the SRL

directly to a full body harness, pass the quick-connect attachment

handle through the same loops as the existing D-ring or connector.

Connect the SRL hook or carabiner to a suitable anchorage.

3.6 USING THE SRL: Connect the SRL to a suitable anchorage.

Connect the SRL hook or carabiner to the appropriate connector on

your full body harness.

Ensure hook or carabiner

is closed and locked onto

the harness connector.

NOTE: Do not use the

following DBI-SALA

hooks and carabiners

to connect to your full

body harness: 2000108,

2007153, and 9510057.

See Figure 9.

When connected to the SRL the worker is free to move about

within the recommended working area. The lifeline should extend

and retract without hesitation or creating a slack line condition as

speeds. If a fall occurs the SRL will lock and arrest the fall. When

disconnecting from the SRL keep the lifeline under control as it

recoils back into the device. A tag line may be required to extend

or retract the lifeline.

3.7 IMPACT INDICATOR: See Figure 10. The SRL incorporates an

impact indicator in the lifeline. The lifeline web is folded over

and stitched with red thread. The stitched fold will pull out at

Figure 9 - Hooks

Figure 8 - Attaching SRL to Harness

15

approximately 450

lbs. (204 kg) If

the red stitching is

intact the SRL has

not been impacted.

If the red stitching

is broken and the

fold torn apart,

the SRL has been

impacted and must

be removed from

service and returned

to an authorized

service center for

repair.

4.0 TRAINING

4.1 It is the responsibility of all users of this equipment to understand

these instructions, and to be trained in the correct installation,

use, and maintenance of this equipment. These individuals must

be aware of the consequences of improper installation or use

of this equipment. This user manual is not a substitute for a

comprehensive training program. Training must be provided on a

periodic basis to ensure prociency of the users.

WARNING: Training must be conducted without exposing the trainee

to a fall hazard. Training must be repeated on a periodic basis.

5.0 INSPECTION

5.1 The i-Safe™ RFID tag on this

SRL can be used in conjunction

with the i-Safe handheld reading

device and the web based

portal to simplify inspection and

inventory control and provide

records for your fall protection

equipment (see Fig. 11).

5.2 FREQUENCY:

• Before Each Use:

OSHA 1910.104, OSHA

1926.502 and ANSI Z359.14

requires an inspection of

equipment before each use. See sections 5.2, 5.3, and 5.4 for

inspection guidelines.

• Annually: ANSI Z359.14 requires a formal inspection of

the SRL be completed by a competent person other than the

user. More frequent inspections by a competent person may

be required based on the nature and severity of workplace

Figure 10 - Impact Indicator

Figure 11 - RFID Tag

i-Safe RFID

Tag

16

conditions affecting the equipment and the modes of use and

exposure time of the equipment. See sections, 5.3, and 5.4

for inspection guidelines. Record results in the inspection and

maintenance log in section 10.0, or use the i-Safe™ inspection

web portal to maintain your inspection records. If you are a

rst-time user, contact a Customer Service representative

in the US at 800-328-6146 or in Canada at 800-387-7484

or if you have already registered, go to: www.capitalsafety.

com/isafe.html. Follow instructions provided with your i-Safe

handheld reader or on the web portal to transfer your data to

your web log.

*NOTE: In Canada, CSA requires SRLs to be serviced within

two years of the manufactured date, and annually thereafter.

• After a Fall Arrest: Inspect impact indicator according

to section 5.3, and the entire SRL according to sections 5.4

and 5.5.

5.3 IMPACT INDICATOR: To inspect the impact indicator, nd the

fold in the lifeline stitched with red thread, as shown in Figure 10.

If the red stitching is broken and the fold torn apart, the SRL has

been impacted and must be removed from service and returned to

an authorized service center for repair. Do not re-stitch the fold.

WARNING: If the SRL has been subjected to fall arrest or impact

forces it must be removed from service and returned to an authorized

service center for repair.

5.4 INSPECTION STEPS:

Step 1. Check for loose screws and bent or damaged parts.

Step 2. Check the housing for distortion, cracks, or other

damage. Ensure the anchorage point is not damaged or

distorted.

Step 3. The lifeline must fully extend and retract smoothly with

no hesitation or slack line condition.

Step 4. Ensure the device locks when the lifeline is pulled

sharply. Lock-up should be positive, with no slipping.

Step 5. All labels must be present and fully legible.

Step 6. Check for corrosion on the entire unit.

Step 7. Check the lifeline for cuts, burns, chemical damage,

or severely abraded areas. The lifeline must not be

damaged.

Step 8. Check the connecting hooks or carabiners for damage,

distortion, or corrosion, and working condition.

Step 9. Inspect each component of the personal fall arrest

17

system according to manufacturer’s instructions.

Step 10. Record the inspection results in the inspection and

maintenance log in section 10.0 or using the I-safe web

portal.

5.5 If the inspection reveals an unsafe or defective condition, remove

the SRL from service and contact an authorized service center for

repair.

NOTE: Only DBI‑SALA or parties authorized in writing may make

repairs to this equipment.

6.0 MAINTENANCE, SERVICING, AND STORAGE

6.1 MAINTENANCE:

A. HOUSING: Periodically clean the exterior of the SRL with

water and a mild detergent. Position the SRL so water

can drain out. Clean the labels as required.

B. LIFELINE: Clean the lifeline with water and a mild detergent.

Rinse and thoroughly air dry. Do not force dry with heat. An

excessive build-up of dirt or other contaminants may prevent

the lifeline from fully retracting, causing a potential free fall

hazard. Return the SRL to an authorized service center for

lifeline replacement if necessary.

C. PERSONAL FALL ARREST SYSTEM COMPONENTS: Clean

and store associated system components according to

manufacturer’s instructions.

6.2 SERVICING: Do not disassemble the SRL. Do not lubricate any

part of the SRL. Additional maintenance and servicing must be

performed by an authorized service center. A return authorization

number must be issued by DBI-SALA. See section 5.2 for servicing

frequency.

6.3 STORAGE: Store the SRL in a cool, dry, and clean environment,

out of direct sunlight. Avoid storing the SRL in areas where

chemical vapors exist. Thoroughly inspect the SRL after extended

storage.

7.0 SPECIFICATIONS

7.1 PERFORMANCE SPECIFICATIONS:

• Capacity (All Models): 75 - 310 lbs. (34 - 141 kg), one

user only

• Working Range, 8 Foot Models:

2.5 ft. - 8 ft (.8 m - 2.4 m)

• Working Range, 16 Foot Models:

1.5 ft. - 16 ft (.5 m - 4.9 m)

• Maximum Arresting Force (All Models)

: 1,350 lbs.

(612 kg)

when tested in accordance with ANSI Z359.14.

18

•

Average Locking Speed (All Models):

4.5 ft./sec. (1.4 m / sec.)

• Maximum Arresting Distance (All Models): 42 in. (1 m)

7.2 PHYSICAL SPECIFICATIONS:

8 FOOT MODELS:

• Overall Dimensions, Quick-Connect Attachment Handle

Models (LxWxH): 6.7 x 3.9 x 2.2 in. (17 cm x 10 cm x 6 cm)

• Overall Dimensions, Order Picker Attachment Handle

Models (LxWxH): 8.9 x 3.9 x 2.2 in. (23 cm x 10 cm x 6 cm)

16 FOOT MODELS:

Overall Dimensions (LxWxH): 7.9 x 5.9 x 2.4 in. (20 cm x 15 cm x 6 cm)

ALL MODELS:

Materials:

Housing: Nylon

Cable Drum: Glass lled nylon

Internal Components: Steel/Aluminum

Lifeline: 3/4 inch nylon web

7.3 PATENTS AND REQUIREMENTS:

• Patents Pending

• Meets Z359.14 Class B, OSHA 1926.502, and OSHA

1910.140.

8.0 TERMINOLOGY

AUTHORIZED PERSON: A person assigned by the employer to perform

duties at a location where the person will be exposed to a fall hazard

(otherwise referred to as “user” for the purpose of these instructions).

RESCUER: Person or persons other than the rescue subject acting to

perform an assisted rescue by operation of a rescue system.

CERTIFIED ANCHORAGE: An anchorage for fall arrest, positioning,

restraint, or rescue systems that a qualified person certifies to be capable

of supporting the potential fall forces that could be encountered during

a fall or that meet the criteria for a certified anchorage prescribed in this

standard.

QUALIFIED PERSON: A person with a recognized degree or professional

certificate and with extensive knowledge, training, and experience in the

fall protection and rescue field who is capable of designing, analyzing,

evaluating and specifying fall protection and rescue systems to the extent

required by this standard.

COMPETENT PERSON: One who is capable of identifying existing and

predictable hazards in the surroundings or working conditions which

are unsanitary, hazardous, or dangerous to employees, and who has

authorization to take prompt corrective measures to eliminate them.

19

ANSI Warning/Inspection Label

9.0 LABELING

i-Safe RFID Label

The following labels must be present and fully legible:

ANSI Warning/Inspection Label

20

MANUEL D’INSTRUCTIONS POUR UTILISATEUR

CORDON D’ASSURANCE AUTO RÉTRACTABLE TALON™

Ce manuel satisfait les instructions du fabricant tel que requis par

ANSI Z359.14 et doit être utilisé comme une partie du programme

de formation de l’employé conformément à la réglementation OSHA.

© Copyright 2007, DB Industries, Inc.

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

dans d''autres langues

- English: 3M 3101006 User manual

- español: 3M 3101006 Manual de usuario

Documents connexes

-

3M 3102003 Manuel utilisateur

-

3M DBI-SALA® Swiveling Roof Anchor 2190071, 1 EA Mode d'emploi

-

3M 7611907 Mode d'emploi

-

3M DBI-SALA® Roof Top Anchor 2100138, 1 EA Mode d'emploi

-

3M 2103690 Mode d'emploi

-

3M PROTECTA® Twin-Leg Self Retracting Lifeline Web 3100412, Red, 6 ft. (1.8 m), 1 ea Mode d'emploi

-

3M DBI-SALA® Saflok Max™ Web Anchor 1231305, 1 EA Mode d'emploi

-

3M PROTECTA® Self Retracting Lifeline - Web 3100433, Red, 20 ft. (6.1 m), 1 EA Manuel utilisateur

-

3M PROTECTA® Self Retracting Lifeline - Web 3100433, Red, 20 ft. (6.1 m), 1 EA Mode d'emploi

-

3M PROTECTA® Self Retracting Lifeline - Cable 3590020, Red, 15 ft. (4.5 m) Mode d'emploi

Autres documents

-

Honeywell Miller MightEvac User Instruction Manual

-

Sharper Image Carabiner AirTag Combination Lock Manuel utilisateur

-

Miller 475 Manuel utilisateur

-

MSA V-EDGE Personal Fall Limiter (PFL) Mode d'emploi

-

Guardian Diablo Web SRL 2.0 Mode d'emploi

-

DeLOCK 60186 Fiche technique

-

Kurgo Auto Zip Line Mode d'emploi

Kurgo Auto Zip Line Mode d'emploi