Grundfos Conex DIA-G Installation And Operating Instructions Manual

- Taper

- Installation And Operating Instructions Manual

Conex

®

DIA-G

Gas warning controller

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

2

3

Table of contents

Conex

®

DIA-G

English (GB)

Installation and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Deutsch (DE)

Montage- und Betriebsanleitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Español (ES)

Instrucciones de instalación y funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . 106

Français (FR)

Notice d'installation et de fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Hrvatski (HR)

Montažne i pogonske upute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Italiano (IT)

Istruzioni di installazione e funzionamento . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Lietuviškai (LT)

Įrengimo ir naudojimo instrukcija . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Nederlands (NL)

Installatie- en bedieningsinstructies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

Polski (PL)

Instrukcja montażu i eksploatacji . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 412

Português (PT)

Instruções de instalação e funcionamento . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Română (RO)

Instrucţiuni de instalare şi utilizare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 514

Русский (RU)

Паспорт, Руководство по монтажу и эксплуатации . . . . . . . . . . . . . . . . . . 565

Türkçe (TR)

Montaj ve kullanım kılavuzu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 616

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 668

English (GB)

4

English (GB) Installation and operating instructions

Original installation and operating instructions

CONTENTS

Page

1. Symbols used in this document

1. Symbols used in this document

4

2. Device settings

5

2.1 Sensor types

7

3. General information

7

4. Applications

7

5. Safety

8

5.1 Risks when safety instructions are not

observed

8

5.2 Obligations of the owner/operations

manager

8

5.3 Avoidance of danger

8

6. Identification

9

6.1 Nameplate

9

6.2 Type key, gas warning controllers

9

6.3 Type key, gas warning systems,

prepacked (with sensors and sensor

equipment)

10

7. Product description and accessories

11

7.1 General description

11

7.2 Dimensional sketches

13

8. Technical data

14

8.1 Signal inputs and outputs

15

8.2 Setting ranges for alarms / limit values

15

8.3 Sensors

15

8.4 Measuring and setting ranges

16

9. Installation

17

9.1 Transport

17

9.2 Intermediate storage

17

9.3 Unpacking

17

9.4 Installation requirements

17

9.5 Installation notes

17

9.6 Installation of the Conex

®

DIA-G

18

9.7 Assembling the Conex

®

DIA-G sensor

interface

19

10. Commissioning/electrical connections

19

10.1 Conex

®

DIA-G terminal assignment

20

10.2 Power supply connection

21

10.3 Connecting a backup battery

22

10.4 Relay outputs

22

10.5 Current output

22

10.6 Terminal assignment for Conex

®

DIA-G

sensor interface

23

10.7 Connection of sensors

24

11. Operation

27

11.1 Initial start-up

27

11.2 Control and display elements

28

11.3 Operating modes

28

11.4 Display elements during initial

commissioning

28

11.5 Operating instructions

29

11.6 Software overview

30

11.7 Main menu

35

11.8 Setup

35

11.9 Parameterising the sensors

41

11.10 Requesting settings in the service menu

45

11.11 Fine adjustment menu

47

11.12 Actions during operation

49

12. Error messages and fault finding

52

12.1 Error messages

52

12.2 Fault finding

53

13. Maintenance

54

14. Disposal

54

Warning

These complete installation and operating

instructions are also available on

www.Grundfos.com.

Prior to installation, read these installation

and operating instructions. Installation and

operation must comply with local

regulations and accepted codes of good

practice.

Warning

If these safety instructions are not

observed, it may result in personal injury.

Caution

If these safety instructions are not

observed, it may result in malfunction or

damage to the equipment.

Note

Notes or instructions that make the job

easier and ensure safe operation.

English (GB)

5

2. Device settings

Note the key settings for the Conex

®

DIA-G.

Setup

Note

The set values can be stored in the "Setup

/ Factory setting" menu so that you can

access them again later.

Sensor 1

Off

Cl

2

sensor 91835237 (314-011)

Cl

2

sensor 96732268 (314-021)

ClO

2

sensor 95700837 (314-041)

ClO

2

sensor 91835237 (314-011)

O

3

sensor 95700838 (314-071)

O

3

sensor 96687714 (314-013)

HCl sensor 95700840 (314-061)

NH

3

sensor 95700839 (314-031)

Sensor 2

Off

Cl

2

sensor 91835237 (314-011)

Cl

2

sensor 96732268 (314-021)

ClO

2

sensor 95700837 (314-041)

ClO

2

sensor 91835237 (314-011)

O

3

sensor 95700838 (314-071)

O

3

sensor 96687714 (314-013)

HCl sensor 95700840 (314-061)

NH

3

sensor 95700839 (314-031)

Limit relay

Fail safe

On (N.C.)

Off (N.O.)

Confirm. LV 2

Yes

No

Alarm relay

Fail safe

On (NC)

Off (NO)

Confirmation

Yes

No

Alarm sensor 1

Limit value 1

On

Off

Limit value 2

On

Off

Test sensor

On

Off

Alarm sensor 2

Limit value 1

On

Off

Limit value 2

On

Off

Test sensor

On

Off

English (GB)

6

Sensor 1

Sensor 2

Current output

Sensor 1

0-20 mA

4-20 mA

Others:

Assignment

min. ppm =

mA

max. ppm =

mA

Current output

Sensor 2

0-20 mA

4-20 mA

Others:

Assignment

min. ppm =

mA

max. ppm =

mA

Auto. test S1

Off

On

days testing interval

Limit value 1

Off

On

ppm

Limit value 2

Off

On

ppm

sec delay

Limit value 1/2

ppm hysteresis

Alarm S1

Off

On

sec delay

Auto. test S2

Off

On

days testing interval

Limit value 1

Off

On

ppm

Limit value 2

Off

On

ppm

sec delay

Limit value 1/2

ppm hysteresis

Alarm S2

Off

On

sec delay

English (GB)

7

2.1 Sensor types

3. General information

These installation and operating instructions contain

all information important for users of the

Conex

®

DIA-G gas warning controller.

• technical data

• instructions on commissioning, use and

maintenance

• safety information.

Should you require further information or should you

encounter problems that are not handled in sufficient

depth in this manual, please contact Grundfos Water

Treatment.

We shall be pleased to support you with our

comprehensive know-how in the fields of measuring

and control technology as well as water treatment.

We always welcome suggestions on how to optimise

our installation and operating instructions to satisfy

our customers.

4. Applications

The Conex

®

DIA-G gas warning controllers are used

to evaluate suitable sensors for monitoring the

concentration of chlorine (Cl

2

),

chlorine dioxide (ClO

2

), ozone (O

3

), ammonia (NH

3

)

or hydrochloric acid (HCl) and to trigger warning and

protective systems in the framework of the possible

uses described in this manual with the sensor types

listed here.

Sensor type

Measuring

parameter

Sensor

Amperometric

sensor (disc)

Cl

2

, ClO

2

91835237

(314-011)

O

3

96687714

(314-013)

Potentiostatic

sensor

Cl

2

96732268

(314-021)

NH

3

95700839

(314-031)

ClO

2

95700837

(314-041)

HCl

95700840

(314-061)

O

3

95700838

(314-071)

Caution

The Conex

®

DIA-G cannot be used for

measuring a gas concentration

continuously or for control according to the

German MAK standard regarding

maximum allowable concentration. Use

only calibrated gas measuring devices for

measuring gas concentration.

Ensure a sufficient safety level when

setting the limit values for the

Conex

®

DIA-G.

Warning

Other applications are not approved and

not permitted. Grundfos cannot be held

liable for any damage resulting from

incorrect use.

English (GB)

8

5. Safety

This manual contains general instructions that must

be observed during installation, operation and

maintenance. This manual must therefore be read by

the installation engineer and the relevant qualified

personnel/operators prior to installation and start-up

and must be available at the installation location of

the Conex

®

DIA-G at all times.

It is not only the general safety instructions

described in this section 5. Safety that must be

observed, but all special safety instructions that are

provided in the other sections.

5.1 Risks when safety instructions are not

observed

If safety instructions are not observed, it may result

in personal injury or damage to the Conex

®

DIA-G. If

safety instructions are not observed, this may lead to

the loss of any claims for damages.

If individual safety instructions are not observed, this

may cause for example the following damage:

• failure of specified methods for recording gas

concentrations and secondary safety equipment

• harm to humans from exposure to electrical,

mechanical and chemical influences.

5.2 Obligations of the owner/operations

manager

The owner/operations manager must ensure that

persons working with the described device fulfil

these requirements:

• They are acquainted with the regulations

concerning working safety and accident

prevention.

• They have been trained in use of the device.

• They have read and understood the warning

information and handling symbols.

The owner/operations manager is also responsible

for ensuring that this manual is kept in the immediate

vicinity of the device and is always available for the

operating personnel and that the local safety

regulations are observed when setting the limit

values for the sensors.

5.3 Avoidance of danger

5.3.1 Safety instructions for the operator

Damage caused by electrical energy must be

prevented. For more details, see for example the

regulations of the VDE, German Association for

Electrical, Electronic and Information Technologies,

and the local power supply company.

5.3.2 Safety instructions for maintenance,

inspection and installation work

The operator is responsible for ensuring that all

maintenance, inspection and installation work is

carried out by authorised and qualified personnel,

who have been adequately trained by reading the

installation and operating instructions.

All safety and protective equipment must be

immediately restarted or put into operation once

work is complete.

Observe the points described in the initial start-up

section prior to subsequent start-up.

Warning

Do not use the device for monitoring

constant concentrations. The device is

designed for detecting leaks.

Warning

Installation and connection of the device

and the associated supplementary

components must only be carried out by

qualified specialists!

The local safety regulations must be

observed!

Warning

Switch off the power supply before

connecting the power supply cable and

relay contacts!

Do not dismantle the device! Maintenance

and repairs must only be carried out by

authorised specialists!

Caution

The mounting location must be selected so

that the housing is not subjected to

mechanical loading.

Check that all settings are correct before

starting up the device!

English (GB)

9

6. Identification

6.1 Nameplate

Fig. 1 Nameplate, Conex

®

DIA-G

6.2 Type key, gas warning controllers

Example: DIA-G, 1-D/A/HC 2-D/A/HC, W-J

TM04 1259 0509

DIA-G, 1-D/A/HC 2-D/A/HC, W-J

308-2000-10012

S/N: 08/11221

Conex DIA-G

110-240V 50/60Hz 24V/DC, 30 VA,

IP 65

96732266P1108060808565

1

2

3

4

5

7

8

9

10

11

12

6

Pos. Description

1 Type designation

2 Model

3 Product

4 Voltage [V]

5 Frequency [Hz]

6 Product number

7 Country of origin

8 Year and week of production

9 Marks of approval, CE mark, etc.

10 Power consumption [VA]

11 Enclosure class

12 Serial number

Example: DIA-G 1-D/A/HC 2-D/A/HC W -J

Conex

®

gas warning system

DIA-G

Dosing Instrumentation Advanced

with gas detection

Sensor 1

D Chlorine gas/chlorine dioxide gas/ozone gas

A Ammonia gas

HC Hydrochloric acid gas

Sensor 2

D Chlorine gas/chlorine dioxide gas/ozone gas

A Ammonia gas

HC Hydrochloric acid gas

Mounting

W Wall-mounted

P Panel-mounted

Voltage

G 1 x 230/240 V, 50/60 Hz

H 1 x 115/120 V, 50/60 Hz

J 110-240 V, 50/60 Hz, 24 VDC

English (GB)

10

6.3 Type key, gas warning systems, prepacked (with sensors and sensor equipment)

Example: DIA-G-P, CLP-OP-B, W-J

Example: DIA-G -P. CLP- OP- B. W -J

Conex

®

gas warning system

DIA-G Dosing Instrumentation Advanced with gas detection

PPrepacked

Sensor 1

CCA Chlorine gas/chlorine dioxide gas, amperometric measurement

OA Ozone gas, amperometric measurement

CLP Chlorine gas, potentiostatic measurement

CDP Chlorine dioxide gas, potentiostatic measurement

OP Ozone gas, potentiostatic measurement

AP Ammonia gas, potentiostatic measurement

HCP Hydrochloric acid gas, potentiostatic measurement

Sensor 2

CCA Chlorine gas/chlorine dioxide gas, amperometric measurement

OA Ozone gas, amperometric measurement

CLP Chlorine gas, potentiostatic measurement

CDP Chlorine dioxide gas, potentiostatic measurement

OP Ozone gas, potentiostatic measurement

AP Ammonia gas, potentiostatic measurement

HCP Hydrochloric acid gas, potentiostatic measurement

Option

B Battery backup

X No battery backup

Mounting

W Wall-mounted

P Panel-mounted (not available at the moment)

Voltage

G 1 x 230/240 V, 50/60 Hz

H 1 x 115/120 V, 50/60Hz

J 110-240 V, 50/60 Hz, 24 VDC

English (GB)

11

7. Product description and

accessories

This universal device offers high-precision

measuring of chlorine, chlorine dioxide, ozone,

ammonia or hydrochloric acid.

• comprehensive limit value functions

• comprehensive alarm functions

• logbook function: chronological recording of key

events with date and time

• user coding function as a means of protection

against access by unauthorised persons and for

system administration

• error message function for indication of

non-functioning sensors

• automatic monitoring of the sensor service life

with warnings about sensors that require

renewal.

7.1 General description

The Conex

®

DIA-G is a gas warning controller for

monitoring gas concentrations, for example in

storage or dosing rooms. With a maximum of two

independently connected sensors, the gas

concentration of chlorine, ozone, chlorine dioxide,

hydrochloric acid or ammonia can be displayed and

monitored. Amperometric sensors (sensor discs) can

be connected directly to the Conex

®

DIA-G, and

potentiostatic sensors can be connected to a

preceding Conex

®

DIA-G sensor interface.

Each of the two sensors is provided with electrically

isolated current outputs (potential-free to power

supply) to output the measured concentration, two

electrically isolated limit value transmitters and an

alarm relay to control the warning and safety

equipment.

The Conex

®

DIA-G meets the high safety

requirements through permanent sensor monitoring,

alarm relays and optional backup mode (connection

of an external backup battery for supplying power to

the Conex

®

DIA-G in case of short-term power

supply interruptions).

How the system operates

• The gas sensors generate a current which is

proportional to the gas concentration in the air.

• The Conex

®

DIA-G gas warning controller

– amplifies the sensor current

– triggers an initial warning, for example when

the first limit value is exceeded

– activates the relevant warning and safety

equipment when the second limit value is

exceeded

– outputs the measured concentration at both

sensors as a 0 (4) - 20 mA signal via the

current outputs (for example for recording).

English (GB)

12

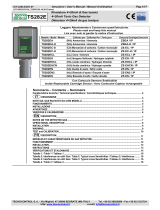

Fig. 2 Gas warning system

The complete gas warning system comprises:

• gas sensors in the gas container and gas dosing unit area

• the Conex

®

DIA-G gas warning controller

• warning and safety equipment: horn, flashing warning system, sprinkling installation.

TM03 7022 4506

4

6

5

7

3

2

1b

1a

Conex DIA-G

Sensor 1

Sensor 2

OKEsc

Alarm

Pos. Description

1a Amperometric gas sensor

1b Potentiostatic gas sensor with Conex

®

DIA-G sensor interface

2 Gas container

3 Gas dosing unit

4 Conex

®

DIA-G gas warning controller

5Horn

6 Flashing warning system

7 Sprinkling installation

English (GB)

13

7.2 Dimensional sketches

Fig. 3 Conex

®

DIA-G

Fig. 4 Conex

®

DIA-G sensor interface

TM03 7023 4506

59

125

84

59.5

184.5

212

198

10

145

27

99

Ø 4.5

TM03 7024 4506

120

146.5

101.5

80

42

English (GB)

14

8. Technical data

Caution

Observe the permissible temperature range of the sensors!

Note

Observe the accuracy of the sensor!

Electronics 16-bit microprocessor technology

Display Backlit plain-text display

Display languages German, English, French, Spanish, Russian and Polish

Indication mode In ppm for measured values of both sensors

Permissible temperatures

Conex

®

DIA-G and sensor interface (without sensor):

• operation: 0 to +40 °C

• storage: 0 to +65 °C

Permissible relative air

humidity

Maximum 90 % at 40 °C (no condensation)

Power supply

• 110-240 V - 10 %/+ 10 % (50/60 Hz)

• 24 VDC

Power consumption Approximately 30 VA

Material (enclosure) ABS, resistant to chemicals

Enclosure class IP65 for Conex

®

DIA-G wall-mounting enclosure and sensor interface

Weight Approximately 1.5 kg

Connections Screw terminals for cables up to maximum 2.5 mm

2

Safety functions

• Permanent sensor monitoring or automatic sensor test, interval between

tests adjustable from 0.5 to 30 days

• Wire breakage monitoring of all current outputs

• Optional backup battery with backup indication on the display, allowing

Conex

®

DIA-G to work for at least one hour after power failure

• Automatic adjustment of data specific to the sensor (for example

calibration data)

• Display of the sensor exchange intervals with a plain-text message

Backup battery

All devices can be equipped with an external backup battery as an option.

The backup battery supplies the gas warning controller, including the

electrically isolated relays, but no external devices (for example signal

lamp, aeration, sprinkler system, etc.). The battery lasts for about one hour

after power supply failure.

English (GB)

15

8.1 Signal inputs and outputs

8.2 Setting ranges for alarms / limit values

8.3 Sensors

Amperometric sensor disc Cl

2

, ClO

2

and O

3

Connection via 2-wire cable 0.5 mm

2

with single

screen. Maximum length (maximum distance

between the sensor disc and gas warning controller):

100 metres.

91835237 (314-011)/96687714 (314-013) include the

wall housing with sensor disc.

Potentiostatic sensor Cl

2

, ClO

2

, O

3

, NH

3

, HCl

The sensor is plugged directly into the interface. The

interface is connected to the gas warning controller

using a 4-wire cable with single screening (special

cable for CAN connections). Maximum length

(maximum distance between Conex

®

DIA-G sensor

interface and gas warning controller): 500 metres.

Relay outputs

Five potential-free relay outputs, switchable to NO (normally open) or NC (normally

closed) (fail safe); maximum 250 V / 6 A, maximum 550 VA ohmic load:

• two relays for the limit values of each of the two sensors

• one alarm relay; free assignment to the limit values or to sensor test (see below)

Signal inputs

• Two measured value inputs (for amperometric sensors 1 and 2)

• Internal CANBus, including connections for two sensor interfaces, each for the

operation of one potentiostatic sensor

Signal outputs

Two potential-free current outputs (0) 4 - 20 mA, maximum load of 500 Ω, with cable

breakage monitoring; assignment of 0 (4) - 20 mA to the measuring range of the

selected sensor, or linear assignment of the current output (0-20 mA) to the

measuring value (within the measuring range of the selected sensor)

Switching point for

limit values

• Limit value 1 (warning if exceeded) can be set to any value within the measuring

range.

• Limit value 2 (warning if exceeded) can be set to any value within the measuring

range.

• Limit value 2 can be delayed between 0-180 seconds.

• Hysteresis: 0-50 % of measuring range.

• Limit value 1 and 2 can be acknowledged. The acknowledgement is stored in a

list of events.

Alarm relay

• The alarm relay can be freely assigned to the limit values and/or the sensor test.

• The alarm can be delayed between 0-180 seconds.

English (GB)

16

8.4 Measuring and setting ranges

8.4.1 Measuring parameter and working range for amperometric sensors

8.4.2 Measuring parameter and working range for potentiostatic sensors

Measuring parameter Measuring range Accuracy Temperature range Product number

[ppm] [%] [°C]

Cl

2

, ClO

2

0.00 - 5.00 ± 10 +5 to +45

91835237

(314-011)

O

3

0.00 - 5.00 ± 10 +5 to +45

96687714

(314-013)

Measuring

parameter

Measuring

range

Resolution

at 20 °C

Linearity

Sensitivity drift

per 6 months

Temperature

range

Product

number

[ppm] [ppm]

[%] of

full scale

[%] [°C]

Cl

2

0.00 - 20.00 < 0.05 < 5 < 10 -20 to +40

96732268

(314-021)

NH

3

0 - 100 < 1 < 10 < 5 -20 to +40

95700839

(314-031)

ClO

2

0.00 - 1.00 < 0.03 < 10 < 10 -20 to +40

95700837

(314-041)

HCl 0.0 - 30.0 < 0.7 < 5 < 3 -20 to +40

95700840

(314-061)

O

3

0.00 - 1.00 < 0.02 < 10 < 10 -20 to +40

95700838

(314-071)

Note

The measuring ranges depend on the set sensors and cannot be modified.

English (GB)

17

9. Installation

9.1 Transport

9.1.1 Delivery

The Conex

®

DIA-G is delivered in a cardboard box.

Leave the device in the packaging during transport

and intermediate storage.

9.1.2 Return

Return the Conex

®

DIA-G in its original packaging or

equivalent.

9.2 Intermediate storage

Permissible storage temperature: -20 °C to +65 °C.

9.3 Unpacking

1. Check the device for damage. Install as soon as

possible after unpacking.

2. Do not install or connect damaged devices!

9.4 Installation requirements

Conex

®

DIA-G

• Dry room

• Room temperature: 0 °C to +40 °C

• Vibration-free location.

Sensors

• Dry room.

– Avoid the sensor getting wet! Make sure to

locate it outside the range of the sprinkling

installation.

• Room temperature according to the technical

data for the relevant sensor.

• Vibration-free location.

• Protect the sensor from direct heat, sunlight and

strong draughts!

9.5 Installation notes

Amperometric sensor discs are connected directly to

the Conex

®

DIA-G. If potentiostatic sensors are

used, one Conex

®

DIA-G sensor interface per

sensor is required.

Maximum cable lengths:

• Amperometric sensors: 100 metres

• DIA-G sensor interface for potentiostatic sensors

(CANBus connection): 500 metres.

Warning

Before assembling, disconnect the power

supply!

Enclosure class IP65 is only guaranteed if

the terminal covers are closed and the

appropriate cable glands or dummy caps

fitted.

Caution

Risk of malfunction or damage to the

Conex

®

DIA-G! Do not drop the device.

Caution

Risk of malfunction or damage to the

Conex

®

DIA-G! Grundfos accepts no

liability for damage caused by incorrect

transportation or missing or unsuitable

packaging of the device!

Note

For information on storing the sensors, see

the manual of the gas sensors.

Note

Retain the packing material or dispose of it

according to local regulations.

Caution

The sensor must be replaced after a gas

eruption that has exceeded the measuring

range. Do not expose the sensor to a

higher gas concentration, even during

start-up and test.

Caution

Gas sensors should not be mounted close

to major sources of interference such as

large machines, etc.

Caution

If these assembly requirements are not

observed, there may be damage to the

measuring device or incorrect

measurements!

English (GB)

18

9.6 Installation of the Conex

®

DIA-G

1. Drill three holes (∅8 mm) as shown in the

diagram, and insert the supplied dowels.

2. Unscrew the terminal cover on the device.

3. Tighten the upper middle screw (A).

4. Place the device on this screw (A).

5. Secure the device through the enclosure using

the two other screws (B).

6. Replace the terminal cover.

Fig. 5 Drilling diagram of the Conex

®

DIA-G

Fig. 6 Mounting drawing

Warning

Switch off the power supply before

installing!

Enclosure class IP65 is only guaranteed if

the terminal covers are closed and the

appropriate cable glands or dummy caps

fitted.

Caution

Enclosure class IP65 is only guaranteed if

the terminal cover is correctly sealed!

Do not damage the terminal cover gasket!

The terminal cover gasket must fit exactly!

TM03 7025 4506

198

145

27

10.5

99

TM03 7026 4506

B

B

A

Conex DIA-G

Sensor 1

Sensor 2

OKEsc

Alarm

English (GB)

19

9.7 Assembling the Conex

®

DIA-G sensor

interface

If potentiostatic sensors are used, a separate

Conex

®

DIA-G sensor interface must be installed.

1. Drill four holes (∅6 mm) as shown in the

diagram, and insert the supplied dowels.

Fig. 7 Drilling diagram of Conex

®

DIA-G

sensor interface

2. Unscrew the device cover.

3. Secure the device with the four supplied screws.

4. Replace the device cover.

10. Commissioning/electrical

connections

1. Remove the terminal cover on the front of the

device.

2. Use the appropriate cable entries, and tighten the

screws carefully.

3. Connect the cables used to the terminals

according to the Conex

®

DIA-G terminal

assignment.

4. Close the terminal cover again with correctly

positioned gasket.

Warning

Switch off the power supply before

installing!

Enclosure class IP65 is only guaranteed if

the terminal covers are closed and the

appropriate cable glands or dummy caps

fitted.

TM03 7027 4506

Caution

Enclosure class IP65 is only guaranteed if

the terminal cover is correctly sealed!

Do not damage the terminal cover gasket!

The terminal cover gasket must fit exactly!

108

6

15

50

Warning

Switch off the power supply before

installing!

Enclosure class IP65 is only guaranteed

with the front panel of the terminals

enclosure closed and with appropriate

cable glands or dummy caps.

Warning

Disconnect the power supply before

connecting the power supply cable and the

relay contacts! For safety reasons, the

protective conductor must be connected

correctly!

Observe the local safety regulations!

Protect the cable connections and plugs

against corrosion and humidity.

Caution

Before connecting the power supply cable,

check that the supply voltage specified on

the nameplate corresponds to the local

conditions!

An incorrect supply voltage may destroy

the device!

To guarantee electromagnetic compatibility

(EMC), the input and current output cables

must be screened.

Connect the screening to the screen

ground on one side!

Refer to the wiring diagram! Route the

input, current output and power supply

cables in separate cable channels.

Caution

Enclosure class IP65 is only guaranteed if

the terminal cover is correctly sealed! Do

not damage the gasket on the terminal

cover!

The terminal cover gasket must fit exactly!

Note

Unused terminals must remain open.

English (GB)

20

10.1 Conex

®

DIA-G terminal assignment

Fig. 8 Conex

®

DIA-G terminal

Key for Conex

®

DIA-G terminal diagram

TM04 8396 1411

1

S1

0

1

S2

0

Main in

Sensor 1

SP2

Sensor 2

SP2

Alarm

Input

Bat

24 V

CAN

Sensor

CAN

Interface

Reset

mAmA

Sensor 1

out SP1SP1

NO

NC

24V Out

Sensor

Interface

Bat

ok

mAmA

Sensor 2

+

+++++

+

–

+

––

–––––

LL

LL

HH

HH

LNPE

LNPE

12

12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Assignment Terminal Description

Main in

L1

Power supply connectionN3

PE 5

Main out

L2

Supply for electrically isolated contactsN4

PE 6

Sensor 1/SP 1 7, 8 Limit value relay (setpoint) 1, sensor 1

Sensor 1/SP 2 9, 10 Limit value relay (setpoint) 2, sensor 1

Sensor 2/SP 1 11, 12 Limit value relay (setpoint) 1, sensor 2

Sensor 2/SP 2 13, 14 Limit value relay (setpoint) 2, sensor 2

Alarm

NO 18

Alarm relay with terminal 15, 16 and terminal 18:

normally open contact, or terminal 17: normally

closed contact

NC 17

15, 16

Input Bat

24 V

+19

Input for external battery supply (UPS)

-20

24 V Out Sensor

Interface

+21

24 V supply output for sensor interface

-22

CAN sensor

(sensor interface

connection)

L 23, 24 Terminal 23: input... or terminal 24: output...

H 25, 26 Terminal 25: input... or terminal 26: output...

Screen

27, 28 Terminal 27: input... or terminal 28: output...

CAN interface

(CANBus

connection)

L 29, 30 Terminal 29: input... or terminal 30: output...

H 31, 32 Terminal 31: input... or terminal 32: output...

Screen

33, 34 Terminal 33: input... or terminal 34: output...

Reset

+35

External alarm acknowledgement using switching

contact

-36

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

-

227

227

-

228

228

-

229

229

-

230

230

-

231

231

-

232

232

-

233

233

-

234

234

-

235

235

-

236

236

-

237

237

-

238

238

-

239

239

-

240

240

-

241

241

-

242

242

-

243

243

-

244

244

-

245

245

-

246

246

-

247

247

-

248

248

-

249

249

-

250

250

-

251

251

-

252

252

-

253

253

-

254

254

-

255

255

-

256

256

-

257

257

-

258

258

-

259

259

-

260

260

-

261

261

-

262

262

-

263

263

-

264

264

-

265

265

-

266

266

-

267

267

-

268

268

-

269

269

-

270

270

-

271

271

-

272

272

-

273

273

-

274

274

-

275

275

-

276

276

-

277

277

-

278

278

-

279

279

-

280

280

-

281

281

-

282

282

-

283

283

-

284

284

-

285

285

-

286

286

-

287

287

-

288

288

-

289

289

-

290

290

-

291

291

-

292

292

-

293

293

-

294

294

-

295

295

-

296

296

-

297

297

-

298

298

-

299

299

-

300

300

-

301

301

-

302

302

-

303

303

-

304

304

-

305

305

-

306

306

-

307

307

-

308

308

-

309

309

-

310

310

-

311

311

-

312

312

-

313

313

-

314

314

-

315

315

-

316

316

-

317

317

-

318

318

-

319

319

-

320

320

-

321

321

-

322

322

-

323

323

-

324

324

-

325

325

-

326

326

-

327

327

-

328

328

-

329

329

-

330

330

-

331

331

-

332

332

-

333

333

-

334

334

-

335

335

-

336

336

-

337

337

-

338

338

-

339

339

-

340

340

-

341

341

-

342

342

-

343

343

-

344

344

-

345

345

-

346

346

-

347

347

-

348

348

-

349

349

-

350

350

-

351

351

-

352

352

-

353

353

-

354

354

-

355

355

-

356

356

-

357

357

-

358

358

-

359

359

-

360

360

-

361

361

-

362

362

-

363

363

-

364

364

-

365

365

-

366

366

-

367

367

-

368

368

-

369

369

-

370

370

-

371

371

-

372

372

-

373

373

-

374

374

-

375

375

-

376

376

-

377

377

-

378

378

-

379

379

-

380

380

-

381

381

-

382

382

-

383

383

-

384

384

-

385

385

-

386

386

-

387

387

-

388

388

-

389

389

-

390

390

-

391

391

-

392

392

-

393

393

-

394

394

-

395

395

-

396

396

-

397

397

-

398

398

-

399

399

-

400

400

-

401

401

-

402

402

-

403

403

-

404

404

-

405

405

-

406

406

-

407

407

-

408

408

-

409

409

-

410

410

-

411

411

-

412

412

-

413

413

-

414

414

-

415

415

-

416

416

-

417

417

-

418

418

-

419

419

-

420

420

-

421

421

-

422

422

-

423

423

-

424

424

-

425

425

-

426

426

-

427

427

-

428

428

-

429

429

-

430

430

-

431

431

-

432

432

-

433

433

-

434

434

-

435

435

-

436

436

-

437

437

-

438

438

-

439

439

-

440

440

-

441

441

-

442

442

-

443

443

-

444

444

-

445

445

-

446

446

-

447

447

-

448

448

-

449

449

-

450

450

-

451

451

-

452

452

-

453

453

-

454

454

-

455

455

-

456

456

-

457

457

-

458

458

-

459

459

-

460

460

-

461

461

-

462

462

-

463

463

-

464

464

-

465

465

-

466

466

-

467

467

-

468

468

-

469

469

-

470

470

-

471

471

-

472

472

-

473

473

-

474

474

-

475

475

-

476

476

-

477

477

-

478

478

-

479