SAFETY 1

Safety Precautions 1

FCC Notice (for U.S. Customers) 2

Industry Canada Compliance 2

SÉCURITÉ 3

Consignes de sécurité 3

Conformité aux normes d’Industrie Canada 4

INTRODUCTION 5

Technical Specifications 5

Getting to Know Your Sparx Sharpener 6

What’s In the Box? 7

Grinding Ring Life Indicator Behavior 9

SETUP 11

Assembling the Sharpener 11

Alignment 12

OPERATION 15

Loading a Skate 15

Adjusting the Grinding Ring Height 16

Selecting the Number of Cycles 17

Sharpening skates 18

Unloading a Skate 18

Edge Deburring 19

Powering O 19

Goalie Skates 19

Youth Skates 20

Sharpening New Steel 21

TROUBLESHOOTING 23

Error Types 23

User Interface Prompts 24

Error Codes 25

MAINTENANCE 27

Removing and Emptying the Dust Tray 27

Replacing the Air Filter 27

Traveling with the Sharpener 28

WARRANTY 31

SAFETY 1

SAFETY PRECAUTIONS

1. Before operating the Sparx™ Skate Sharpener, you should

familiarize yourself with the product and read and understand all

applicable instructions and warnings in this manual.

2. Use personal protective equipment. Always wear eye protection

and a dust mask while operating the sharpener.

3. For emergencies: press the n Cancel Button two times. This will

stop the Grinding Ring in its place. Do not stop the Grinding Ring

unless it is an emergency, as this may damage the skate blade.

4. We do not recommend that children under 13 years of age be

permitted to use the Sparx™ Skate Sharpener.

5. The Sparx™ Skate Sharpener is not intended for use by persons

(including children 13 years and over) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning

use of the Skate Sharpener by a qualified adult.

6. Children should be supervised to ensure that they do not play

with the Sparx™ Skate Sharpener.

7. The Sparx™ Skate Sharpener may only be used for sharpening skates.

8. Only Sparx™ Grinding Rings may be used with this machine.

9. Set up the product securely on a stable surface and in a protected

location. It must be placed where no one can step on or trip over

the Power Cord and where the Power Cord cannot be damaged.

10. Always use the Sparx™ Skate Sharpener in a dry, well-lit and non-

condensing environment. To avoid the risk of electric shock, do not

use the Sparx™ Skate Sharpener in wet or damp conditions.

11. To avoid injury, always use caution when operating the Sparx™

Skate Sharpener or when changing the Grinding Ring.

12. Do not attempt to touch the Grinding Ring, Carriage, or Skate

Clamp while the Grinding Ring is moving. Wait for the Carriage and

Grinding Ring to come to a complete stop before attempting any

adjustments or Grinding Ring replacement.

13. Make sure that the Thumb Nut is tightened down onto the

Grinding Ring before starting any grinding operation

14. Do not leave the Sparx™ Skate Sharpener running unattended.

15. Never disconnect the Power Cord by pulling the wire to

disconnect it from the socket.

16. Store the Sparx™ Skate Sharpener in a dry place, out of the reach

of children.

17. Maintain the sharpener according to the Maintenance section of

this manual. Emptying the Dust Tray and Replacing the Air Filter, at

specified intervals, are necessary steps for performance and safety.

18. If at any time the product does not operate normally, see the

Troubleshooting section of this manual.

19. There are no user-serviceable parts on the sharpener. The

sharpener should only be repaired by a professional Sparx™ Hockey

technician, using only original spare parts. Unauthorized repairs

could lead to hazardous conditions for the user and/or void the

warranty.

20. For any further questions about the sharpener, please contact

Sparx™ Hockey Support at 1-855-SPARXHQ (1-855-772-7947) or by

email at help@sparxhockey.com.

Warning: Please see the manual for operating instructions.

Caution: Pinch point hazard. Keep hands, hair and other body parts

clear of the Skate Clamp area.

1

SAFETY

SAFETY2

FCC NOTICE

(FOR U.S. CUSTOMERS)

This device complies with Part 15 of the FCC Rules:

Operation is subject to the following conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, Including

interference that may cause undesired operation

Changes and Modifications not expressly approved by Velasa

Sports, Inc. can void your authority to operate this equipment under

Federal Communications Commissions rules.

INDUSTRY CANADA

COMPLIANCE

This device complies with Industry Canada license-exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause

undesired operation of the device.

SÉCURITÉ 3

CONSIGNES DE SÉCURITÉ

1. Avant d’utiliser l’aûteuse de patins SparxMC, vous devez vous

familiariser avec le produit et lire et comprendre toutes les

instructions et mises en garde dans ce manuel.

2. Portez un équipement de protection individuelle. Portez toujours

des lunettes de sécurité et un masque anti-poussières lorsque vous

utilisez l’aûteuse de patins.

3. En cas d’urgence : appuyez deux fois de suite sur le bouton

n Annuler (Cancel). Ceci immobilise immédiatement la meule

d’aûtage. N’arrêtez la meule d’aûtage qu’en cas d’urgence, car

cela pourrait endommager la lame du patin.

4. Il n’est pas recommandé que les enfants de moins de 13 ans soient

autorisés à utiliser l’aûteuse de patins SparxMC.

5. L’aûteuse de patins SparxMC ne doit pas être utilisée par des

personnes (y compris des enfants de 13 ans et plus) ayant des

capacités physiques, sensorielles ou mentales réduites, ou un

manque d’expérience et de connaissances, à moins qu’elles

soient surveillées ou qu’elles aient reçu une bonne formation sur

l’utilisation de l’aûteuse par un adulte compétent.

6. Les enfants doivent être surveillés pour s’assurer qu’ils ne jouent

pas avec l’aûteuse de patins SparxMC.

7. L’aûteuse de patins SparxMC doit être utilisée exclusivement pour

l’aûtage de patins.

8. La machine doit être utilisée exclusivement avec des meules

d’aûtage SparxMC.

9. Pour assurer la sécurité de tout le monde, installez la machine

sur une surface stable et dans un endroit protégé. Elle doit être

placée dans un endroit où il n’y a aucun risque que quelqu’un puisse

marcher ou trébucher sur le cordon d’alimentation ou le cordon

d’alimentation puisse être endommagé.

10. Utilisez l’aûteuse de patins SparxMC toujours dans un

environnement sec, bien éclairé, et sans condensation. Pour éviter

tout risque de décharge électrique, n’utilisez jamais l’aûteuse de

patins SparxMC dans des conditions humides ou mouillées.

11. Pour éviter les blessures, soyez toujours prudent lors

de l’utilisation de l’aûteuse de patins SparxMC, ou lors du

remplacement de la meule d’aûtage.

12. N’essayez pas de toucher la meule d’aûtage, le guide-meule

mobile ou la pince de serrage pendant la rotation et le mouvement

de la meule. Attendez l’arrêt complet du guide-meule et de la meule

d’aûtage avant de tenter un réglage ou le remplacement de la meule.

13. Assurez-vous que l’écrou à ailettes est serré sur la meule

d’aûtage avant de commencer l’aûtage

14. Ne laissez jamais l’aûteuse de patins SparxMC sans surveillance

pendant qu’elle est en marche.

15. Ne débranchez jamais le cordon d’alimentation en tirant sur le

cordon.

16. Rangez l’aûteuse de patins SparxMC dans un endroit sec, hors de

la portée des enfants.

17. Faites l’entretien de l’aûteuse selon les consignes de ce manuel.

Le vidage du bac à poussière et le remplacement du filtre à air, à des

intervalles déterminés, sont des étapes nécessaires à la performance

et à la sécurité.

18. Si, à tout moment, la machine cesse de fonctionner normalement,

consultez la section Diagnostic des pannes de ce manuel.

19. L’aûteuse ne comporte aucune pièce réparable par l’utilisateur.

Elle ne doit être réparée que par un technicien professionnel SparxMC

Hockey, exclusivement avec des pièces de rechange d’origine.

Les réparations non autorisées pourraient créer des conditions

dangereuses pour l’utilisateur ou annuler la garantie.

20. Pour toute question au sujet de l’aûteuse, veuillez communiquer

avec le service technique de SparxMC Hockey au (855-772-7947) ou

par courriel à help@sparxhockey.com.

Mise en garde : Veuillez consulter les instructions dans le manuel.

Attention : Danger de pincement. Gardez les mains, les cheveux et

d’autres parties du corps à l’écart de la zone de la pince de serrage.

1

SÉCURITÉ

SÉCURITÉ4

CONFORMITÉ AUX NORMES

D’INDUSTRIE CANADA

Le présent appareil est conforme aux CNR d’Industrie Canada

applicables aux appareils radio exempts de licence. L’exploitation

est autorisée aux deux conditions suivantes : (1) l’appareil ne doit

pas produire de brouillage, et (2) l’utilisateur de l’appareil doit

accepter tout brouillage radioélectrique subi, même si le brouillage

est susceptible d’en compromettre le fonctionnement.

INTRODUCTION 5

SK ATE COMPATIBILIT Y

Hockey Skates

Goalie Skates

Figure Skates*

*Requires an additional adapter, which is sold separately.

DIMENSIONS AND WEIGHT

Width: 26.8 Inches / 680 mm

Height: 7.6 Inches / 194 mm

Depth: 15.5 Inches / 390 mm

Weight: 38.5 Pounds / 17.5 kg

ELECTRICAL

Line Voltage: 100–240 Volts AC (50–60 Hz single phase)

Maximum Power Consumption: 200 W

INTRODUCTION

2

TECHNICAL SPECIFICATIONS

INTRODUCTION6

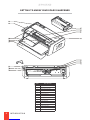

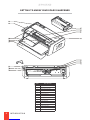

PART DESCRIPTION

AKeypad

BClamp Lever

CProtective Slot Covers

DDust Tray

EGlass Door

FTravel Screw Slot

GLever Dock

HCarriage

JAlignment Adjustment Knob

KPower Input Port

LAir Filter

MSkate Clamp

NGrinding Ring Shaft

PHeight Adjustment Knob

QThumb Nut

A

B

C

K

N

G

F

D

L

P

H

E

M

Q

J

GETTING TO KNOW YOUR SPARX SHARPENER

INTRODUCTION8

PART BUTTON DESCRIPTION

APlay Initiates the sharpening.

BCycle Counter

• Shows the current number of cycles selected.

• Shows error codes.

CGrinding Ring Life Indicator Indicates Grinding Ring life status. See Grinding Ring

Life Indicator Behavior table on page 13.

DCancel / Error

• Push 1 time to stop the Carriage at the conclusion of

the current pass.

• Push 2 times for emergency stop, motor stops

immediately.

• When illuminated red, the sharpener is in an error

state, see Troubleshooting section of manual.

EMinus Cycles / Move Left

• Subtracts cycles from the Cycle Counter.

• If in Move Mode, moves Carriage to the left.

FAdd Cycles / Move Right

• Adds cycles from the Cycle Counter.

• If in Move Mode, moves Carriage to the right.

GMove Initiates Move Mode.

HAlignment Initiates Alignment Mode.

JAir Filter Indicates replacement needed.

A

JF HE GD

B C

INTRODUCTION 9

ICON ACTION DESCRIPTION

Circle is white and steady. The Grinding Ring has more than 10% of life

remaining.

Circle is white and pulsing.

Grinding Ring has less than 10% of life remaining.

We Recommend that the user order a replacement

Grinding Ring by visiting www.sparxhockey.com.

Circle is white and blinking. User has attempted to start Alignment Mode while a

Grinding Ring is installed.

Circle is red and steady. No Grinding Ring installed.

Circle is red and pulsing.

During sharpening, the Grinding Ring has less than

10% of life remaining. We Recommend that the user

order a replacement Grinding Ring by visiting www.

sparxhockey.com.

Circle is red and blinking. Grinding Ring is Empty.

Circle half red/half white - alternate

blinking.

User has attempted to sharpen with a cycle count

greater than the number of cycles remaining on the

Grinding Ring.

GRINDING RING LIFE

INDICATOR BEHAVIOR

In normal operation, each part of the Grinding Ring Life Indicator corresponds to 10% of the

Grinding Ring’s life. These parts are the one circle and the nine bars to the right (10 parts

total or 100%). The circle represents the final 10% of Grinding Ring life and each bar to the

right is an additional 10%. When a part is illuminated, that corresponding 10% life is present

on the Grinding Ring. When the part is no longer illuminated that amount of the wheel life

has been consumed.

The circle of the Grinding Ring Life Indicator can also behave in other ways to indicate

dierent operating conditions to the user. Refer to the table below for more information.

3

SETUP 11

SETUP

ASSEMBLING THE SHARPENER

To watch the How-To video, visit sparxhockey.com/assembly.

1 INSTALL THE CLAMP LEVER

Slide the Clamp Lever (A) onto the Lever Dock (B). Press the

lever down until it clicks into place. When the Clamp Lever is

engaged, it will lay at a slight angle.

2 REMOVE THE TRAVEL GUARD

Open the Skate Clamp by pressing and holding down the

Clamp Lever. Remove the Travel Guard. Release the Clamp Lever.

A

B

1

2

3 REMOVE THE TRAVEL SCREW

Remove the Travel Screw (A) by turning counter-clockwise until

loose.

4 STORING THE TRAVEL SCREW

Install the Travel Screw into the storage location on the Travel

Guard (A) by turning clockwise until hand-tight. Do not

over-tighten.

A

A

Transporting or moving the Sharpener without the

Travel Guard & Travel Screw installed voids your

Warranty and/or Extended Service Plan. Always

remove the Travel Guard & Travel Screw before

operating the Sparx Sharpener.

SETUP12

towards the user) into the Skate Clamp. Place the Optical

Alignment Tool into the slot and let it fall into place. Release

the Clamp Lever.

3 INITIATE ALIGNMENT MODE

Press the c Alignment Button to send the Carriage to its

alignment position. When the Carriage is in place, a tone will

sound and the case will illuminate white.

4 LOCATE THE TAB AND GROOVE

Look through the eyepiece of the Optical Alignment Tool and

locate the indicator tab (A) of the Optical Alignment Tool and

the groove (B) on the Alignment Ring.

AB

5 PLUG IN THE POWER CORD

Plug the Power Cord into the Power Input Port on the back of

the sharpener. Plug the other end into a wall outlet. Toggle the

switch on the Power Input Port to the on position (I=on, 0=o).

ALIGNMENT

To watch the How-To video, visit sparxhockey.com/alignment.

The Alignment process is required when you first receive

your Sparx™ Sharpener and also after every time the

sharpener is moved and/or travels.

1 INSTALL THE ALIGNMENT RING

Open the Glass Door. The Carriage will automatically move into

the install position, and the sharpener will play a “ready” tone.

While holding the Grinding Ring Shaft (C), unscrew the Thumb

Nut (A). Slide the Alignment Ring (B) onto the Grinding Ring

Shaft (C), with the label facing out. Replace and tighten the

Thumb Nut until hand-tight. Close the Glass Door.

2 INSTALL THE OPTICAL ALIGNMENT TOOL

Press down on the Clamp Lever to open the Skate Clamp.

Place the Optical Alignment Tool (with Sparx™ logo facing

A

A

B

C

SETUP 13

Alignment Ring (right) lines up with the indicator tab of the

Alignment Tool (left), as shown in step 5. Close the Glass Door

when aligned.

8 END ALIGNMENT MODE

End Alignment Mode by pressing the c Alignment Button.

9 REMOVE THE OPTICAL ALIGNMENT TOOL

Press down on the Clamp Lever to open the Skate Clamp.

Remove the Optical Alignment Tool.

10 REMOVE THE ALIGNMENT RING

Open the Glass Door. The Carriage will automatically move into

the install position and the sharpener will play a “ready” tone.

While holding the Grinding Ring Shaft, unscrew the Thumb Nut

and remove the Alignment Ring.

11 INSTALL THE GRINDING RING

While holding the Grinding Ring Shaft (C), slide the Grinding

Ring (B) on the Grinding Ring Shaft (C), label facing out, and

replace and tighten the Thumb Nut (A) until hand-tight. Close

the Glass Door.

5 INSPECT THE ALIGNMENT

If the indicator tab of the Alignment Tool is not aligned with

the groove on the Alignment Ring (as shown below), move to

step 6.

If the indicator tab of the Alignment Tool is aligned with the

groove on the Alignment Ring (as shown below) skip to step 8.

6 LOCATE THE ALIGNMENT

ADJUSTMENT KNOB

Open the Glass Door and locate the gray y Alignment

Adjustment Knob (A) inside of the sharpener.

7 ADJUST THE ALIGNMENT

While looking through the Optical Alignment Tool, turn the

Alignment Adjustment Knob until the groove on the

A

A

B

C

OPERATION 15

4

OPERATION

We recommend inserting the skate into the Skate Clamp

with the toe pointing to the right. For most skate blades, this

orientation allows for the greatest flexibility in Grinding Ring

height adjustment. It is, however, acceptable to insert the

skate with the toe facing in either direction.

LOADING A SKATE

*For loading goalie skates and youth skates,

see the end of this section.

To watch the How-To video, visit sparxhockey.com/loadskate.

1 LOAD THE SKATE

Press and hold down the Clamp Lever to open the Skate Clamp.

With the skate toe pointing right and the laces tucked into the

skate, set the skate into the Skate Clamp slot letting the plastic

blade holder rest on top of the clamps. Center the skate blade

in the Skate Clamps. Release the Clamp Lever.

2 CLOSE THE PROTECTIVE SLOT COVERS

Move each Protective Slot Cover (A) in toward the

skate until they touch the blade holder and the Safety

Lights (B) extinguish.

B B

A

OPERATION16

ADJUSTING THE GRINDING

RING HEIGHT

To watch the How-To video, visit sparxhockey.com/ringheight.

For every pair of skates sharpened, you must assess

the height of the Grinding Ring and adjust if necessary.

We will first introduce a few new concepts, and then move into the

actual adjustment. We want to first define an intersection zone,

where the vertical face of the blade (B) meets the nearly horizontal

face of the blade (C).

This zone can be a curved section of blade (A) like that shown in the

figure below or in some cases, it can be a point where surfaces (B)

and (C) meet.

When the intersection zone is a curved surface (A as shown above)

the Grinding Ring can safely initially contact the blade anywhere in

this region (A).

A

B

C

When the intersection zone is a point, which is more common with

skates that have been sharpened multiples times (A as shown above),

the first contact between the Grinding Ring and the blade should be

just below the point.

A

B

C

1 INITIATE MOVE MODE

Press the m Move Button on the Keypad. This will set the

Grinding Ring into Move Mode and allow you to control

its movement.

2 INSPECT THE CONTACT POINT

Use the l Left and r Right Buttons to touch the Grinding

Ring to the skate blade. Inspect its contact point and be sure it

is in the desired position. In the graphic below you will see an

example of a contact point that is too high (B) and too low (C).

A Grinding Ring contacting in the right zone is shown below as

A. If the Grinding Ring is not in a desired position, follow step 3.

If the Grinding Ring is in a desired position, skip to step 6.

If the skate blade is worn down the graphic below shows a

contact point that is too low (B) and a Grinding Ring contacting

the blade at the proper point (A).

B

A

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

dans d''autres langues

- English: Sparx ES100 Operating instructions

Autres documents

-

Drill Master XP Manuel utilisateur

-

Drill Doctor 350x Manuel utilisateur

-

Drill Doctor XP Manuel utilisateur

Drill Doctor XP Manuel utilisateur

-

Drill Doctor XP2 Manuel utilisateur

Drill Doctor XP2 Manuel utilisateur

-

Drill Doctor 750X Manuel utilisateur

-

Dremel 675 Manuel utilisateur

-

Drill Doctor 360X Manuel utilisateur

Drill Doctor 360X Manuel utilisateur

-

Hobart 2812 ML-104959 Manuel utilisateur

-

Dremel 675 Manuel utilisateur