Tennant M-STRIVE Mode d'emploi

- Catégorie

- Machine à plancher

- Taper

- Mode d'emploi

FRANÇAISESPAÑOLENGLISH

MANUAL DEL OPERADOR

MANUEL OPÉRATEUR

OPERATOR MANUAL

DUAL TECHNOLOGY CARPET CLEANER

LIMPIADOR DE ALFOMBRAS DE TECNOLOGÍA DUAL

DISPOSITIF DE NETTOYAGE DE MOQUETTES DOUBLE TECHNOLOGIE

®

9003506

Rev. 00 (04-2007)

*9003506*

www.nobles.com

STRIVE

More than clean, it’s ReadySpace.

t

R

R

Home

Find...

Go To..

OPERATION

2Nobles Strive (04--07)

This manual is furnished with each new model.

It provides necessary operation and maintenance

instructions and an illustrated parts list.

Read this manual completely and understand the

machine before operating or servicing it.

A complete illustrated Parts Manual is also furnished

with each new model. Use the Parts Manual to order

replacement parts. To ensure prompt delivery, follow

the “HOW TO ORDER PARTS” instructions printed in

the Parts Manual.

This machine will provide excellent service. However,

the best results will be obtained at minimum costs if:

SThe machine is operated with reasonable care.

SThe machine is maintained regularly - per the

machine maintenance instructions provided.

SThe machine is maintained with manufacturer

supplied or equivalent parts.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials,

old machine components such as

batteries, hazardous fluids such as

antifreeze and oil, in a safe

environmentally way according to your

local waste disposal regulations.

Always remember to recycle.

Tennant Company

PO Box 1452

Minneapolis, MN 55440

Phone: (800) 553--8033 or (763) 513--2850

www.nobles.com

Nobles®and the Nobles logo are United States registered trademarks of

Tennant Company.

Specifications and parts are subject to change without notice.

Copyright E2007 Tennant Company. All rights reserved.

Printed in U.S.A.

MACHINE DATA

Please fill out at time of installation for future reference.

Model No.-

Install. Date -

Serial No.-

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 3

TABLE OF CONTENTS (ESPAÑOL....29) (FRANÇAIS....61)

SAFETY PRECAUTIONS 4....................

SAFETY LABELS 5...........................

MACHINE COMPONENTS 6...................

CONTROL CONSOLE SYMBOLS 7............

MACHINE INSTALLATION 8...................

UNCRATING MACHINE 8..................

INSTALLING BATTERIES 8................

DUAL CLEANING TECHNOLOGY 9............

HOW THE DUAL TECHNOLOGY WORKS 9.

MACHINE SETUP 10..........................

PREPARING MACHINE FOR READYSPACE

CLEANING 10.............................

PREPARING MACHINE FOR RESTORATIVE

EXTRACTION CLEANING 11................

FILLING SOLUTION TANK 12...............

ADJUSTING CONTROL CONSOLE

HEIGHT 12................................

MACHINE OPERATION 12.....................

PRE--OPERATION CHECKS 12..............

OPERATING MACHINE 12..................

WHILE OPERATING MACHINE 13...........

ACCESSORY TOOL CLEANING

(OPTION) 14..............................

OPERATING ACCESSORY TOOLS: 14.......

MACHINE CIRCUIT BREAKERS 15..........

HOUR METER 15..........................

DRAINING TANKS 16..........................

CHARGING BATTERIES 16....................

MACHINE MAINTENANCE 17..................

DAILY MAINTENANCE 17...................

WEEKLY MAINTENANCE 18................

MONTHLY MAINTENANCE 19...............

MOTOR MAINTENANCE 21.................

BATTERY MAINTENANCE 21...............

PRIMING SOLUTION SYSTEM 22...........

MACHINE JACKING 22........................

TRANSPORTING MACHINE 22.................

STORING MACHINE 23........................

RECOMMENDED STOCK ITEMS 23.............

TROUBLESHOOTING 24.......................

MACHINE SPECIFICATIONS 26................

MACHINE DIMENSIONS 26....................

SOLUTION FLOW DIAGRAM

(AFTER SERIAL NUMBER 10314332) 27........

SOLUTION FLOW DIAGRAM

(BEFORE SERIAL NUMBER 10314332) 28......

Home

Find...

Go To..

OPERATION

4Nobles Strive (04--07)

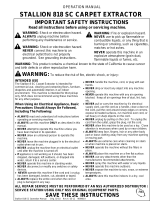

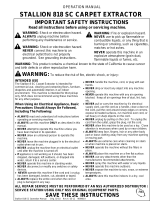

SAFETY PRECAUTIONS

This machine is intended for commercial use. It is

designed exclusively to clean carpets and

upholstery in an indoor environment and is not

constructed for any other use. Only use

recommended accessory tools and commercially

available carpet cleaners intended for machine

application.

All operators must read, understand and practice

the following safety precautions.

The following warning alert symbol and the “FOR

SAFETY” heading are used throughout this manual as

indicated in their description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

Failure to follow these warnings may result in

personal injury, electrical shock, fire or explosion.

WARNING: Fire Or Explosion Hazard:

-- Do Not Use Flammable Liquids Or Operate

Machine In Or Near Flammable Liquids,

Vapors Or Combustible Dusts.

This machine is not equipped with explosion proof

motors. The electric motors will spark upon start

up and during operation which could cause a flash

fire or explosion if machine is used in an area

where flammable vapors/liquids or combustible

dusts are present.

-- Do Not Pick Up Flammable Materials Or

Reactive Metals.

-- Batteries Emit Hydrogen Gas. Keep Sparks

And Open Flame Away. Keep Battery

Compartment Open When Charging.

WARNING: Electrical Hazard. Disconnect

Battery Cables Before Servicing Machine.

WARNING: Pinch Point Hazard. Stay Clear Of

Scrub Head Lift Area.

The following information signals potentially

dangerous conditions to the operator or

equipment:

FOR SAFETY:

1. Do not operate machine:

-- With flammable liquids or near flammable

vapors as an explosion or flash fire may

occur.

-- Unless trained and authorized.

-- Unless operator manual is read and

understood.

-- If not in proper operating condition.

2. Before operating machine:

-- Make sure all safety devices are in place

and operate properly.

-- Place “wet floor” signs as needed.

3. When using machine:

-- Go slow on inclines and slippery surfaces.

-- Reduce speed when turning.

-- Report machine damage or faulty

operation immediately.

-- Never allow children to play on or around.

-- Follow mixing and handling instructions

on chemical containers.

4. Before leaving or servicing machine:

-- Stop on level surface.

-- Turn off machine.

-- Remove key.

5. When servicing machine:

-- Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

-- Disconnect battery connections before

working on machine.

-- Block machine tires before jacking up.

-- Jack machine up at designated locations

only. Block machine up with jack stands.

-- Use hoist or jack that will support the

weight of the machine.

-- Do not power spray or hose off machine.

Electrical malfunction may occur.

-- Wear protective gloves and eye protection

when handling batteries or battery cables.

-- Avoid contact with battery acid.

-- Use manufacturer supplied or approved

replacement parts.

-- All repairs must be performed by a

qualified service person.

-- Do not modify the machine from its

original design.

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 5

6. When transporting machine:

-- Turn machine off.

-- Use a recommended ramp when

loading/unloading on/off truck or trailer.

-- Lower scrub head.

-- Place blocks behind wheels and use

tie--down straps to secure machine.

SAFETY LABELS

The safety labels appear on the machine in the locations indicated. Replace labels if they are missing or become

damaged or illegible.

WARNING LABEL -- Located on recovery tank lid.

BATTERY CHARGE LABEL --

Located on bottom side of recovery tank.

WARNING: Fire Or Explosion

Hazard. Batteries Emit Hydrogen

Gas. Keep Sparks And Open Flame

Away. Keep battery Compartment

Open When Charging.

PINCH POINT HAZARD LABEL --

Located on scrub head shroud and near the

scrub head lift actuator.

WARNING: Pinch Point Hazard.

Stay Away Of Scrub Head Lift Area.

Home

Find...

Go To..

OPERATION

6Nobles Strive (04--07)

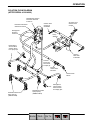

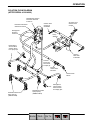

MACHINE COMPONENTS

210

1

13

5

4

6

3

89

12

20

27

23

24

22

7

21

19 14

18 17

16 15

34

31

30

28

35

29

33

25, 26

11

32

1. Control Grips

2. Control Console

3. Speed Control Knob

4. Battery Meter

5. Main Power Indicator Light

6. Scrub Head Lift/Lower Switch

7. Bottle Holder

8. Brush Pressure Meter

9. Brush Pressure Switch

10. Control Console Height Adjustment Lever

11. Solution On/Off Switch

12. Circuit Breaker Panel

13. Main Power Key Switch

14. Solution Tank Sight Gauge

15. Recovery Tank Drain Hose

16. Accessory Tool Vacuum Hose Connector

17. Accessory Tool Solution Hose Coupler

18. Solution Tank Filter

19. Solution Tank Drain Hose

20. Solution Tank Rear Fill Port

21. Solution Tank Front Fill Port

22. Solution Tank

23. Recovery Tank

24. Recovery Tank Lid

25. Battery Charge Receptacle

26. Hour Meter

27. Battery Compartment

28. ReadySpace Rollers

29. ReadySpace Pre--Treatment Detergent

30. ReadySpace Vacuum Shoe (2 supplied)

31. Extractor Vacuum Shoe

32. ReadySpace Flush Line (2)

33. Scrub Head

34. Spray Tip Bumper

35. Extractor Brushes

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 7

CONTROL CONSOLE SYMBOLS

Main Power

Indicator Light Main Power 10A

Circuit Breaker

Battery Meter

Slow Speed Brush Motor

17A Circuit Breaker

Brush Motor

17A Circuit Breaker

Off--Aisle Wand

(Accessory Tool)

Drive Motor 20A

Circuit Breaker

Fast Speed

Scrub Head Lift/

Transport Position

Scrub Head Lower/

Cleaning Position

Brush Pressure

Solution Flow

Home

Find...

Go To..

OPERATION

8Nobles Strive (04--07)

MACHINE INSTALLATION

UNCRATING MACHINE

1. Carefully check shipping crate for signs of

damage. Report damages at once to carrier.

2. Check the contents list, contact distributor for

missing items.

Contents:

DMachine

D2 Extractor Brushes

D2 ReadySpace Rollers

D1 Extractor Vacuum Shoe

D2 ReadySpace Vacuum Shoes (installed)

D2 Scrub Head Flush Lines (installed)

DScrub Head Vacuum Tube (Installed)

DReadySpace Pre-Treatment detergent (1 gal.)

D24DC/120AC 20A Battery Charger (Option)

D4 6VDC, 235AH Batteries (Option -- Installed)

DBattery Tray (installed)

D3 381mm (15”) Battery Cables

D8 Battery Post Covers

D8 Battery Cable Rubber Boots

D6mm Hex Head Tool

DOperator Training CD (#1019260)

3. To uncrate the machine, remove the shipping

hardware and straps that secure the machine to

the pallet. Use the attached ramp and carefully

back the machine off the pallet. Make sure the

scrub head is in the raised position.

ATTENTION: Use the supplied ramp when

uncrating the machine to prevent machine

damage.

INSTALLING BATTERIES

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Hood Open When

Charging.

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries and battery cables. Avoid

contact with battery acid.

Recommended Battery Specifications:

Four 6 volt, deep cycle, 235 AH batteries. Maximum

battery dimensions are 181 mm (7.13 in) W x 260 mm

(10.25 in) L x 292 mm (11.50 in) H.

1. Park the machine on a level surface and remove

the key from the machine.

2. Lift the recovery tank to access the battery

compartment (Figure 1). Remove the loose battery

cables from the compartment.

FIG. 1

3. Carefully install the batteries into the battery

compartment tray and arrange the battery posts

as shown (Figure 2).

Machine Front

5

RED

BLACK

3

12

4

Connect wire #47 from machine’s wire harness

FIG. 2

4. Before connecting the battery cables, make sure

the terminals and posts are clean. Use a post

cleaner and wire brush if necessary.

NOTE: Apply a light coating of non-metallic grease or

protective spray on the cable connections to prevent

battery corrosion.

5. Connect the cables to the battery posts in

numerical order as labeled (Figure 2), RED TO

POSITIVE & BLACK TO NEGATIVE. Use the

battery post covers and rubber boots supplied.

6. After installing the batteries, check the battery

meter charge level. The machine must be in full

operation for an accurate reading (See MACHINE

OPERATION). Charge batteries if needed.

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 9

DUAL CLEANING TECHNOLOGY

The machine offers two cleaning technologies,

Restorative Extraction and Soil Transfer Extraction

which is referred to as ReadySpace. By using both

technologies you can easily develop a cleaning

program to greatly extend the use-life of your carpet.

With the simple exchange of a vacuum shoe and two

rollers or brushes you can easily switch from one

technology to the other.

Restorative Extraction: Use this technology

periodically to thoroughly clean to the base of the

carpet. The amount and type of daily traffic are

important factors to determine how often restorative

extraction should be performed. This type of cleaning

should be planned in advance to allow enough time for

the extracted carpet to dry.

ReadySpace: Use this technology to clean visible

soils on a daily basis or as needed to maintain a high

level of carpet cleanliness. ReadySpace may be used

during normal business hours because often the

carpet is dry in less than 30 minutes. Drying time may

vary due to carpet type and climate conditions.

NOTE: Before using ReadySpace, first use restorative

extraction if carpets are heavily soiled. Then begin

your ReadySpace cleaning program.

HOW THE DUAL TECHNOLOGY WORKS

Restorative Extraction: Hot water and cleaning

detergent from the solution tank is sprayed directly

onto the carpet. As the machine moves forward, two

counter--rotating chevron brushes agitate the solution

deep into the carpet. As the machine continues to

move forward, the vacuum shoe recovers the dirty

solution out of the carpet.

Spray

Nozzles

Vacuum

Shoe

Brush #1 Brush #2

Machine Direction

ReadySpace: Cleaning detergent is pre--sprayed on

the carpet with the use of a pump--up sprayer. After

allowing the detergent to dwell for about 5--10 minutes,

the machine is then put to work. Hot water is sprayed

directly on two counter--rotating nylon fiber rollers, not

the carpet. Then much of the water is removed from

the rollers using two vacuum shoes, leaving the rollers

damp. The damp rollers then agitate the carpet,

working both sides of the carpet fiber, at the same

time transferring the soil to the rollers. Again, hot rinse

water is sprayed on the soiled rollers allowing the two

vacuum shoes to easily extract the soil from the

rollers.

Spray

Nozzles

Vacuum

Shoe #1 Vacuum

Shoe #2

Roller #1 Roller #2

Home

Find...

Go To..

OPERATION

10 Nobles Strive (04--07)

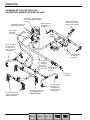

MACHINE SETUP

PREPARING MACHINE FOR READYSPACE CLEANING

Push the retainer tab

upward to engage the

solution flush line tip.

Step 4: Install

the ReadySpace

vacuum shoe. Use

the screws removed

from Step 2.

Connect the

vacuum hose and

the vacuum tube as

shown.

READYSPACE

VACUUM SHOE

Step 3: Install the two ReadySpace Rollers.

Step 1: Unlatch the idler plates and remove

the two extractor brushes if installed.

Step 2: Disconnect the vacuum hose and

remove the extractor vacuum shoe if installed.

6mm hex head tool required.

(2) 6mm SOCKET

HEAD CAP SCREWS

IDLER

PLATE

Equipment Needed:

1) Two ReadySpace Rollers

2) Rear ReadySpace

Vacuum Shoe

3) 6 mm Hex Head Tool

(supplied with machine)

1

2

3

Step 5: Connect the solution flush line to the vacuum shoe

(See DETAIL). Repeat for opposite side.

DETAIL

VACUUM

TUBE

SCRUB HEAD

FOR SAFETY: Before preparing machine,

turn machine off and remove key.

EXTRACTOR

VACUUM

SHOE

(2) 6mm SOCKET

HEAD CAP SCREWS

VACUUM HOSE

SOLUTION

FLUSH LINE

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 11

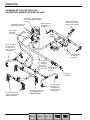

PREPARING MACHINE FOR RESTORATIVE EXTRACTION CLEANING

(2) 6mm SOCKET

HEAD CAP SCREWS

(2) 6mm SOCKET

HEAD CAP SCREWS

IDLER

PLATE

Equipment Needed:

1) Two Extractor Brushes

2) Extractor Vacuum Shoe

3) 6 mm Hex Head Tool

(supplied with machine)

3

Step 3: Disconnect the solution flush lines from the

rear vacuum shoe (See DETAIL A).

VACUUM

TUBE

SCRUB HEAD

FOR SAFETY: Before preparing machine,

turn machine off and remove key.

Step 1: Unlatch the idler plates and remove

the two ReadySpace rollers if installed.

Step 5: Install the two extractor

brushes (See DETAIL B).

Step 2:

Disconnect the

vacuum hose and

the vacuum tube

from the rear

ReadySpace

vacuum shoe if

installed.

Step 6: Install the extractor vacuum shoe.

Make sure that the shoe is positioned behind the

two support tabs. Use the screws removed from

Step 4. Connect the vacuum hose to the extractor

vacuum shoe as shown.

Step 4: Remove the ReadySpace vacuum shoe.

6 mm hex head tool required.

Push the retainer tab up-

ward to disengage the

solution flush line tip.

DETAIL A

SOLUTION

FLUSH LINE

NOTE:

“I” indicates idler plate end.

The brushes V--pattern

(chevron) should point

towards each other.

TOP VIEW

DETAIL B

EXTRACTOR

VACUUM

SHOE

2

1

READYSPACE

VACUUM SHOE

NOTE: To prevent misplacing,

DO NOT remove the disabled

solution flush lines and the

vacuum tube from the scrub head.

SUPPORT TABS (2)

IDLER

PLATE

Home

Find...

Go To..

OPERATION

12 Nobles Strive (04--07)

FILLING SOLUTION TANK

The machine may be filled from either the rear, using

the hose fill--port, or from the front using the bucket

fill--port (Figure 3).

NOTE: When filling solution tank with a bucket, make

sure that the bucket is clean. Do not use the same

bucket for filling and emptying the machine.

Fill the solution tank to the 75 liter mark with hot water,

60°C (140°F) maximum (Figure 3).

FOR RESTORATIVE EXTRACTION CLEANING:

Pour a recommended cleaning detergent into the

solution tank. Follow mixing instructions on the bottle.

FOR READYSPACE CLEANING: Do not add

extractor cleaning detergents into the solution tank.

Cleaning detergent must be pre--sprayed on the carpet

with the use of a pump--up sprayer.

75L

FIG. 3

ATTENTION: When using the machine for

restorative extraction cleaning, only use

recommended cleaning detergents in the solution

tank. Machine failure due to improper detergent

usage will void the manufacturer’s warranty.

WARNING: Fire or Explosion Hazard. Never

Use Flammable Liquids.

ADJUSTING CONTROL CONSOLE HEIGHT

Pull the console height adjustment lever and lift or

lower the console to a comfortable operating height.

Release lever to lock the position (Figure 4).

FIG. 4

MACHINE OPERATION

FOR SAFETY: Do not operate machine unless

operator manual is read and understood.

PRE--OPERATION CHECKS

NOTE: Refer to the Machine Maintenance section for

further details.

-Vacuum floor and remove any debris.

-Check battery meter charge level.

-ReadySpace Cleaning: Check rollers for wear.

-Inspect spray nozzles for proper spray pattern.

-ReadySpace Cleaning: Inspect roller vacuum shoes

for debris.

-Make sure recovery tank float shut--off screen is

clean.

-ReadySpace Cleaning: Make sure solution tank is

filled with only water, no cleaning detergents.

-Restorative Extraction Cleaning: Check spray

pressure at tips. Solution system may require

priming (See PRIMING SOLUTION SYSTEM).

OPERATING MACHINE

Before ReadySpace Cleaning, pre-spray the carpet

with the ReadySpace Pre-Treatment detergent

according to the directions on the bottle (Figure 5).

Allow the detergent to dwell for 5--10 minutes.

NOTE: The ReadySpace Pre--Treatment detergent is

specially formulated for ReadySpace Cleaning. Using

a pre--treatment detergent other than specified may

result in poor cleaning performance.

FIG. 5

1.Turnthekeyandthesolutionswitchtotheon(I)

position (Figure 6).

NOTE: Machines manufactured before serial number

10243221 are not equipped with the solution switch

upgrade. To install a solution on/off switch, order kit

part number 9001593.

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 13

FIG. 6

2. Lower the scrub head by pressing the scrub head

switch (Figure 7).

NOTE: If the machine is set up for ReadySpace

cleaning, a 20 second priming process will

automatically begin spraying solution when the scrub

head is lowered.

FIG. 7

3. To begin cleaning, rotate the control grips forward

and gradually turn the speed control knob to the

recommended cleaning speed (Figure 8).

ReadySpace Cleaning: 30m (100 ft.) per minute.

Restorative Extraction Cleaning: 15m (50 ft.) per

minute.

NOTE: The control grips activate the drive, brushes

and solution flow.

FIG. 8

To operate the machine in reverse, simply rotate

the control grips backwards. The machine will

continue to clean in reverse during ReadySpace

cleaning. This allows you to back clean over

heavily soiled areas, into corners and tight spaces.

When reversing during restorative extraction the

scrub head will raise and the cleaning stops.

4. Adjust the brush pressure meter. For best cleaning

results, adjust the brush pressure meter within the

green zone as shown below (Figure 9).

ATTENTION: Do not operate the machine with the

brush pressure meter in the red zone, circuit

breakers will trip.

For ReadySpace

For Restorative

Extraction

FIG. 9

5. To stop the machine, position the machine on a

level surface and gradually release the control

grips.

6. After restorative extraction cleaning, place air

movers in the area to reduce the drying time.

7. Perform the DAILY MACHINE MAINTENANCE

procedures.

WHILE OPERATING MACHINE

WARNING: Fire Or Explosion Hazard. Do Not

Pick Up Flammable Materials Or Reactive Metals.

1. Overlap each cleaning path by 50 mm (2 in).

2. Use a collapsing rectangle pattern when cleaning

large rooms (Figure 10).

FIG. 10

Home

Find...

Go To..

OPERATION

14 Nobles Strive (04--07)

3. Restorative Extraction Cleaning: Turn the solution

switch off when turning 180°and just before

coming to a stop. This will prevent un-recovered

solution on floor.

4. If excessive foam appears in the recovery tank,

pour a recommended foam control solution into

the tank.

ATTENTION: Do not allow foam to enter the float

shut-off screen, vacuum motor damage will result.

Foam will not activate the float shut-off screen.

5. Do not operate machine on inclines that exceed 3°

when cleaning or 11°while transporting.

FOR SAFETY: When using machine, go slow on

inclines and slippery surfaces.

6. Observe the battery meter discharge level

(Figure 11). When the meter begins to flash, stop

scrubbing and transport the machine to the

recharging area. When two lights begin to flash

alternately, the scrub head will automatically raise

to the transport position. This will protect the

batteries from total discharge. Recharge batteries

immediately.

FIG. 11

7. Observe the solution tank level (Figure 12). Do not

allow the solution tank to run dry when restorative

extraction cleaning. If tank runs dry, the solution

system will need to be reprimed (See PRIMING

SOLUTION SYSTEM).

FIG. 12

8. When leaving the machine unattended, park the

machine on a level surface and remove the key.

ACCESSORY TOOL CLEANING (OPTION)

Optional accessory tools allow you to clean upholstery

and carpeted areas that the machine is unable to reach,

such as alcoves, stairs, corners and small rooms.

Preparing Machine for Accessory Tool Cleaning:

1. Park the machine on a level surface and turn the

key to the off position.

2. Connect the accessory tool’s solution hose to the

coupler located at the rear of the machine

(Figure 13).

FIG. 13

3. Disconnect the lower vacuum hose from the

machine and replace it with the accessory tool’s

vacuum hose (Figure 14).

FIG. 14

4. Attach the accessory tool to the hoses.

Operating Accessory Tools:

1. Turn the key to the on ( I ) position.

2. Press the solution switch towards the accessory

tool symbol, off (O) position (Figure 15).

NOTE: To move the machine when using the

accessory tool, you must turn the solution switch on to

activate the drive system if the machine is set up for

ReadySpace Cleaning.

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 15

FIG. 15

3. Lower the scrub head to activate the vacuum

suction (Figure 16).

FIG. 16

4. Place the accessory tool on the area to be

cleaned. Squeeze the trigger on the accessory

tool and slowly pull the tool backwards while

applying downward pressure (Figure 17). Release

the trigger 6 inches from end of stroke. When

returning to the next stroke, push the tool forward

over the same path with trigger released. Continue

this pull and push method with a 50--100mm

(2--4 inch) overlap.

NOTE: When cleaning upholstery, always follow the

cleaning instructions sewn in the furniture by the

manufacturer.

WARNING: Fire Or Explosion Hazard. Do Not

Pick Up Flammable Materials Or Reactive Metals.

FIG. 17

5. After cleaning, relieve the water pressure from the

accessory tool before disconnecting the solution

hose. Squeeze trigger for five seconds after

turning the key off.

MACHINE CIRCUIT BREAKERS

The machine is equipped with four resettable circuit

breakers to protect the machine from damage. If a

circuit breaker should trip during operation, determine

the cause, allow motor to cool and then manually reset

the breaker button. The circuit breaker panel is located

at rear of machine (Figure 18).

10 Amp. Main Circuit Breaker

20 Amp. Drive Motor Circuit Breaker

17 Amp. Brush Motor Circuit Breaker #1

17 Amp. Brush Motor Circuit Breaker #2

FIG. 18

Each vacuum motor is protected with a 30 amp fuse.

The fuses are located in the wire harness that is

connected to each vacuum motor. When replacing a

fuse never substitute a higher amp rated fuse than

specified (Part No. 768688 -- Fuse, 30AMP).

FOR SAFETY: When servicing machine, all repairs

must be performed by a qualified service person.

HOUR METER

The hour meter records the number of total hours the

brush motors have been powered on. Use the hour

meter to determine when to perform recommended

maintenance procedures and to record service history

(Figure 19).

FIG. 19

Home

Find...

Go To..

OPERATION

16 Nobles Strive (04--07)

DRAINING TANKS

Drain and rinse out the tanks after every use. Janitor

closets with floor sinks are best suited for waste water

disposal. Use a five gallon bucket if floor sink is

unavailable.

1. Raise the scrub head to the transport position and

transport the machine to draining site. Turn the

key to the off position.

2. Remove the drain hose cap and slowly lower the

hose over the drain site (Figure 20). Lift the hose

to stop the flow. The recovery tank drain hose is

located on the right side and the solution tank

drain hose is located on the left side.

Recovery

Tank

Hose

Solution

Tank Hose

FIG. 20

NOTE: When using a bucket to drain the recovery

tank, do not use the same bucket to fill the solution

tank.

3. Rinse out the recovery tank and the float shut-off

screen with clean water (Figure 21).

FIG. 21

4. Replace the drain hose caps securely after

draining.

CHARGING BATTERIES

ATTENTION: To prolong the life of the batteries

and to provide optimum machine performance,

ONLY recharge the batteries after a total of 30

minutes of use or more. Do not leave batteries

discharged for lengthy periods.

BATTERY METER: When the battery meter begins to

flash, stop scrubbing and recharge batteries. When

two lights begin to flash alternately, the scrub head will

automatically raise to the transport position. This will

protect the batteries from total discharge.

The following charging instructions are intended for

battery chargers supplied with the machine. Only use

a battery charger with the following specifications to

prevent battery damage.

BATTERY CHARGER SPECIFICATIONS:

SOUTPUT VOLTAGE - 24 VOLTS

SOUTPUT CURRENT - 20 AMPS

SAUTOMATIC SHUTOFF CIRCUIT

SFOR DEEP CYCLE BATTERY CHARGING

1. Transport the machine to a well--ventilated area

for charging.

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

2. Park the machine on a level surface and turn the

key off.

3. Before charging the batteries, periodically check the

electrolyte level in each battery cell (Figure 22).

The electrolyte level (A) should slightly cover the

battery plates (B). Add distilled water as needed.

DO NOT OVERFILL, the fluid may expand and

overflow while charging. Replace cell caps before

charging (Figure 22).

A

B

FIG. 22

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 17

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling batteries and battery cables. Avoid

contact with battery acid.

4. Connect the charger’s AC power supply cord to a

properly grounded receptacle.

5. Connect the charger’s DC cord to the machine’s

battery receptacle located under the recovery tank

(Figure 23). Rest the recovery tank on the support

stand to promote ventilation during charging.

FIG. 23

6. The charger will automatically begin charging and

shut off when fully charged.

NOTE: The machine will not operate once the battery

charger is connected.

ATTENTION: Do not disconnect the charger’s DC

cord from the machine’s receptacle when the

charger is operating. Arcing may result. If the

charger must be interrupted during charging,

disconnect the AC power supply cord first.

WARNING: Fire Or Explosion Hazard.

Batteries Emit Hydrogen Gas. Keep Sparks And

Open Flame Away. Keep Battery Compartment

Open When Charging.

7. After charging, check the electrolyte level (A)

again. The level should be approximately 1 cm

(3/8”) from the bottom of the fill--port (B) (Figure

24). Add distilled water if needed. DO NOT

OVERFILL.

A

B

FIG. 24

MACHINE MAINTENANCE

To keep the machine in good working condition, simply

follow the daily, weekly and monthly maintenance

procedures.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface and turn off

machine.

WARNING: Electrical Hazard. Disconnect

Battery Cables Before Servicing Machine.

ATTENTION: Contact an Authorized Service

Center for machine repairs. Machine repairs

performed by other than an authorized person will

void your warranty.

DAILY MAINTENANCE

(After Every Use)

1. Drain and rinse out the recovery tank (Figure 25).

FIG. 25

2. Rinse off the float shut-off screen located in

recovery tank (Figure 26).

FIG. 26

3. Drain and rinse out the solution tank.

Home

Find...

Go To..

OPERATION

18 Nobles Strive (04--07)

4. ReadySpace Cleaning: Remove the splash shroud

and inspect the rollers for wear. If the gap between

the two rollers is greater than 4mm (5/32”) replace

the rollers (Figure 27). Always replace rollers as

aset.

Replace rollers

if gap is greater

than shown.

GAP

Splash

Shroud

FIG. 27

5. Clean the machine housing with an all purpose

cleaner and damp cloth (Figure 28).

FOR SAFETY: When servicing machine, do not

power spray or hose off machine. Electrical

malfunction may occur.

FIG. 28

6. Recharge the batteries (Figure 29). See

CHARGING BATTERIES.

NOTE: To prolong the battery life, ONLY recharge the

batteries after a total of 30 minutes of use or more.

FIG. 29

WEEKLY MAINTENANCE

(Every10HoursofUse)

1. Flip the ReadySpace rollers end-for-end every 10

hours of use (Figure 30). The roller life is rated for

at least 100 hours of use under normal cleaning

conditions. If the gap between the two rollers is

greater than 4mm (5/32”) replace the rollers.

FIG. 30

2. Remove any debris build--up from the underside of

the scrub head (Figure 31).

FIG. 31

3. Remove the front and rear roller vacuum shoe

covers and remove any debris (Figure 32).

FIG. 32

4. Remove any entangled carpet fibers and debris

from the brushes (Figure 33). Replace brushes if

worn. To determine when to replace worn brushes

observe the brush pressure meter.

Home

Find...

Go To..

OPERATION

Nobles Strive (04--07) 19

If unable to adjust the pressure into the green

zone this may be a good indication that the

brushes should be replaced.

FIG. 33

5. Remove any debris lodged in the carpet extraction

vacuum shoe (Figure 34).

FIG. 34

6. Inspect the spray tips for proper spray pattern

(Figure 35). If spray pattern is obstructed, clean or

replace the spray tips (See MONTHLY

MAINTENANCE).

ReadySpace

SprayTips(2)

Restorative Extraction

SprayTips(2)

FIG. 35

MONTHLY MAINTENANCE

(Every80HoursofUse)

1. Remove the solution tank filter from underneath

the machine and rinse out the screens. Make sure

the solution tank is empty before removing filter

(Figure 36).

FIG. 36

2. Flush the plumbing system with an approved

acetic acid solution to dissolve normal alkaline

buildup. Follow procedure below:

a. Remove rollers/brushes from the machine.

b. Pour 11 liters (3 gal) of hot water into the

solution tank, do not exceed 60°C (140°F).

c. Add the acetic acid solution according to the

mixing directions on the bottle.

FOR SAFETY: When using machine, follow mixing

and handling instructions on chemical containers.

d. Place the machine in an area with a floor drain.

e. Block the wheels and turn the speed control

knob to slowest setting.

f. Operate both cleaning technologies for one

minute each over the floor drain.

NOTE: Rear vacuum shoe exchange is

required to operate both ReadySpace and

Restorative Extraction cleaning technologies.

g. Turn the key off and let the machine set

overnight to allow the acetic acid solution to

breakdown the alkaline buildup.

h. Next day, disperse the remaining acetic acid

solution and rinse the solution system with 11

liters (3 gal) of clean water.

3. Remove the four quick--release spray tips from the

scrub head (Figure 35). Turn spray tip caps

counter--clockwise to remove. Soak the tips and

screens in an acetic acid solution for up to six

hours (Figure 37). Follow the mixing directions on

the bottle. Do not use pointed objects to clean tips,

damage will occur.

Home

Find...

Go To..

OPERATION

20 Nobles Strive (04--07)

IMPORTANT: When replacing the spray tips,

make sure to install the green spray tip assembly

(tip #11002) above the ReadySpace rollers and

the white spray tip assembly (tip #11005E) into the

front bumper. NOTE: The spray tip filter is not

required for ReadySpace.

ReadySpace

Spray Tip Assembly (2)

GREEN CAP

Restorative Extraction

Spray Tip Assembly (2)

WHITE CAP

FIG. 37

Check the spray pattern direction after installing

the spray tips. The ReadySpace spray tips should

spray directly between the two rollers. The

Restorative Extraction spray pattern should

slightly overlap at a 3°angle (Figure 38).

ReadySpace Spray Pattern Restorative Extraction

Spray Pattern

Rollers

Front Machine Bumper

TOP VIEW

FIG. 38

4. Inspect the spray tip pattern in the two

ReadySpace flush lines (4 spray tips). If tips are

clogged, remove the flush lines and soak them in

an acetic acid solution for up to six hours

(Figure 39). Do not remove tips from flush lines.

NOTE: During ReadySpace operation the flush line

spray tips will spray every 21/2minutes for 3 seconds.

ReadySpace Flush

Line Spray Tip (4)

FLUSH LINE (2)

Push retainer tab to

release spray tip.

FIG. 39

5. Maintain the batteries (See BATTERY

MAINTENANCE).

6. Lubricate the caster grease fittings with a water

resistant grease (Figure 40).

FIG. 40

7. Lubricate all pivot points with silicone spray then

coat with a water resistant grease to maintain

smooth operation.

8. Check the machine for water leaks and loose nuts

and bolts.

9. Periodically check the belt tension on the two

brush motors. Tighten the belt if you’re able to

twist it beyond 90°at midpoint (Figure 41).

FOR SAFETY: When servicing machine,

disconnect the battery connections.

FIG. 41

Home

Find...

Go To..

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

Tennant M-STRIVE Mode d'emploi

- Catégorie

- Machine à plancher

- Taper

- Mode d'emploi

dans d''autres langues

Documents connexes

Autres documents

-

Nobles EX-SC-716 Mode d'emploi

-

Nobles EX-SC-1020 Mode d'emploi

-

Kärcher Armada® BRC 40/22 C Le manuel du propriétaire

-

Kärcher Clipper™ DUO Le manuel du propriétaire

-

Windsor Clipper DUO Le manuel du propriétaire

-

Nobles Speed Scrub 500 (SS500) 9015515 rev01 NA Mode d'emploi

-

Nobles SS350 Manuel de l’opérateur Manuel utilisateur

-

Windsor Commodore DUO Le manuel du propriétaire

-

NSS Enterprises Stallion 8 SC Mode d'emploi

NSS Enterprises Stallion 8 SC Mode d'emploi

-

Nobles M-SS300 Mode d'emploi