CD-WAx-00-2 Series

Wall Mount CO

2

Transmitters

Installation Instructions

CD-WA0-00-2, CD-WAD-00-2

Part No. 24-10863-9 Rev. B

Issued April 8, 2016

Deutsch

Português

中文

English

Français

Italiano

Español

Nederlands

Čeština

Svenska

Polski

Русский

European Single Point of Contact:

JOHNSON CONTROLS

WESTENDHOF 3

45143 ESSEN

GERMANY

NA/SA Single Point of Contact:

JOHNSON CONTROLS

507 E MICHIGAN ST

MILWAUKEE WI 53202

USA

APAC Single Point of Contact:

JOHNSON CONTROLS

C/O CONTROLS PRODUCT MANAGEMENT

NO. 22 BLOCK D NEW DISTRICT

WUXI JIANGSU PROVINCE 214142

CHINA

1

ENGLISH

CD-WAx-00-2

Measurement type

Carbon dioxide, temperature

Output

2 analog output channels

See type label on transmitter

Supply voltage

18 ... 35 VDC

20 … 30 VAC

Power consumption

< 2 W

Dimensions (h × w × d)

132.7 × 81 × 30 mm

Compliance: United States

UL Listed, File E107041, CCN

PAZX, UL 916, Energy

Management Equipment, FCC

Compliant to CFR 47, Part 15,

Subpart B, Class A

Compliance: Canada

UL Listed, File E107041, CCN

PAZX7, CAN/CSA C22.2 No.

205-12, Energy Management

Equipment, Industry Canada

Compliant, ICES-003

North American Emissions Compliance

United States

This equipment has been tested and found to comply with the

limits for a Class A digital device pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when this equipment is

operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential

EN

2

area may cause harmful interference, in which case users will

be required to correct the interference at their own expense.

Canada

This Class (A) digital apparatus meets all the requirements of

the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la Classe (A) respecte toutes les

exigences du Règlement sur le matériel brouilleur du Canada.

Product Safety Information

IMPORTANT: The CD-WAx-00-2 Series Wall Mount CO

2

and

Temperature Transmitters are intended to provide an input to

equipment under normal operating conditions. Where failure or

malfunction of the transmitter could lead to personal injury or

property damage to the controlled equipment or other property,

additional precautions must be designed into the control

system. Incorporate and maintain other devices, such as

supervisory or alarm systems or safety or limit controls,

intended to warn of or protect against failure or malfunction of

the transmitter.

IMPORTANT : Le CD-WAx-00-2 Series Wall Mount CO

2

and

Temperature Transmitters est destiné à transmettre des

données entrantes à un équipement dans des conditions

normales de fonctionnement. Lorsqu'une défaillance ou un

dysfonctionnement du CD-WAx-00-2

Series Wall Mount CO

2

Transmitters risque de provoquer des

blessures ou d'endommager l'équipement contrôlé ou un autre

équipement, la conception du système de contrôle doit intégrer

des dispositifs de protection supplémentaires. Veiller dans ce

cas à intégrer de façon permanente d'autres dispositifs, tels

que des systèmes de supervision ou d'alarme, ou des

dispositifs de sécurité ou de limitation, ayant une fonction

d'avertissement ou de protection en cas de défaillance ou de

dysfonctionnement du CD-WAx-00-2 Series Wall Mount CO

2

and Temperature Transmitters.

3

CAUTION: Risk of Electric Shock.

Disconnect the power supply before making

electrical connections to avoid electric shock.

MISE EN GARDE : Risque de décharge

électrique.

Débrancher l'alimentation avant de réaliser tout

raccordement électrique afin d'éviter tout risque de

décharge électrique.

CAUTION: Risk of Property Damage.

Do not apply power to the system before checking

all wiring connections. Short circuited or improperly

connected wires may result in permanent damage to

the equipment.

MISE EN GARDE : Risque de dégâts matériels.

Ne pas mettre le système sous tension avant d'avoir

vérifié tous les raccords de câblage. Des fils formant

un court-circuit ou connectés de façon incorrecte

risquent d'endommager irrémédiablement

l'équipement.

CAUTION: Risk of Property Damage.

Do not run low voltage cable in the same conduit or

wiring troughs with high voltage wires. Running low

and high voltage wires in the same conduit or wiring

troughs may damage the equipment or cause

system malfunction.

MISE EN GARDE : Risque de dégâts matériels.

Ne pas faire courir un câble basse tension dans les

mêmes gaines ou goulottes électriques que des

câbles haute tension. L'installation de fils basse

tension et haute tension dans les mêmes gaines ou

goulottes électriques risque d'endommager

l'équipement ou de provoquer des

dysfonctionnements du système.

EN

4

All w

iring should conform to local codes and must be

carried out by authorized personnel only. Check all

wiring connections before applying power to the

system.

Make

sure that the line power supply is in

accordance with the power supply specified on

page 1.

Short-circuited or improperly connected wires may

result in permanent damage to the equipment.

If you

connect more than one transmitter to a single

24 VAC transformer, always connect the phase (~)

to the +Vs connector in each transmitter.

When ins

talling the transmitter, do not touch

exposed contacts on the component board.

When

opening or closing the transmitter, avoid

damaging the transmitter electronics with the two

plastic supports on the bottom of the mounting base.

The tr

immers only turn 135 degrees each way, less

than half a rotation. Do not force the trimmer past

the stopping point.

Not adhering to these operational instructions could

cause injury or damage the equipment. Retain this

document.

5

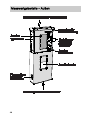

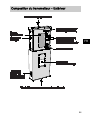

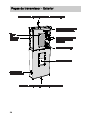

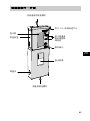

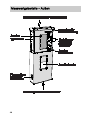

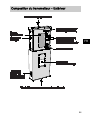

Transmitter Parts - Outside

EN

6

Transmitter Body

Mounting Base

7

Selecting the Location

The conditions at the location should represent well the area of

interest. Do not install the transmitter on the ceiling. Avoid

placing the transmitter near heat and moisture sources, close

to the discharge of the supply air ducts, and in direct sunlight.

Plan the routing of the cable when selecting the location. You

can bring the cable to the transmitter from above, or from the

center opening of the mounting base.

When bringing a cable through the wall, note that the hole

may also supply air from outside the room into the

transmitter. This may affect the measurement readings. For

example, fresh concrete binds CO

2

and may cause low

readings, especially in new buildings. Seal the cable opening

if necessary.

EN

8

Opening and Closing

To open, use a screwdriver to push down the tab that holds

the transmitter cover and mounting base together. Pull the

mounting base away from the cover, starting from the top.

To cl

ose, connect the bottom of the transmitter first, and tilt the

top forward to close the tab. Do not push on the screen.

Closing the transmitter starts it up if power is supplied to the

screw terminals.

9

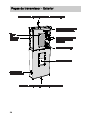

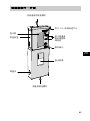

Installing the Mounting Base

Use the mounting holes to attach the mounting base securely.

Use at least two screws (not included). The arrow on the

mounting base must point straight up after installation.

Proper orientation is important: air must flow through the

vents on the bottom and top.

50

34

27

Ø 4.4

33.5

30.5

29.8

59.5

EN

10

General Wiring Instructions

When wiring, observe the terminal label on the mounting base.

Maximum wire size is 2 mm

2

(AWG14).

If the cable between the sensor and the

controller is over 3 meters, it should be shielded.

The shield would be connected at the controller

end of the cable.

Keep high and low voltage wiring separated.

When using multi-stranded wire apply a cable

ferrule to the cable end.

You can bring the cable to the

housing from above or from

behind (recommended).

If you are wiring a

CD-WAx-00-2 series

transmitter from above, use a

< Ø 5 mm cable, and route it

from the left side of the

mounting base.

11

Wiring CD-WAx-00-2

Recommended wiring for long cables:

-Vs ter

minal is internally connected to GND terminal, so you

can also use the -Vs terminal as common ground. Maximum

cable resistance is 2.5 Ω (24V supply, 0 ... 10 V output):

EN

12

DIP Switch Settings

DIP

Position

Setting

1

Non-metric

Non-metric units (°F).

Metric

Metric units (°C).

2

Not used

3

0...5V

Set analog output channels to 0 ... 5 V

0...10V

Set analog output channels to 0 ... 10 V

4

Not used

5

Not used

6

Not used

7

Not used

8

Custom

Configuration through service port only.

Ignores all other DIP switch settings.

DIP

Configuration by DIP switches only.

13

Transmitter Startup

When the transmitter is powered on, it

displays a sequence of information screens.

The screens are shown for a few seconds

each.

The first screen identifies the transmitter and

the connected measurement modules,

and shows if the transmitter is operating

normally (status OK) or if there is an error

(status ERROR).

The following screen(s) show the

configuration of the analog output channels.

After the startup screens the transmitter

shows the measurement screen. It shows

the measured parameters and currently

active indicators.

It is normal for CO

2

measurement to read

0 ppm for a few seconds after the startup.

EN

14

Trimmer Adjustment (T)

Before starting the adjustment, compare the

reading of the transmitter to a calibrated

reference instrument so you know how much

adjustment is needed. You can use, for

example, the HM70 hand-held humidity and

temperature meter.

To enter the adjustment screen, rotate the

trimmer slightly during normal measurement.

If the trimmer is not centered, you see the

trimmer centering screen first. Simply turn the

trimmer to the center and wait for the

progress bar to complete.

In the adjustment screen, turn the trimmer to

set the desired correction. To commit the

change, stop turning the trimmer and wait.

If you wish to apply a greater correction than

allowed by the trimmer in a single adjustment,

re-enter the adjustment screen and apply a

new correction. Corrections applied using the

trimmers are cumulative.

15

Trimmer Adjustment (CO

2

)

Transm

itter models with CO

2

measurement

have an inlet for calibration gas. Supply the

calibration gas with a known concentration

(for example, 1000 ppm) to this inlet using a

3 mm inner diameter silicone tube and a

0.4 l/min flow.

Turn on the gas flow and wait for three

minutes for measurement to stabilize. If you

are adjusting without calibration gas, avoid

breathing on the transmitter. You should only

adjust the transmitter when the CO

2

reading

is stable.

Rotate the CO

2

trimmer slightly during

normal measurement. If the trimmer is not

centered, you see the trimmer centering

screen first. Simply turn the trimmer to the

center and wait for the progress bar to

complete.

In the adjustment screen, turn the trimmer to

set the desired correction. To commit the

change, stop turning the trimmer and wait.

The transmitter will show with a text screen if

the adjustment was successful, or failed due

to an unstable CO

2

reading.

Repeated trimmer adjustments are

cumulative. Wait for a few minutes between

adjustments to allow the CO

2

reading to

stabilize.

EN

16

Indicators

MI70 connection indicator

Shown on top left of the screen if an MI70

Indicator is connected to the service port.

Alert indicator and error text

Shown on bottom of screen if there is an error

active. Followed by an error text. If more than

one error is active, the error text will cycle

through the errors.

When the alert indicator and error text are

shown, typically one or more measurement

readings are replaced with stars. This means

these measurements are affected by the error.

17

Errors

Error Type Cause and Possible Solution

HTM10 error Problem with TM10 module.

- Check that the module sits firmly in

place. Remove and reconnect.

- Replace the module if unable to

remove the problem.

GM10 error Problem with GM10 module.

- Check that the module sits firmly in

place. Remove and reconnect.

- Check that supply voltage is in range.

- Replace the module if unable to

remove the problem.

Internal error Internal problem with the transmitter.

- Restart the transmitter.

- Replace the unit if the error persists.

EN

18

DEUTSCH

CD-WAx-00-2

Art der Messung

Kohlendioxid, Temperatur

Ausgang

2 Analogausgangskanäle,

siehe Etikett auf dem

Messwertgeber

Speisespannung

18 ... 35 V DC

20 … 30 V AC

Stromverbrauch

< 2,0 W

Abmessungen (H × B × T)

132,7 × 81 × 30 mm

Produktsicherheitsinformationen

Der K

ontakt mit Komponenten, auf denen

gefährliche Spannung anliegt, kann zu einem

Stromschlag führen und schwere Körperschäden

oder sogar den Tod zur Folge haben.

Der el

ektrische Anschluß ist nach den örtlichen

Vorschriften durch autorisiertes Personal

durchzuführen. Überprüfen Sie alle

Kabelverbindungen bevor Sie den

Messwertgeber einschalten.

Stellen Sie sicher, dass die

Versorgungsspannung mit dem angegebenen

Wert auf Seite 18 übereinstimmt.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

Johnson Controls CD-WA 00-2 Series Installation Instructions Manual

- Taper

- Installation Instructions Manual

- Ce manuel convient également à

dans d''autres langues

- English: Johnson Controls CD-WA 00-2 Series

- Deutsch: Johnson Controls CD-WA 00-2 Series

- português: Johnson Controls CD-WA 00-2 Series

Documents connexes

Autres documents

-

Vaisala HMD65 Manuel utilisateur

-

Vaisala HMD62 Manuel utilisateur

-

Vaisala HMS82 Manuel utilisateur

-

Vaisala DPT145 Manuel utilisateur

-

Swegon TAC5-TAC6 Le manuel du propriétaire

-

Vaisala MHT410 Manuel utilisateur

-

Vaisala HMD110/112 Manuel utilisateur

-

Vaisala Indigo 500 Series Manuel utilisateur

-

Vaisala MMT330 Le manuel du propriétaire

-

sauter EGQ 281 Assembly Instructions