Operating Instructions

LEVEL SWITCH 8110

- contactless electronic switch

2

Contents

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

Contents

1 About this document

1.1 Function ........................................................................................................................... 3

1.2 Target group ..................................................................................................................... 3

1.3 Symbolism used ............................................................................................................... 3

2 For your safety

2.1 Authorised personnel ....................................................................................................... 4

2.2 Appropriate use ................................................................................................................ 4

2.3 Warning about incorrect use ............................................................................................. 4

2.4 General safety instructions ............................................................................................... 4

2.5 Safety label on the instrument .......................................................................................... 5

2.6 CE conformity ................................................................................................................... 5

3 Product description

3.1 Conguration .................................................................................................................... 6

3.2 Principle of operation........................................................................................................ 6

3.3 Adjustment ....................................................................................................................... 7

3.4 Storage and transport....................................................................................................... 7

4 Mounting

4.1 General instructions ......................................................................................................... 9

4.2 Mounting instructions ..................................................................................................... 11

5 Connecting to power supply

5.1 Preparing the connection ............................................................................................... 13

5.2 Wiring plan ..................................................................................................................... 13

6 Setup

6.1 Indication of the switching status .................................................................................... 17

6.2 Simulation ...................................................................................................................... 17

6.3 Function chart ................................................................................................................ 18

7 Maintenanceandfaultrectication

7.1 Maintenance .................................................................................................................. 19

7.2 Rectify faults ................................................................................................................... 19

8 Dismounting

8.1 Dismounting steps.......................................................................................................... 20

8.2 Disposal ......................................................................................................................... 20

9 Supplement

9.1 Technical data ................................................................................................................ 21

9.2 Dimensions .................................................................................................................... 24

Editing status: 2014-02-11

3

1 About this document

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

1 About this document

1.1 Function

This operating instructions manual provides all the information you

need for mounting, connection and setup as well as important instruc-

tionsformaintenanceandfaultrectication.Pleasereadthisinforma-

tion before putting the instrument into operation and keep this manual

accessible in the immediate vicinity of the device.

1.2 Target group

This operating instructions manual is directed to trained specialist

personnel. The contents of this manual should be made available to

these personnel and put into practice by them.

1.3 Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious

damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or

destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

SIL applications

This symbol indicates instructions for functional safety which must be

particularly taken into account for safety-relevant applications.

•

List

The dot set in front indicates a list with no implied sequence.

→

Action

This arrow indicates a single action.

1 Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of bat-

teries and accumulators.

4

2 For your safety

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

2 For your safety

2.1 Authorised personnel

All operations described in this operating instructions manual must

be carried out only by trained specialist personnel authorised by the

plant operator.

During work on and with the device the required personal protective

equipment must always be worn.

2.2 Appropriate use

The LEVEL SWITCH 8110 is a sensor for point level detection.

Youcannddetailedinformationabouttheareaofapplicationin

chapter "Product description".

Operational reliability is ensured only if the instrument is properly

usedaccordingtothespecicationsintheoperatinginstructions

manual as well as possible supplementary instructions.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbi-

traryconversionsormodicationsareexplicitlyforbidden.

2.3 Warning about incorrect use

Inappropriate or incorrect use of the instrument can give rise to

application-specichazards,e.g.vesseloverllordamagetosystem

components through incorrect mounting or adjustment.

2.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and guidelines. The instrument must only be operated in a

technicallyawlessandreliablecondition.Theoperatorisresponsible

for the trouble-free operation of the instrument.

During the entire duration of use, the user is obliged to determine the

compliance of the necessary occupational safety measures with the

current valid rules and regulations and also take note of new regula-

tions.

The safety instructions in this operating instructions manual, the na-

tional installation standards as well as the valid safety regulations and

accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbi-

traryconversionsormodicationsareexplicitlyforbidden.

The safety approval markings and safety tips on the device must also

be observed.

5

2 For your safety

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

2.5 Safety label on the instrument

The safety approval markings and safety tips on the device must be

observed.

2.6 CE conformity

ThedevicefulllsthelegalrequirementsoftheapplicableECguide-

lines.ByaxingtheCEmarking,weconrmsuccessfultestingofthe

product.

YoucanndtheCECerticateofConformityinthedownloadsection

of our homepage.

6

3 Product description

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

3 Product description

3.1 Conguration

The scope of delivery encompasses:

•

LEVEL SWITCH 8110 point level switch

•

Test magnet

•

Documentation

– this operating instructions manual

– ifnecessary,certicates

The LEVEL SWITCH 8110 consists of the components:

•

Housing with electronics

•

Processttingwithtuningfork

Fig. 1: LEVEL SWITCH 8110

Thenameplatecontainsthemostimportantdataforidenticationand

use of the instrument:

•

Article number

•

Serial number

•

Technical data

•

Article numbers, documentation

3.2 Principle of operation

LEVEL SWITCH 8110 is a point level sensor with tuning fork for point

level detection.

It is designed for industrial use in all areas of process technology and

can be used in liquids.

Typicalapplicationsareoverllanddryrunprotection.Withatuning

fork of only 38 mm length, LEVEL SWITCH 8110 can be also mount-

ed e.g. in pipelines from DN 25. The small tuning fork allows use in

vessels, tanks and pipes. Thanks to its simple and robust measuring

system,LEVELSWITCH8110isvirtuallyunaectedbythechemical

and physical properties of the liquid.

Scope of delivery

Constituent par

ts

T

ype plate

Application area

7

3 Product description

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

Itfunctionsevenunderdicultconditionssuchasturbulence,airbub-

bles, foam generation, buildup, strong external vibration or changing

products.

Function monitoring

The electronics module of LEVEL SWITCH 8110 continuously moni-

tors via frequency evaluation the following criteria:

•

Strong corrosion or damage on the tuning fork

•

Loss of vibration

•

Linebreaktothepiezodrive

If a malfunction is detected or in case of power failure, the electronics

takesonadenedswitchingcondition,i.e.thecontactlesselectronic

switch opens (safe condition).

Thetuningforkispiezoelectricallyenergisedandvibratesatitsme-

chanicalresonancefrequencyofapprox.1100Hz.Whenthetuning

fork is submerged in the product, the frequency changes. This change

is detected by the integrated electronics module and converted into a

switching command.

LEVEL SWITCH 8110 is a compact instrument, i.e. it can be oper-

ated without external evaluation system. The integrated electronics

evaluates the level signal and outputs a switching signal. With this

switching signal, a connected device can be operated directly (e.g. a

warning system, a pump etc.).

Thedataforpowersupplyarespeciedinchapter"Technical data".

3.3 Adjustment

The switching status of LEVEL SWITCH 8110 can be checked with

closed housing (signal lamp). Products with a density > 0.7 g/cm³

(0.025 lbs/in³) can be detected.

3.4 Storage and transport

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

based on ISO 4180.

The packaging of standard instruments consists of environment-

friendly, recyclable cardboard. For special versions, PE foam or PE

foil is also used. Dispose of the packaging material via specialised

recycling companies.

Transport must be carried out in due consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or con-

cealed defects must be appropriately dealt with.

Functional principle

V

oltage supply

Packaging

Transport

Transport inspection

8

3 Product description

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

•

Not in the open

•

Dry and dust free

•

Not exposed to corrosive media

•

Protected against solar radiation

•

Avoiding mechanical shock and vibration

•

Storage and transport temperature see chapter "Supplement -

Technical data - Ambient conditions"

•

Relative humidity 20 … 85 %

Storage

Storage and transport

temperature

9

4 Mounting

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

4 Mounting

4.1 General instructions

Make sure that all parts of the instrument coming in direct contact

with the process, especially the sensor element, process seal and

processtting,aresuitablefortheexistingprocessconditions,such

as process pressure, process temperature as well as the chemical

properties of the medium.

Youcanndthespecicationsinchapter"Technical data" and on the

nameplate.

In general, LEVEL SWITCH 8110 can be installed in any position. The

instrument only has to be mounted in such a way that the tuning fork

is at the height of the desired switching point.

Keep in mind that the swichting point can vary dependent on the

installation position.

The switching point refers to the medium water (1 g/cm³/0.036 lbs/

in³). Please keep in mind that the switching point of the instrument

shiftswhenthemediumhasadensitydieringfromwater.

2

3

1

11 mm

(0.43")

34 mm

(1.34")

Fig. 2: Vertical mounting

1 Switching point in water

2 Switching point with lower density

3 Switching point with higher density

Suitability for the process

conditions

Switching point

10

4 Mounting

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

2

1

Fig. 3: Horizontal mounting

1 Switching point

2 Switching point (recommended mounting position, particularly for adhesive

products)

Use the recommended cables (see chapter "Connecting to power

supply") and tighten the cable gland.

You can give your LEVEL SWITCH 8110 additional protection against

moisture penetration by leading the connection cable downward in

front of the cable entry. Rain and condensation water can thus drain

o.Thisappliesmainlytooutdoormountingaswellasinstallationin

areas where high humidity is expected (e.g. through cleaning pro-

cesses) or on cooled or heated vessels.

Fig. 4: Measures against moisture penetration

Do not hold LEVEL SWITCH 8110 on the tuning fork.

Theprocessttingmustbesealedifthereisgaugeorlowpressurein

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

Themax.permissiblepressureisspeciedinchapter"Technical

data" or on the type label of the sensor.

Moisture

T

r

ansport

Pressure/Vacuum

11

4 Mounting

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

The vibrating level switch is a measuring instrument and must be

treated accordingly. Bending the vibrating element will destroy the

instrument.

Warning:

The housing must not be used to screw the instrument in! Applying

tightening force can damage internal parts of the housing.

Use the hexagon above the thread for screwing in.

4.2 Mounting instructions

For threaded versions of LEVEL SWITCH 8110 in combination with a

mounting boss with O-ring in front and welding marking.

LEVELSWITCH8110withthreadsizes¾"and1"haveadened

thread runout. This means that every LEVEL SWITCH 8110 is in the

same position after being screwed in. Remove therefore the supplied

atsealfromthethreadofLEVELSWITCH8110.Thisatsealisnot

requiredwhenusingaweldedsocketwithfront-ushseal.

Before welding, unscrew LEVEL SWITCH 8110 and remove the rub-

ber ring from the welded socket.

Theweldedsocketisprovidedwithamarking(notch).Forhorizontal

mounting, weld the socket with the notch facing upward or downward;

inpipelines(DN25toDN50)alignedwiththedirectionofow.

1

Fig. 5: Marking on the welded socket

1 Marking

Incaseofhorizontalmountinginadhesiveandviscousproducts,

the surfaces of the tuning fork should be vertical in order to reduce

buildup on the tuning fork. The position of the tuning fork is indicated

by a marking on the hexagon of LEVEL SWITCH 8110. With this,

you can check the position of the tuning fork when screwing it in.

When the hexagon touches the seal, the thread can still be turned by

approx.halfaturn.Thisissucienttoreachtherecommendedinstal-

lation position.

In adhesive and viscous products, the surfaces of the tuning fork

should protrude into the vessel to avoid buildup. Therefore sockets for

angesandmountingsbossesshouldnotexceedacertainlength.

Handling

Welded socket

Adhesive products

12

4 Mounting

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

30 mm

(1.18")

Fig. 6: Adhesive products

IfLEVELSWITCH8110ismountedinthellingstream,unwanted

false measurement signals can be generated. For this reason, mount

LEVEL SWITCH 8110 at a position in the vessel where no disturbanc-

es,e.g.fromllingopenings,agitators,etc.,canoccur.

To make sure the tuning fork of LEVEL SWITCH 8110 generates as

littleresistanceaspossibletoproductow,mountthesensorsothat

the surfaces are parallel to the product movement.

Inowingmedium

Flows

13

5 Connecting to power supply

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

5 Connecting to power supply

5.1 Preparing the connection

Always keep in mind the following safety instructions:

•

Connect only in the complete absence of line voltage

The instrument is connected with standard two-wire cable without

screen. If electromagnetic interference is expected which is above the

test values of EN 61326 for industrial areas, screened cable should

be used.

Use cable with round cross section. Depending on the plug connec-

tion, you have to select the outer diameter of the cable respectively so

thatthesealeectofthecableglandisensured.

•

Valve plug ISO 4400, ø 4.5 … 7 mm

•

Valve plug ISO 4400 with IDC crimping technology, ø 5.5 … 8 mm

Use cable with a round wire cross section and tighten the cable gland.

When mounting outdoors, on cooled vessels or in moist areas in

which cleaning is made with steam or high pressure, the sealing of

the cable gland is very important.

5.2 Wiring plan

2

1 2

Fig. 7: Overview of the connection versions

1 Valve plug ISO 4400

2 Valve plug ISO 4400 with IDC method of termination

Note safety instructions

Connection cable

Cable glands

Housing overview

14

5 Connecting to power supply

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

Valve plug ISO 4400

For this plug version, standard cable with round wire cross-section

can be used. Cable diameter 4.5 … 7 mm, protection IP 65.

1

4

5

6

7

8

9

10

2 3

Fig. 8: Connection, valve plug ISO 4400

1 Pressure screw

2 Pressure disc

3 Seal ring

4 Fixing screw

5 Seal washer

6 Plug housing

7 Plug insert

8 Proleseal

9 Control lamp

10 LEVEL SWITCH 8110

Valve plug, QuickOn ISO 4400

For this plug version you can use standard cable with round wire

cross-section. The inner cables must not be dismantled. The plug

connects the cables automatically when screwing in. Cable diameter

3.5 … 6.5 mm, protection IP 65.

Plug versions

15

5 Connecting to power supply

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

1 2 3 4

5

Fig. 9: Connection, valve plug ISO 4400 with IDC crimping technology

1 Compression nut

2 Cable

3 Seal ring

4 Terminal insert

5 Plug housing

We recommend connecting LEVEL SWITCH 8110 in such a way that

the switching circuit is open when there is a level signal, line break or

failure (safe condition).

Warning:

The instrument must not be operated without an intermediately

connected load, because the electronics would be destroyed if con-

nected directly to the mains. It is not suitable for connection to low

voltage PLC inputs.

Examples for typical applications:

•

Loadresistanceat24VDC:88…1800Ω

•

Rated power, relay 253 V AC: > 2.5 VA

•

Rated power, relay 24 V AC: > 0.5 VA

For direct control of relays, contactors, magnet valves, warning lights,

horns etc.

Domestic current is temporarily lowered below 1 mA after switching

otheloadsothatcontactors,whoseholdingcurrentislowerthan

the constant domestic current of the electronics (3 mA), are reliably

switchedo.

Contactless electronic

switch

16

5 Connecting to power supply

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

R

L

R

L

3

2 1

3

2 1

N- L1+ L1+ N-

Max. Min.

PE

PE

Fig. 10: Wiring plan, contactless electronic switch with valve plug ISO 4400

PE Protective ground

RL Load resistance (contactor, relay, etc.)

17

6 Setup

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

6 Setup

6.1 Indication of the switching status

The switching status of the electronics can be checked via the signal

lamps (LEDs) integrated in the upper part of the housing.

The signal lamps have the following meaning:

•

Green lights - voltage supply connected

•

Yellow lights - vibrating element covered

•

Redlightsbriey-functiontestduringinstrumentstart(for0.5s)

•

Red lights - shortcircuit or overload in the load circuit (sensor

output high-impedance)

•

Redashes-Erroronthevibratingelementortheelectronics

(sensor output high impedance)

6.2 Simulation

The LEVEL SWITCH 8110 has an integrated function for simula-

tion of the output signal which can be activated magnetically. Please

proceed as follows:

→

Hold the test magnet (accessory) against the circle symbol with

the label "TEST" on the instrument housing

Fig. 11: Simulation of the output signal

The test magnet changes the current switching condition of the instru-

ment. You can check the change on the signal lamp. Please note that

all connected device are activated during the simulation.

If LEVEL SWITCH 8110 does not switch over after several tests with

the test magnet, you have to check the plug connection and the

connection cable and try it again. If there is no switching function, the

electronics will be defective. In this case you have to exchange the

electronics or return the instrument to our repair department.

Caution:

It is absolutely necessary that you remove the test magnet from the

instrument housing after the simulation.

18

6 Setup

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

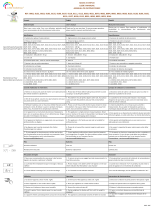

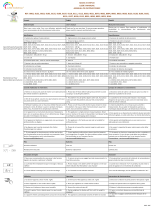

6.3 Function chart

The following chart provides an overview of the switching conditions

depending on the set mode and the level.

Level Switching sta-

tus

Control lamp

Yellow - cov-

erage

Control lamp

Green - voltage

indication

Control lamp

Red - fault sig-

nal

Mode max.

closed

Mode max. open

Mode min. closed

Mode min. open

Fault any open any

19

7Maintenanceandfaultrectication

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

7 Maintenanceandfaultrectication

7.1 Maintenance

If the instrument is used properly, no special maintenance is required

in normal operation.

7.2 Rectify faults

The operator of the system is responsible for taking suitable meas-

ures to rectify faults.

LEVELSWITCH8110oersmaximumreliability.Nevertheless,faults

can occur during operation. These may be caused by the following,

e.g.:

•

Sensor

•

Process

•

Voltage supply

•

Signal processing

Therstmeasuretobetakenistochecktheoutputsignal.Inmany

cases,thecausescanbedeterminedthiswayandthefaultsrectied.

Error Cause Rectication

Green signal

lampo

Voltage supply in-

terrupted.

Check the voltage supply and the ca-

ble connection

Electronics de-

fective

Exchange the instrument or send it in

for repair

Red signal lamp

lights (switching

output high-im-

pedance)

Error with the

electrical con-

nection

Connect the instrument according to

the wiring plan

Shortcircuit or

overload

Check the electrical connection

Red signal lamp

ashes(switching

output high-im-

pedance)

Virbating fre-

quency out of

specication

Check the vibrating element on build-

up and remove it

Buildup on the vi-

brating element

Check the vibrating element and

the sensor if there is buildup and re-

move it

Vibrating element

damaged

Check if the vibrating element is dam-

age or extremely corroded

Depending on the reason for the fault and the measures taken, the

steps described in chapter "Set up" may have to be carried out again.

Reaction when malfunc-

tions occur

F

ailur

e reasons

Faultrectication

Checking the switching

signal

Reaction after fault recti-

cation

20

8 Dismounting

LEVEL SWITCH 8110 • - contactless electronic switch

41765-EN-140211

8 Dismounting

8.1 Dismounting steps

Warning:

Before dismounting, be aware of dangerous process conditions such

as e.g. pressure in the vessel, high temperatures, corrosive or toxic

products etc.

Take note of chapters "Mounting" and "Connecting to power supply"

and carry out the listed steps in reverse order.

8.2 Disposal

The instrument consists of materials which can be recycled by spe-

cialised recycling companies. We use recyclable materials and have

designed the parts to be easily separable.

WEEE directive 2002/96/EG

This instrument is not subject to the WEEE directive 2002/96/EG and

the respective national laws. Pass the instrument directly on to a spe-

cialised recycling company and do not use the municipal collecting

points. These may be used only for privately used products according

to the WEEE directive.

Correctdisposalavoidsnegativeeectsonhumansandtheenviron-

ment and ensures recycling of useful raw materials.

Materials: see chapter "Technical data"

If you have no way to dispose of the old instrument properly, please

contact us concerning return and disposal.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

Burkert 8110 Mode d'emploi

- Taper

- Mode d'emploi

- Ce manuel convient également à

dans d''autres langues

- English: Burkert 8110 Operating instructions

- Deutsch: Burkert 8110 Bedienungsanleitung

Autres documents

-

SICK LFC Mode d'emploi

-

SICK LFV230 Tuning Fork Mode d'emploi

-

SICK LFV230 Hygenic Mode d'emploi

-

SICK LFV 200 Hygienic version Mode d'emploi

-

SICK LFV200 Manuel utilisateur

-

Vega VEGAWAVE 61 Mode d'emploi

Vega VEGAWAVE 61 Mode d'emploi

-

LITTLE BALANCE 8107 PONTON Le manuel du propriétaire

LITTLE BALANCE 8107 PONTON Le manuel du propriétaire

-

GN Netcom GN 8110 USBxp Manuel utilisateur

-

Dura Heat DuraHeat DFA-170C Manuel utilisateur

-

Jabra GN8110 Le manuel du propriétaire