Daintree GE Lumination LSA Series Guide d'installation

- Taper

- Guide d'installation

Lumination

TM

Sensor Accessory

LSA Series Installation

Installation Guide

IND541

BEFORE YOU BEGIN

Read these instructions completely and carefully.

Save these instructions for future use.

WARNING/AVERTISSEMENT

RISK OF FIRE OR ELECTRIC SHOCK

• Turn power off before inspection, installation or removal.

• Follow all NEC and local codes.

• Do not make or alter any open holes in an enclosure of wiring or

electrical components during kit installation.

• Wear safety glasses and proper aid during installation and

maintenance.

• Install this kit only in the luminaires that has the construction

features and dimensions shown in the photographs and/or

drawings.

• Above ceiling access required.

• While the sensor is designed to withstand Electrostatic Discharge

(ESD), it is always advisable to touch a grounded metal object

before handling the sensor, particularly in an operating fixture.

RISQUES D’INCENDIE OU DE DÉCHARGES ÉLECTRIQUES

• Coupez l’alimentation avant d’’inspecter, installer ou déplacer le luminaire.

• Respectez tous les codes NEC et codes locaux.

• Ne pas percer ou altérer les trous d’un boitier contenant filou

composanélectriqu durant l’installation.

• Porter des lunettes de sécurité et les aides appropriéeslors de l’installation

et de l’entretien.

• Installez ce kit uniquement dans les appareils d’éclairagequi a les

caractéristiques de la construction et les dimensions indiquées dans les

photographies et/ou dessins.

• Accès requis au-dessus du plafond.

• Bien que le capteur soit conçu pour résister aux décharges électrostatiques

(ESD), il est toujours conseillé de toucher un objet métallique mis à la terre

avant de manipuler le capteur, en particulier dans une installation en

fonctionnement.

Specifications

Description Code for Sensor Accessory

Save These Instructions

These instructions do not purport to cover all details or variations in components nor to provide for every possible contingency to be

met in connection with installation, operation or maintenance. Should further information be desired or should particular problem arise

which are not covered sufficiently for the purchaser's purpose, the matter should be referred to General Electric Company. Current,

powered by GE does not claim liability for any installation not performed according to a this guide or not by a qualified electrician.

Prepare Electrical Wiring

Electrical Requirements

• The LED luminaire must be connected to the mains

supply according to its ratings on the product label.

Grounding Instructions

• The grounding and bonding of the overall system

shall be done in accordance with National Electric

Code (NEC) Article 600 and local codes.

T1 (WIT100 Sensor) - Daintree One (120-277 VAC)

TT (WIT100 Sensor) - Daintree EZ Connect (120-277 VAC)

TZ (WIZ100 Sensor) - Daintree Enterprise (120-277 VAC)

TM (WMZ10 Sensor) - Daintree Enterprise Multi-Sensor

(120-277 VAC)

CONTACT FACTORY for details and limitations when seeking to add this device to a luminaire being used with an emergency system other

than Battery Backup.

COMPONENTS SUPPLIED AND IDENTIFICATION

NOTE:

• All cables are CMP (Plenum) rated.

• Identification sticker labels are to be placed on or near luminaire and on a floor plan for mapping

WIT100

• T1 - Daintree One Sensor

OR

• TT - D

aintree EZ Connect

Sensor

• CMP Cable

• Identification sticker labels

WIZ100

• TZ - Daintree Enterprise

Sensor

• CMP Cable

• Identification sticker labels

WMZ10

• TM - Daintree Enterprise

Multi-Sensor

• CMP Cable

• Identification sticker labels

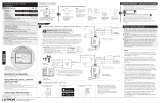

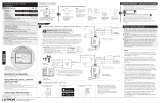

OPTION A - NON ENCLOSED SENSOR INSTALLATION

SENSOR ACCESSORY INSTALLATION WITH GE CURRENT LED FIXTURE (SQ OPTION)

DISCONNECT POWER

INSTALL SENSOR UNIT DIRECTLY

INTO CEILING

1 2

Disconnect incoming power to the fixture at the

panel

Hole in ceiling – up

to installer on

where to place the

hole next to

luminaire

Mounting Option – Using ONLY CMP

(Plenum) Rated Cable

Make a hole in ceiling where sensor is to be

mounted. It is recommended that the diameter of

the hole be slightly smaller than the outer

diameter of the sensor body. The recommended

diameter of the hole should be approximately

5/8” or 16mm. The sensor should be wedged into

softer (e.g. drywall or ceiling tile) material for

extra grip. The sensor will have either snap arms

or a nut to fasten to ceiling.

2

CONNECT SUPPLIED

SENSOR CABLE

ROUTE SENSOR CABLE OUT OF

FIXTURE

3

4

AC Line

AC Line

Follow

appropriate

codes for type of

grommet to be

used.

Connect sensor cable to luminaire or accessory box.

If the sensor cable is not mounted on the knockout

plate, remove the knockout plate to access the

sensor cable. The luminaire or accessory box will

have a black and red cable with a male connector

located inside the electrical cavity. Remove a

knockout hole on the knockout plate. Follow

appropriate codes for type of grommet to be used

for the sensor cable to pass through the hole. NOTE:

The sensor cable connector may be mounted on the

outside of the knockout plate. In this case plug the

sensor cable in without removing knockout plate.

Route the sensor cable through the knockout hole

and/or bushing into luminaire and make the

connection. Fasten the knockout plate back to

luminaire. All work happens above ceiling. The

luminaire does not have to be removed.

LOCATE SENSOR LOCATION

INSTALL SENSOR IN CEILING

5

6

Depending on sensor mounting, route cable

through created hole in ceiling. Make sure sensor

is connected to the cable.

Installation is complete

3

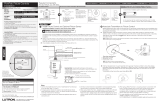

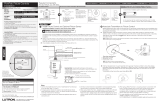

OPTION B - ENCLOSED SENSOR INSTALLATION

SENSOR ACCESSORY INSTALLATION WITH GE CURRENT LED FIXTURE (SQ OPTION)

COMPONENTS REQUIRED CREATE HOLE IN CEILING

1 2

Materials to be supplied by

installer:

• Standard electrical enclosure

box (UL listed)

• Electrical conduit (UL listed)

Materials ordered separate

as an accessory from

Current:

• Cover plate and mounting

screws

Mounting Option – When conduit is required by

code

Make hole in ceiling to accommodate a standard

UL listed electrical enclosure compatible with

cover plate.

MOUNT ELECTRICAL BOX INSTALL SENSOR ON COVER

PLATE

3 4

Mount the electrical box to the ceiling following

appropriate codes.

Place sensor cable

into appropriate

sized electrical

conduit per code.

If sensor

connector does

not fit conduit

diameter, cut and

splice sensor cable

wires following

appropriate codes.

CONNECT SENSOR ATTACH COVER PLATE

5 6

Use supplied cover

plate and attach

sensor. Once

connected to cover

plate, connect the

sensor to the

sensor cable.

Use supplied screws to attach cover plate to

electrical box. Installation is complete.

4

OPTION C - SENSOR ACCESSORY INSTALLATION STANDALONE UNIT

(NO LED FIXTURE).

FOLLOW OPTION A OR B FOR NON ENCLOSED OR ENCLOSED INSTALLATION

DISCONNECT POWER VERIFY POWER SUPPLY AND

SENSOR ARE COMPATIBLE

1 2

Remove power by switching circuit breaker to the

off position.

+

COMPATIBLE

POWER SUPPLY

(WMZ10 only)

OR LCA KIT

=

MAKE ELECTRICAL

CONNECTIONS

CEILING INSTALLATION (SEE

OPTION A OR B)

3 4

Install the sensor unit into the ceiling following the

same steps as mentioned in Option A or B of this

installation guide.

120-277VAC

LINE

NEUT

DC+

DC-

DC+ (RED)

DC- (BLACK)

OPTION A

• Direct ceiling install

(CMP cable used)

OPTION B

• Metal box/conduit

install

To verify a compatible power supply, please refer to

the Power Supply Compatibility List table on the Multi-

Sensor (TM) spec sheet. Note: Connect TM sensor to GE

Lighting Solutions LLC LED drivers or control modules

not capable of providing greater than 15VA power,

including but not limited to models listed in Power

Supply Compatibility List.

Connect wires from the power supply or LCA Kit to the

sensor input wires. Connect the power supply input wires

to the appropriate power source. Use only U.L. approved

wire connectors for all electrical connections. Be sure to

insulate unused leads INDIVIDUALLY to 600Vrms using U.L.

approved wire connectors.

TM MULTI-SENSOR

ORIENTATION MARK

TM MULTI-SENSOR

ORIENTATION REQUIREMENT

5 6

For the WMZ10 TM Multi-Sensor there is an arrow on the

lens. This arrow is a mark or indicator for the direction of

the sensor.

When the sensor is installed, all sensors should face the

same direction. The arrow can be used to point all sensors

in one direction. As a reference all sensors installed should

have the arrow pointing North.

N

EW

S

5

SENSOR REPLACEMENT

IDENTIFY SENSOR MODEL INSTALLED

1

TZ (WIZ100)

T1/TT (WIT100)

TM (WMZ10)

REMOVE SENSOR FROM CEILING OR LED FIXTURE

2

FOR T1/TT & TM SENSORS

FOR TZ SENSOR

Grab sensor top as

indicated by arrows above

Gently pull sensor down

until connector is visible.

Disconnect sensor from

cable.

Leave cable available for

replacement sensor.

Depending on fixture type

or application, remove lens

or open fixture door with

sensor installed.

Disconnect sensor from

cable.

Remove nut from sensor. Sensor is removed.

6

INSTALL REPLACEMENT SENSOR

3

FOR T1/TT & TM SENSORS

FOR TZ SENSOR

Locate sensor cable.

Connect the sensor to the

sensor cable on fixture.

Orient the cable on the sensor

unit so it faces the end of the

fixture to prevent shadowing.

Push sensor in position until

it can no longer be pushed.

It will snap into position.

Attach replacement sensor

to lens or door depending

on application.

Push sensor through the hole

and use nut to secure. Make

sure the cable on the sensor

unit is facing the edge of the

lens to prevent shadowing.

Connect sensor unit to

cable on fixture.

Reinstall lens or door

depending on application.

NOTE:

• Identification sticker labels are to be placed on or near luminaire and on a floor plan for mapping

7

FOR STANDALONE SENSOR ACCESSORIES THE FOLLOWING STATEMENTS APPLY

Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate

this equipment. This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation. This device contains license-exempt transmitter(s)/receiver(s) that comply with Innovation, Science and Economic

Development Canada’s license-exempt RSS(s). Operation is subject to the following two conditions:

1. This device may not cause interference.

2. This device must accept any interference, including interference that may cause undesired operation of the device.

L’émetteur/récepteur exempt de licence contenu dans le présent appareil est conforme aux CNR d’Innovation, Sciences et

Développement économique Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux

conditions suivantes:

1. L’appareil ne doit pas produire de brouillage;

2. L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le

fonctionnement.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

―Reorient or relocate the receiving antenna.

―Increase the separation between the equipment and receiver.

―Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

―Consult the dealer or an experienced radio/TV technician for help.

To satisfy FCC/ISED RF exposure requirements a separation distance of 20 cm or more must be maintained between the antenna of this

device and persons during operation. Operation at closer than 20cm is not permitted

Pour être conforme aux limites d’exposition aux ondes RF des normes FCC/ISED, une distance de séparation d’au moins 20 cm doit être

maintenue entre l’antenne de cet appareil et toute personne pendant son opération. Mettre en opération cet appareil a une distance

plus rapprochée que 20 cm n’est pas permis.

FOR SENSOR INSTALLATION INTO LED FIXTURES THE FOLLOWING STATEMENTS APPLY

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. CAN

ICES-005 (A) / NMB-005 (A)

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

T1/TT: WIT100 (Daintree One/EZ Connect Sensor)

FCC ID: PUU-WIT100

IC ID: 10798A-PUUWIT100

TZ: WIZ100 (Daintree Enterprise Sensor)

FCC ID: PUU-WIZ100

IC ID: 10798A-PUUWIZ100

TM: WMZ10 (Daintree Enterprise Multi-Sensor)

FCC ID: 2AS3F-WMZ10

IC ID: 25008-WMZ10

All trademarks are the property of their respective owners. Information provided is subject to change without

notice. All values are design or typical values when measured under laboratory conditions. GE Current a

Daintree Company is a business of the General Electric Company. © 2019 GE.

www.LED.com

IND541 (REV 09/23/19) A-1017098

Additional Regulatory Information

(consult regulatory standards for more information)

Purpose of Control Operating Control

Method of Mounting Control Independently Mounted Control. Sensor

modules intended for flush mounting

into a recessed cavity

Type of Action and Additional

Features

Type 1

Control Pollution Degree 2

Function/Software Class & Structure Class A

Rated Impulse Voltage 330V

Note: Any external cables connected to T1, TT, & TZ devices are NOT to exceed 3 meters

length. Any external cables connected to TM devices are NOT to exceed 30 meters

length.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

Daintree GE Lumination LSA Series Guide d'installation

- Taper

- Guide d'installation

dans d''autres langues

Documents connexes

Autres documents

-

OMNISIGHT MEGA1 Millimeter Wave Radar Manuel utilisateur

OMNISIGHT MEGA1 Millimeter Wave Radar Manuel utilisateur

-

GE current IND673 Manuel utilisateur

-

Lutron Electronics Vive Series Guide d'installation

Lutron Electronics Vive Series Guide d'installation

-

Lutron Electronics PowPak FCJ-010 Guide d'installation

Lutron Electronics PowPak FCJ-010 Guide d'installation

-

Legrand FSP-301B Low Voltage, High/Low/Off, PIR Fixture Integrated Outdoor Sensor In IP66 Enclosure Guide d'installation

-

Legrand FSP-301 Guide d'installation

-

Legrand FSP-311B High/Low/Off, PIR Fixture Integrated Outdoor Sensor In IP66 Enclosure Guide d'installation

-

wattstopper FSP-311B-S-L7-G Guide d'installation

-

Legrand FSP-321B Single/Dual Phase (Universal), High/Low/Off, PIR Fixture Integrated Outdoor Sensor In IP66 Enclosure Guide d'installation

-

Legrand FSP-321 Guide d'installation