Raypak 50-I-M Manuel utilisateur

- Catégorie

- Accessoires de piscine hors terre

- Taper

- Manuel utilisateur

Ce manuel convient également à

Catalog No. 6100.64A

Eective: 02-15-20

Replaces: New

P/N 241827 Rev 1

INSTALLATION

AND OPERATION

MANUAL

FOR YOUR SAFETY: Do not store or use gasoline or other ammable vapors and

liquids or other combustible materials in the vicinity of this or any other appliance. To

do so may result in an explosion or re.

Crosswind

Side Discharge

Heat Pump Pool Heater

NOTE: The instructions in this manual are for the use of qualied individuals specially trained and experienced

in the installation and maintenance of this type of equipment and related system components. Installation and

service personnel are required by some states to be licensed. Persons not qualied shall not attempt to install,

service, or maintain this equipment.

This manual should be maintained in legible condition and kept adjacent to the heat pump pool heater or in a

safe place for future use.

Inverter Models

CROSSWIND-30-I through -65-I

On/O Models

CROSSWIND-40-O through -65-O

(Canada Only)

2

While your unit is being installed by your professional and

licensed installer of choice, please take this opportunity to

quickly register your unit. With the necessary information

in hand, registering your new heat pump pool heater

only takes a few moments and is the best way to ensure

ecient warranty support during the warranty time frame.

See Figure 1 at the bottom of the page to locate and

record your model and serial number. Once you have

done this, please make sure you also have the following

information on hand:

• Name, phone number, and email address of

homeowner.

• Physical address of where the unit is installed; please

include any ‘subdivision’ or similar information.

• Any service challenges present at the house/

neighborhood: gated community, locked access at

house, guard dog, etc.

• Date of installation of the new unit.

• Name and phone number of the professional and

licensed entity that performed the installation for you.

With all of the above information in hand, please contact

us and ask to register your brand new heat pump,

(800)-260-2758 M-F 8:30 - 4:30 EST

or do this online at:

http://warranty.raypak.com

You will be given a Warranty Registration Conrmation

number which you should notate and keep in an

easily remembered accessible location along with

your Installation and Operation Manual, a copy of your

warranty (provided with your manual) and the above

information.

Warranty Registration Conrmation #:

ATTENTION: Please Take This Opportunity to Quickly Register Your Unit

This would also be a good time to review both the manual

and the warranty so that you are aware of how to correctly

operate your new equipment as well as how to keep from

voiding any aspects of your warranty. During the life of

your unit, please feel free to use the phone number on

the last page below to contact us with any questions you

may have about operation, warranty, and/or service.

Thank you very much choosing us to satisfy your pool

heating needs.

0000000000000000

NAME PLATE

BARCODE

SERIAL NUMBER

F10759

For location of this label on your unit, see Figure 8

Figure 1. Model and Serial Number Information

3

CONTENTS

1. WARNINGS ............................................................. 4

Pay Attention to These Terms .................................4

General Precautions ...............................................5

2. WATER CHEMISTRY ............................................. 5

3. BEFORE INSTALLATION ...................................... 6

Installation Considerations ......................................6

Automatic Chlorinators and Chemical Feeders.......6

Installation Requirements........................................7

Components for Inverter Models .............................9

Components for On/O Models ..............................9

Specications and Dimensions .............................10

Water Connections ................................................ 11

4. ELECTRICAL WIRING ......................................... 13

Wiring .................................................................... 13

Electrical Connections...........................................13

Automation Control, ..............................................13

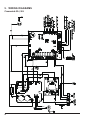

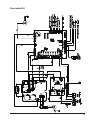

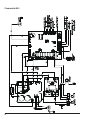

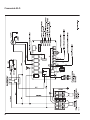

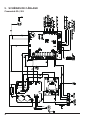

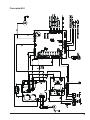

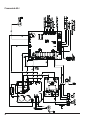

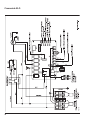

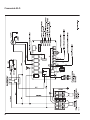

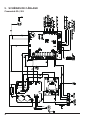

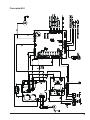

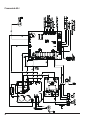

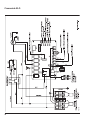

5. WIRING DIAGRAMS ............................................ 14

Crosswind-30-I, 50-I ..............................................14

Crosswind-40-I ...................................................... 15

Crosswind-65-I ...................................................... 16

Crosswind-40-O ....................................................17

Crosswind-50-O ....................................................18

Crosswind-65-O ....................................................19

6. CONTROLS ........................................................... 20

Inverter Models Only ............................................. 20

On/O Models Only ...............................................21

Using the On/O Display Unit ...............................21

7. OPERATING INSTRUCTIONS ............................ 22

Start-Up Procedures .............................................22

Before Start-Up .....................................................22

Starting ..................................................................22

After Start-Up ........................................................22

Maintenance..........................................................23

Cold Weather Operation .......................................23

Testing ................................................................... 23

8. TROUBLESHOOTING ......................................... 24

Fault Codes ...........................................................24

9. TECHNICAL PARAMETERS .............................. 25

10. REPLACEMENT PARTS ..................................... 26

11. ILLUSTRATED PARTS LIST ............................... 27

Inverter Models .....................................................27

On/O Models ....................................................... 28

12. WARRANTY .......................................................... 29

4

1. WARNINGS

Pay Attention to These Terms

A

DANGER

Indicates the presence of immediate hazards which will cause severe personal injury, death or

substantial property damage if ignored.

A

WARNING

Indicates the presence of hazards or unsafe practices which could cause severe personal injury,

death or substantial property damage if ignored.

A

CAUTION

Indicates the presence of hazards or unsafe practices which could cause minor personal injury

or product or property damage if ignored.

CAUTION

CAUTION used without the warning alert symbol indicates a potentially hazardous condition

which could cause minor personal injury or product or property damage if ignored.

NOTE

Indicates special instructions on installation, operation, or maintenance which are important but

not related to personal injury hazards.

A

CAUTION: Improper chemical content in a swimming

pool or spa can damage the heat pump pool heater. DO

NOT add pool/spa chemicals to the pool/spa via the

skimmer or any other apparatus (feeder, chlorinator, etc.)

That is on the inuent side (i.e. inow side) of the heater.

This will damage the heat pump pool heater and could

void the heat pump pool heater warranty. ALWAYS follow

the product manufacturer’s directions when adding any

chemicals to your pool.

A

CAUTION: These heat pump pool heaters are

charged with R-410A refrigerant. Ensure that all service

work is done with gauges and equipment suitable for

R-410A.

A

WARNING: This pool/spa heat pump pool heater

is an electromechanical machine that incorporates a

pressurized refrigerant gas in a sealed system. ONLY

trained and qualied service personnel are authorized to

install or service this equipment. Without proper training

and knowledge of such equipment, any attempt to install

or service the unit could result in serious injury or even

death.

A

CAUTION: Please do not place hands into the outlet

of the swimming pool heater, and do not remove the

heater fan screen at any time.

A

CAUTION: Elevated water temperature can

be hazardous. The U.S. Consumer Product Safety

Commission has these guidelines:

1. Spa water temperatures should never exceed 104°F

(40°C). A temperature of 100°F (38°C) is considered

safe for a healthy adult. Special caution is suggested

for young children.

2. Drinking of alcoholic beverages before or during spa

or hot tub use can cause drowsiness which could

lead to unconsciousness and subsequently result in

drowning.

3. Pregnant Women Beware! Soaking in water over

102°F (39°C) can cause fetal damage during the rst

three months of pregnancy resulting in the birth of a

brain-damaged or deformed child.

4. Before entering the spa or hot tub, users should

check the water temperature with an accurate

thermometer; spa or hot tub thermostats may err

in regulating water temperatures by as much as 4°F

(2.2°C).

5. Persons with a medical history of heart disease,

circulatory problems, diabetes, or blood pressure

problems should obtain a physician’s advice before

using pools or hot tubs.

6. Persons taking medications which induce

drowsiness, such as tranquilizers, antihistamines,

or anticoagulants, should not use spas or hot tubs.

5

General Precautions

Attention

1. Follow the instructions to set a comfortable water

temperature and avoid overheating.

2. Please don’t stack anything near the heat pump

that can block air flow to the inlet or exhaust area,

or the efficiency of the heater will be reduced

and/or stopped. For unit clearance information,

see Figure 2.

3. Please do not put hands into the outlet of the heater,

and do not remove the screen of the fan at any time.

4. If there are abnormal conditions such as noise,

smell, smoke, or electrical leakage, please switch off

the heater immediately and contact the local dealer.

Don’t try to repair it yourself.

5. Do not use or stock combustible gas or liquid such

as thinners, paint and fuel close the heater in order

to avoid fire.

6. The piping between the pool and the heater should

be less than 30 ft (9.1 m) long, or heater performance

may suffer.

Safety

1. Please keep the main power supply switch far away

from children.

2. If a power outage happens while the heater is running,

the heater will restart automatically when power is

restored. Please switch off the power supply when

there is a power outage, and reset the temperature

when power is restored.

3. Please switch off the main power supply in the event

of lightning and stormy weather to prevent machine

damage from a lightning strike.

4. If the heater is stopped for a long time, please cut

off the power supply and drain water completely from

the heater by opening the union of the inlet pipe.

Special Attention

Please read this instruction manual carefully and operate

strictly according to the user manual before starting the

heat pump, otherwise the heat pump may be damaged or

cause you unnecessary harm.

This product is only for heating swimming pool or spa

water, and cannot be used for other applications.

Inlet and outlet water nozzles are not designed to bear the

weight of external pipes. Support the piping independently.

Make sure power is turned o before opening the case and

performing service work.

1. The heater must be installed by a qualified electrician.

2. Set heating temperature within the recommended

range to maximize comfort.

3. Keep the air inlet and exhaust free from obstructions.

4. This heater has a power-off memory function.

5. When the ambient temperature is at or below 32°F

(0°C) make sure the main power switch is turned off

and all water is drained from the heat exchanger.

6. Never place your hand or any other object into the air

inlet or exhaust of the heater.

7. If you see, hear, smell or otherwise sense anything

unusual (such as abnormal noise, smell, smoke, or

electrical leakage) switch off the main power switch

immediately and contact your local dealer installer.

8. Do not attempt to repair the heater yourself.

2. WATER CHEMISTRY

NOTE: Corrosive water causes damages which will not

be covered under warranty.

Chemical imbalance can cause severe damage to your

heater and associated equipment. Maintain your water

chemistry according to Table A. If the mineral content

and dissolved solids in the water become too high, scale

forms inside the heat exchanger tubes, reducing heater

eciency and damaging the heater. If the pH drops below

7.2, this will cause corrosion of the heat exchanger and

severely damage the heater. Heat exchanger damage

resulting from corrosive water will not be covered by

the warranty.

For your health and the protection of your pool equipment,

it is essential that your water be chemically balanced. The

following levels must be used as a guide for balanced

water.

A

CAUTION: Free chlorine must not exceed 5 ppm

which can damage the heater and is not covered under

warranty.

• Occasional chemical shock dosing of the pool or spa

water should not damage the heater providing the

water is balanced.

• Automatic chemical dosing devices and salt

chlorinators are usually more efficient in heated

water. Unless controlled, they can lead to excessively

high chlorine levels which can damage your heater.

• Further advice should be obtained from your pool

or spa builder, accredited pool shop, or chemical

supplier for the correct levels needed for your pool.

6

Automatic Chlorinators

and Chemical Feeders

All chemicals must be introduced and completely diluted in

the pool or spa water before being circulated through the

heater. Do not place sanitizing chemicals in the skimmer.

High chemical concentrations will result when the pump is

not running (e.g. overnight).

Table A. Pool Water Chemistry

3. BEFORE INSTALLATION

A

WARNING: This heat pump pool heater is an

electromechanical machine that incorporates a

pressurized refrigerant gas in a sealed system. ONLY

trained and qualied service personnel are authorized to

install or service this equipment. Without proper training

and knowledge of such equipment, any attempt to install

or service the unit could result in serious injury or even

death.

This manual contains important information on the use,

maintenance and troubleshooting of your new heat pump

pool heater. This unit must be properly installed, maintained

and operated for optimal performance.

This heater is an extremely ecient, economical machine

designed specically for pool heating. It is similar in design

and operation to a typical residential air conditioning

system. The unit employs a hermetic motor/compressor

operating in a refrigeration cycle to extract heat from

ambient air and deliver it to the circulating pool water.

As with all heat pump pool heaters, and compared to

other types of heaters such as gas or oil-red, this heater

has lower BTU/hr heating capacity. As a result, it will be

required to operate longer to accomplish the desired

results. It may, at certain times, operate as much as 24

hours per day. However, this should not be of concern

to the owner, because the unit is designed to operate

continuously. Even though it may operate continuously for

many hours, it will still heat the pool with greater economy

than other types of fossil fuel heaters.

Place a recommended cover over the pool at night and

other non-use periods. This will keep evaporation, the

main cause of main heat loss, to a minimum, and will

greatly reduce pool heating costs. During warmer weather,

the cover may be required only at night.

INSTALLATION

Installation Considerations

Locate the heater carefully to minimize installation costs

while providing maximum eciency of operation, and to

allow adequate service access, as follows:

For unrestricted air intake and service access, position

each side of the unit according to Figure 2.

A

WARNING: This unit is designed for outdoor

installation; DO NOT install it in an enclosed area such

as a shed or garage.

To minimize water piping, locate the unit as close as

possible to the existing pool pump and lter.

Irrigation water should be directed away from the heater as

irrigation water spray can damage the heater.

Rain water run os - the unit is designed to operate

outdoors and can be exposed to rain. However, rain water

run o falling directly onto the unit can cause damage and/

or shorten the life of your unit. This may also void your

warranty. Install rain gutters or rain diverters on your roof

if the unit is installed in a position where contact with rain

run o may occur.

Recommended Level(s) Fiberglass Pools Fiberglass Spas Other Pool and Spa Types

Water Temperature 68-88°F (20-31°C) 89-104°F (31-40°C) 68-104°F (20-40°C)

pH 7.3-7.4 7.3-7.4 7.6-7.8

Total Alkalinity (ppm) 120-150 120-150 80-120

Calcium Hardness (ppm) 200-300 150-200 200-400

Salt (ppm) 4500 Maximum 4500 Maximum 4500 Maximum

Free Chlorine (ppm)* 2-3 2-3 2-3

Total Dissolved Solids (ppm) 3000 Maximum** 3000 Maximum** 3000 Maximum**

*Free Chlorine MUST NOT EXCEED 5 ppm!

**In saltwater chlorinated pools, the total TDS can be as high as 6000 ppm.

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical backup

into the heater when the pump is shut o.

See plumbing diagrams starting with Figure 9.

NOTE: High chemical concentrates from feeders

and chlorinators that are out of adjustment will cause

rapid corrosion to heat exchanger. Such damage is not

covered under the warranty.

7

A

WARNING: Do not install the unit within 3 ft (0.9 m)

of fossil-fuel-burning heaters. Air intake along the sides

of this heater could disturb the combustion process of

the unit, and could cause damage or personal injury.

Mount the unit on a level, sturdy base, preferably a

concrete slab. The size of the base should be at least 3 ft

by 3 ft (0.9 m x 0.9 m).

Installation Requirements

The heater must be installed by a pool professional. End

users are not qualied to install the heater. Damage may

occur to the heater or threaten the safety of the user.

1. The heater must be installed OUTSIDE in a well

ventilated area to avoid air recirculation, and in a

place with adequate room for both installation and

maintenance. Please refer to the following illustration.

2. This unit requires a minimum of 12" (305 mm) of

clearance from walls, shrubbery, equipment, etc.

around the entire perimeter of the heater. This allows

for ample air intake. Ample clearance around the air

outlet is required to prevent recirculation of air. We

recommend not placing the unit underneath eaves,

decks, or porches, as this causes recirculation of

discharged air, thereby reducing the efficiency of the

heater, or even stopping it.

3. Do not stack anything that will block air flow near the

inlet or outlet areas, or have any barrier within 20"

(508 mm) behind the main heater, or the efficiency of

the heater will be reduced.

4. The heater needs a pool pump (to be supplied by

the user). For recommended pump flow rates,

see Table J for Inverter Models, or Table K for

On/Off Models.

5. When the heater is running, there will be condensation

water discharged at the base. Place the drainage

nozzle into the condensation outlet and attach it

securely, then contact a drainage pipe from it to the

drain.

6. The piping between pool and the heater should be

less than 30 ft (9.1 m), or heater performance cannot

be ensured.

7. For best results, insulate the pipes between the pool

and heater.

8. It is important to keep the area next to the heater

clear of shrubs, bushes and chemicals containers.

These could prevent air from circulating fully through

the heater, and will aect the operation of the heater

or damage the heater.

9. When installed in areas where freezing temperatures

can be encountered, drain the water circuit to prevent

possible freeze-up damage. See page 23 for

proper procedures.

10. If the heater is below the water line of the pool, an

external WFS might be needed.

12"

(305 mm)

MINIMUM

VERTICAL

CLEARANCE

12"

(305 mm)

MINIMUM

12"

(305 mm)

MINIMUM

59"

(1500 mm)

MINIMUM

12"

(305 mm)

MINIMUM

F10762

Figure 2. Ventilation Clearances

8

GAS

HEATER

3 FT

(0.9 m)

MIN

AIR

FLOW

60" (1.52 m) MIN

12"

(0.3 m)

MIN

F10771

Figure 3. Installation Clearances

Inverter Models 60Hz (Heating and Cooling)

Models Raypak P/N Rheem P/N RUUD P/N Jacuzzi P/N

CROSSWIND-30-I 17738 17742 17746 17750

CROSSWIND-40-I 17739 17743 17747 17751

CROSSWIND-50-I 17740 17744 17748 17752

CROSSWIND-65-I 17741 17745 17749 17753

On/O Models 60Hz (Heating and Cooling)

Models Raypak P/N Rheem P/N RUUD P/N Jacuzzi P/N

CROSSWIND-40-O 18122 18125 18128 18131

CROSSWIND-50-O 18123 18126 18129 18132

CROSSWIND-65-O 18124 18127 18130 18133

Table B. Model Identication

9

FAN

EVAPORATOR

COMPRESSOR

TITANIUM HEAT

EXCHANGER

REACTOR

4-WAY VALVE

EXPANSION VALVE

HIGH AND LOW

PRESSURE VALVE

LOW PRESSURE

PROTECTION SWITCH

WATER FLOW

SWITCH

HIGH PRESSURE

PROTECTION SWITCH

F10754

TOUCH CONTROLLER

UNION

WATER OUTLET

1-1/2" PVC UNION

WATER INLET

1-1/2" PVC UNION

Figure 4. Inverter Model - Component Locations,

Front View

Figure 5. Inverter Model - Component Locations,

Right Side View

EVAPORATOR

FAN

COMPRESSOR

HIGH AND LOW

PRESSURE VALVE

4-WAY VALVE

WATER

FLOW

SWITCH

FRONT OF

HEAT

PUMP

LED

CONTROLLER

LOW PRESSURE

PROTECTION

SWITCH

HIGH PRESSURE

PROTECTION SWITCH

TITANIUM

HEAT

EXCHANGER

WATER INLET

1-1/2" PVC UNION

LED CONTROLLER

WATER OUTLET

1-1/2" PVC UNION

F10757

Figure 6. On/O Model - Component Locations,

Front View

Figure 7. On/O Model - Component Locations,

Right Side View

Components for Inverter Models

Components for On/O Models

10

Figure 8. Dimensions

F10755

E

F

G

B

C

H

A

D

SERIAL NUMBER

LABEL LOCATED

HERE

OUTLET

INLET

Specications and Dimensions

Inverter Models

Models A B C

D

(Width)

E

(Length)

F G

H

(Height)

Weight

lb (kg)

CROSSWIND-30-I

12.4

(315)

23.2

(312)

12.3

(312)

13.4

(340)

39

(991)

11.4

(290)

2.9

(74)

25.9

(657)

104

(47)

CROSSWIND-40-I

12.4

(315)

23.2

(312)

12.3

(312)

13.4

(340)

39

(991)

11.4

(290)

2.9

(74)

25.9

(657)

106

(48)

CROSSWIND-50-I

12.4

(315)

23.2

(312)

12.3

(312)

13.4

(340)

39

(991)

13

(330)

2.9

(74)

25.9

(657)

115

(52)

CROSSWIND-65-I

15.6

(395)

23.2

(312)

15.4

(390)

16.5

(420)

39

(991)

14.2

(360)

2.9

(74)

25.9

(657)

137

(62)

On/O Models

Models A B C

D

(Width)

E

(Length)

F G

H

(Height)

Weight

lb (kg)

CROSSWIND-40-O

12.4

(315)

23.2

(590)

12.3

(312)

12.4

(315)

39

(991)

11

(280

3

(77)

25.9

(657)

126

(57)

CROSSWIND-50-O

15.6

(395)

24

(610)

15.4

(390)

15.6

(396)

39

(-991)

12.2

(310)

3

(77)

25.9

(657)

150

(68)

CROSSWIND-65-O

15.6

(395)

23.2

(590)

15.2

(387)

15.6

(396)

39

(991)

15

(380)

3

(77)

29.8

(757)

172

(78)

Table C. Basic Product Data - in. (mm)

11

Figure 9. Swimming Pool Heat Pump Piping Layout

WATER TO SWIMMING POOL

SHUT OFF

DIVERTER VALVES

PUMP

FILTER

POOL

WATER IN

DRAINAGE

POWER CORD

OUTLET

INLET

F10772

Water Connections

A

CAUTION: The heater inlet and outlet connections

are NOT interchangeable. They must be connected as

instructed below.

A

WARNING: Chemical feeders can result in serious

damage to, or premature failure of the heater and may

void the heater warranty. Install a check valve and/

or a Hartford loop AFTER the heater and BEFORE any

chlorinating devices. Install any automatic chemical

feeders AFTER the heater.

1. Connect the heater in the return water line between

the lter and the pool/spa. See the piping layout

shown in Figure 9.

2. Connect the lter outlet to the tting marked at the

bottom front of the unit.

3. Connect the tting marked to the return piping to the

pool/spa. The inlet/outlet connection ttings of the

unit are 1-1/2 inch PVC unions.

Water connections from the heater to the main return

line can be PVC pipe or exible pipe approved for the

purpose and, in either case, should be at least equal in

size to the main pool/spa circulation piping.

1. Shuto diverter valves, preferably three-way valves

which allows for a bypass route, on the inlet and

outlet lines of the heater are required:

a. to protect (completely bypass) the heater from

any harmful chemical treatments (i.e. acid

wash, back-to-back super chlorinators, stain

treatments, etc.); or

b. to isolate the heater for service/repair or freeze

preparation and still allow pool/spa circulation to

continue.

Install any automatic chemical feeders downstream of

the heater. See the piping layout shown in Figure 9.

Note that some municipalities do not allow the use of a

shuto valve on the euent/outlet side of any heating

equipment, especially when there is one on the inlet

side. These entities typically instead allow a PVC tee

and spring check valve on the euent/outlet side. This is

acceptable and can also double as your protection from

chemical feeders and chlorinators that are downstream

of the unit.

Operate the pump and check the system for leaks.

12

RAYPAK, INC.

GENERAL NOTES:

1. THIS SYSTEM HAS BEEN DESIGNED AND SHALL BE

FABRICATED IN ACCORDANCE WITH THE REQUIREMENTS OF

THE FLORIDA BUILDING CODE SIXTH EDITION (2017). THIS

SYSTEM MAY BE USED WITHIN AND OUTSIDE THE HIGH

VELOCITY HURRICANE ZONE. THIS DESIGN IS NOT

INTENDED TO CERTIFY IMPACT RESISTANCE OF THE

MECHANICAL UNIT CABINETRY.

2. NO 33-1/3% INCREASE IN ALLOWABLE STRESS HAS BEEN

USED IN THE DESIGN OF THIS SYSTEM.

3. ALL DIMENSIONS AND THE MINIMUM WEIGHT (100 LB

MINIMUM) OF MECHANICAL UNIT SHALL CONFORM TO

LIMITATIONS STATED HEREIN. ALL MECHANICAL

SPECIFICATIONS (CLEAR SPACE, TONNAGE, ETC.) SHALL BE

AS PER MANUFACTURER RECOMMENDATIONS AND ARE THE

EXPRESS RESPONSIBILITY OF THE CONTRACTOR.

4. ANCHORS REFERRED TO HEREIN SHALL BE ELCO ULTRACON

SS4 OR ANY EQUIVALENT RATED CAPACITY ANCHOR,

INSTALLED TO 3000 PSI MIN CONCRETE. SEE ANCHOR

SCHEDULE FOR ANCHOR REQUIREMENTS. ALL FASTENERS

SHALL HAVE APPROPRIATE CORROSION PROTECTION TO

PREVENT ELECTROLYSIS.

5. ALL CONCRETE SPECIFIED HEREIN IS NOT PART OF THIS

CERTIFICATION. AS A MINIMUM, ALL CONCRETE SHALL BE

STRUCTURAL CONCRETE 4" MIN. THICK AND SHALL HAVE

MINIMUM COMPRESSIVE STRENGTH OF 3000 PSI, UNLESS

NOTED OTHERWISE.

6. THE CONTRACTOR IS RESPONSIBLE TO INSULATE ALL

MEMBERS FROM DISSIMILAR MATERIALS TO PREVENT

ELECTROLYSIS.

7. ELECTRICAL GROUND, WHEN REQUIRED, TO BE DESIGNED &

INSTALLED BY OTHERS.

8. THE ADEQUACY OF ANY EXISTING STRUCTURE TO

WITHSTAND SUPERIMPOSED LOADS SHALL BE VERIFIED BY

THE ONSITE DESIGN PROFESSIONAL AND IS NOT INCLUDED

IN THIS CERTIFICATION.EXCEPT AS EXPRESSLY PROVIDED

HEREIN, NO ADDITIONAL CERTIFICATIONS OR

AFFIRMATIONS ARE INTENDED.

9. THE SYSTEM DETAILED HEREIN IS GENERIC AND DOES NOT

PROVIDE INFORMATION FOR A SPECIFIC SITE. FOR SITE

CONDITIONS DIFFERENT FROM THE CONDITIONS DETAILED

HEREIN, A LICENSED ENGINEER OR REGISTERED ARCHITECT

SHALL PREPARE SITE SPECIFIC DOCUMENTS FOR USE IN

CONJUNCTION WITH THIS DOCUMENT.

SITE-SPECIFIC PRESSURE REQUIREMENTS AS DETERMINED IN

ACCORDANCE WITH ASCE 7-10 AND CHAPTER 16 OF THE FLORIDA

BUILDING CODE SHALL BE LESS THAN OR EQUAL TO THE DESIGN

PRESSURE CAPACITY VALUES LISTED HEREIN FOR ANY ASSEMBLY

AS SHOWN. DESIGN PRESSURE REQUIREMENTS SHALL BE

DETERMINED BY A REGISTERED DESIGN PROFESSIONAL ON A

JOB-SPECIFIC BASIS IN ACCORDANCE WITH THE GOVERNING

CODE.

DESIGN NOTES:

ANCHOR SCHEDULE:

CONCRETE:

(4" THICK MIN,

3000 PSI MIN.)

SUBSTRATE DESCRIPTION

CROSSWIND-30-I

23.23"

UNIT DIMENSIONS & MODELS:

APPROVED DESIGN

CRITERIA:

50.2 PSF LATERAL

41.2 PSF UPLIFT

WIND LOAD

WIND LOAD EVALUATION OF HEAT PUMP CROSSWIND MODELS: AT GRADE MOUNTED APPLICATIONS

(1)-1/4"Ø ELCO ULTRACON SS4, 1.75" EMBEDDED INTO 3 KSI

CONCRETE, 2.5" MIN. EDGE DISTANCE, 3" MIN. SPACING TO ANY

ADJACENT ANCHOR OR ANY EQUIVALENT RATED CAPACITY ANCHOR.

MECHANICAL UNIT

N.T.S

ISO VIEW

MODELS

"A" "B"

"C"

"D"

23.23"

23.23"

23.23"

12.40"

12.40"

12.40"

15.55"

13.39" 37.83"

13.39"

13.39"

16.54"

37.83"

37.83"

37.83"

"E"

25.91"

"F"

12.29"

WEIGHT

101 LBS

25.91"

25.91"

25.91"

12.29"

12.29"

15.35"

126 LBS

150 LBS

172 LBS

MECHANICAL UNIT

CONCRETE

SUBSTRATE

(BY OTHERS)

CROSSWIND-40-I

CROSSWIND-50-I

CROSSWIND-65-I

SCAN HERE :

OR, GO TO

ECALC.IO/TER

ABOUT THIS DOCUMENT

ENGINEER-CERTIFIED ORIGINALS, VARIATIONS

& MORE INFORMATION CAN BE FOUND BY

VISITING

ENGINEERINGEXPRESS.COM/STORE

OR BY SCANNING OR USING

THE WEB ADDRESS FOUND HERE >

THIS DOCUMENT NOT VALID WITHOUT

ORIGINAL ENGINEER CERTIFICATION

CONCRETE SLAB BY

OTHERS, TYP.

N.T.S.

MECHANICAL UNIT

FRONT VIEW

"D"

"E"

"F"

"E"

N.T.S.

MECHANICAL UNIT

FRONT VIEW

MECHANICAL UNIT

(SEE MODEL IN TABLE)

N.T.S. ELEVATION

TIE-DOWN DETAIL

UNIT BASE

RAIL

MECHANICAL

UNIT

CONCRETE SLAB

(BY OTHERS)

SEE CONCRETE SCHEDULE FOR

ANCHOR SPECIFICATIONS

MECHANICAL

UNIT

N.T.S.

TIE-DOWN LAYOUT

PLAN

"B"

"A"

"C"

"D"

Figure 10. Hurricane Tie Down Instructions

See "Table C. Basic Product Data - in. (mm)"

on page 10 for dimensions and weights.

13

4. ELECTRICAL WIRING

Wiring

Electrical installation should be done by a licensed

electrician only.

1. Make sure the power supply is at the rated voltage of

the appliance.

2. Ground the heater.

3. Wiring must be installed by a professional installation

technician and follow the circuit diagram.

Electrical Connections

Electrical installation should be done by a licensed

electrician only.

Refer to the unit rating plate below the control panel for

precise power requirements for your unit, and for ampacity

and over-current protection requirements.

All wiring must be in accordance with the National Electrical

Code, NFPA No. 70, latest edition, and all applicable state

and local codes. The wiring diagrams are located on page

14 through page 18.

A

WARNING: This heater MUST be installed using

exible conduit for supply wiring to the unit. This will

allow movement of the conduit whenever the junction

box is removed for service.

Locate the equipment disconnect means within 3 ft.

(0.9 m) of the heater’s electrical enclosure, or as close to

the heater as possible. Always satisfy applicable codes

and standards.

In sizing power wiring, be especially aware of up-sizing

requirements necessary due to wiring distances. Always

satisfy applicable codes and standards.

NOTE: Refer to the National Electrical Code, Article

680, for general requirements for swimming pools and

equipment, and to Article 440 for special considerations

necessary for circuits supplying hermetic refrigeration

motor/compressors.

This heater is pre-wired to work with external control

systems, heat-on-demand options, and other external

time clock overrides. Refer to the external control

system’s instructions.

Models Power

Min.

Circuit

Ampacity

Breaker Size

(Amp)

min. max.

CROSSWIND-30-I

208-230VAC

60HZ/1PH

12A 15A 15A

CROSSWIND-40-I

12A 15A 15A

CROSSWIND-50-I

16A 20A 20A

CROSSWIND-65-I

20A 20A 25A

CROSSWIND-40-O

12A 15A 15A

CROSSWIND-50-O

16A 20A 20A

CROSSWIND-65-O

17.2A 25A 25A

* Reference only - see National Electric Code or local codes for wire gauge length

limits.

Table D. Electrical Power Requirements

Automation Control,

2-Wire System - Heat Only

The Crosswind inverter models have a temperatures

sensor for temperature automation control.

Heater 2-Wire Controllers (Heat Only)

1. Install wires from the automation controller for “Heat”

on the terminal strip inside the heater electrical

compartment on the side of the heater.

2. Remove the jumper wire on the terminal block from

terminals marked #5 and #6. See Figure 11, and

wiring diagrams on page 14 through page 19.

L1 L2 P1 P2

5 6

PUMP CONTROLPOWER

208 -230V/60HZ

CUSTOMER REMOTE

CONTROL SWITCH

CONNECTOR

YLW/GRN

Figure 11. Automation Control 2-Wire System Connection

3. Install the automation control wires for “Heat” to

terminals #5 and #6.

4. Set temperature setting on the heater to 104°F

(40°C).

NOTE: When the automation controller has a

HEAT command the unit will be in the HEAT mode.

When the automation controller does not have a HEAT

command the unit will be in the OFF mode.

14

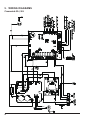

5. WIRING DIAGRAMS

Crosswind-30-I, 50-I

15

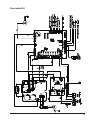

Crosswind-40-I

16

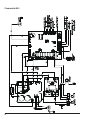

Crosswind-65-I

17

F10766

Crosswind-40-O

18

F10767

Crosswind-50-O

19

Crosswind-65-O

20

6. CONTROLS

Inverter Models Only

The Display controls general operation. The layout, main

functions and buttons are shown below.

HEATING

CAPACITY %

COMPRESSOR

HEATING

Figure 12. Operation Display, Models -30-I through -65-I

Symbol Designation Button Functions

Press 3 seconds to unlock/lock

screen

ON/OFF Power On/O

Speed Smart/Silent Mode

Up Temperature Adjustment

Down Temperature Adjustment

Table E. Display Button Functions

Power On

Press the LOCK button

for 3 seconds to light up screen,

then press POWER to power on the heater.

Adjust/Set Temperature:

When screen is unlocked, press UP or DOWN to

display or adjust the set temperature.

To change from Fahrenheit to Celsius, press the and

the for 3 seconds.

Smart/Silent mode selection

Smart mode, as default, will be activated when the HEAT

PUMP is on, and the screen shows .

Press FAN to enter Silent Mode. The display screen

will show .

NOTE: Select Smart Mode for initial heating.

Screen Lock

If no button is used within 30 seconds, the screen will lock

automatically. At this point the backlight will turn o and 0%

will display.

Alternatively you can lock the display by pressing the

LOCK button

for 3 seconds to achieve the same result.

To unlock the screen and use any other button, follow the

Power On instruction above.

Defrosting

Auto Defrosting:

1. When the heater is defrosting, HEATING will

continually flash.

2. After defrosting, HEATING will stop flashing.

Manual Defrosting:

1. When heater is heating, press FAN and MINUS

together for 5 seconds to start manual defrosting,

will flash continuously.

After defrosting, HEATING will stop ashing.

NOTE: Manual defrosting intervals should be more than

30 minutes and the compressor should run for more

than 10 minutes.

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

Raypak 50-I-M Manuel utilisateur

- Catégorie

- Accessoires de piscine hors terre

- Taper

- Manuel utilisateur

- Ce manuel convient également à

dans d''autres langues

- English: Raypak 50-I-M User manual

Documents connexes

Autres documents

-

Fartools RWP 400 Le manuel du propriétaire

-

Rheem TWPH-4550EHT10 Le manuel du propriétaire

-

Waterco Electroheat Pool Heat Pump Mode d'emploi

-

Nautyl PHCP50 Installation and User Manual

Nautyl PHCP50 Installation and User Manual

-

BLACK DECKER BD-137 Manuel utilisateur

-

Calorex I-PAC 8-12-16-22 Inverter Swimming Pool Heat Pump Guide d'installation

-

Pentair Pool UltraTemp ETi Chauffe-Piscine Hybride Le manuel du propriétaire

-

Zodiac Edenpac 5D Instructions For Installation And Use Manual

-

Rheem P-M406A-E Le manuel du propriétaire

-

Rheem P-M407A-EN-C Le manuel du propriétaire