Quick TCD 1062 Manual For Use And Installation

- Taper

- Manual For Use And Installation

REMOTE CONTROL

TCD 1062

Manuale di installazione ed uso COMANDO REMOTO TCD 1062

Manual for use and installation REMOTE CONTROL TCD 1062

Mode d’emploi et d’installation COMMANDE A DISTANCE TCD 1062

Installations- und Benutzerhandbuch FERNSTEUERUNG TCD 1062

Manual de instalación y uso MANDO REMOTO TCD 1062

High

Quality

Nautical

Equipment

REV 002a

IT

EN

FR

DE

ES

3

TCD 1062 - REV002A

pag. 4 CARATTERISTICHE E INSTALLAZIONE: installazione del TCD 1062

pag. 5 INSTALLAZIONE: installazione del TCD 1062

pag. 6 INSTALLAZIONE: collegamento elettrico - schema elettrico dei collegamenti

pag. 7 FUNZIONAMENTO: comando remoto TCD 1062 - comando propulsore - comando interruttore di linea

pag. 8 FUNZIONAMENTO: abilitazione del TCD 1062 - azionamento del propulsore - azionamento del propulsore di poppa

pag. 9 FUNZIONAMENTO: disabilitazione - comandi remoti multipli in parallelo - funzionamento comando interruttore di linea

pag 10 ERRORI E PROBLEMI DI SISTEMA: errore checksum flash - problemi con reset automatico - problemi con reset manuale

pag. 11 MANUTENZIONE - DATI TECNICI

INDICE

pag. 12 CHARACTERISTICS AND INSTALLATION: installation of the TCD 1062

pag. 13 INSTALLATION - installation of the TCD 1062

pag. 14 INSTALLATION - electric connections - electrical connections diagram

pag. 15 OPERATION - TCD 1062 remote control - thruster command - main switch command

pag. 16 OPERATION - TCD 1062 enablement - activation of thruster - bow thruster activation

pag. 17 OPERATION - disablement - multiple remote controls in parallel - main switch command functionning

pag 18 SYSTEM ERRORS AND PROBLEMS - automatic reset problems - manual reset problems

pag. 19 MAINTENANCE - TECHNICAL DATA

INDEX

Seite 20 CARACTÉRISTIQUES ET INSTALLATION: installation de la commande a distance

Seite 21 INSTALLATION: Installation de la commande a distance

Seite 22 INSTALLATION: branchement electrique - schéma electrique des branchements

Seite 23 FONCTIONNEMENT: commande à distance TCD 1062 - commande propulseur - commande interrupteur de ligne

Seite 24 FONCTIONNEMENT: activation de la commande à distance - actionnement du propulseur - actionnement du propulseur de poupe

Seite 25 FONCTIONNEMENT:

désactivation - commandes à distance multiple en parallele - fonctionnement commande interrupteur de ligne

Seite 26 ERREURS ET PROBLEMES DE SYSTEME: problemes avec remise a zero automatique - problemes avec remise a zero manuelle

Seite 27 MAINTENANCE - CARACTÉRISTIQUES TECHNIQUES

SOMMAIRE

pág. 28 EIGENSCHAFTEN UND INSTALLATION: installation der TCD 1062

pág. 29 INSTALLATION: installation der TCD 1062

pág. 30 INSTALLATION: Stromanschluss - Elektrischer Schaltplan der Verbindungen

pág. 31 BETRIEB: Fernsteuerung TCD 1062 - Steuerung Maschinenanlage - Steuerung Leitungsschalter

pág. 32 BETRIEB: Fernsteuerfreigabe - Betätigung des Antriebs - Betätigung des Bug-Antriebs

pág. 33 BETRIEB

: Ausschalten - Parallel geschaltete mehrfache Fernsteuerungen - Funktionsweise Der Steuerung Des Leitungsschalters

pág 34 SYSTEMFEHLER UND PROBLEME: Probleme mit dem Automatischen Zurücksetzen - probleme mit dem manuelle zurücksetzen

pág. 35 WARTUNG - TECHNISCHE DATEN

INHALTSANGABE

pág. 36 CARACTERISTÍCAS E INSTALACIÓN: instalación del TCD 1062

pág. 37 INSTALACIÓN: instalación del TCD 1062

pág. 38 INSTALACIÓN: conexión eléctrica - esquema eléctrico de las conexiones

pág. 39 FUNCIONAMIENTO: mando remoto TCD 1062 - mando propulsor - Mando interruptor de línea

pág. 40 FUNCIONAMIENTO: habilitación del TCD 1062 - accionamiento del propulsor - Accionamiento del propulsor de popa

pág. 41 FUNCIONAMIENTO:

deshabilitación - mandos remotos múltiples en paralelo - funcionamiento del mando del interruptor de línea

pág 42 ERRORES Y PROBLEMAS DEL SISTEMA: problemas con reinicialización automática - problemas con reinicializaciónmanual

pág. 43 MANTENIMIENTO - ESPECIFICACIONES TECNICAS

INDICE

IT

EN

FR

DE

ES

4

CARATTERISTICHE E INSTALLAZIONE

TCD 1062 - REV002A

IT

TCD 1062 - Comando remoto con comando interruttore di linea integrato

Il TCD 1062 può funzionare solo in un sistema in cui sia presente un interruttore di linea TMS.

Il TCD 1062 è stato progettato per comandare i propulsori di manovra prodotti da Quick

®

.

Altri vantaggi che il TCD 1062 offre sono:

• Interfaccia utente semplice ed intuitiva.

• Alimentazione universale (da 8 a 31 Vdc).

• Funzionamento in un ampio intervallo di temperature ambiente.

• Possibilità di collegare più comandi remoti TCD in parallelo.

• Facilità di installazione tramite connettori (prolunghe opzionali).

• Sistema di priorità automatica.

• Protezione contro l’inversione di polarità (anche TSC), cortocircuito in uscita, attività prolungata dei propulsori e

interruzione del cablaggio di comando dei propulsori.

• Comando interruttore di linea thruster (TSC) integrato.

INSTALLAZIONE

PRIMA DI UTILIZZARE IL TCD 1062, LEGGERE ATTENTAMENTE IL PRESENTE MANUALE D'USO. IN CASO

DI DUBBI CONTATTARE IL RIVENDITORE O IL SERVIZIO CLIENTI QUICK

®

.

In caso di discordanze o eventuali errori tra il testo tradotto e quello originario in italiano, fare riferimento al testo

italiano o inglese.

Questo dispositivo è stato progettato e realizzato per essere utilizzato su imbarcazioni da diporto.

Non è consentito un utilizzo differente senza autorizzazione scritta da parte della società Quick

®

.

Il TCD 1062 è stato progettato e realizzato per gli scopi descritti in questo manuale d’uso. La società Quick

®

non si

assume alcuna responsabilità per danni diretti o indiretti causati da un uso improprio del TCD 1062, da una errata

installazione o da possibili errori presenti in questo manuale.

LA MANOMISSIONE DEL TCD 1062 DA PARTE DI PERSONALE NON AUTORIZZATO FA DECADERE LA

GARANZIA.

LA CONFEZIONE CONTIENE:

TCD 1062 - cornice - dima di foratura - condizioni di garanzia - il presente manuale di

installzione ed uso.

INSTALLAZIONE DEL TCD 1062

Di seguito sarà descritta una procedura di installazione tipica.

Non è possibile descrivere una procedura che sia applicabile a tutte le situazioni, adattare questa procedura per

soddisfare i propri requisiti. Individuare la posizione più adatta dove praticare la sede per alloggiare il TCD 1062

seguendo questi criteri:

• Il TCD 1062 deve essere posizionato in modo da essere facilmente manovrabile dall’operatore.

• Scegliere una posizione che sia liscia e piana.

• Deve essere presente un accesso posteriore per l’installazione e la manutenzione.

• Deve esistere spazio sufficiente dietro alla posizione scelta per collocare il retro del TCD 1062 e i cablaggi.

• La parte posteriore del TCD 1062 deve essere protetta da acqua e umidità.

• Porre particolare attenzione quando si effettuano i fori sui pannelli o su parti dell’imbarcazione.

Questi fori non devono indebolire o causare rotture alla struttura dell’imbarcazione.

F

F

5

INSTALLAZIONE

TCD 1062 - REV002A

IT

POWER

OFF

POWER

ON

INSTALLAZIONE DEL TCD 1062

Il TCD 1062 risponde agli standard EMC (compatibilità elettromagnetica) ma è richiesta una corretta installazione per

non compromettere le proprie prestazioni e quelle dei comandi posti nelle vicinanze.

Per questo motivo il TCD 1062 deve essere distante almeno:

• 25 cm dalla bussola.

• 50 cm da un qualsiasi apparecchio radio ricevente.

• 1 m da qualsiasi apparato radiotrasmittente (escluso SSB).

• 2 m da qualsiasi apparato radiotrasmittente SSB.

• 2 m dal percorso del fascio radar.

Dopo aver scelto la posizione del TCD 1062, procedere come riportato di seguito:

• Posizionare la dima di foratura (fornita in dotazione) sulla superficie dove sarà installato il TCD 1062.

• Marcare il centro di ogni foro.

• Realizzare l'asola per alloggiare il retro del comando remoto.

• Rimuovere la dima ed eventuali bave presenti sui fori.

• Inserire il TCD 1062 nella sede.

• Fissare il TCD 1062 al pannello tramite quattro viti a testa svasata (non in dotazione).

• Posizionare la cornice sul TCD 1062.

6

TCD 1062 - REV002A

IT

COLLEGAMENTO ELETTRICO

Il TCD 1062 risponde agli standard EMC (compatibilità elettromagnetica) ma è richiesta una corretta installazione per

non compromettere le proprie prestazioni e quelle dei comandi posti nelle vicinanze.

Per questo motivo i cavi del TCD 1062 devono essere distanti almeno:

• 1 m dai cavi che trasportano segnale radio (escluso radiotrasmittenti SSB).

• 2 m dai cavi che trasportano segnale radio di radiotrasmittenti SSB.

Seguire le regole riportate di seguito per la realizzazione dell’impianto elettrico relativo al TCD 1062:

• Collegare i connettori del TCD 1062 al connettore proveniente dal propulsore di manovra (utilizzare uno sdoppiatore,

non in dotazione).

• Inserire un interruttore per accendere e spegnere il TCD 1062 (non in dotazione).

• Posizionare l’interruttore in modo che sia facilmente raggiungibile nel caso in cui sia necessario spegnere l’apparec-

chio per evitare situazioni di pericolo.

• Inserire un fusibile da 4A rapido sulla linea di alimentazione del TCD 1062 (non in dotazione).

• Inserire un fusibile da 100mA sulla linea di alimentazione del comando interruttore di linea TSC (non in dotazione).

• Dimensionare correttamente la sezione dei cavi in funzione della loro lunghezza.

• Non utilizzare la tensione proveniente dal gruppo batterie motori o propulsori per alimentare il TCD 1062.

• Alimentare il TCD 1062 solo dopo aver effettuato e verificato l’esattezza di tutti i collegamenti elettrici.

*

*

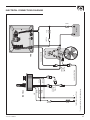

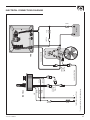

SCHEMA ELETTRICO DEI COLLEGAMENTI

BATTERIA

ROSSO

NERO

SDOPPIATORE

per TCD

(TCDSP)

ALLA BATTERIA SERVIZI

INTERRUTTORE

FUSIBILE

* Negativo dei gruppi batteria in comune.

INSTALLAZIONE

FUSIBILE

MOTORE

ROSSO

NERO

TCD 1062

TMS

SDOPPIATORE

per TMS

(TMSSP)

FUSIBILE

INTERRUTTORE

PROLUNGA

PROLUNGA

FUSIBILE

7

TCD 1062 - REV002A

IT

FUNZIONAMENTO

FUNZIONAMENTO DEL TCD 1062

L’interfaccia utente è composta da 1 pulsante di abilitazione, 1 joystick, 1 interruttore a fungo, 2 LED di abilitazione, 2

LED di direzione , 1 LED Power OFF e 1 LED Power ON.

LED DI ABILITAZIONE LED DI ABILITAZIONE

PULSANTE DI ABILITAZIONE

COMANDO PROPULSORE

Pulsante di abilitazione

Il pulsante abilita o disabilita il comando remoto.

Joystick

Quando il joystick viene spostato a destra, a fine corsa, si muove a destra la poppa o la prua dell’imbarcazione a

seconda del propulsore comandato.

Quando il joystick viene spostato a sinistra, a fine corsa, si muove a sinistra la poppa o la prua a dell’imbarcazione a

seconda del propulsore comandato.

LED di abilitazione

I LED di abilitazione segnalano lo stato di abilitazione / disabilitazione del comando propulsore.

LED di direzione

I LED di direzione segnalano il movimento verso destra o sinistra dell'imbarcazione.

I LED di abilitazione e direzione, inoltre, sono utilizzati per segnalare eventuali errori o problemi.

COMANDO INTERRUTTORE DI LINEA

Interruttore a Fungo

Quando l’interruttore a fungo viene premuto disabilita i comandi presenti in linea.

LED Power

Segnalano lo stato del comando di linea.

Utilizzare l’interruttore posto sulla linea di alimentazione per accendere e spegnere il TCD 1062.

Una volta collegata l’alimentazione il TCD 1062 effettua il test dei LED.

Il test dei LED avviene accendendo contemporaneamente tutti i LED per 2 secondi.

Se non vengono rilevati errori o problemi il TCD 1062 si pone nello stato disabilitato (vedi disabilitazione del TCD 1062).

ATTENZIONE:

esercitarsi ad azionare i propulsori in acque libere, per evitare di danneggiare l’imbarcazione con

manovre avventate.

FUNGO

JOYSTICK

LED POWER ON LED POWER OFF

LED DI DIREZIONE SINISTRA LED DI DIREZIONE DESTRA

8

TCD 1062 - REV002A

IT

ABILITAZIONE DEL TCD 1062 (COMANDO PROPULSORE)

Per abilitare il TCD 1062 premere e tenere premuto il pulsante di abilitazione per almeno 1 secondo (con l’interruttore a

fungo non premuto).

Trascorso questo periodo i LED di abilitazione inizieranno a lampeggiare con una frequenza maggiore.

Rilasciando il pulsante di abilitazione, i LED di abilitazione e il LED Power ON rimarranno accesi in maniera permanente e

il TCD 1062 risulterà abilitato.

AZIONAMENTO DEL PROPULSORE

Azionamento del propulsore di prua

ATTENZIONE:

una volta rilasciato il joystick di direzione, l’imbarcazione continuerà a muoversi a causa

dell’inerzia del moto.

Durante la fase di azionamento del propulsore, il relativo LED di direzione si accenderà in maniera permanente.

Per muovere a destra la prua, muovere verso de-

stra, a fine corsa, la leva del joystick.

Per muovere a sinistra la prua, muovere verso sini-

stra, a fine corsa, la leva del joystick.

FUNZIONAMENTO

Azionamento del propulsore di poppa

A causa dei limiti di spazio nella prua, alcune imbarcazioni sono dotate solo di un propulsore di poppa.

In questo caso, tale propulsore sarà utilizzato nello stesso modo in cui si utilizza il propulsore di prua (vedi paragrafo

Azionamento del propulsore di prua

).

Nota:

Il comando introduce un ritardo di 2 secondi nel caso in cui il propulsore sia azionato in una direzione e si tenti di azio-

narlo nella direzione opposta (passaggio immediato da destra a sinistra o viceversa).

9

TCD 1062 - REV002A

IT

FUNZIONAMENTO

DISABILITAZIONE DEL TCD 1062 (COMANDO PROPULSORE)

La disabilitazione del TCD 1062 abilitato si ha nei seguenti casi:

• Premendo il pulsante di abilitazione.

• Quando con più comandi remoti in parallelo se ne abilita un altro.

• Trascorsi 6 minuti dall’abilitazione senza effettuare operazioni o dall’ultimo movimento del joystick.

• Quando viene premuto l’interruttore a fungo.

(In questa condizione i LED di abilitazione lampeggiano a bassa frequenza e il joystick è disabilitato, mentre il LED

Power OFF rimane acceso fisso).

Il passaggio allo stato di disabilitazione è segnalato dal comando con un suono prolungato di circa un secondo e il suc-

cessivo lento lampeggio dei led di abilitazione. I pulsanti di direzione (TCD1022) o il joystick (TCD 1042) sono disabilitati.

COMANDI REMOTI MULTIPLI IN PARALLELO

E’ possibile installare più comandi remoti in parallelo. In questo caso, si ha il funzionamento di un solo comando remoto

alla volta. Il comando remoto attivo è sempre l’ultimo che viene abilitato; gli altri comandi remoti posti in parallelo ven-

gono automaticamente disabilitati.

Quando si comanda il propulsore dall’ultimo comando remoto abilitato, la direzione del movimento dell’imbarcazione

sarà segnalata dall’accensione del relativo LED anche sugli altri comandi remoti disabilitati.

FUNZIONAMENTO COMANDO INTERRUTTORE DI LINEA

Non appena l’interruttore di linea è alimentato si accenderanno per 2 secondi i LED Power ON e Power OFF.

Dopodichè, se l’interruttore a fungo non è premuto, il LED Power ON inizierà a lampeggiare lentamente, indicando che il

sistema è in attesa, mentre il LED Power OFF sarà spento.

Se si abilita il comando del propulsore, il LED Power ON si accenderà in maniera fissa indicando che il comando del pro-

pulsore e il comando TMS in linea sono abilitati.

Nel caso in cui l’interruttore a fungo sia premuto, il LED Power OFF si accenderà e i comandi TCD presenti in linea e il

TMS si disabiliteranno (LED Power ON spento).

Per sbloccare l’interruttore a fungo bisogna ruotare il pomello rosso in senso antiorario.

Disabilitazione/abilitazione del suono del comando.

E’ possibile disabilitare le segnalazioni acustiche emesse dal comando.

Di seguito la procedura da eseguire:

• Togliere l’alimentazione al comando.

• Mantenere premuto il tasto di abilitazione e alimentare il comando che emetterà un breve suono.

• Rilasciare il tasto di abilitazione attendendo che il comando esegua il test dei led e si ponga in stato disabilitato (lampeg-

gio lento dei led di abilitazione).

E’ possibile riabilitare le segnalazioni acustiche emesse dal comando.

Di seguito la procedura da seguire:

• Togliere l’alimentazione al comando.

• Mantenere premuto il tasto di abilitazione e alimentare il comando che emetterà due brevi suoni.

• Rilasciare il tasto di abilitazione attendendo che il comando esegua il test dei led e si ponga in stato disabilitato (lampeg-

gio lento dei led di abilitazione).

10

TCD 1062 - REV002A

IT

Il reset di questa classe di problemi avviene, una volta rimossa la causa che li ha generati, spegnendo e riaccendendo il

comando. In presenza dei problemi 3, 4, 5, potrebbe essere necessario lo spegnimento e la riaccensione dei dispositivi

esterni che hanno segnalato il problema. Riferirsi al loro manuale di installazione ed uso.

ERRORI DI SISTEMA (COMANDO PROPULSORE)

Durante la fase di accensione il TCD 1062 può segnalare la presenza di errori di sistema.

Errore checksum flash

Nel caso in cui venga riscontrato l’errore, tutti i LED lampeggiano velocemente.

In questo caso è necessario contattare al più presto un punto assistenza o il servizio clienti Quick

®

.

PROBLEMI DI SISTEMA (COMANDO PROPULSORE)

Di seguito si riportano i problemi di sistema, suddivisi in due categorie:

problemi con reset automatico e problemi con reset manuale.

PROBLEMI CON RESET AUTOMATICO

Il reset di questa classe di problemi avviene automaticamente, non appena scompare la causa che ha generato il pro-

blema.

Bassa tensione di alimentazione

Il problema è segnalato se la tensione di alimentazione scende al di sotto di 10.5Vdc per più di un secondo. Il reset del

problema avviene se la tensione di alimentazione supera la soglia di 11.5Vdc per più di un secondo. Verificare lo stato di

carica del gruppo batterie da cui è derivata l’alimentazione o l’impianto elettrico.

In presenza del problema i LED di abilitazione si spengono per un breve istante.

Protezione contro l’attività prolungata del motore

Dopo 5 minuti e 40 secondi circa di utilizzo continuo (o equivalente) del propulsore, il comando al propulsore è inibito

per un periodo di tempo pari a 20 minuti, permettendo un parziale raffreddamento del propulsore (per il raffreddamento

totale occorrono tipicamente circa 40 minuti).

In presenza di questo problema i LED di direzione rosso e verde lampeggiano in contemporanea con i LED di abilitazione

con segnalazione acustica intermittente (la durata della segnalazione acustica è di 10 secondi per ogni minuto).

Il sistema memorizza il tempo di raffreddamento parziale trascorso per il propulsore; se il sistema è erroneamente spen-

to (disconnessa l’alimentazione all'unità TCD) prima che siano trascorsi 20 minuti, alla riaccensione è necessario atten-

dere il tempo di raffreddamento parziale residuo prima di potere utilizzare il comando del propulsore.

Trascorso il tempo di raffreddamento totale il propulsore potrà essere nuovamente utilizzato per 5 minuti e 40 secondi.

PROBLEMI CON RESET MANUALE

Il comando segnalerà, attraverso un diverso numero di lampeggi dei LED di abilitazione, la presenza di eventuali proble-

mi con reset manuale. In corrispondenza dei lampeggi si udirà un breve suono.

Di seguito la tabella di corrispondenza dei lampeggi con i problemi a reset manuale:

ERRORI E PROBLEMI DI SISTEMA

N° LAMPEGGI PROBLEMA DESCRIZIONE

1

Sovraccarico sulla

linea elettrica di

comando

Il problema è segnalato in caso in cui il comando rilevi un corto circuito o un sovraccarico

sulla linea elettrica di comando del propulsore. Verificare il cablaggio delle linee elettriche

del comando al propulsore e l'assorbimento dei teleruttori installati sul propulsore.

2

Interruzione della linea

elettrica di comando

Il problema è segnalato in caso in cui il comando rilevi una interruzione della linea elettrica

di comando del propulsore. Verificare il cablaggio delle linee elettriche del comando al

propulsore.

3

Problema presente

sul propulsore BTR*

Il sistema di controllo del propulsore BTR ha rilevato un problema.

Riferirsi al manuale di installazione ed uso del BTR.

4

Problema presente

nello switch

parallelo/serie*

Il sistema di controllo dello switch PSS ha rilevato un problema.

Riferirsi al manuale di installazione ed uso del PSS.

5

Problema presente

su TMS*

L'interruttore di linea TMS ha rilevato un problema legato al teleruttore di comando del

propulsore. Riferirsi al manuale di installazione ed uso del TMS.

* Se installato.

11

TCD 1062 - REV002A

IT

QUICK

®

SI RISERVA IL DIRITTO DI APPORTARE MODIFICHE ALLE CARATTERISTICHE TECNICHE DELL'APPARECCHIO E AL CONTENUTO DI QUESTO MANUALE SENZA ALCUN PREAVVISO.

(1)

Con tensione di alimentazione inferiore a 8 Vdc il comando può resettarsi.

(2)

Valore tipico con comando remoto disabilitato.

(3)

Valore tipico con comando abilitato.

(4)

Escluso retro del comando (IP20).

CARATTERISTICHE TECNICHE

MANUTENZIONE

Il TCD 1062 non richiede una particolare manutenzione.

Per assicurare il funzionamento ottimale del TCD 1062 verificare, una volta all’anno, i cavi e le connessioni elettriche.

Pulire il TCD 1062 con un panno morbido inumidito d’acqua.

Non utilizzare prodotti chimici o abrasivi per pulire il TCD 1062.

MANUTENZIONE - DATI TECNICI

MODELLO

TCD 1062

CARATTERISTICHE COMANDO INTERRUTTORE DI LINEA

Tensione di alimentazione (1) da 8 a 31 Vdc

Assorbimento di corrente a riposo (2) 10 mA

Assorbimento massimo (3) 40 mA

CARATTERISTICHE COMANDO PROPULSORE

Portata in corrente dei comandi

destro e sinistro del propulsore

4 A

Tensione di alimentazione (1) da 8 a 31 Vdc

Assorbimento di corrente a riposo (2) 10 mA

Assorbimento massimo

(3)

55 mA + assorbimento bobina teleruttore

CARATTERISTICHE GENERALI

Temperatura operativa da -20 a +70 °C

Grado di protezione

(4)

IP 65

Standard EMC EN 60945 - FCC PART 15 RULES 47

Peso 110 g

Dimensioni compreso cornice (L x L) 78 x 131 mm

12

CHARACTERISTICS AND INSTALLATION

EN

TCD 1062 - REV002A

TCD 1062 - Remote control with integrated line switch control

TCD 1062 can only work in a system with a TMS line switch.

TCD 1062 was designed to control manoeuvre thrusters manufactured by Quick

®

.

Other important advantages of the TCD 1062 are:

• Simple and intuitive user interface.

•

Universal supply

(from 8 to 31 Vdc).

• Can work in a wide range of ambient temperatures.

• Possibility of connecting several TCD remote controls in parallel.

• Easy to install by means of connectors (optional extensions).

• Automatic priority system.

• Protection against reverse polarity, output short circuit, prolonged activity of thrusters and interruption of thrusters

controls wiring.

• Integrated thruster (TSC) line switch control.

INSTALLATION

BEFORE USING THE TCD 1062, READ THIS INSTRUCTION MANUAL CAREFULLY.

IN CASE OF DOUBTS, CONTACT QUICK

®

CUSTOMER SERVICE OR YOUR LOCAL DEALER.

In case of discordance or errors in translation between the translated version and the original text in the Italian

language, reference will be made to the Italian or English text.

This device was designed and constructed for use on recreational crafts.

Other forms of use are not permitted without written authorization from the company Quick

®

.

The TCD 1062 is designed and constructed for the purposes described in this instruction manual. Quick

®

shall not be

held responsible for any direct or indirect property damage or personal injury caused by inappropriate or unintended

use of the TCD 1062, incorrect installation or any errors that may be present in this manual.

THE WARRANTY SHALL BE VOID IF THE TCD 1062 IS TAMPERED WITH OR ALTERED BY NON AUTHORISED

PERSONNEL.

THE PACKAGE CONTAINS:

TCD 1062 - frame - drilling template - conditions of warranty - manual for use and installa-

tion.

INSTALLATION OF THE TCD 1062

The typical installation procedure is described herein, it is not possible to describe a procedure applicable for all situa-

tions that may be encountered.

Adapt this procedure to satisfy your own personal requirements.

Locate the most suitable position to house the TCD 1062 following the recommendations given below:

• The TCD 1062 must be positioned so that it can easily be manoeuvred by the operator.

• Select a smooth and flat area.

• Access from the rear must be available for installation and maintenance purposes.

• There must be enough space behind the chosen position in order to accommodate the rear of the TCD 1062 and the

wires.

• The rear part of the TCD 1062 must be protected from water and damp.

• Pay careful attention when drilling the panels or parts of the boat.

These holes should not weaken or break/crack the boat's structure.

F

F

Manual for use and installation

13

INSTALLATION

EN

TCD 1062 - REV002A

POWER

OFF

POWER

ON

INSTALLATION OF THE TCD 1062

The TCD 1062 complies with EMC standards (electromagnetic compatibility) but requires correct installation to avoid

compromising its performance and that of the surronding instruments.

For this reason the TCD 1062 must be positioned at a distance of at least:

• 25 cm away from the compass.

• 50 cm away from any radio receivers.

• 1 m away from any radio transmitters (except for SSB).

• 2 m away from any radio transmitters SSB.

• 2 m away from the path of the radar beam.

After choosing where to position the TCD 1062, proceed as follows:

• Position the drilling template (provided) on the surface where the TCD 1062 will be installed.

• Mark the centre of each hole.

• Make the slot to house the back of the remote control.

• Remove the template and any burrs present in the holes.

• Insert the TCD 1062 into its seat.

• Fix the TCD 1062 to the panel with four countersunk head screws (not provided).

• Position the frame on the TCD 1062.

14

EN

TCD 1062 - REV002A

INSTALLATION

ELECTRIC CONNECTIONS

The TCD 1062 complies with EMC standards (electromagnetic compatibility) but requires correct installation to avoid

compromising its performance and that of the surronding instruments.

For this reason the TCD 1062 wires must be positioned at a distance of at least:

• 1 m away from cables that carry radio signals (except SSB radio transmitters).

• 2 m away from cables for SSB radio transmitter signals.

Follow the rules below to construct the electrical installation relative of the TCD 1062:

• Connect the TCD 1062 connectors to the connectors coming from the thrusters (use a splitter, not supplied).

• Put in a switch, to turn on and shut off the TCD 1062 (not provided).

• Position the switch so that it is within easy reach should it be necessary to shut off the remote control in an emer-

gency.

• Insert a 4A quick-acting fuse on the TCD 1062 power supply line (not provided).

• Insert a 100mA quick-acting fuse on the TSC command power supply line (not provided).

• Use wires, for the remote control power supply, with a correct cross section according to their length.

• Do not use supply from the motors or thrusters battery circuit for the TCD 1062.

• Before switching on the power to the TCD 1062, check that all the electrical connections are correct.

*

*

ELECTRICAL CONNECTIONS DIAGRAM

BATTERY

RED

BLACK

SPLITTER

for TCD (TCDSP)

TO THE SERVICES BATTERY

SWITCH

FUSE

* Common negative for the battery groups.

FUSE

MOTOR

RED

BLACK

TCD 1062

TMS

SPLITTER

for TMS

(TMSSP)

FUSE

SWITCH

EXTENSION

EXTENSION

FUSE

15

EN

TCD 1062 - REV002A

OPERATION

TCD 1062 FUNCTIONING

The user interface is composed of 1 enabling button, 1 joystick, 1 mushroom push-button switch, 2 enabling Leds, 2

direction Leds , 1 LED Power OFF and 1 LED Power ON.

ENABLING LED ENABLING LED

ENABLING BUTTON

THRUSTER COMMAND

Enabling button

The button enables or disables the remote control.

Joystick

When the joystick is moved to the right, at the end of its stroke, the stern or the bow of the boat move to the right

depending on the thruster controlled.

When the joystick is moved to the left at the end of its stroke, the stern or the bow of the boat move to the left depend-

ing on the thruster controlled.

Enabling Leds

The enabling Leds indicate the enabled/disabled status of the thruster command.

Direction leds

The direction leds indicate the movement of the boat to the right or left.

The direction and enabling LEDs, moreover, are used to signal any error or problem which may occur.

MAIN SWITCH COMMAND

Mushroom push-button switch

When the mushroom push-button switch is pressed, it disables the controls on the line.

LED Power

They indicate the status of the line control.

Use the switch on the supply line to switch the TCD 1062 on and off.

Once the supply has been connected, the TCD 1062 will test the LEDs.

For the LED test, all the LEDs will come on simultaneously for 2 seconds.

If no errors or problems are detected, the TCD 1062 will then go to the disabled state (see TCD 1062 disablement).

WARNING:

practice controlling the thrusters in open water, to avoid damaging the boat with accidentally wrong

manoeuvres.

MUSHROOM

JOYSTICK

LED POWER ON LED POWER OFF

STERN LEFT DIRECTION LED STERN RIGHT DIRECTION LED

16

EN

TCD 1062 - REV002A

OPERATION

TCD 1062 ENABLING (THRUSTER COMMAND)

To enable the TCD 1062, press the enabling button and keep it pressed for at least 1 second (without the mushroom

push-button switch pressed).

After this time, the enabling LEDs will start flashing faster.

Releasing the enabling button, the enabling Leds and the Power ON Leds will remain on and the TCD 1062 will be ena-

bled.

THRUSTER ACTIVATION

Bow thruster activation

WARNING:

once the direction joystick has been released, the boat will continue to move according to the inertia

of the movement.

When controlling the thruster, the relative direction LED will remain on.

To move the bow to the right, move the joystick to

the right at the end of its stroke.

To move the bow to the left, move the joystick to

the left at the end of its stroke.

Stern thruster activation

As space is limited in the bow, some boats are only equipped with a stern thruster.

In this case, this thruster will be used the same way as the bow thruster (see paragraph

Bow thruster activation

).

Note:

There is a delay of 2 seconds if the thruster is activated in one direction and then immediately activated in the opposite

direction (immediate movement from right to left or vice versa).

17

EN

TCD 1062 - REV002A

OPERATION

TCD 1062 DISABLING (THRUSTER COMMAND)

The remote control is disabled in the following cases:

• When the enabling button is pressed.

• When there are several remote controls in parallel and another is activated.

• Once 6 minutes elapse from the enablement and not any other operation is performed or from the last time the joy-

stick is moved.

• When the mushroom push-button switch is pressed.

(In this condition, the enabling Leds will flash slowly and the joystick will be disabled, while the Power OFF Leds re-

main on).

Passage to the disabled state is signalled from the control with a prolonged sound of around one second and the fol-

lowing slow flashing of the enablement leds. The TCD1062 is disabled.

MULTIPLE REMOTE CONTROLS IN PARALLEL

Several TCD series remote controls can be installed in parallel. In this case, only one remote control can function at a

time. The active remote control is always the last one to be activated; the other in parallel are automatically disabled.

When a thruster is commanded by the last remote control enabled, the boat movement direction will be indicated by

the relative LED which will light up also on the other disabled remote controls.

MAIN SWITCH COMMAND FUNCTIONING

As soon as the main switch command is powered, the Power ON and Power OFF LEDs will switch on for two seconds.

Afterwards, if the mushroom push-button is not pressed, the Power ON LED will start flashing slowly indicating that the

system is on hold, whereas the Power OFF LED will be off.

If a thruster command connected to the system is enabled, the Power ON LED will switch on steady, showing that the

thruster command and TMS main switch command are enabled.

In case the mushroom push-button is pressed, the Power OFF LED will switch on and the TCD controls present and the

TMS will be disabled (Power ON LED off).

In order to release the mushroom push-button, the red knot must be turned clockwise.

Disablement/enablement of the sound of the control

The acoustic signals emitted by the control can be disabled.

Carry out the following procedure:

• Remove power to the control.

• Keep the enablement key pressed and supply power to the control which will emit a short sound.

• Release the enablement key and wait for the control to perform the testing of the LEDs and for it to be disabled (slow

flashing of the enablement LEDs).

The acoustic signals emitted by the control can be re-enabled.

Carry out the following procedure:

• Remove power to the control.

• Keep the enablement key pressed and supply power to the control which will emit two short sounds.

• Release the enablement key and wait for the control to perform the testing of the LEDs and for it to be disabled (slow

flashing of the enablement LEDs).

18

EN

TCD 1062 - REV002A

SYSTEM ERRORS AND PROBLEMS

SYSTEM ERRORS (THRUSTER COMMAND)

When the TCD 1062 is switched on, it may signal the presence of system errors.

Checksum error flash

If the error is detected, all the leds will flash quickly.

In this case an assistance point or the Quick

®

customer service must be contacted as soon as possible.

SYSTEM PROBLEMS (THRUSTER COMMAND)

System problems are listed below, divided into two categories:

automatic reset problems and manual reset problems.

AUTOMATIC RESET PROBLEMS

Resetting after problems of this type occurs automatically, as soon as the cause that has generated the problem disappears.

Low voltage supply

The problem is signalled if the power supply voltage descends below 10.5Vdc for more than one second. Resetting after

this problem occurs if the power supply voltage exceeds the threshold of 11.5Vdc for more than one second.

Check the charge state of the battery group that supplies is derived or the electrical circuit.

In the case of this problem, the enabling leds go off for a moment.

Protection against prolonged motor activity

After about 5 minutes and 40 seconds (or equivalent) of continuous use of the thruster, the control of the thruster is disabled

for 20 minutes, time needed for the partial cooling of the relevant thruster (total cooling usually takes about 40 minutes).

Whenever this problem occurs, the relevant green and red direction leds flash together to the enablement LED with an

intermittent sound alarm (the duration of this sound alarm is 10 seconds per minute).

The system saves this partial cooling time elapsed for the thruster; if the system is accidentally turned off (power cut off

to the relevant TCD unit) before 20 minutes elapse, upon re-starting, you will have to wait for the remaining partial cool-

ing time before using the control of the thruster.

Once this partial cooling time is over, you will be able to use the control of the (stern or bow) thruster again for a period

of time calculated by the system and proportional to the time the thruster was not used (which may be less than 5 min-

utes and 40 seconds).

Once the total cooling time is over, the thruster may be used again for 5 minutes and 40 seconds.

MANUAL RESET PROBLEMS

The control will signal, with a certain number of flashes of the enablement LEDs, the presence of any manual reset prob-

lems. Together with the flashes a short sound can be heard.

What follows is the correlation table between the flashes and the manual reset problems:

The resetting of this class of problems occurs, once the cause that has generated them has been removed, by switching off and

switching back on the remote control.

When problems 3, 4, 5 are present, it may be necessary to turn off and turn back on the external devices that signalled the pro

-

blem. Refer to their installation and use manual.

N. OF

FLASHES

PROBLEM DESCRIPTION

1

Overload on the

command electrical line

The problem is signalled when the control detects a short circuit or an overload on the command

electrical line of the propeller. Check the wiring of the electrical line of the remote control to the

propeller and the absorption of the remote control switches installed on the propeller.

2

Interruption on the

command electrical line

The problem is signalled when the control detects an interruption on the command electrical line of

the propeller.

Check the wiring of the electrical line of the remote control to the propeller.

3

Problem present on the

BTR* propeller.

The control system of the BTR propeller has detected a problem.

Refer to the BTR use and maintenance manual.

4

Problem present in the

parallel/series switch*

The control system of the PSS switch has detected a problem. Refer to the PSS use and maintenance

manual.

5

Problem present on

TMS*

The TMS line switch has detected a problem connected to the remote control switch of the propeller.

Refer to the TMS use and maintenance manual.

* If installed.

19

EN

TCD 1062 - REV002A

QUICK

®

RESERVES THE RIGHT TO MODIFY THE TECHNICAL CHARACTERISTICS OF THE EQUIPMENT AND THE CONTENTS OF THIS MANUAL WITHOUT PRIOR NOTICE.

MAINTENANCE - TECHNICAL DATA

(1)

With supply voltage less than 8 Vdc the remote control can reset.

(2)

Typical value with remote control disabled.

(3)

Typical value with remote control enabled.

(4)

Excluding the back of the remote control (IP20).

TECHNICAL DATA

MAINTENANCE

The TCD 1062 needs no particular maintenance.

To ensure optimum performance from the TCD 1062, once a year check the cables and the electrical connections.

Clean the TCD 1062 with a soft cloth dampened with water.

Do not use chemical or abrasive products to clean the TCD 1062.

MODEL

TCD 1062

MAIN SWITCH COMMAND CHARACTERISTICS

Supply voltage (1) from 8 to 31 Vdc

Quiescent current (2) 10 mA

Maximum current absorption (3) 40 mA

THRUSTER COMMAND CHARACTERISTICS

Current capacity of right or left

single thruster commands.

4 A

Supply voltage (1) from 8 to 31 Vdc

Quiescent current (2) 10 mA

Maximum current absorption

(3)

95 mA + absorption of the contactor coil

GENERAL

Operating temperature from -20 to +70 °C

Protection rating

(4)

IP 65

EMC Standard EN 60945 - FCC PART 15 RULES 47

Weight 110 g

Dimensions including frame (L x L) 78 x 131 mm

20

CARACTÉRISTIQUES ET INSTALLATION

FR

TCD 1062 - REV002A

TCD 1062 - Commande à distance avec commande interrupteur de ligne intégré

La commande TCD 1062 ne peut fonctionner que dans un système où il y a un interrupteur de ligne TMS.

La commande TCD 1062 a été conçue pour commander les propulseurs de manœuvre des produits Quick

®

.

Voici d’autres avantages importants que le TCD 1062 offre:

• Interface utilisateur simple et intuitive.

• Alimentation électrique universelle (de 8 à 31 Vdc).

• Fonctionnement dans une large gamme de temperature.

• Possibilité de brancher plusieurs commandes à distance en parallèle.

• Facilité d’installation au moyen de connecteurs (rallonges en option).

• Système de priorité automatique.

• Protection contre l’inversion de polarité, court-circuit en sortie, activité prolongée des propulseurs et interruption du

câblage de commande des propulseurs.

• Commande interrupteur de ligne thruster (TSC) intégré.

INSTALLATION

AVANT D’UTILISER LE TCD 1062, LIRE ATTENTIVEMENT CE MANUEL D’UTILISATION.

EN CAS DE DOUTE, CONTACTER LE REVENDEUR OU LE SERVICE APRES VENTE CLIENTS QUICK

®

.

En cas de discordances ou d’erreurs éventuelles entre la traduction et le texte original en italien, se référer au

texte italien ou anglais.

Ce dispositif a été conçu et réalisé pour être utilisé sur des bateaux de plaisance.

Tout autre emploi est interdit sans autorisation écrite de la société Quick

®

.

Le TCD 1062 a été étudiée et réalisée pour les buts décrits dans ce manuel d’utilisation. La société Quick

®

ne peut être

tenue responsable des dommages directs ou indirects causés par une utilisation impropre de le TCD 1062, par une mau-

vaise installation ou par de possible erreurs présentes dans ce livret.

LA GARANTIE N’EST PAS VALABLE SI LA COMMANDE EST OUVERTE PAR UN PERSONNEL NON AUTORISE.

L'EMBALLAGE COMPREND:

TCD 1062 - châssis - gabarit de perçage - conditions de garantie - mode d’emploi et

d’installation.

INSTALLATION DE LE TCD 1062

Ci-dessous nous avons décrit une procédure d'installation typique. Il est impossible de décrire une procédure qui soit

applicable à toutes les situations. Adapter cette procédure afin de répondre à vos exigences propres. Trouver la position

la plus adaptée pour réaliser les logements qui vont recevoir la commande à distance en suivant les critères suivants:

• le TCD 1062 doit être placée de façon à être facilement manœuvrable par l’opérateur.

• Il doit y avoir un espace suffisant derrière la position choisie pour placer l’arrière de la commande ainsi que les câblages.

• L'arrière de le TCD 1062 doit être protégé contre l'eau ou l'humidité.

• Il doit y avoir un espace suffisant derrière la position choisie pour placer le dos de le TCD 1062 à distance et les

connecteurs.

• La partie arrière de le TCD 1062 doit être protégée contre tout contact avec l'eau et l'humidité.

• Faire particulièrement attention quand vous réalisez les orifices sur les panneaux ou sur certaines parties de l'embarcation.

Ces orifices ne doivent pas fragiliser ou causer la rupture de la structure de l'embarcation.

F

F

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

Quick TCD 1062 Manual For Use And Installation

- Taper

- Manual For Use And Installation

dans d''autres langues

- italiano: Quick TCD 1062

- English: Quick TCD 1062

- español: Quick TCD 1062

- Deutsch: Quick TCD 1062

Documents connexes

Autres documents

-

Burkert 1062 Operating Instructions Manual

-

DJ-Tech i-Mix MKII Manuel utilisateur

-

CARLO GAVAZZI EM27072DMV53XOSN Guide d'installation

-

DJ-Tech i-Mix Reload MKII Manuel utilisateur

-

CARLO GAVAZZI EM28072DMV53X2SX Guide d'installation

-

CARLO GAVAZZI EM27172DMV63X2SN Guide d'installation

-

CARLO GAVAZZI WM50 Guide d'installation

-

Sony RM-D100K Manuel utilisateur

-

Bticino FM1ACH Mode d'emploi