GEZE Powerturn F/R-IS Manuel utilisateur

- Catégorie

- Protection contre le feu

- Taper

- Manuel utilisateur

IQ lock – self-locking

panic locks for 1- and

2-leaf doors

IQ lock AUT

IQ lock EL / IQ lock EL DL

IQ lock EM / IQ lock EM DL

IQ lock C / IQ lock C DL

EN Commissioning and connection

instructions

157720-06

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

2

Contents

Key to symbols ......................................................................................................................................................................3

Product designation ...........................................................................................................................................................3

Product liability.....................................................................................................................................................................3

Abbreviations ........................................................................................................................................................................3

1 Safety notes ...............................................................................................................................................................4

1.1 Intended use ....................................................................................................................................................................................................... 4

1.2 Technical safety .................................................................................................................................................................................................4

1.3 Safety-conscious working ..............................................................................................................................................................................5

1.4 Cleaning and care .............................................................................................................................................................................................5

1.5 Accessories ..........................................................................................................................................................................................................5

1.6 Assembly and installation ............................................................................................................................................................................. 5

1.7 Use of motor locks IQ lock EL/IQ lock EL DL on re and smoke protection doors ....................................................................5

2 Your contribution to environmental protection ..........................................................................................6

3 Functions and properties .....................................................................................................................................7

3.1 Overview of functions ..................................................................................................................................................................................... 7

3.2 Explanation of terms, functions and properties ....................................................................................................................................7

4 Technical data ...........................................................................................................................................................9

4.1 IQ lock ...................................................................................................................................................................................................................9

4.2 Rod drive IQ AUT ............................................................................................................................................................................................ 10

4.3 Power supply NT 19.2-24 ............................................................................................................................................................................10

4.4 Power supply NT 6.3-24 ............................................................................................................................................................................... 10

4.5 Power supply NT HDR-30-24 ...................................................................................................................................................................... 11

4.6 Power supply NT HDR-60-24 ...................................................................................................................................................................... 11

4.7 Motor lock control MST 210 .......................................................................................................................................................................11

5 Electrical connection ........................................................................................................................................... 12

5.1 Motor lock control MST 210 in connection with IQ lock EL / IQ lock EL DL .............................................................................. 12

5.2 Rod drive IQ AUT ............................................................................................................................................................................................ 19

5.3 Lever lock IQ lock EM ....................................................................................................................................................................................21

5.4 Contact lock IQ lock C .................................................................................................................................................................................. 22

6 Wiring diagrams .................................................................................................................................................... 23

6.1 IQ lock EL with motor lock control MST 210 ........................................................................................................................................23

6.2 Standard connection IQ LOCK EL / MST 210 with low-pass lter from HW 159073 .............................................................. 24

6.3 IQ lock EL with programme switch and activation ............................................................................................................................25

6.4 IQ lock EL with EMD (-F, -I) and activation ............................................................................................................................................. 26

6.5 IQ lock EL with EMD (-F, -I), TZ 320 SN and activation ....................................................................................................................... 28

6.6 IQ lock EL with TSA160 NT (-F, -I) and activation ................................................................................................................................. 30

6.7 IQ lock EL with TSA160 NT (-F, -I), TZ 320 SN and activation ........................................................................................................... 32

6.8 IQ lock EL with EMD (-F, -I) and smoke control unit ...........................................................................................................................34

6.9 IQ lock EL with TSA160 NT (-F, -I) & smoke control unit .................................................................................................................... 35

6.10 IQ lock EL with smoke control unit (RSZ 6) ...........................................................................................................................................36

6.11 IQ lock EL with smoke control unit (RSZ 5) ...........................................................................................................................................37

6.12 IQ lock EL with smoke control unit FA GC 150/160 ........................................................................................................................... 38

6.13 IQ lock EL with TZ 320 SN and activation .............................................................................................................................................. 40

6.14 IQ lock EL with K600 and activation ........................................................................................................................................................ 42

6.15 IQ lock EL with K600, TZ 320 SN and activation .................................................................................................................................. 44

6.16 IQ lock AUT with K600 and activation .................................................................................................................................................... 46

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

3

Key to symbols

Important information and technical notes are highlighted to explain correct operation.

Symbol Meaning

means "important note"

means “additional Information”

X Symbol for an action: This means you have to do something.

only applies for IQ lock for 1-leaf doors

only applies for IQ lock DL for 2-leaf doors

Product designation

Lock type 1-leaf 2-leaf

Electric full-panic motor lock – IQ lock AUT

Electrical motor lock IQ lock EL IQ lock EL DL

Electro-mechanical lever lock IQ lock EM IQ lock EM DL

Mechanical contact lock IQ lock C IQ lock C DL

Mechanical lock IQ lock M IQ lock M DL

Product liability

In compliance with the liability of the manufacturer for his products as defined in the German “Product Liability

Act”, compliance with the information contained in this brochure (product information and intended use, misuse,

product performance, product maintenance, obligations to provide information and instructions) must be en-

sured. Failure to comply releases the manufacturer from his statutory liability.

Abbreviations

VB Solid leaf

RR Tubular frame

6.17 IQ lock AUT with K600, TZ 320 SN and activation .............................................................................................................................. 48

6.18 IQ lock AUT with EMD (-F, -I) and activation ......................................................................................................................................... 50

6.19 IQ lock AUT with TSA160 NT (-F, -I) and activation ............................................................................................................................. 52

6.20 IQ lock AUT with Powerturn IS .................................................................................................................................................................. 54

7 What if? ....................................................................................................................................................................57

8 Maintenance ..........................................................................................................................................................61

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

4

Safety notes

1 Safety notes

1.1 Intended use

Self-locking panic locks are components used to lock emergency exit doors/panic exit doors on rescue routes.

When self-locking anti-panic locks are used, the technical data and environment conditions of these installation

and operating instructions must be taken into account.

The safety features of these products are important for conformity with EN 179 and EN 1125. No modifications of

any kind are permitted other than those described in these instructions.

XOperate the locks only in installation positions typical for locks i.e. vertical with horizontally locking bolt.

XAlways operate the locks in such a way that the panic function works in the direction of escape.

XUse these locks on emergency exit doors in accordance with EN 179 and panic exit doors in accordance with

EN 1125 only in connection with the officially approved sliding door fittings (see certificates for consistency of

performance, chapter 7).

The self-locking panic locks are suitable for use on single- and double-leaf panic doors.

àThey are not designated for use on double-action doors.

àUse in transport technology (pedestrian traffic and transport of goods by road, rail, air and water) must be

agreed with the manufacturer.

The product should be installed or incorporated in such a way that effortless access to the product is guaranteed

during any repairs and/or maintenance, and that any removal costs do not stand out of proportion to the value of

the product.

Trouble-free functioning of the locks is only ensured if a carry bar and a door closer system in accordance with EN

1158 with closing sequence control are mounted.

Before mounting the emergency exit locks ensure that the door is fitted properly and not distorted in any way.

XInstall the emergency exit locks only in hollow doors that are designed for this purpose by the manufacturer.

The horizontal bar must be mounted in such a way that the greatest possible effective bar length is achieved.

XAvoid safety risks during the installation of emergency exit devices with handle operation (in particular in case

of doors with graded surfaces: jamming of fingers or clothes).

XIf necessary, adapt installation to the majority of the users:

àInstallation height for children smaller than 900–1000 mm

àDoor closer installation in such a way that children, elderly or impaired persons are not impeded

Only devices conforming to standard may be used for keeping emergency exit and panic exit doors closed.

In conformity with the specifications of German building regulation laws, a lock of the VS-typeA in accordance

with DINEN179 or DIN1125 (lock only for 1-leaf doors) can also be used in the active leaf of a 2-leaf door if:

a) the passive leaf lock is secured against incorrect operation and

b) the passage width of the active leaf is sufficient for an escape route.

1.2 Technical safety

àImproper installation and maintenance work or repairs can lead to significant hazards for the user. Installation

and maintenance work or repairs may only be carried out by GEZE and their authorised specialists.

àDamage to GEZE IQ locks can endanger your safety. Check them for visible signs of damage. Never put a dam-

aged lock into operation.

àWarranty claims will be rendered invalid if the lock is not repaired by GEZE or an authorised GEZE service

partner.

àGEZE only guarantees that safety requirements are met if genuine GEZE spare parts are used. Faulty compo-

nents may only be replaced by genuine parts.

àGEZE self-locking panic locks must not be opened.

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

5

Safety notes

1.3 Safety-conscious working

Work on the electrical equipment (IQ AUT, IQ lock EL, IQ lock EL DL, IQ lock EM, IQ lock EM DL, IQ lock C,

IQlockCDL) may only be performed by a qualified electrician.

Locks may only be installed by a specialist from the respective trade (locksmith, carpenter etc.).

Only genuine GEZE spare parts or accessories approved by GEZE may be used.

Please contact GEZE for information about the later connection of further accessory parts.

àRemove the lock before drilling the fixing points for the sliding door fittings.

àDo not put any greases, lubricants or oils in the lock. Avoid water penetrating the lock case or the formation of

condensation.

àOnly use lubricants approved by GEZE for lubricating the outer parts (bolt, latch), see chapter 1.4.

àNever paint or varnish over the lock face plate or any other parts of the locks.

àRemove the lock before doing any painting work.

àThe handle pin must not be forced through the lock follower.

àThe door leaf must not be carried by the handle.

1.4 Cleaning and care

GEZE self-locking panic locks may only be oiled or greased using lubricants approved by GEZE.

Lubricant Manufacturer Comment

Klübersynth LI 44-22 Klüber Lubrication Slightly wet the latch and bolt

Fin Lube TF Interflon Spray onto the latch and bolt from the

outside

1.5 Accessories

GEZE self-locking panic locks may only be used with the accessories prescribed by GEZE.

XOnly use genuine GEZE accessories.

àIf other parts are attached or installed, any warranty, guarantee and/or product liability claims will be rendered inva-

lid.

1.6 Assembly and installation

Some safety rules must always be observed during fitting and installation of the self-locking GEZE panic locks.

These must be noted and followed, since the device can otherwise be damaged and result in hazards for the

user:

XWhen installing the locks, make sure you following building regulations and any specifications issued by the

door manufacturer.

àThe lock must not be modified in any way.

àLock and original strike plate (1-leaf) as well as lock and original strike box (2-leaf) form one unit. Perfect func-

tion is only possible in combination.

àIf installation is faulty or improper, all manufacturer guarantee and liability claims will be rendered invalid.

1.7 Use of motor locks IQ lock EL/IQ lock EL DL on fire and smoke protection doors

GEZE motor locks, IQ lock EL for 1-leaf and IQ lock EL DL for 2-leaf fire and smoke protection doors may be used

in all modes of operation (permanently unlocked, secured by day, night mode).

It must be guaranteed that in the event of a fire in the case of the modes of operation "permanently unlocked"

and "secured by day" the electrical activation of the lock is no longer possible, the lock can no longer be un-

locked and the cross latch and bolt engage securely in the strike plate at all times.

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

6

Your contribution to environmental protection

In order to interrupt this electrical activation in case of a fire, permissible fire detectors with trigger mechanisms,

in accordance with the DIBt guideline, must be employed for hold-open systems.

When motor locks are used on fire and smoke protection doors, three different installation situations can occur.

The following chapters must be heeded in this case.

1.7.1 Release via on-site fire alarm system

Connection of an on-site fire alarm system (BMA) to the motor lock control (MST 210).

This connection is implemented via the "smoke detector" input especially provided. A potential-free

or non-isolated contact is required by the fire alarm system for this.

The planning of the installation of the smoke detectors is implemented on-site. It should be pointed out that

when motor locks are used, smoke detectors in accordance with the above-mentioned guideline must be fitted.

Smoke development on both sides of the door must be detected by the fire alarm system.

1.7. 2 Release via trigger mechanism of hold-open systems

In accordance with the DIBt guideline for hold-open systems, the following is necessary, taking account of the

difference for the use of the "permanently unlocked" and "secured by day" modes of operation described:

Ceiling height above lintel lower edge ≤ 1m

2 ceiling-mounted detectors are required

Deviation from DIBt guideline:

The installation of only one lintel-mounted detector is not authorised in this case, since the fire can only be de-

tected on one side if the door is closed.

Ceiling height above lintel lower edge > 1 m

2 ceiling-mounted detectors and 1 lintel-mounted detector are required. This corresponds to 2 ceiling-mounted

detectors and 1 smoke control unit.

The smoke control unit (RSZ 5 and RSZ 6, includes power supply + 1 lintel-mounted detector) is connected di-

rectly to the MST in accordance with wiring diagram.

1.7. 3 Motor lock in "night mode" mode of operation

The motor lock is used in "night mode" mode of operation only. In the "night mode" mode of operation, the

automatic bolt projection of 20mm is implemented every time the door is closed. The GEZE SecuLogic access

control, for example, regulates controlled admission. In this case, the bolt is retracted and the door can be passed

through against the direction of escape.

With the motor lock control MST 210, different release times can be set using a DIP switch.

Setting of the release time

Opening time "x" = 1 s

Setting options for release time:

Switch Switch position Release time

1ON x + 1 s

2ON (x) + 2 s

3ON (x) + 5 s

4ON (x) + 10 s

Example:

Set release time = 9 s

In order to ensure that the lock locks itself mechanically (particular for fire protection), the hold-open time must

not exceed 4seconds. For this reason only switches 1 and 2 may be active in case of the DIP switch.

In the case of fire protection doors it must be ensured that the door does not burst open due to the seal pressure.

2 Your contribution to environmental protection

àWhen disposing of the self-locking panic locks, separate the different materials and have them recycled.

àLegal regulations must be observed during the disposal of self-locking panic locks.

àGEZE self-locking panic locks are certified with the Environmental Product Declaration according to ISO 14025

from the Institut Bauen und Umwelt e.V. (Institute for Construction and the Environment). This statement of

approval describes the specific environmental performance of the IQ locks and confirms that the GEZE lock

family promotes environmentally friendly and healthy construction work.

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

7

Functions and properties

3 Functions and properties

3.1 Overview of functions

Function / property IQ lock AUT * IQ lock EL/

ELDL

IQ lock EM/

EMDL

IQ lock C/

C DL

IQ lock M/

M DL

Panic function

Mechanical self-locking

Electrical timeout function – – –

Statement of approval for emergency exits

Statement of approval for fire protection doors

Resistance Class (RC) 3 – IQ lock EL IQ lock EM IQ lock C IQ lock M

Secured by day with electric strike function ** ** – – –

Motor-driven unlocking – – –

Permanently unlocked – – –

Outside handle, can be electrically engaged – – – –

Automatic locking mechanism in the event

of a power failure

*** – – –

Automatic resetting of the release if door is

not opened

– – –

Input for fire alarm system (locking) – – –

Unlocking by key ****

Operating voltage 24V 12–24V 12V, 24V,

48V

– –

Feedback contacts for lock states –

Optional sabotage monitoring or cylinder

contact

–

Can be used on the left and right –

Same installation dimensions for all IQ locks *****

Backset 35, 40, 45, 55, 60, 65, 70, 80, 100

Distance 72, 74, 78, 92, 94

9 mm handle follower

àcontinuous –

àdivided – – – –

Statement of approval in accordance with

EN 1125

Statement of approval in accordance with

EN 179

Statement of approval in accordance with

EN 14846

– – – –

Statement of approval in accordance with

EN 12209

– IQ lock EL IQ lock EM IQ lock C IQ lock M

Statement of approval in accordance with

EN 1634

VdS statement of approval – IQ lock EL IQ lock EM IQ lock C IQ lock M

available

– not possible

Rod drive IQ AUT and IQ lock EL DL = IQ lock AUT

** Active leaf for IQ lock DL

*** In connection with a power storage device / power pack

**** Unlocking via active leaf

***** IQ AUT 42 x 400 x 15.5 mm

3.2 Explanation of terms, functions and properties

Panic function

The lock can be unlocked at any time by pressing the door handle/panic bar in the direction of escape.

Door fittings

According to DIN EN 179 or 1125 the door fittings must be tested together with the lock. Tested door fittings can

be found in the certificates for consistency of performance at www.geze.com/geze/downloads.

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

8

Functions and properties

Mechanical re-locking

Locking of the two cross latches is activated by actuating the auxiliary latch.

Locking of the two cross latches only takes place after this has engaged and positioned itself in the strike plate.

Bolt projection only takes place after the cross latch has been positioned in the strike plate.

Electrical timeout function

During release time, manipulation attempts on the auxiliary latch by the control unit are ignored and the bolt

remains retracted.

After the set release time has expired, the bolt is extended when the auxiliary latch is activated. The control unit

detects the manipulation attempt by the check on the door position and the motor retracts the bolt again.

Secured by day with electric strike function

In adjustable daytime operation, the bolt remains retracted even if the door has closed and the two cross latches

are in place.

The door cannot be passed from the outside, from the inside escape is possible at all times through the panic

function.

In connection with access control, for example, shortest possible opening times well under one second are now

achieved, which has only been possible with electric strikes before.

Exception: In the event of a fire the door is completely locked. The motor lock control unit is activated directly by

the fire alarm system in this case (see chapter 1.7).

Permanently unlocked

Alongside automatic re-locking ("night mode" mode of operation) and secured daytime operation ("secured by

day" mode of operation), the third mode of operation "permanently unlocked" is possible (see Setting perma-

nently unlocked, chapter 5.1).

Here, the bolt is retracted and the cross latches are unstable. The door can be pulled or pushed open at any time

by hand.

Exception: In the event of a fire the door is locked completely after the door leaf has closed.

The motor lock control unit is activated directly by the fire alarm system in this case.

Outside handle, electrically engaged

When the supply voltage is applied to the lock, the outside handle is engaged and remains engaged as long as

current is flowing (fail-secure principle).

As soon as the voltage supply stops, the outside handle is disabled and the door can no longer be opened using

the handle. The panic function is retained.

Thanks to the exchange function integrated in all our locks, the lock can be opened using the matching key (e.g.

by the fire brigade).

Automatic locking mechanism in the event of a power failure

In the event of a power failure, the motor is activated via the capacitor integrated in the control unit in such a way

that the slide bolt in the lock can move to the "night mode" position. This automatically pre-closes the bolt when

the door is closed.

If the door is still open at this point, the bolt projection is controlled via the auxiliary latch when the door is

closed.

Input for fire alarm system

The automatic locking mechanism of the motor lock in the event of a fire is activated via the input for the fire

alarm system on the motor lock control unit.

This takes place automatically no matter which mode of operation is selected (night mode, secured by day

orpermanently unlocked).

Feedback contacts for lock states

The number and type of signals as well as the maximum load of the switch contacts can be found in chapters 5.1

and 5.3.

Sabotage monitoring

The power supply cable is monitored to check for interruptions in the cable. In addition, the cover of the motor

lock control can be integrated in the monitoring process by means of a cover lift-off contact.

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

9

Technical data

4 Technical data

4.1 IQ lock

ID no. See price list

IQ lock function àPanic function

àMechanical self-locking

àDivided cross latch

Additional function IQ lock EL àMotor-driven unlocking < 1 second

àThree modes of operation (night mode / secured by day / permanently

unlocked)

àElectrical timeout function

àFeedback contacts for lock states

àOptional sabotage monitoring or cylinder contact

Additional function IQ lock EM àOutside handle, can be electrically engaged

àFeedback contacts for lock states

àOptional sabotage monitoring or cylinder contact

Additional function IQ lock C àFeedback contacts for lock states

àOptional sabotage monitoring or cylinder contact

Dimensions (without face plate) àSolid leaf: 15.2mm × 165mm × (backset+15.5mm) (W × H × D)

àTubular frame: 15.2mm × 177mm × (backset+15.5mm) (W × H × D)

Operating voltage IQ lock EL: 12–24V DC

IQ lock EM: 12V DC, 24V DC, 48V DC

Current consumption IQ lock EL 160mA at 12V DC

max. 1A briefly at 12V DC

80mA at 24V DC

max. 500mA briefly at 24V DC (incl. MST 210)

Current consumption IQ lock EM 350mA at 12V DC

210mA at 24V DC

105mA at 48V DC

Max. contact rating of the relays 30 V DC / 500 mA

Resistance to forcing 10,000 N

Technical specification àPerfectly closing doors with door closer

àAlways use genuine GEZE strike plate

àClearance between face plate and strike plate 3–7mm

àNo door seals which cause pressure

àBolt projection must be horizontal

Climate / surroundings àService temperature: –10 … +50°C, max. 75% rel. hum., no condensation

àStorage temperature: –20 … +50°C, max. 75% rel. hum., no condensation

àSprinkling not permissible

àNot suitable for use in very dusty atmosphere (e.g. corn mills)

àNot suitable for use in aggressive or highly corrosive atmosphere

(e.g.chlorinated swimming baths)

àNot suitable for vibration (e.g. vehicles)

àCannot be used in potentially explosive atmospheres

Statements of approval àEN 179 Emergency exit devices

àEN 1125 Panic exit devices

àEN 12209 Mechanical locks

àEN 14846 Electro-mechanical locks

àEN 1634 Fire resistance and smoke protection test

àVdS

àCE

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

10

Technical data

4.2 Rod drive IQ AUT

ID no. 153755

Function Motor-driven unlocking of the passive leaf (< 1.8 seconds)

Dimensions (without face plate) 42 × 400 × 15.5 mm (W × H × D)

Operating voltage 24V DC (±15%)

Current consumption max. 1.5A at 24V DC

Resistance to forcing 10,000 N

Climate / surroundings àService temperature: –20 … +60°C, max. 75% rel.hum., no condensation

àSprinkling not permissible

àNot suitable for use in very dusty atmosphere (e.g. corn mills)

àNot suitable for use in aggressive or highly corrosive atmosphere (e.g.

chlorinated swimming baths)

àNot suitable for vibration (e.g. vehicles)

àCannot be used in potentially explosive atmospheres

Statements of approval àEN 179 Emergency exit devices

àEN 1125 Panic exit devices

àEN 1634 Fire resistance and smoke protection test

àCE

4.3 Power supply NT 19.2-24

ID no. 089862

Function Power supply for IQ lock EL / IQ lock EL DL

Input voltage 230V AC (+10 / –15%)

Input current 250mA

Output voltage 24V DC (±5%)

Output current 800mA

Output power 19.2W

Dimensions 92 × 32 × 32mm (W × H × D)

Type of installation Flush-mounted installation

Connection Wire sleeves type 10CC

IP rating IP54 - according to data sheet IP20

Protection class II

Environmental conditions àAmbient temperature –10°C … +50°C ;

àStorage temperature –40°C … +70°C

Guidelines/standards EN 60950-1; EN 55022 , EN 55024

4.4 Power supply NT 6.3-24

ID no. 109637

Function Power supply for IQ lock EM/ IQ lock EM DL

Input voltage 230V AC (±15%)

Input current 150mA (short-term 300mA)

Output voltage 24V DC (–8%, +5%)

Output current 260mA

Output power 6.3W

Dimensions 88 × 88 × 53 mm (W × H × D) (dimensions of the surface-mounted casing)

Type of installation Flush-mounted installation (scope of delivery, pre-mounted in

surface-mounted casing ID 103662)

Connection Screw terminals 1.0 ... 2.5 mm²

IP rating IP20

Protection class II

Environmental conditions àService temperature: 0 .... +60°C

àStorage temperature: -20 ... +60°C

àRelative humidity max. 93% (at 40°C)

Guidelines/standards DIN EN 50 081-1, DIN EN 55011, EN 50082-2

DIN EN 61 000-4-2, -3, -4, -5, -6, -11

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

11

Technical data

4.5 Power supply NT HDR-30-24

ID no. 151425

Function Power supply for IQ AUT

Input voltage 230V AC (±15%)

Input current 480mA

Output voltage 24V DC (±10%)

Output current 1.5A

Output power 36W

Dimensions 78 × 93 × 56 mm (W × H × D)

Type of installation Top hat rail (DIN-TS35/7.5 or 15 possible)

Connection Screw terminals

IP rating IP54

Protection class II

Environmental conditions Service temperature: -20 .... +60°C

Relative humidity 20 ... 90%

Guidelines/standards UL60950-1 : EN 55011, EN 55032

4.6 Power supply NT HDR-60-24

ID no. 151424

Function Power supply for several components

Input voltage 230V AC (± 15%)

Input current 0.8A

Output voltage 24V DC (±10%)

Output current 2.5A

Output power 60W

Dimensions 78 × 93 × 56 mm (W × H × D)

Type of installation top hat rail

Connection Screw terminals 2.5mm²

IP rating IP54

Protection class II

Environmental conditions Service temperature: -10 .... +50 °C

Guidelines/standards UL60950-1; UL508

4.7 Motor lock control MST 210

XFollow the mechanical installation instructions for motor lock IQ lock.

ID no. 103671

Function Control unit for motor lock IQ lock EL / IQ lock EL DL

Dimensions 140 × 140 × 79mm (W × H × D)

Weight 0.3kg

Operating voltage 12–24V DC (–10%, +15%)

Current consumption à160mA at 12V DC

àmax. 1A briefly at 12V DC

à80mA at 24V DC

àmax. 500mA briefly at 24V DC (incl. IQ lock)

Terminals Plug/screw terminals, max. cable cross-section 1 mm²

Max. contact rating of the relays (X2) 30V DC / 1A

Max. lock switch contact load (X3) 30 V DC / 500 mA

Max. length of connection cable to the lock

10m

IP rating in accordance with DIN 40050 IP54

Environmental conditions in accordance

with DIN 40040

àService temperature: JWF (–10…+50°C, max. 75% rel. hum.,

no condensation)

àStorage temperature: HPE (–25…+85°C, max. 95% rel. hum.,

no condensation)

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

12

Electrical connection

5 Electrical connection

XUse wire-end ferrules for wire cores.

àWork on the electrical equipment (IQ AUT, IQ lock EL, IQ lock EL DL, IQ lock EM, IQ lock EM DL) may only be

performed by a qualified electrician.

àThe electrical connection work must be carried out in accordance with the relevant regulations of the VDE and

local utility companies.

The electrical connection for the motor locks (IQ AUT, IQ lock EL, IQ lock EL DL) and lever locks (IQlockEM,

IQlockEMDL) must be carried out according to the enclosed wiring diagrams.

The technical data listed (see chapter 4) must be taken into account:

àThe nominal voltage of the motor / magnet in the lock with the output voltage of the power supply or device

to be activated.

àThe power consumption of the motor / magnet with the output power of the power supply or device to be

activated.

àThe maximum switching power of the switch contacts with the respective power to be switched.

5.1 Motor lock control MST 210 in connection with IQ lock EL / IQ lock EL DL

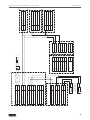

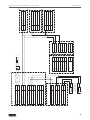

5.1.1 Connections

X10 Cover monitoring (OUT)

23 NC

22 COM

X8 Cylinder contact /

Sabotage (OUT)

25 NO / NC

24 COM

X5 Door contact (IN)

6 NO / NC

2 24V ext.

X4 Smoke detector (IN)

9 NC

8 COM

XA jumper must be inserted if

no smoke detector is used.

See the following pages for fur-

ther application options (24V)

X3 Bolt switch contact (OUT)

21 COM

20 NO

X6 Mode of operation (IN)

4 Day / night mode

2 24V ext.

5 Release

2 24V ext.

Jumper

JP1 Smoke detector function

JP2 12V / 24V

2322

X10

24 25

X8

26

X5

89

X4

2021

X3

52

X6

42

31

X7

1213

X2

1011 16 17

14 15 18 19

231

X1

27 28 34 35

32 3338 39

36 37

JP1 JP2

F1

F2

X9

X11

LED1

ON

1234

LED6

LED5

LED4

LED3

LED2

Light emitting diodes

LED1 Supply voltage LED4 Fault/alarm

LED2 Day/night mode

(day=on) LED5 Door handle

LED3 Release LED6 Door status

X7 Supply

1 GND in

3 12V / 24V DC in

X1 Lock

27 Cable black

28 Cable red

2 Cable blue

31 Cable pink

32 Cable grey

33 Cable yellow

34 Cable green

35 Cable brown

36 Cable white

37 Cable violet

38 Cable red/blue

39 Cable grey/pink

X2 Outputs

10 Relay day/night mode COM

11 Relay day/night mode NO

12 Relay release COM

13 Relay release NO

14 Relay fault/alarm COM

15 Relay fault/alarm NC

16 Relay door handle COM

17 Relay door handle NO

18 Relay door status COM

19 Relay door status NO

X9 RS485 interface

X11 Programming interface

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

13

Electrical connection

Light emitting diode displays

Function Cause Consequence Remedy

LED1 off Power supply interrupted No control unit function Check voltage source

LED1 on Control unit and lock

are working normally

LED1 flashing evenly Fault Check electrical connections

LED2 on Day circuit active Bolt not extended and latch-

es in place

LED2 off Night mode circuit active Bolt extended, door locked

LED3 on Activation active Door can be opened

LED3 off Night mode circuit active Door bolt extended

(locked)

LED4 on Fault-free lock function

LED4 off Fault/alarm

LED5 on Handle is actuated

LED6 on Door closed (auxiliary latch

and door contact closed)

Setting of the release time

Opening time "x" = 1 s

Setting options for release time:

Switch Switch position Release time

1ON x + 1 s

2ON (x) + 2 s

3ON (x) + 5 s

4ON (x) + 10 s

Example:

Set release time = 9 s

Release times of 1–19 s can thus be set with a pulse control of the release input terminals X6.2 and X6.5. If a

longer release time or continuous release is required, this is to be realised by a correspondingly long activation

time or a continuous contact. Setting of the release time is also used to set the duration of the contacting of the

release relay (X2.12 and X2.13).

Inputs

Terminal Signal Function

X7.1 GND in GND supply

X7. 3 12 V / 24 V in 12 V / 24 V DC supply

X5.2 24 V external Contact connected: Door closed

X5.6 External door contact

X4.8 Smoke detector Connection of smoke detector with potential-free con-

tact or as 24 V supply voltage (see page 3)

X4.9 Smoke detector

X6.2 24 V external Contact connected: Mode of operation release

X6.5 Release Contact open: Mode of operation as selected below

X6.2 24 V external

Contact connected: Mode of operation "secured by day"

X6.4 Night mode / day Contact open: Mode of operation "night mode"

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

14

Electrical connection

Outputs

Terminal Signal Contact Function

X2.10 Relay night mode / day NO Contact closed: Mode of operation day

Contact open: Mode of operation night mode

X2.11 Relay night mode / day COM

X2.12 Relay release / activation

Drive unit

NO Contact closed: Mode of operation release /

door can be passed unlocked

Contact open: No release

X2.13 Relay release / activation

Drive unit

COM

X2.14 Relay fault / power failure NC Contact open: no fault/no alarm,

normal operating state

Contact closed with: power failure, system failure, alarm

X2.15 Relay fault / power failure COM

X2.16 Door handle NO Contact closed: Door handle actuated

Contact open: Door handle not actuated

X2.17 Door handle COM

X2.18 Door contact NO Contact closed: Door contact and auxiliary latch actuated

Contact open: Door contact or auxiliary latch not actuated

X2.19 Door contact COM

X3.20 Bolt contact NO Contact closed when bolt extended 95%. Contact is

not evaluated by control unit.

X3.21 Bolt contact COM

X8.25 Cable monitoring NC/

cylinder contact NO

NO Cylinder contact closes a contact when the installed cyl-

inder is turned or optional cable monitoring takes place

X8.24 Cable monitoring /

Cylinder contact

COM

X10.23 Cover monitoring /

MST 210

NC Casing cover monitoring, closes a contact when the

casing cover of the MST 210 is opened.

X10.22 Cover monitoring /

MST 210

COM

Setting daytime operation

If the contact between terminals X6.2 and X6.4 is closed (permanent contact) the lock runs in daytime operation.

If the contact is opened, the lock runs in permanently night mode. This means that the lock automatically locks

every time the door is closed.

Setting permanently unlocked

If the contact between terminals X6.5 and X6.2 is closed (permanent contact) the motor lock runs in permanent-

ly unlocked mode of operation. If the contact is opened, the lock runs in daytime or permanently night mode

depending on the pre-set (contact between the terminals X6.2 and X6.4 closed or open).

5.1.2 Terminal assignment for connection cable lock IQ lock EL to MST 210, terminal strip X1

Terminals MST 210 Cable colour Connector IQ lock EL Description/function

X1.27 Cable black PIN 1 Motor –

X1.28 Cable red PIN 2 Motor +

X1.2 Cable blue PIN 3 24 V

X1.31 Cable pink PIN 4 Basic setting (permanently night)

X1.32 Cable grey PIN 5 daytime operation

X1.33 Cable yellow PIN 6 Release

X1.34 Cable green PIN 7 Door handle

X1.35 Cable brown PIN 8 Auxiliary latch NO

X1.36 Cable white PIN 9 Locked

X1.37 Cable violet PIN 10 Locked

X1.38 Cable red/blue PIN 11 Cable monitoring or cylinder contact

canbe selected via switch

X1.39 Cable grey/pink PIN 12 Sabotage or cylinder contact can be

selected via switch

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

15

Electrical connection

Connector IQ lock EL

6 12

1 7

6 12

7

1

PIN

1

2

3

4

5

6

7

8

9

10

11

12

Connector IQ lock EL /

IQ lock EL DL (1)

black

red

blue

orange

grey

Yellow

green

brown

white

violet

white/black

white/brown

Connector power supply

cable (2)

black

red

blue

pink

grey

Yellow

green

brown

white

violet

red/blue

grey/pink

5.1.3 Low-pass filter (TPF)

New from mid-2014.

The low-pass filter (TPF) ensures improved activation of the motor lock IQ lock EL / IQ lock EL DL. Here, the motor

control cable (red and black cables) are not connected directly to the motor lock control MST 210, they are con-

nected with terminal X12 of the additional PCB TPF.

The TPF has been optimised for the new motor drive unit in the lock and for the new software (see chapter 5.1.4

and chapter 5.1.6). Taking the conditions listed in chapter 5.1.7 into account, the TPF can also be used for locks

with an older building design.

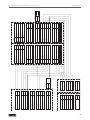

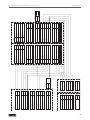

Insert TPF board on MST 210

232

2

X10

24 25

X8

26

X5

89

X4

2021

X3

52

X6

42

31

X7

1213

X2

10 11 16 17

14 15 18 19

231

X1

27 28 34 35

32 3338 39

36 37

JP1 JP2

F1

F2

X9

X11

LED1

ON

1234

LED6

LED5

LED4

LED3

LED2

1

2

X13

X12

X11

Low-pass lter

X11

Low-pass lter

X11

XInsert the TPF board (1) onto slot X9 of the motor lock control MST 210 (2).

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

16

Electrical connection

Wire TPF to MST 210

XWire terminal X11 (TPF) to terminal X1

(MST 210).

23 22

X10

24

25

X8

26

X5

89

X4

2021

X3

52

X6

42

31

X7

1213

X2

10 11 16 17

14 15 18 19

231

X1

27 28 34 35

32 3338 39

36 37

JP1 JP2

F1

F2

X9

X11

LED1

ON

1234

LED6

LED5

LED4

LED3

LED2

X13

X11

27 28

X12

27

28

Wire TPF with motor lock IQ lock EL / IQ lock EL DL

XConnect the red and black cables from

motor lock IQ lock EL / IQ lock EL DL

withX12.

XConnect all the other cables from motor

lock IQlockEL / IQlockELDL to terminal

X1 of the motor lock control MST 210.

23 22

X10

24 25

X8

26

X5

89

X4

20 21

X3

52

X6

42

31

X7

1213

X2

10 11 16 1

7

14 15

18 19

231

X1

27 28 34 35

32 3338 39

36 37

JP1 JP2

F1

F2

X9

X11

LED1

ON

1234

LED6

LED5

LED4

LED3

LED2

X13

X11

27 28

X12

27

28

BK RD

Cable IQ lock EL /

Cable IQ lock EL DL

5.1.4 Motor lock control MST 210 with new software from version 3.0

In order to improve the performance of the GEZE motor locks IQ lock EL / IQ lock EL DL even further, GEZE will be

delivering the motor lock control MST 210 with new software from mid-2014.

XFor optimum use of this new version, take the respective combination possibilities between old and new

products as listed in chapter 5.1.7 into account.

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

17

Electrical connection

5.1.5 Install the MST210 printed circuit board under the cover extension kit

1

1

c

For installation of the printed circuit board under a cover extension kit, the hatched printed circuit board ele-

ments must be broken off.

XUse a pair of pliers to break off the hatched printed circuit board elements (1) at the breaking point.

XInstall the printed circuit board on the mounting bracket under the cover extension kit.

5.1.6 IQ lock EL / IQ lock EL DL with new motor HW 11504x, C0

In order to improve the performance of the GEZE motor locks IQ lock EL / IQ lock EL DL even further, GEZE will be

integrating a new motor from mid-2014.

XFor optimum use of this new version, take the respective combination possibilities between old and new

products as listed in chapter 5.1.7 into account.

5.1.7 Combination possibilities between old and new components

Due to the changes described in chapters 5.1.3 to 5.1.6 different combination possibilities can occur.

For you to be able to identify the optimum solution for your application, the following table lists the combination

possibilities with respective effect on the function.

Motor in the lock Software Low-pass filter (TFP) Comment

new new with optimal

new old with permissible only without function "secured by day"

old old without current status

The following combinations are not permissible:

Motor in the lock Software Low-pass filter (TFP) Comment

new old without not permissible

old old with not permissible

old new with not permissible

new new without not permissible

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

18

Electrical connection

5.1.8 Smoke detector

A smoke detector can be connected via terminal X4, signal numbers 8 and 9. The smoke detector disconnects the

control unit from its supply voltage and thus makes the lock – no matter which mode of operation is currently set

– return to its safe initial position (night mode) via the built-in power storage device.

Connection possibilities

If the system is operated without smoke detectors, a jumper must be installed between terminals 8 and 9.

Jumper position JP1 Connection for smoke detector Description

98

X4

Connection via external 24 V supply

voltage (protected against reverse polarity)

98

X4

Connection via potential-free opener

contact

Operating voltage

Jumper position JP2 Description

12 V operating voltage

24 V operating voltage

Safety fuses

Designation Value Description

F1 1 A, SMF 125 V, fast-acting Input fuse, 24 V internal

F2 1 A, SMF 125 V, fast-acting Fuse for smoke detector external supply

5.1.9 Sabotage monitoring or cylinder contact

24 25

A switch (see chapters 6.4.1 and 6.4.2) on the motor lock is used to select between the modes of operation sabo-

tage and cylinder contact. (On delivery the switch is set to cylinder contact).

There is a rectangular recess in the lock case approx. 5 mm above the handle follower at the right of the lock case

edge. Here you can use a screwdriver (size 1) to switch the mode of operation (S = Sabotage, Z = Cylinder contact).

Cylinder contact

In the mode of operation cylinder contact, actuation of the lock cylinder is reproduced at terminals X8.25 and

X8.24. The cover is also monitored at terminals X10.23 and X10.22.

Cylinder contact Cover monitoring

24 25 22 23

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

19

Electrical connection

Cable and cover monitoring MST 210

Terminal X10.22 is connected with terminal X8.25 to use sabotage monitoring (comprising cable and cover mon-

itoring). The sabotage monitoring signal is then tapped via terminals X10.23 and X8.24. The circuit is opened in

the event of a fault (cover open or cable fault).

Cover monitoring/cable monitoring

24

X8

25 23

X10

22

5.2 Rod drive IQ AUT

5.2.1 Connections

X1 - connection for power supply device, inputs and outputs

Connection Wire colour Signal Function

X1.1 blue – BU Power supply GND in

X1.3 red – RD 24V (DC in)

X1.2 – – 24V DC

X1.5 brown – BN Input Release

X1.20 white – WH Output 1 Output 1 (locked)

X1.21 grey – GY COM

X1.22 pink – PK Output 2 Unlocked

X1.21 grey – GY COM

22212042 41

X1

X5

X4

5231

4142 43

21

Input

A potential-free contact (normally open contact) must be connected to pins X1.2 and X1.5. If the contact is acti-

vated, IQ AUT moves to the unlocked position where it remains for the hold-open time. The time starts once the

contact has been disconnected.

Output

IQ AUT has two outputs with the potential which is connected to pin X1.21. The output "unlocked" is closed when

the drive rod is in the unlocked position. Output 1 can be set (see Service menu).

X4 - connection for ST220

Connec-

tion

Signal Function

X4.1

Connection for ST220

GND

X4.2 24V DC

X4.42 RS485-A

X4.41 RS485-B

X4.43 –

X5 - connection for GEZE-BUS (e.g.: IO 320)

Connection Wire colour Signal Function

X5.42 yellow – YE GEZE-BUS RS485-A

X5.41 green – GN RS485-B

IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

20

Electrical connection

DIP switch (back of PCB)

àThe DIP switch (1) can be used to switch the terminating resistor for RS485 on and off.

àIf there are more than two bus devices, the resistance must be switched on in the first and last device.

43

ON

OFF

22

x1

21 20 5231

41 42 21

X4

1

5.2.2 Service menu

Level 0 Level 1 Level 2 Value range Factory setting Comment

Configuration Speed 45% to 85% 60%

Hold-open time 2 to 60 sec 10 sec

Language àGerman

àFrench

àEnglish

German

Output 1 àLocked

àSW + 6 sec

àAlarm

Locked See below

Fire protection Yes/no no See below

System information Maintenance Yes/no Yes: When maintenance

is due

System init. Yes/no Yes: When system is

initialised

Motor replaced Yes/no Yes: When the motor was

replaced

Cycle [Number

ofcycles]

The current number of

cycles

Product informa-

tion

HW ver. Vx.x

SW ver. Vx.x

Ser. no. xxxxxx

Diagnosis Motor state

Current (A) The value is updated as

long as the enter key on

ST220 is kept pressed.

Temperature

Duration (sec)

Current state

Sensor state [see below]

Alarm memory [Cycle]

[Alarm description]

See fault description

Command Start motor

Acknowledge

alarm

Factory setting

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

GEZE Powerturn F/R-IS Manuel utilisateur

- Catégorie

- Protection contre le feu

- Taper

- Manuel utilisateur

dans d''autres langues

- English: GEZE Powerturn F/R-IS User manual

Documents connexes

Autres documents

-

Burg-Wächter TS 4000 V Le manuel du propriétaire

-

BFT Vista SW Manuel utilisateur

-

BFT Vista SLC Manuel utilisateur

-

BFT Vista TL Manuel utilisateur

-

SsangYong NEW CHAIRMAN Le manuel du propriétaire

-

Alpine SEC-8205 Manuel utilisateur

-

Autostart AS-2385TWS Le manuel du propriétaire

Autostart AS-2385TWS Le manuel du propriétaire

-

Orbit OB-3681 Le manuel du propriétaire

-

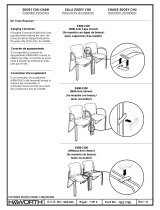

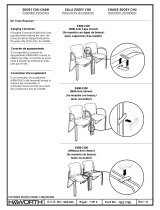

Haworth 7021-7768d Mode d'emploi

Haworth 7021-7768d Mode d'emploi