Garland US Range Cuisine Series Heavy Duty Griddle Top Range Owner Instruction Manual

- Catégorie

- Fours

- Taper

- Owner Instruction Manual

Part # 1009067 Rev13 (12/04/09) Page 1

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

GARLAND COMMERCIAL INDUSTRIES, LLC

185 East South Street

Freeland, Pennsylvania 18224

Phone: (570) 636-1000

Fax: (570) 636-3903

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Enodis

U

Swallow e

Telephone

:

Fax: 081-8

4

Part # 1009067 Rev13 (12/04/09) © 2004 Garland Commercial Industries, LLC

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF

THIS OR ANY OTHER

APPLIANCE

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY,

OR DEATH. READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

INSTALLATION AND

OPERATION MANUAL

GARLAND 36 E SERIES

HEAVY DUTY ELECTRIC

RANGES AND BROILERS

PLEASE READ ALL SECTIONS OF THIS MANUAL

AND RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS

COMMERCIAL COOKING EQUIPMENT AND

MUST BE INSTALLED BY PROFESSIONAL

PERSONNEL AS SPECIFIED.

INSTALLATION AND ELECTRICAL CONNECTION

MUST COMPLY WITH CURRENT CODES:

IN CANADA - THE CANADIAN ELECTRICAL

CODE PART 1 AND / OR LOCAL CODES.

IN USA – THE NATIONAL ELECTRICAL CODE

ANSI / NFPA – CURRENT EDITION.

ENSURE ELECTRICAL SUPPLY CONFORMS WITH

ELECTRICAL CHARACTERISTICS SHOWN ON

THE RATING PLATE.

Part # 1009067 Rev13(12/04/09)Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the state of california to cause cancer and/or birth defects

or other reproductive harm. Installation and servicing of this product could expose you to airborne

particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers

is known to the state of California to cause cancer.

Part # 1009067 Rev13 (12/04/09) Page 3

TABLE OF CONTENTS

IMPORTANT INFORMATION.............2

DIMENSIONS AND SPECIFICATIONS,

36E SERIES RANGES....................4

DIMENSIONS AND SPECIFICATIONS,

ER36 BROILER .........................5

DIMENSIONS AND SPECIFICATIONS,

ATTACHMENTS ........................6

GENERAL INFORMATION ...............7

Product Information .........................7

Rating Plate ..................................7

Optional extended warranty .................7

INSTALLATION.........................8

Clearances and Setting .......................8

Legs .........................................8

Electrical Connections ........................8

Wiring Diagram ..............................8

Circuit Breakers and Fuses ....................8

Main Line Entrance ...........................9

Terminal Block ...............................9

Sanitary Counter Top Seal ....................9

Assembly of Battery ..........................9

Installation Instructions for Mounting

The ER36 (Salamander) To 36E Series ..........9

Installation Instructions for Mounting

The Double Deck High Shelf 36E Series ......10

Ventilation ..................................10

OPERATION...........................10

Ovens ......................................10

Controls

Preheat

General

Range Base Convection Oven (RC)

Range Base Convection Oven Operation

Problem / Solution

Motor Care

Top Sections ................................12

Cooking Top – Open Type Burners

Boiling Plates

All Purpose Plates

Griddle Plates

Operation of Broiling Section

MAINTENANCE AND CLEANING........15

Painted Finishes ............................15

Stainless Steel ..............................15

Oven Inner Door Liner and Oven Deck

(Porcelain Enamel) ..........................15

Interior Cleaning of Standard Aluminized

Steel Interior Surfaces. .......................15

Cleaning and Care of Top Surface Heating

Burners .....................................16

Cleaning of Griddle, All Purpose Plates and

Boil Plates ..................................16

Broiler Section ..............................16

WIRING DIAGRAMS ...................17

Part # 1009067 Rev13(12/04/09)Page 4

DIMENSIONS AND SPECIFICATIONS, 36E SERIES RANGES

36"

[914mm]

24"

[610mm]

6"

[152mm]

6"

[152mm]

6"

[152mm]

REAR

ELECTRICAL

33-3/4"

[ 857mm]

14-1/2"

[368mm]

6"

[152mm]

36"

[914mm]

30"

[762mm]

1 8"

[457mm]

1 5"

[381mm]

18"

[ 457mm]

63"

[1600mm]

With "DD

"

HI SHELF

31-3/8"

[797mm]

With STD

BACKGUARD

MODEL

TOTAL

kW

3-PHASE

kW PER PHASE

ALL VOLTAGES

NOMINAL AMPERES PER LINE

SINGLE PHASE

THREE PHASE

208V 240V 460V

X-Y Y-Z X-Z 208V 240V 460V X Y Z X Y Z X Y Z

36ER32, 36ER38 21.5 6.5 5 10 103 91 47 69 48 64 61 43 56 31 22 28

36ER32-3 36ER33-88 20.7 6.5 1.2 10 99 88 NA 69 45 60 61 40 53 NA NA NA

36ER33 19.1 6.5 4.2 8.4 92 81 NA 62 45 54 55 40 47 NA NA NA

36ER33-99 18.7 4.2 8 6.5 90 79 NA 45 52 61 40 45 54 NA NA NA

36ER35, 36ER36 18.5 6.5 6 6 89 78 40 53 53 51 46 46 44 24 24 23

36ER39 18.5 6.5 4 8 89 79 40 61 45 50 54 39 45 28 20 23

36ET32, 36ET38 15 5 5 5 72 64 33 42 42 42 37 37 37 19 19 19

36ET/ES32-3, 36ET/ES33-88 14.2 5 4.2 5 68 60 NA 42 39 39 37 34 34 NA NA NA

36ET/ES33 12.6 4.2 4.2 4.2 61 53 NA 35 35 35 31 31 31 NA NA NA

36ET/ES33-99 12.1 4.2 4 4 58 52 NA 35 35 34 31 31 30 NA NA NA

36ET/ES35, 36ET/ES36 12 0 6 6 58 51 26 29 29 51 25 25 44 13 13 23

36ET/ES39 12 4 4 4 58 51 26 34 34 34 30 30 30 15 15 15

36ERC32 20.4 5.4 5 10 98.1 85 NA 65 44 63 56 38 54 NA NA NA

36ERC32-3 19.6 5 4.6 10 94.2 81.7 NA 44 40 61 38 35 53 NA NA NA

36ERC33 18 5 4.6 8.4 86.5 75 NA 56 40 55 49 35 47 NA NA NA

36ERC33-88 19.6 5 4.6 10 94.2 81.7 NA 63 40 61 55 35 53 NA NA NA

36ERC33-99 17.6 8.2 4.4 5 84.6 73.3 NA 56 53 40 48 46 34 NA NA NA

36ERC35 17.4 5 6 6.4 83.7 72.5 NA 52 46 44 45 40 38 NA NA NA

36ERC36 17.4 5.4 6 6 83.6 72.5 NA 48 48 50 42 42 44 NA NA NA

36ERC38 20.4 5 5.4 10 98.1 85 NA 63 44 65 55 38 56 NA NA NA

36ERC39 17.4 5.4 4 8 83.7 72.5 NA 56 40 58 49 34 44 NA NA NA

Note for Model Numbers: ER= Oven Base, ET= Modular TOP, ES=Storage Base, ERC=Convection Oven Base

CLEARANCES

ENTRY TO COMBUSTIBLE WALL

SIDES REAR

1

41-1/4" (1048mm) 36-1/4" (921mm) 3" (76mm) 1/2" (13mm)

1

Rear Clearance for Convection ovens is 2” (51mm)

Part # 1009067 Rev13 (12/04/09) Page 5

DIMENSIONS AND SPECIFICATIONS, ER36 BROILER

REAR

ELECTRICAL

2-3/4"

[70mm]

28-1/4"

[718mm]

14"

[356mm]

17-1/4"

[413mm]

36"

[914mm]

1-5/8"

[41mm]

18"

[757mm]

11-1/32"

[280mm]

32-1/4"

[819mm]

3-1/2"

[89mm]

ELECTRICAL LOADING CHART: MODEL ER36

VOLTAGE TOTAL kW

NOMINAL AMPERES

PER LINE

SINGLE PHASE

208 7.00 33.7

240 7.00 29.2

460 5.51 12.0

NOTE: When ER36 models are wired independently from the range, they are only available as single phase. Refer to wiring

diagrams for detailed range mount electrical data.

COMBUSTIBLE WALL CLEARANCES

Left Side Right Side Back

6” (152mm) 4-1/2” (114mm) 1/2” (13mm)

Part # 1009067 Rev13(12/04/09)Page 6

DIMENSIONS AND SPECIFICATIONS, ATTACHMENTS

36"

[914mm]

24"

[610mm]

6"

[152mm]

REAR

ELECTRICAL

INLET

30"

[762mm]

18"

[457mm]

15"

[381mm]

15-9/32"

[388mm]

18"

[457mm]

6"

[152mm]

6"

[152mm]

6"

[152mm]

33-3/4"

[857mm]

18"

[457mm]

63"

[1600mm]

With "DD"

Hi Shelf

31-3/8"

[797mm]

With STD.

Backguard

Modular Top

12" [305mm]

ELECTRICAL LOADING CHART : MODELS 36ES(ET)16 & 36-ES(ET)15

VOLTAGE TOTAL kW

NOMINAL AMPERES PER LINE

SINGLE PHASE

208 6.00 28.8

240 6.00 25.0

460 6.00 13.0

CLEARANCES

ENTRY

TO COMBUSTIBLE

WALL

CRATED UNCRATED SIDES REAR

20-3/4"

(527mm)

18-14"

9464mm)

3"

(76mm)

1/2"

(13mm)

Garland products are not approved or authorized for home or

residential use, but are intended for commercial applications

only. Garland will not provide service, warranty, maintenance

or support of any kind other than in commercial applications.

Part # 1009067 Rev13 (12/04/09) Page 7

GENERAL INFORMATION

Product Information

36 Series Ranges are designed to battery with other 36 Series

equipment.

Construction

Heavy duty modular construction minimizes the use of hard

to clean screws and bolts on exterior of range. Cleaning is

made easier and more complete.

Circuit Breakers

Supplied standard except for open elements. Fuses are used

for open elements.

Grease Troughs

Front and rear, catch excess grease and spillage. Drain into

grease pans located under range top.

Service

Service and maintenance is done completely from the front.

Oven Base

Giant capacity oven is 26 1/2” (667 mm) wide x 29” (736 mm)

deep x 12 1/2” (318 mm) high. Heavy duty thermostat with

pilot light provides temperature control between 200°F

(93°C) and 500°F (290°C). Top element 3 k.W. and bottom

element 3.5 k.W. each controlled by three heat switch for

exibility of heat. One heavy duty rack is standard. Additional

racks are available at extra cost. Exclusive heat ow oven

design eliminates hot spots and gives consistently even oven

temperatures. Aluminum clad steel oven interior reects heat

back to product and ensures long life. Oven door and oven

deck nished in porcelain. Oven door is heavy duty typed

designed to bear in excess of 250 lbs, (113Kg) load. Spring

adjustment is accessible from front of range.

Storage Base

A storage base with stainless steel doors is available.

Modular Top

For mounting on a custom made stand.

Venting

All ranges are supplied with standard 3” (76 mm) high

stainless steel vent riser. Double Deck High Shelf available

in sizes from 18” (476 mm) to 72” (1829 mm) wide. Standard

nish is stainless steel front with brushed chrome splash wall

and aluminum clad back. Optional nish is stainless steel

shelves, sides and back. A satisfactory power ventilator such

as Vent Master properly adapted to the range may be used.

Rating Plate

When corresponding with the factory refer to the particular

unit by the correct model number (including prex and sux

letters and numbers) and the serial or code number. The

rating plate axed to the unit contains this information.

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

Unit rating plate is located behind the lower front panel.

Optional extended warranty

Garland,

With a tradition of superior equipment quality and

performance, oers you, our valued customer, an additional

one year limited warranty beyond our standard one year

coverage.

This additional coverage for parts and labor may be

purchased on a new equipment order or up to 60 days after

the equipment purchase. Please contact your Equipment

Dealer or Maintenance & Repair Center (list enclosed) to take

advantage of this exception oer.

Thank you for using Garland products. It is our pleasure to

serve you.

Part # 1009067 Rev13(12/04/09)Page 8

INSTALLATION

Clearances and Setting

CLEARANCES

MODEL TYPE

TO COMBUSTIBLE WALL

SIDES REAR*

Range and Range

Attachments

3" (76mm) 1/2" (13mm)

Broiler with Range 6” (152mm) 1/2” (13mm)

* Rear clearance for convection oven base models is

2” (51mm).

Proper placement of the range will ensure operator

convenience and satisfactory performance. Adequate

clearance must be provided for servicing, ventilation and

proper operation. The range must be kept free and clear of

combustible material.

Legs

All units are shipped with N.S.F. approved legs. These legs

must be installed to provide a minimum clearance of 6”

between the oor and bottom of the unit in order to meet

National Sanitation Foundation requirements.

1. Locate unit in its nal position.

2. Raise the rear and block it. Insert the bullet foot into the

leg cone. Tap with mallet until the bullet foot seats up to

the collar. Unit may now be leveled by adjusting hex head

portion of the bullet foot. Repeat for all four legs.

Electrical Connections

Before attempting the electrical connection, the rating

plate should be checked to ensure that the unit’s electrical

characteristics and the supply electrical characteristics agree.

The Garland 36E series complies with the standards CSA

C222 no. 109-latest edition, the UL197-latest edition and the

NSF #4-latest edition. The installation & connection of this

appliance must comply with the current codes. In Canada-

the Canadian Electrical Code Part 1 and in the USA-The

national Electrical Code.

1. Switch panel size.

2. Overload protection.

3. Wire type.

4. Wire size.

5. Temperature limitations of the wires.

6. Method of connection (Cable, Conduit, etc.)

Wiring Diagram

IMPORTANT: Input voltage and phasing must match the

units voltage and phasing.

A wiring diagram is attached to the main back of each unit.

Visually check all electrical connections. Energize electric

service to units. The range is wired standard for three phase

connections. If it is necessary to change to single phase,

please refer to wiring diagrams. Service and unit voltage

must agree. Unit rating plate is located behind the lower

front panel.

Circuit Breakers and Fuses

Heavy duty circuit breakers and fuses are provided to assure

you many years of safe trouble-free operation. They are

located behind the lower front panel.

Garland

Terminal Bock

Located behind

Panel.

Circuit

Breakers

Fuses

Part # 1009067 Rev13 (12/04/09) Page 9

Main Line Entrance

Two (2) alternate entrance location are provided as follows:

1. Through bottom of range. Center line of bottom entrance

hole is 8 3/4” from left and 5” from front base. If conduit

is used, allow an 8 1/2” extension for units installed with

legs adjusted to 6” height, a 5” extension when legs are

adjusted to a minimum height, a 3” extension when legs

are not used.

2. Through back of range. Center line of back entrance is 11”

from left side and 2” up from base of range.

Terminal Block

The terminal block, as well as grounding lug, is mounted

in fuse compartment behind lower from panel. To remove

panel, loosen screws and lift up and out using louver as

handle. All units are equipped with circuit breakers and

provided with a panel in front of terminal block.

Sanitary Counter Top Seal

When a broiler or “T” Section (Top Section) is installed

without legs on a counter top it must be sealed completely

around base with a silicone sealant in compliance with N.S.F.

Standards.

Assembly of Battery

All units should be placed in their respective battery

positions. Remove packing material. The protective covering

on stainless steel should also be removed. Level each unit to

the oven rack by adjusting legs. Where legs are not used, unit

must be leveled by using shims. Use a spirit level and level

unit four (4) ways; across front and back and front to back

along left and right sides. The two (2) 5/16” hex head bolts

and nuts labeled “Remove and use for Banking” should be

removed and used for joining unit together through ends of

main front top and main back top.

Installation Instructions for Mounting

The ER36 (Salamander) To 36E Series

1. Back of Range must be easily accessible.

2. Install Salamander support brackets to range by slipping

Salamander support brackets into the opening in the

burner box sides so bottom ange of Salamander

support bracket ts over 10-24 stud in range. Securely

fasten with 10-24 hex nut and lock washers.

3. Securely fasten Salamander support brackets at the rear

to burner box sides with 1/4 - 20 x 3/4 slot truss head

machine screws, hex nuts and lock washers.

4. Remove lower front panel from Salamander.

5. Place Salamander on the rear of the Range Lining up

holes in Salamander support brackets with holes on

Range.

6. Securely fasten Salamander to Range with

5/16 - 18 x 1 hex head machine screws, hex nuts and

washers. Replace Salamander lower front panel removed

in step 4.

7. Remove Salamander control panel.

8. The two (2) wires coiled on top right section of range

should be run through hole in back of Salamander and

into wiring compartment.

9. Attach two (2) wires to terminal block per encloses wiring

diagram.

10. Replace Salamander control panel removed in step 7.

11. A burner box back panel, which is installed at the back

of the range, is supplied with the salamander. This panel

covers the exposed back of the burner box where the

mounting brackets are attached. Use the metal machine

screws to secure this panel to the back of the range.

Salamander

Support

Salamander

Bracket

Burner Box

Side

Burner

Back

Salamander

Bracket

INSTALLATION continued

Part # 1009067 Rev13(12/04/09)Page 10

Installation Instructions for Mounting

The Double Deck High Shelf 36E Series

1. Back of range must be easily accessible.

2. Remove the at head bolt “A” from each side of high shelf

only when place next to a high shelf, Salamander.

3. Place backguard, high shelf on the rear of the Range

slipping the support brackets into the opening in the

burner box side.

4. Securely fasten support brackets to the burner box sides

with (4) 1/4 - 20 x 3/4 slot truss head machine screws

or (4) #10B x 1/2 Phillips sheet metal screws. Hardware

package will be supplied.

5. Remove lower front panel of the high shelf.

6. Replace at head bolts removed in step 2 so that each high

shelf is bolted to adjacent high shelf at “A”.

7. Replace lower front panel of high shelf.

INSTALLATION continued

Upright

Burner Box

Side

1/4 - 20 x 3/4

Slot Truss Head

Machine Screws or

#10B x 1/2 Phillips

Sheet Metal Screws

4 Req.

Bolt "A"

Ventilation

An adequate ventilation system is recommended for all

commercial electrical cooking appliances. For further

information please refer to “Vapor Removal From cooking

Equipment” National Fire Protection Association Standards.

OPERATION

Ovens

Controls

On standard units, the controls for the lower oven section

are located on the right end of the switch pane. Each oven

is equipped with top and bottom heating units. Two (2)

three heat, heavy duty reversible switches allow for separate

operation of each heating unit. An oven thermostat and

indicator lamp are also provided for each oven. Regardless

of Switch Settings of Upper and Lower heating Units, the

Thermostat Has Complete Control of the Temperature of the

Oven.

Preheat

Turn top heating unit (Switch at left of thermostat dial) to

“High”. Turn bottom heating unit (Switch at right of the

thermostat dial) to “High.” Set oven thermostat dial to desired

temperature. Pilot lamp will now come “ON,” indicating

oven has not reached desired temperature. When desired

temperature is reached, pilot lamp will go “OFF”. At this time,

top heating switch may be turned “OFF” or set as desired.

Bottom heating unit may be left at “High” or set as desired.

Part # 1009067 Rev13 (12/04/09) Page 11

During preheat period, keep oven door closed. With oven

operating on rated voltage, it will require approximately 18

to 20 minutes to reach 450°F from a cold start.

Personal preferences of dierent operators dictate time and

temperature requirements for various cooking operations.

For this reason, no times or temperatures are suggested here.

If in doubt, consult a good cookbook on volume cooking.

General

Baking or roasting may be done in the oven on the oven rack

provided with each oven. Best baking or roasting results will

be obtained with only one rack of product at a time. Multi-

rack loading will greatly change bake/roast characteristics

and “done” times. Do not bake or roast directly on the oven

bottom. In choosing pans, be sure pan size will allow space

between back, sides and oven door to allow for proper heat

circulation. Personal preferences of dierent chefs and food

service operators dictate temperature and time requirements

for various oven cooking operations. For this reason, no

cooking times or temperatures are suggested here. If in

doubt, consult a good cookbook on volume food service.

Range Base Convection Oven (RC)

As a guide, set oven temperature 25° to 50° lower than called

for in recipes directions using standard or conventional

ovens. Cooking time may be less depending upon the

product you are preparing. 2% to 5% is a general rule.

Product should be watched the rst time it is prepared.

Cooking time and oven temperature will vary depending

upon such factors as size of load, temperature of product,

and mixture of recipe, particularly moisture. When you

have established satisfactory time and temperature for our

products, record them on a chart and keep as a reference

guide.

OPERATION continued

Preheat oven thoroughly before use. To reach 350°F takes

approximately 20 minutes. For optimum results oven should

be preheated for 30 minutes to allow for thorough heat

saturation. The load should be centered on the oven racks

to allow for proper heat circulation around the sides. Load

size – the oven will hold three (3) 18” x 26” sheet pans, six

(6) 12” x 20” x 2.5” steam table pans or one (1) 17.75” x 25.75”

roast pan. Never place pans directly on the oven bottom.

Always use the lowest rack position which will allow the

air to circulate within the oven cavity. Load and unload

food as quickly as possible to prevent an excessive drop

in temperature. Avoid using warped pans since level pans

bake more evenly. Do not use a deep pan for shallow cakes,

cookies, etc, as circulation across the surface is essential for

even cooking and browning. To prevent excessive shrinkage,

roast meats at a low temperature (250° to 325°F)

When rethermalizing frozen products preheat the oven 50°

higher than cooking temperature to compensate for heat

loss during and after loading. Thermostat must be returned

to cooking temperature after loading.

Range Base Convection Oven Operation

Activate the power switch to the cook position. Set the fan

speed switch to the desired fan speed. Set oven thermostat

to the desired oven temperature. Allow 20 to 30 minutes to

preheat.

When nished using the oven it should be cooled below

150° before shutting down. Turn the power switch to “cool

Down” and open the oven door. Allow fan to operate for

approximately 30 minutes. To shut down the oven turn the

thermostat and the power switch to the o position.

CAUTION: Motor must operate during cooking cycle. Failure

to do so will shorten motor life!

We recommend, at the end of a bake or roast period, when

the oven will be idle for any period of time to set the oven

thermostat to the lowest temperature setting and allow the

oven to operate. By doing this, the oven motor will keep

itself cool by operating and you will save preheat time for

next ovens’ use. If this procedure is not desirable than we

recommend that the oven be cooled down below 150°F

between baking or roasting periods.

Part # 1009067 Rev13(12/04/09)Page 12

OPERATION continued

Problem / Solution

Heavy Duty Range Convection Oven

Problem Solution

Cakes are dark on the sides

and not done in the center

Lower oven temperature

Cakes edges are too brown Reduce number of pans or

lower oven temperature

Cakes have light outer color Raise temperature

Cake settles slightly in the

center

Bake longer or raise oven

temperature slightly.

Do not open doors too

often or for long periods

Cake ripples Overloading pans or batter

is too thin

Cakes are too coarse Lower oven Temperature

Pies have uneven color pans Reduce number of pies per

rack or eliminate use of

bake pans

Cupcakes crack on top Lower oven temperature

Meats are browned and not

done in center

Lower temperature and

roast longer.

Meats are well done and

browned

Reduce time. Limit amount

of moisture

Meats develop hard crust Reduce temperature or

place pan of water in oven.

Rolls have uneven color Reduce number of size

pans.

Motor Care

The motor on your Garland range base convection is

maintenance free since it is constructed with self-lubricating

sealed ball bearing. It is designed to provide durable service

when treated with ordinary care. Be sure to follow the cool

down procedure as mentioned in the above paragraphs or

to lower the oven temperature during idle periods. Failure

to follow the prescribe procedure may not void warranties,

but, may cause your oven motor to fail when you need it the

most.

Top Sections

Cooking Top – Open Type Burners

High speed tubular heating units are each provided with a

three heat switch. Each high speed tubular heating unit is

rated a 2.1 k.w. designed to give speed and exibility where

sauce pans are used. It should be pointed out that these are

NOT designed or intended for use in heavy (stock pot) duty

service. Use of large stock pots will severely damage surface

elements. It is recommended that only utensils of 8” to 10”

diameter (with a capacity no greater than 1 U.S. gallon), be

used.

Surface heating units should not be left on high heat if not

covered by a cooking utensil. Turn switch to “O” or “Low”

when units are idling. Failure to do this will shorten the life of

the surface heating elements.

NEVER USE LARGE STOCK POTS ON SURFACE HEATING

ELEMENTS!

Top View

of 36ER33

Six

Heating

Units

Switch

Panel

Part # 1009067 Rev13 (12/04/09) Page 13

Boiling Plates

Remove all factory applied protective material (gelled

mineral oil) by washing with a hot, mild detergent or soap

solution, then dry thoroughly. Before using follow seasoning

procedure in the Griddle Plate Section. All Boiling Plates are

provided with separate front and back heating units. Each

heating unit is operated by a three heat (High-Med-Low-O),

heavy duty reversible switch. Switches are grounded in sets

of two (2) for each 12” of plate. In each group, the switch at

the left operates the front section, the switch at the right

operates the back position.

General Boiling plates are recommended for all stock pot

cooking, These plates are the most exible boiling plates

available. The 36” (914 mm) x 24” (610 mm) steel top, has six

heat zones. Total top input of 12.0 k.W.

Switch

Panel

Six

Heat

Zones

Top View

of 36ER39

OPERATION continued

All Purpose Plates

Remove all factory applied protective material (gelled

mineral oil) by washing with a hot, mild detergent or soap

solution, then dry thoroughly. Before using follow seasoning

procedure in the Griddle Plate Section. Each All Purpose Plate

is thermostatically controlled from 250°F to 700°F. thermostat

dials are marked from 1 to 10. Approximate temperatures

settings are as follows.

MODE DIAL SETTING TEMPERATURE

Simmer 1-2 250°F to 300°F

Fry 2-5 300°F to 450°

Boil 5-8 450° to 600°F

Pan Fry & Fast boil 8-10 600°F to 700°

TOP View

of 36ER36

Two

Heat

Zones

Switch

Panel

Part # 1009067 Rev13(12/04/09)Page 14

Griddle Plates

All steel griddle plates are controlled by thermostats

permitting separate temperatures to be maintained at

any time. Heavy Griddle work recommended for quantity

cooking where even temperature and fast recovery is

required. Top plate has welded 2 1/2” (64 mm) high side

splash guards. Griddle Top: One 36” (914 mm) x 24” (610

mm) polished steel plate, has three heat zones each

thermostatically controlled from 150°F (38°C) to 450°F

(232°C) with indicator lamp. Total top input of 15.0 k.W.

preheats to 350°F (180°C) in eight minutes.

Remove all factory applied protective material (gelled

mineral oil) by washing with a hot, mild detergent or soap

solution, then dry thoroughly.

Three

Heat

Zones

Switch

Panel

Grease

Drains

Top View

of 36ER38

Seasoning

Before being used for the rst time, all griddles must be

“Seasoned.” The following method is recommended:

• Apply a thin coat of cooking oil to the griddle surface,

about one ounce per square foot of griddle surface.

Spread over the entire griddle surface with a cloth to

create a thin lm. Wipe o any excess oil with a cloth.

• Turn on all thermostats, set at 150°F setting. Some

discoloration will occur when heat is applied to steel.

• Heat the griddle slowly for 15 to 20 minutes. Then wipe

away oil. Repeat the procedure 2 to 3 times until the

griddle has a slick, mirror like nish. Do this until you have

reached the desired cooking temperature.

Important: Do not attain 450°F during “break-in” period.

Note: Steel griddle surface will tone (blue discoloration) from

heat. This toning will not diminish function or operation and

is not a defect.

The griddle will not require reseasoning if it is used properly.

If the griddle is over heated and product begins to stick to

the surface it may be necessary to repeat the seasoning

process again. If the griddle is cleaned with soap and water it

will be necessary to reseason the griddle surface again.

Operation of Broiling Section

Heavy Duty Electric Broilers are available in single or double

deck model mounted on an oven or storage base. It is also

available as a single deck or double deck modular section.

Broiling Compartments has broiler rack in each section

riding in a spring counter-balanced raising and lowering

mechanism, adjustable to 15 positions. The rack may be

raised to with 1/2” of the heating elements. The 24” by 22-

5/8” broil rack, with attached drip shield, rolls in and out

easily on six roller bearings. A lock stop prevents the rack

from accidentally being pulled out of the tracks, yet the

rack and drip shield may be readily removed for cleaning.

The large porcelain enameled grease pan is removed for

cleaning. Bae spoilers within the pane prevent spillage

during removal.

Heating Elements: Two inconel sheathed heating element

packages are provided; one service the rear half of the

broiling compartment, the other the front half. The element

package for the front half of the broiling compartment is

controlled by a three position heat heavy duty reversible

switch mounted at the bottom of the panel. Each switch

adjusts from full OFF to HIGH, MEDIUM and LOW modes.

Each broiler section is provided with a pilot indicator lamp

mounted in the control panel. When the lamp is lit, it signals

that energy is being applied to the elements. Each element

package has a maximum rating of 6 k.W. providing a 12 k.W.

maximum total for each section

OPERATION Continued

Part # 1009067 Rev13 (12/04/09) Page 15

MAINTENANCE AND CLEANING

We suggest maintenance and repairs to be performed by an

Garland Authorized Service Agent. The listing provided with

your range is titled “Maintenance and Repair Centers”.

CAUTION: Remember! Water and electricity do not mix, do

not use excessive water, heavily soaked sponges or rags to

clean switch panels or areas near electrical connections!

NOTE: RUST can form on raw steel and cast iron parts. Be

sure parts are dried thoroughly after cleaning. In warm, moist

environments, raw parts may require protection. Wipe down

with light coating of oil, rust inhibitor, or polish as applicable.

Painted Finishes

Establish a regular cleaning schedule. Any spills should be

wiped o immediately.

The oven should be permitted to cool down before cleaning

exterior surfaces.

Wipe exposed, cleanable surface when cool with a mild

detergent and hot water. Stubborn residue spots may be

removed with a light weight non metallic scouring pad. Dry

thoroughly with a clean cloth.

Stainless Steel

For routine cleaning just wash with a hot water and

detergent solution.

Stainless steel should be cleaned using a mild detergent, a

soft cloth and hot water. If necessary to use a nonmetallic

scouring pad, always rub in the direction of the grain in the

metal to prevent scratching. Use a water based stainless

cleaner (Drakett Twinkle), if you want a high shine. Wash just

a small area at a time or the water will evaporate leaving the

chemicals behind causing streaking.

Rinse the washed area with a clean sponge dipped in a

sanitizing solution and wipe dry with a soft clean cloth

before it can dry.

Use a paste (of water and a mild scouring powder) if you

have to, but never rub against the grain. All stainless steel has

been polished in one direction. Rub with the polish lines to

preserve the original nish. Then thoroughly rinse as before.

To prevent ngerprints there are several stainless steel

polishes on the market that leave an oily or waxy lm. Do not

use on surfaces that will be in contact with food.

Stainless steel may discolor if overheated. These stains can

usually be removed by vigorous rubbing with a scouring

powder paste.

Use only stainless steel, wood or plastic tools if necessary

to scrape o heavy deposits of grease and oil. Do not use

ordinary steel scrapers of knives as particles of the iron may

become imbedded and rust. STEEL WOOL SHOULD NEVER BE

USED.

Either a typical bleach solution or hot water can be used to

sanitize stainless steel with out harm.

Oven Inner Door Liner and Oven Deck

(Porcelain Enamel)

The porcelain Oven Inner door Liner and Oven Deck can

be cleaned with oven cleaners such as “Easy-O”, or “Dow

Cleaner”. Follow product manufacture’s instructions for

proper use. CAUTION: Do not get any oven cleaner on any

painted surface, the oven cleaner will remove the paint!

CAUTION: Do not get any oven cleaner on Aluminized Steel

Inner Surfaces, it will cause the surface to turn a deep blue

color and may mar the aluminized surface.

Interior Cleaning of Standard Aluminized

Steel Interior Surfaces.

The oven sides and top linings are formed of heavy gauge

steel with an aluminum fused into its surface to provide

for the reectance of heat back to the food being prepared

and to virtually eliminate the possibility of rust formation.

Establish a regular cleaning schedule or wipe o on the same

day when spillovers occur.

1. Cool down oven.

2. Remove oven racks.

3. Lift rack guides on either side of oven o of holders, pull

the top away from the cavity wall, when it’s cleared the

clips push down and remove. Racks and guides may

be run through dishwasher while oven cavity is being

cleaned.

4. Use a concentrated detergent on a plastic pad to remove

burned on soil. Do Not Use Steel Wool, Oven Cleaner Or

Abrasive Powders. These will remove the aluminum. Rinse

with warm water on a soft cloth. Be sure to remove all

traces of detergent. Any discoloration which may remain

after the soil build-up has been removed will not aect

the performance of the oven.

5. To reinstall reverse procedure. Place the bottom of the

rack guide against the cavity wall. Keeping the top pulled

away from the wall lift up. Push the top of the rack guide

against the wall and push down locking it into place.

Part # 1009067 Rev13(12/04/09)Page 16

Cleaning and Care of

Top Surface Heating Burners

Surface units may be raised to permit removal of spillover

bowls under the surface burners. Spillover bowls may be

cleaned, wiped dry and replaced. Drip trays under the front

control panel may also be removed, washed, rinsed, wiped

dry and replaced. Cooking top may be wiped with a damp

cloth using a mild detergent and wary water. You may also

follow pervious instructions for “cleaning Stainless Steel

Exterior.”

Cleaning of Griddle, All Purpose Plates and

Boil Plates

To produce evenly cooked, perfectly browned griddle

products, keep griddle free from carbonized grease.

Carbonized grease on the surface hinders the transfer of

heat from the griddle surface to food product. This results

in uneven browning and loss of cooking eciency, and

worst of all, carbonized grease tends to cling to the griddle

foods, giving them a highly unsatisfactory and unappetizing

appearance. To keep the griddle clean and operating at peak

performance, follow these simple instructions.

A. After Each Use clean griddle thoroughly with a grill

scraper or spatula. Wipe o any excess debris left from

cooking process.

B. Once A Day clean griddle surface with a grill brick and

grill pad. Remove grease container and clean thoroughly,

in same manor as any ordinary cooking utensil.

MAINTENANCE AND CLEANING continued

C. Once A Week clean griddle surface thoroughly. If

necessary, use a grill stone or grill pad over the griddle

surface. Rub with grain of the metal while still warm. A

detergent may be use on the plate surface to help clean

it, but care must be taken to be sure it is thoroughly

removed. After removal of detergent, the surface of the

plate should be covered with a thin lm of oil to prevent

rusting. To remove discolorations, use a non-abrasive

cleaner. Before re-using the griddle must be reseasoned.

Keep griddle drain tube to grease container clear at all

times on those models without side grease container.

CAUTION: This griddle plate is steel, but the surface is

relatively soft and can be scored or dented by careless use

of spatula. Be careful not to dent, scratch, or gouge the plate

surface. This will cause food to stick in those areas. Also, note

since this is a steel griddle if a light coating of oil is not always

present rust will develop on unexposed areas.

Broiler Section

Broil rack, rack carriage and drip pan may be removed for

cleaning.

Lift broil rack out of carriage. Pull rack carriage forward to

rack stops and raise. Carriage may now be pulled out of

tracks. Raise and pull grease pan forward and out. Entire

interior of broiler may now be cleaned. After washing and

drying, reassemble parts by reversing previous steps.

After cleaning Boil Plates, All Purpose Plates, Griddles,

Tubular Heating Units, Ovens and Broilers, wash front and

back grease troughs and drip trays with hot, mild detergent

or soap solution and dry thoroughly.

Part # 1009067 Rev13 (12/04/09) Page 17

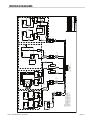

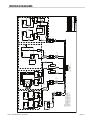

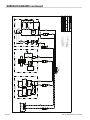

WIRING DIAGRAMS

36ER-ET-ES 208V/240V

1

36E SERIES

SEPT 22,2002NANB

31

4514760

875W

1125W

875W

1125W

1500W

1500W

1500W

2000W

H3

H1

H2

H6

H4

H5

o6

o5

o4

o3o2o1

212019 22 23 24

16

15

18

17

5000W

G1

G2

G4

G3

11

12

o7

o8

S2

13

14

o7

o8

S1

S3 S4

98

o9

o9

G5

3

5

4

6

12

5

3

6

4

12

5

3

6

4

12

3

5

1

4

6

2

4

6

3

5

21

34

56

12

P3

1

P1

2

P2

43

P3 P1

123

P2

4

P3 P1

123

P2

4

UPPER OVEN ELEMENTS LOWER OVEN ELEMENTS

4321

P3 P1 P2

4321

P3 P1 P2

4KW BOIL TOP

1

12

2COM

COM

THERMOSTAT

THERMOSTAT

30A

40A

40A

30A 30A

40A

ER 7kW

SALAMANDER

40A

40A

30A

40A

P3

1

P1 P2

324

OPEN TOP GRIDDLE-ALL PURPOSE TOP OVEN

200-550F

TB

LEFT

CENTER

RIGHT

RIGHT

CENTER

LEFT

CENTER

RIGHT

LEFT

TO TERMINAL BLOCK

(See page 2 for terminal block connection)

RIGHT

LEFT

CENTER

CENTER

RIGHT

LEFT

RIGHT

CENTER

LEFT

INNER

OUTER

INNER

OUTER

:

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

:

:

TITLE:

DATE

SCALE

DR.

SHT OF

CHK. BY

REV

REV.#

DATE

DR.DESCRIPTION

REVISIONS

MODEL:

36ER32; 36ER32-3; 36ER33;

36ER33-88;36ER33-99;36ER38;36ER39

36ES32; 36ES32-3; 36ES33; 36ES33-88;

36ES33-99;36ES38;36ES39;36ES17

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39;36ET17

Part # 1009067 Rev13(12/04/09)Page 18

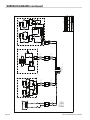

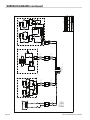

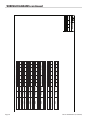

WIRING DIAGRAMS continued

36ER-ET-ES 208V/240V

1

36E SERIES

SEPT 22,2002NANB

32

4514760

3 PHASE CONNECTION

SINGLE PHASE CONNECTION

NO SALAMANDER

WITH SALAMANDER

E2

S2

E1

4

6

2

3

9

S1

5

1

8

E2

E1

S2

6

4

2

S1

3

5

1

E2

E1

4

6

5

3

2

1

E2

S2

E1

S1

4

6

2

9

5

3

8

1

E2

E1

4

2

2

5

S2

S1

1

3

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

SALAMANDER

TOP LEFT

TOP CENTER

TOP RIGHT

OVEN

OVEN

TOP LEFT

TOP CENTER

TOP RIGHT

SALAMANDER

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

TOP LEFT

TOP CENTER

TOP RIGHT

TOP LEFT

TOP CENTER

TOP RIGHT

SALAMANDER

SALAMANDER

TOP RIGHT

TOP CENTER

TOP RIGHT

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

TOP CENTER

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

SALAMANDER

TOP LEFT

TOP LEFT

TOP CENTER

SALAMANDER

TOP CENTER

TOP RIGHT

TOP LEFT

OVEN

TOP RIGHT

OVEN

TOP LEFT

TO CIRCUIT BREAKER PANEL

TO CONTROL PANEL

TOP CENTER

TOP RIGHT

TOP LEFT

TOP RIGHT

SALAMANDER

TOP LEFT

TOP CENTER

SALAMANDER

36ER32; 36ER32-3; 36ER33; 36ER33-88;

36ER33-99;36ER38;36ER39

G

Z

Y

X

36ER32; 36ER32-3; 36ER33; 36ER33-88;

36ER33-99;36ER38;36ER39

G

X

Z

Y

36ES32; 36ES32-3; 36ES33; 36ES33-88;

36ES33-99;36ES38;36ES39

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39

G

Z

Y

36ES32; 36ES32-3; 36ES33; 36ES33-88;

36ES33-99;36ES38;36ES39;36ES17

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39;36ET17

X

G

Z

Y

X

36ES32; 36ES32-3; 36ES33; 36ES33-88;

36ES33-99;36ES38;36ES39

36ET32; 36ET32-3; 36ET33; 36ET33-88;

36ET33-99;36ET38;36ET39

G

Z

Y

X

:

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

:

:

TITLE:

DATE

SCALE

DR.

SHT OF

CHK. BY

REV

REV.#

DATE

DR.DESCRIPTION

REVISIONS

Part # 1009067 Rev13 (12/04/09) Page 19

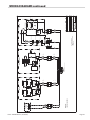

36ER-ET-ES 208V/240V

1

36E SERIES

SEPT 22,2002NANB

33

4514760

:

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

:

:

TITLE:

DATE

SCALE

DR.

SHT OF

CHK. BY

REV

REV.#

DATE

DR.DESCRIPTION

REVISIONS

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ER 32

208 21.5 6.5 10 5 103.4 69.2 48.0 63.6

240 21.5 6.5 10 5 89.6 60.0 41.6 55.1

36 ER 32 SAL

208 28.5 6.5 10 12 137.0 69.2 78.2 91.7

240 28.5 6.5 10 12 118.8 60.0 67.7 79.5

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ER 32-3

208 20.7 6.5 10 4.2 99.5 69.2 44.9 60.7

240 20.7 6.5 10 4.2 86.3 60.0 38.9 52.6

36 ER 32-3 SAL

208 27.7 6.5 10 11.2 133.2 69.2 74.6 88.3

240 27.7 6.5 10 11.2 115.4 60.0 64.6 76.5

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ER 33

208 19.1 6.5 8.4 4.2 91.8 62.2 44.9 53.4

240 19.1 6.5 8.4 4.2 79.6 53.9 38.9 56.3

36 ER 33 SAL

208 26.1 6.5 8.4 11.2 125.5 62.2 74.6 81.9

240 26.1 6.5 8.4 11.2 108.8 53.9 64.6 71.0

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ER 33-88

208 20.7 6.5 10 4.2 99.5 69.2 44.9 60.7

240 20.7 6.5 10 4.2 86.3 60.0 38.9 52.6

36 ER 32 SAL

208 27.7 6.5 10 11.2 133.2 69.2 74.6 88.3

240 27.7 6.5 10 11.2 115.4 60.0 64.6 76.5

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ER 33-99

208 18.7 6.5 8 4.2 89.9 60.5 44.9 51.6

240 18.7 6.5 8 4.2 77.9 52.4 38.9 44.7

36 ER 33-99 SAL

208 25.7 6.5 8 11.2 123.6 60.5 74.6 80.3

240 25.7 6.5 8 11.2 107.1 52.4 64.6 69.6

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ER 38

208 21.5 6.5 10 5 103.4 69.2 48.0 63.6

240 21.5 6.5 10 5 89.6 60.0 41.6 55.1

36 ER 38 SAL

208 28.5 6.5 10 12 137.0 69.2 78.2 91.7

240 28.5 6.5 10 12 118.8 60.0 67.7 79.5

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ER 39

208 18.5 6.5 8 4 88.9 60.5 44.1 50.9

240 18.5 6.5 8 4 77.1 52.4 38.2 44.1

36 ER 39 SAL

208 25.5 6.5 8 11 122.6 60.5 73.7 79.4

240 25.5 6.5 8 11 106.3 52.4 63.8 68.8

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 17

36 ET 17

208 10 5 5 0 48.1 41.6 24.0 24.0

240 10 5 5 0 41.7 36.1 20.8 20.8

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 32

36 ET 32

208 15 5 5 5 72.1 41.6 41.6 41.6

240 15 5 5 5 62.5 36.1 36.1 36.1

36 ES 32 SAL

36 ET 32 SAL

208 22 7 5 10 105.8 50.2 71.1 63.6

240 22 7 5 10 91.7 43.5 61.7 55.1

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 32-3

36 ET 32-3

208 14.2 5 5 4.2 68.3 41.6 38.4 38.4

240 14.2 5 5 4.2 59.2 36.1 33.2 33.2

36 ES 32-3 SAL

36 ET 32-3 SAL

208 21.2 7 5 9.2 101.9 50.2 67.7 60.0

240 21.2 7 5 9.2 88.3 43.5 58.6 52.0

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 33

36 ET 33

208 12.6 4.2 4.2 4.2 60.6 35.0 35.0 35.0

240 12.6 4.2 4.2 4.2 52.5 30.3 30.3 30.3

36 ES 33 SAL

36 ET 33 SAL

208 19.6 7 4.2 8.4 94.2 47.1 64.2 53.4

240 19.6 7 4.2 8.4 81.7 40.8 55.6 46.3

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 33-88

36 ET 33-88

208 14.2 5 5 4.2 68.3 41.6 38.4 38.4

240 14.2 5 5 4.2 59.2 36.1 33.2 33.2

36 ES 33-88 SAL

36 ET 33-88 SAL

208 20.4 7 4.2 9.2 98.1 47.1 67.7 57.1

240 20.4 7 4.2 9.2 85.0 40.8 58.6 49.5

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 33-99

36 ET 33-99

208 12.2 4 4 4.2 58.7 33.3 34.1 34.1

240 12.2 4 4 4.2 50.8 28.9 29.6 29.6

36 ES 33-99 SAL

36 ET 33-99 SAL

208 19.2 7 4 8.2 92.3 46.4 63.4 51.8

240 19.2 7 4 8.2 80.0 40.2 54.9 44.9

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 38

36 ET 38

208 15 5 5 5 72.1 41.6 41.6 41.6

240 15 5 5 5 62.5 36.1 36.1 36.1

36 ES 38 SAL

36 ET 38 SAL

208 22 7 5 10 105.8 50.2 71.1 63.6

240 22 7 5 10 91.7 43.5 61.7 55.1

MODEL VOLTAGE TOTAL KW

LOADING PER PHASE AMPERAGE

X-Y X-Z Y-Z 1 Phase X Y Z

36 ES 39

36 ET 39

208 12 4 4 4 57.7 33.3 33.3 33.3

240 12 4 4 4 50.0 28.9 28.9 28.9

36 ES 39 SAL

36 ES 39 SAL

208 19 7 4 8 91.3 46.4 62.5 50.9

240 19 7 4 8 40.2 79.2 54.2 44.1

WIRING DIAGRAMS continued

Part # 1009067 Rev13(12/04/09)Page 20

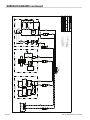

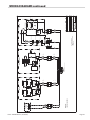

WIRING DIAGRAMS continued

36ER 208V/240V 18"SECTION

1

36E SERIES

SEPT 22,2002NANB

31

4514761

1400W

1600W

1400W

1600W

1500W

1500W

1500W

2000W

B3

B1

B2

B6

B4

B5

2019 22 23 24

16

15

18

17

1400W

A3

A4

A7

A5

11

12

S2

13

14

B7

B8

S1

S3 S4

98

1600W

1600W

1400W

A1 A2

21

A6

34

12

3

1

4

2

2

43

1

2

43

1

P3

1

P1

2

P2

4

3

P1P3

12

P2

43

ALL PURPOSE TOP

P3

1

P1

2

P2

43

UPPER OVEN ELEMENTS

LOWER OVEN ELEMENTS

4321

P3 P1 P2

BOIL TOP

THERMOSTAT

THERMOSTAT

40A 40A 40A40A

ER 7kW

SALAMANDER

40A40A40A40A

OVEN

TO TERMINAL BLOCK

(See page 2 for terminal block connection)

200-550F

TB

RIGHT

LEFT

RIGHT

LEFT

LEFT

RIGHT

LEFT

RIGHT

OUTER

INNER

OUTER

INNER

:

ALL DIMENSIONS ARE IN INCHES

TOLERANCE ±0.015" UNLESS OTHERWISE SPECIFIED

:

:

:

TITLE:

DATE

SCALE

DR.

SHT OF

CHK. BY

REV

REV.#

DATE

DR.DESCRIPTION

REVISIONS

MODEL:

36ER35 36ER36

36ET35 36ET36

36ES35 36ES36

36ET15 36ET16

36ES15 36ES16

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

La page est en cours de chargement...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

Garland US Range Cuisine Series Heavy Duty Griddle Top Range Owner Instruction Manual

- Catégorie

- Fours

- Taper

- Owner Instruction Manual

dans d''autres langues

Documents connexes

-

Garland E20 Series Owner Instruction Manual

-

U.S. Range E20 Series spécification

-

Garland E20 Series Owner Instruction Manual

-

Garland GIR36C Mode d'emploi

-

Garland Enodis UIR60 Manuel utilisateur

-

Garland E20 Series Owner Instruction Manual

-

Garland GF24-T Mode d'emploi

-

Garland E20 Series Owner Instruction Manual

-

Garland XG24CE Mode d'emploi

-

Garland E20 Series Mode d'emploi

Autres documents

-

Buffalo CD679 Le manuel du propriétaire

-

ROLLER GRILL SEM 800 PDS Instructions for Use and Installation

-

Vulcan 36ESB C36ESB Salamander Broiler Le manuel du propriétaire

-

Vulcan 36ESB Le manuel du propriétaire

-

Vulcan 36ESB Manuel utilisateur

-

Salamander Designs FPS Series Manuel utilisateur

-

Vulcan C36ESB Manuel utilisateur

-

Vulcan EV36S-4FP12G Le manuel du propriétaire

-

Lang LG-48M Fiche technique

-

RM FTR 704 G Instructions For Installation And Use Manual