13

ALARM RESET

Power Failure

ALARM RESET

Temp

NOTE

Door Ajar

Temp

• Power failure - If power to the appliance is inter-

rupted the System Status indicator will turn-off and

the "Power Failure" indicator will ash. Additionally, an

"ALARM RESET" indicator will be displayed below the

"On/Off" keypad. No audible tone will sound. This alarm

condition can be reset by momentarily pressing the

"On/Off" keypad. If this alarm occurs, it is recommend-

ed that you check the condition of any perishables,

even if the appliance is operating normally and the tem-

perature has recovered, as prolonged power outages

could result in excessive temperature excursions which

may spoil perishables.

• Temperature alarm - If the storage compart-

ment temperature deviates excessively from your

set-point temperature for an extended period of time,

the "TEMP" indicator will ash, and an audible tone

will sound every 60 seconds. Additionally, an "ALARM

RESET" indicator will be displayed below the "ON/

OFF" keypad.

Multiple alarms are possible, i.e.- "Door Ajar" for a pro-

longed period may trigger a "Temp" alarm, in which case

both "Door Ajar" and "Temp" indicators will activate.

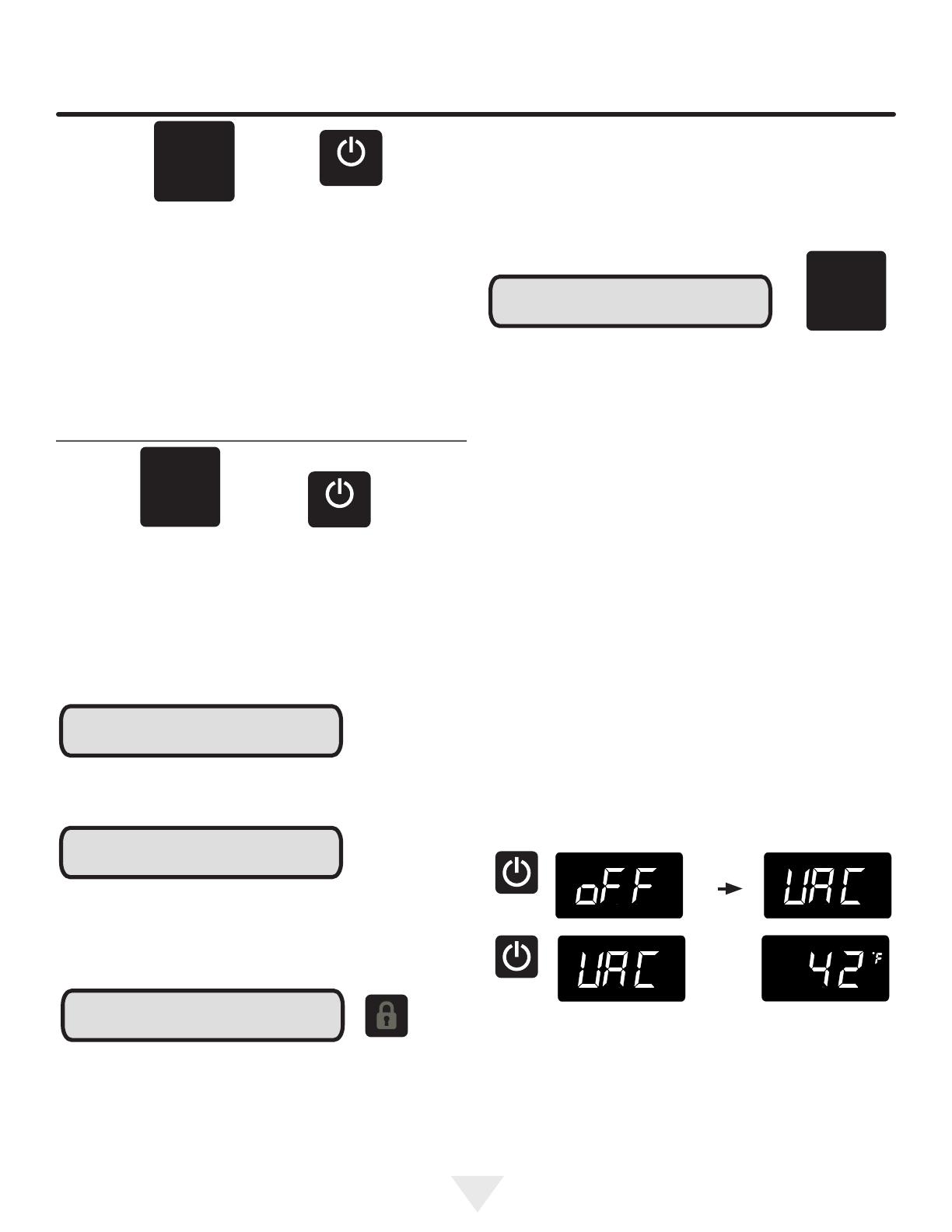

Vacation mode (Single and Dual Zone):

This operating mode can be used to save energy during

high cost energy periods, or when you won't be using your

appliance for an extended period of time by disabling the

lights, alarm tones, and keypad entry tones. Vacation mode

also serves as a Sabbath mode, disabling functions and

its controls in accordance with the weekly Sabbath and

religious holidays observed within the Orthodox Jewish

community. When used as Sabbath mode, you may open

or close the door at any time to access contents without

concern of directly turning on or off any lights, digital read-

outs, solenoids, fans, valves, compressor, icons, tones, or

alarms.

When activated, the display, alarm indicators and tones,

keypad touch tones, interior lights, and all options are dis-

abled. All keypad functions are disabled, with the exception

of the "On/Off" keypad which is required to exit Vacation-

mode. Storage compartment temperatures are monitored

and controlled at the settings prior to entering Vacation

mode.

To enter Vacation Mode (with the control out of sleep

mode), press and hold the "On/Off" keypad until the display

goes past "OFF" and reads "VAC". The display will ash

"VAC" 3-times to acknowledge your request, then will

display "VAC" continuously until Vacation mode is exited.

A power outage will not exit Vacation mode, exiting can

only be accomplished manually. To exit Vacation mode and

return to normal operation, press and hold the "On/Off"

keypad until the control displays the temperature.

USING YOUR ELECTRONIC CONTROL

NOTE

The audible alarm can be muted, for each occurrence, by

pressing the lock keypad.

This alarm condition can be reset by momentarily pressing

the "On/Off" keypad. If this alarm occurs it is recommended

that you check the condition of your stored contents, even

though the appliance is operating normally and the temper-

ature has recovered, as prolonged temperature excursions

could spoil perishables.

NOTE

NOTE

After a high temperature alarm condition, check all perish-

ables to ensure they are safe for consumption.

The temperature alarm may occur as a result of high usage

or introduction of warm contents to the storage compart-

ment. If the temperature alarm continues to occur, your unit

may require service.