1

ORIGINAL

I

NSTRUCT

I

ONS

1

A GUIDE

TO

GOOD DRILLING

PRACTICE

To get the best

possible performance

from your new

Magne�c

Drilling Machine

,

please read this

carefully

BEFORE using the

drill.

DE

NL

ES

HB350

Magne�c Drill

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

FR

PT

CH

VN

FA

AR

INSTRUÇÕES ORIGINAIS

Ursprüngliche Anweisungen

Instruc�ons originales

Originele instruc�es

Instrucciones originales

HƯỚNG DẪN CƠ BẢN

BEFORE YOU START

To help you get the best possible performance

from your new Magnetic Drilling Machine, this

guide contains simple, sensible pointers for the

safe, eective, and long-term use of the

equipment.

Please read it ca refully

before using

the

drill.

• Ensure that you have observed all the general

and speciety procedures.

Explanation

of the pictograms

on

the

specification plate

of the Makita

HB350

DANGER!

Indicates an imminent danger or risk to

life and health of a general nature.

ELECTRICAL

DANGER!

This means a direct pending danger or

risk to life due to electricity.

CAUTION!

Indicates a possible danger or risk of

slight injury or damage to property.

WEAR

EYE & EAR PROTECTORS

USE SAFETY

STRAP!

to aach the tool to the workpiece.

READ THE MANUAL

Read the manual before operang

the machine.

WEEE compliance cercate:- on request

All magnec drilling systems are fully compliant.

with RoHS regulans.

Due to the presence of hazardous components in the

equipment, used electrical and electronic equipment may

have a negave impact on the environment and human

health.

Do not dispose of electrical and electronic appliances with

household waste.

In accordance with the European Dircecve on waste

Electrical and electronic equipment should be collected

separately and delivered to a separate collecon point

for municipal waste, operang in accordance with the

environmental protecn regulaons.

this is indicated by the symbol of the crossed out

wheeled bin placed on the equipment.

CONTENTS

•

HB350 Specion

•

The Broach Cuing Concept

•

Intended Use

•

General Safety Instrucons

•

Material and Cuing speeds

•

Feeds and Speeds

•

Fitting Safety Guard & Strap and Oil

Bottle

•

Fitting Cuers

•

Panel Operaon

•

Motor diagram & parts list

•

Stand diagram & parts list

•

EC Declaraon

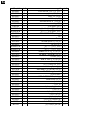

CUTTING TIME

CUTTING TIME

HB350

SPECIFIFCATION

Cutter capacity - 35mm

Chuck Capacity - 13mm

No load speed - 850 rpm

Power consumption - 1050w

Clamping

force -

8000N (

815

kg)

L

x H x W (mm) - 225 x 490 x

195

Weight

- 11.

Voltage - 110/230v

Sound pressure level - 89.13 dB(A)

Sound Power level - 100.12 dB(A)

I

NCLUDES

:

Integral c oo l a n t s y s tem ,

Warra nty

,

Carrying case, Allen keys, Safety

strap &

Guard

• Due to our continuing programme of research and

development, these specifications are subject to change

without notice.

THE BROACH CUTTING CONCEPT

If you are unfamiliar with the use of annular

(or broaching) cutters, take a few minutes to

read this guide - you will benefit from the better

performance and longer life of the tool if you

understand the concept.

Annular c utters only c u t m arterial at the

periphery of the hole, rather than converting

the entire hole to shavings. As a result, the time

and energy required to make the hole is lower

than for a traditional twist drill.

The b r o ach hing c a p a c ity of a m ac hine i s

therefore, greater than the twist drill capacity.

The slug ejected after the cut also has a higher

scrap value than shavings.

Op�onal Accessories

For details of options, either refer to the catalog or inquire at the store of

purchase or a Makita sales office.

If you need any assistance for more details regarding these accessories, ask your local Makita

Service Center.

• HSS Cutter

• TCT Cutter

• Drill chuck

INTENDED USE

The intended use of this magnetic drill is to drill holes in ferrous metals. The magnet is used to hold

the drill in place whilst the drill is functioning. It is designed for use in fabrication, construction,

railways, petrochemical, and any other applications when drilling ferrous metal.

Any deviation from its intended use will not be covered by warranty.

GENRAL POWER TOOL SAFETY INSTRUCTIONS

General power tool safety warnings

WARNING Read all safety warnings, instructions, illustrations, and specifications provided with this

power tool. Failure to follow all instructions listed below may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-

operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids,

gases, or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges, and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase.

CAUTION: These accessories or as achments are recommended for use with

your Makita tool specified in this manual. The use of any other accessories or

attachments might present a risk of injury to persons. Only use accessory or

attachment for its stated purpose.

the risk of electric shock.

e) When opera�ng a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

f) If opera�ng a power tool in a damp loca�on is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of electric shock.

NOTE The term “residual current device (RCD)” can be replaced by the term “ground fault circuit

interrupter (GFCI)” or “earth leakage circuit breaker (ELCB)”.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when opera�ng a power tool. Do not use a

power tool while you are �red or under the influence of drugs, alcohol, or medica�on. A moment of

inatten�on while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protec�on. Protective equipment such as a dust

mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce

personal injuries.

c) Prevent uninten�onal starting. Ensure the switch is in the off position before connec�ng to power

source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energizing power tools that have the switch on

invites accidents.

d) Remove any adjus�ng key or wrench before turning the power tool on. A wrench or a key left attached

to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Always keep proper footing and balance. This enables better control of the power tool

in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away.

from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts.

g) If devices are provided for the connec�on of dust extrac�on and collec�on facili�es, ensure these are

connected and properly used. Use of dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore

tool safety principles. A careless action can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your applica�on. The correct power

tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack, if detachable, from

the power tool before making any adjustments, changing accessories, or storing power tools. Such

preven�ve safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tools or these instructions for power tools.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely

to bind and are easier to control.

g) Use the power tool, accessories, and tool bits etc. in accordance with these instruc�ons, taking into

account the working condi�ons and the work to be performed. Use of the power tool for operations

different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean, and free from oil and grease.

Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected

situations.

5) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

MAGNETIC DRILL SAFETY

INSTRUCTIONS

• Always inspect the whole unit before use.

• Regular maintenance is essential - check nuts,

screws etc. for tightness before each use.

• Check cable and plug for damage.

• Never use blunt or damaged cutters.

• Never use a larger diameter cutter than

specified for the machine.

• Always use the s a f e t y g ua r ds where

fitted and ensure they are operating correctly.

• Always wear goggles and gloves

• Remove rings, watches, ties etc. that could

tangle in the moving parts.

• Secure the unit with the safety strap before

drilling.

• The machine is for use on steel from 6 mm

thick with no air gap between the magnet core

and the workpiece. Curvature, paint, and

surface irregularities create an air gap. Keep

the air gap to a minimum.

• Keep the magnet and workpiece clean & free of

debris and swarf.

• Do not start the motor before ensuring that

the magnetic stand is clamped firmly to the

workpiece.

• Only use a general oil-based m e t a l cutting

oil.

• While drilling horizontally or overhead, use a

cutting paste or an appropriate coolant spray.

• Always disconnect from the power source

before cha n g i n g c u t t e r o r working on th e

machine.

• In the event of a jammed cutter, disconnect

from the power supply and free the jam before

reconnecting the tool.

• On swivel machines, ensure that the swivel

base is locked in the required position.

• Do not attempt to change speed while

the drill is running.

• Only use accessories recommended by the

manufacturer.

• Never lift or carry the unit by the power cord,

always use the handle.

• Never modify the tool in any way.

MAINTENANCE

INSTRUCTIONS

• Occasionally apply a few drops of oil to the

rack toothing.

• The bearings of the feed shaft are self-

lubricating and must not be greased

• Grease the sliding surface of the carriage

with MOLYCOTE grease.

• When not in use or being transported the

unit should be kept in the case supplied.

• After use ensure unit is clean of swarf and

dirt.

• Parts that are worn or damaged should be

r e p l a c e d immediately with g e n u i n e

manufacturer’s replacements.

• Ensure all cutting edges are sharp when in

operation. Using blunt cutting tools may lead

to an overload of the motor.

• Aft er e v e r y 30 m i n u t e s r u nn i n g, itis

recommended that the machine is laid on its

side to permit grease to run across the gear

train.

• After repeated use, the cradle may become

loose. This is remedied by adjusting the tension

screws on the side of the body. Put 2.5mm hex

wrench into head of cradle retaining nuts,

using 8mm Spanner undo the locking nuts anti-

clockwise, holding the hex wrench without

moving grub screws.

Using the hex wrench gently tighten screws in

series until the cradle moves freely in the slide

but does not allow the motor to wobble.

When a d j u s t m ent is c o m plete re -tighten

locking nuts clockwise, ensuring the grub

screws do not move from their new positions.

IMPORTANT!

– TO

PREVENT DAMAGE

TO THE

CIRCUITRY,

NEVER USE

ELECTROMAGNETIC DRILLING MACHINES

AND

WELDING EQUIPMENT

ON THE SAME W O R KP I E C E

SIMULTANEOUSLY.

6

MATERIAL AND CUTTING

SPEEDS

• The ease with which material can be drilled

is dependent on several factors including

tensile strength and abrasion resistance.

Whilst hardness and/or strength is the usual

criterion, wide variations in machinability can

exist among material showing similar physical

properties.

• The cutting conditions can be dependent

upon requirements for tool life and surface

finish and further restricted by the rigidity of the

tool and work piece, lubrication, and machine

power available.

• The harder the material the lower the

cutting speed. Some materials of low hardness

contain abrasive constituents leading to rapid

cutting-edge wear at high speeds. Feed rates

are governed by rigidity of set up, volume of

material to be removed, surface finish and

available machine power.

• It is preferable to set and maintain a constant

surface speed (RPM) for a given material and vary

the feed rate within defined limits.

• Machine feed is measured in inches or

millimeters per minute and is the product of

RPM x number of teeth in the cutter x feed per

tooth. Too light or excessively high feed rates

will both cause premature cutter failure. Heavy

feeds on hard materials will cause chipping of

the cutting edge and excessive heat generation.

• Slender and lo ng shank e d cutters are

restricted in feed rate due to deflection, and

wherever possible the largest and most robust

tool must be used. This is important for harder

materials. Steel up to 400 HB is the potential

limit for conventional M2 HSS tools.

Above 300 HB, cobalt alloy cutters should be

considered for increased tool life. In softer

grades of material, cobalt alloy cutters may give

increased output by increasing speeds and feed

rates by up to 50%. Tungsten Carbide cutters

permit surface speeds and feed rates up to

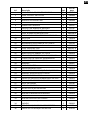

FEEDS AND SPEEDS

CUTTING SPEEDS

Suggested speed rates for varying cutter sizes/materials

TOOL FEED RATE

(Metric)

MATERIAL

Feed rate (mm/min)

Cutter Diameter (mm)

Cutter Diameter (inches)

ALUMINIUM - 60

BRASS - 45

MILD STEEL - 24

HI TENSILE STEEL - 9

TOOL FEED RATE

(Imperial)

MATERIAL

Feed rate

(inches/min)

MILD STEEL - 1”

PLEASE NOTE

:

These figures are quoted as a star ng point. Actual performance will be dictated by material

type, thickness and hardness, applica on, and cu er condi on.

Speed (RPM)

Speed (RPM)

10 706050403020 80

3/8” 3/4” 1.3/16” 1.9/16” 2” 2.3/8” 2.3/4” 3.1/8”

BRASS - 1 3/4

”

ALUMINIUM - 23/8

”

HI TENSILE STEEL - 3/8”

FITTING THE SAFETY GUARD

DRILL GUARD INSTRUCTIONS

Ensure drill unit is isolated from power supply.

Fit guard to drill as shown.

When drilling, the guard should always be in

contact with the surface being drilled. As the

drill is lowered, the guard will rise in relation.

to the drill.

FITTING THE OIL

BOTTLE

The cutting oil bottle is held in a sprung bracket

attached to the top of the drill body. Fit the

bracket by removing one of the cap screws from

the top plate and replace the bolt through the

fixing lug on the bottle bracket, tightening the

bolt enough to allow some radial movement of

the bracket. The coolant tube is a push fit into

the self-seal gland at the base of the tap and a

similar fitting on the lower arbor bracket.

FITTING THE SAFETY STRAP

The supplied safety strap should be used

wherever possible as a safety precaution in the

event of a power failure releasing the magnet;

particularly in situations where the machine is

clamped onto a vertical surface or in an inverted

position.

SAFETY STRAP INSTRUCTIONS

When the machine has been clamped to the

workpiece in the correct position for drilling,

the strap should be fed through the channel

between the body of the drill and the magnet,

then passed around a substantial part of the

workpiece. The free end should then be passed

through the buckle, pulled tight and locked.

Once the cut is complete, the strap should be

released, and the machine supported before the

magnet is disengaged.

FITTING THE CUTTER

Fig. 1

Fig. 2

Fig. 3

Fig. 4

E

nsure power

is off before

working

on the machine

Insertion of pilot pin

• The pilot pin is used to both center the cutter and to

eject the slug on completion of the cut. It has a flat side.

to allow coolant to run down to reach the center of the

cut where the heat is greatest. Slide the pin through the

hole in the center of the cutter shank

.

FITTING THE CUTTER

Fig 1.

To insert the cutter in the arbor, first loosen the grub screws,

using an M5 hexagonal wrench. Ensure the grub screws are

sufficiently loose enough to allow the shank of the cutter to

enter freely.

Fig 2.

Ensure the drive flats on the cutter shank are fully aligned with

the two grub screws in the machine arbor.

Fig 3.

Ensuring the shank of the cutter is fully inserted inside the arbor,

tighten the grub screws fully to give the cutter a secure fitting

inside the arbor.

Fig 4.

The cutter is now ready for use.

FIT THE SAFTY STRAP

APPLYING COOLANT

• Cutting oil ensures longer cutter life and enables the

slug to be ejected cleanly.

• Oil will be automatically delivered to the cutter when

the cut commences

• When cutting on vertical surfaces or upside down, cutting

paste, gel or foam is recommended. It is best applied inside

the cutter before drilling.

N.B. Safety strap and guards have been omitted from the photo’s for c

l

ar

i

ty.

OPERATION

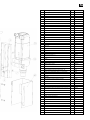

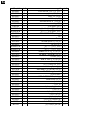

B350 MOTOR PARTS

EN

Nr.

Description

Qty

Part No

1

CARBON BRUSH ASSY. 6.3X10X18

2

EBD002

2

BRUSH HOLDER ASSY.

2

EBD001

3

SCREW M4 X 12

2

EBD003

4

SPRING WASHER M4

2

EBD004

5

PHILIPS HEAD SELF-TAP SCREW 4.8X45

4

EBD005

6

BACK COVER

1

EIB527

7

FIELD COIL CASING

1

EIB526

8

FIELD COIL ASSY 110V

1

EBD008-A

FIELD COIL ASSY 230V

1

EBD008-B

9

PHILIPS HEAD SELF - TAP SCREW 3.9X60

2

EBD009

10

BAFFE

1

EBD010

11

O RING

1

EBD011

12

BALL BEARING (8-22-7) 608 2Z

3

UDC022

13

DUST WASHER

1

EBD012

14

ARMATURE ASSY 110V

1

EBD013-A

ARMATURE ASSY 230V

1

EBD013-B

15

CIRCLIP 28MM X 1.2 B TYPE

1

EBD014

16

BALL BEARING (12-28-8) 6001 2Z

1

UDC023

17

GEAR CASE COVER

1

EBD015

18

CIRCLIP 10MM X 1 A TYPE

1

EBD016

19

GASKET

1

EBD017

20

INTER SHAFT ASSY.

1

EBD018

21

SPINDLE GEAR

1

EBD019

22

BALL BEARING (17-35-10) 6003 2RS

1

UDC004

23

OIL SEAL 20-30-7 B TYPE

2

EBD020

24

GEAR CASE

1

EBD021

25

PHILIPS HEAD SELF-TAP SCREW 4.8 X 60

4

EBD022

26

BALL BEARING 6904 2RS

1

EBD025

27

ARBOR BODY.

1

EIB528

28

ARBOR SPRING

1

EBD026

29

ARBOR EJECTION PLUG

1

EBD027

30

ARBOR WASHER

1

EBD028

31

ARBOR RUBBER WASHER

1

EBD029

32

ARBOR CIRCLIP

1

EBD030

33

CARBON BRUSH WASHER

2

EBD031

34

CARBON BRUSH FIXING SCREW

2

EBD032

35

PG9 PUSH FIT GLAND

1

40025

36

MOTOR LOCATING KEY

1

M1019

EN

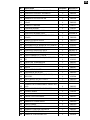

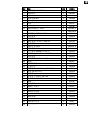

HB350 STAND PARTS

EN

Nr.

Description

Qty

Part No

1

CONDUIT (large dia 12mm) - PMA-PCLT-10B.50

1

M0443

2

M6 X 16 CAP HEAD SCREW

3

SC616CAP

3

SLIDE HB350 MAKITA

1

M1000

4

M6 X 25 CAP HEAD SCREW

7

SC625CAP

5

HANDLE KNOB (10mm KNOCK ON)

3

M0841

6

10MM X 130MM HANDLE (SMALL)

3

BD043

7

M4 X 6 BUTTON HEAD SCREW

8

SC46BUT

8

WARNING PLATE MAKITA HB350 CE JAPAN

CE JAPANMAKITA HB350 CE JAPAN

MAKITA HB350 CE JAPAN

M1002

WARNING PLATE MAKITA HB350 CE BELGIUM

BELGIUM

M1003

WARNING PLATE MAKITA HB350 CSA JAPAN

M1014

WARNING PLATE MAKITA HB350 UKCA UK

M1018

WARNING PLATE MAKITA HB350 RCM AUSTRALIA

M1021

9

25A - BRIDGE RECTIFIER (395-4310)

1

M0401

10

M5 X 16 CAP HEAD SCREW

3

SC516CAP

11

OILFEED TOP BRACKET - (MB30 BODY)

1

M0811A

12

BRASS RAIL (MB30)

2

M0101

13

RACK (MB30)

1

M0831

14

OIL CUP RETAINING CLIP COMPLETE

1

10076C

15

M5 NYLOC

6

10085B

16

M5X25 KNURLED POINT GRUB SCREW

5

10085A

17

CAPACITOR

1

RD43118

18

BUSH (PINION) - 33 X 28 X 20 OILITE BUSH

2

M0081

19

PINION END CAP - DEEP

1

M0072

20

O CLIP 8-11 BOCLIP8/11

1

RD47179

21

D5000 OIL CUP ASSEMBLY

1

30046A

22

U-06040(30MC) 6MM X 4MM CLEAR POLYURETHANE TUBE

1

BD029

23

MAKITA HB350 CONTROL PANEL PLATE

1

M1001

24

M16 PUSH FIT GLAND - PMA BVND-M160GT

1

40026

25

MB30 BODY BLACK

1

M0001BLK

26

M16 PIGTAIL GLAND COMPLETE WITH LOCK NUT - BBSM 16

1

10231

27 USA CABLE - 14 GAUGE - 3M - AB-CAB-870

C

ABL03

EUROPEAN CABLE C/W MOULD PLUG - AB-CAB-876 - 3M

C

ABL04

MAKITA BRAZIL CABLE C/W PLUG 220V - 3M

C

ABL05

3MTR-110V MAINS LEAD BLACK C/W IND PLUG

C

ABL06

ARGENTINA CABLE C/W PLUG - 230V - 3M

C

ABL08

AUS/NZ-3M MAINS CABLE C/W MOULDED PLUG-AB-CAB-866

CABL09

28

M8 WASHER FOR ARBOR INTERNAL

1

RD47187

29

M4 BRASS NUT

1

NUT-M4-B

30

HB350 MAGNET BASE

1

M1020

31

M4 X 6 SLOTTED CSK MC SCREW - BZP

5

SC46CSK

32

M4 X 12 CSK MC SCREW - BRASS

1

SC412CSK-B

33

M4 SHAKE PROOF WASHER-BZP-WSH-227-004-ZC221

9

SPWR-M4

34

PINION - (SMALL)

1

M0041

35

EIBENSTOCK BHM35 DRILL UNIT - 110V MAKITA BLUE

EIB522

EIBENSTOCK BHM35 DRILL UNIT - 230V MAKITA BLUE

EIB523

36

DRILL STOP/START SWITCH - 110V - KJD17F/120V/50HZ -

KJD17-P2-F2-V1-M2-A1

NCP001

DRILL STOP/START SWITCH - 230V - KJD17F-230V-50HZ-

KJD17F-P2-F2-V3-M2-A1

NCP002

37

MAGNET SWITCH - NCP PANEL - B418CG00000

1

NCP006

38

G.F.S. (MB30)

1

M0441

39

1/8 BSP-6MM BLACK PUSH FIT

1

50015

40

GUARD TO SUIT NEW UNI 1 MBQ35N/EQ35N/EBM35

1

VISO18

41

318-565 VARISTOR (V150LA10A)

W18XC522

VARISTOR HIGHSURGE 20MM 275 VRMS

W18XC521

42

248-447 FUSE HOLDER

1

W18XC511

43

2A FUSE (RAPID 26-2469)

1

W18XC512

44

WASHER SMBK1869836HPU

1

UOD009

EN

ORIGINAL

EC Declaration of Conformity

We as the manufacturers Makita Europe N.V.

Business address Jan-Baptist Vinkstraat 2

3070 Kortenberg

BELGIUM

Authorize Hiroshi Tsujimura for the compilation of the technical file and

declare under our sole responsibility that the product(s);

Designation …………………............ Magnetic Drill

Designation of Type(s) …………….. HB350

Fulfills all the relevant provisions of 2006/42/EC

and also fulfills all the relevant provisions of the following EC/EU

Directives:

− 2014/30/EU

− 2011/65/EU

and are manufactured in accordance with the following Harmonised

Standards:

EN 62841-1:2015, EN ISO 12100:2010, EN 61000-6-2:2005, EN 61000-

6-4:2007+A1:2011,

EN 61000-3-2:2014, EN 61000-3-3:2013, EN IEC 63000:2018

Place and date of declaration: Kortenberg, Belgium, 12.2.2021

Responsible person: Hiroshi Tsujimura

Director - Makita Europe N.V.

BEVOR SIE

BEGINNEN

Dieser Leitfaden enthält einfache, praktische

Hinweise für einen sicheren, effektiven Betrieb

über eine lange Lebensdauer und die

bestmögliche Leistung Ihrer neuen

Magnetbohrmaschine.

Bie lesen Sie diesen Leiaden vor dem

Gebrauch der Bohrmaschine sorgfälg.

• Sicherstellen, dass alle allgemeinen und

speziellen Sicherheitsvorkehrungen eingehalten

werden.

Erklärung der Piktogramme auf dem

Typenschild der Makita HB350

GEFAHR!

Weist auf eine unmittelbare

Lebensgefahr oder eine Gefährdung

Ihrer Gesundheit von allgemeiner Natur

hin.

ELEKTRISCHER SCHLAG!

Weist auf eine direkte Lebensgefahr

oder ein Risiko durch elektrische Schläge

hin.

VORSICHT!

Weist auf eine mögliche Gefahr oder ein

Risiko von leichten Verletzungen oder

Sachschäden hin.

SCHUTZBRILLE UND GEHÖRSCHUTZ

TRAGEN

SPANNGURT BENUTZEN!

Der Spanngurt dient zum Befestigen des

Werkzeuges am Werkstück.

BEDIENUNGSANLEITUNG LESEN

Vor Gebrauch der Maschine die

Bedienungsanleitung lesen.

WEEE-Konformitätsbescheinigung: auf Anfrage erhältlich.

Alle Magnetbohrsysteme sind vollständig mit den RoHS-

Richtlinien konform.

Elektro- und Elektronik-Altgeräte können schädliche

Auswirkungen auf die Umwelt und die Gesundheit haben,

weil sie Gefahrenstoffen enthalten.

Elektro- und Elektronikgeräte dürfen nicht im

Haushaltsmüll entsorgt werden.

Gemäß der europäischen Verordnung über

Elektro- und Elektronik-Altgeräte

müssen diese in Übereinstimmung mit den

Umweltschutzbestimmungen separat gesammelt

und an eine separate kommunale

Abfallentsorgungsstelle geliefert werden.

Dies wird durch das Symbol mit der

durchgestrichenen Mülltonne auf dem Gerät

angegeben.

INHALT

•

HB350 – Technische Daten

•

Das Konzept des Räumschneidens

•

Verwendungszweck

•

Allgemeine Sicherheitshinweise

•

Material und

Schnittgeschwindigkeiten

•

Vorschübe und Drehzahlen

•

Befestigen des Spanngurtes und

Einsetzen der Ölflasche

•

Einsetzen des Schneidwerkzeuges

•

Bedienkonsole

•

Motorzeichnung & Teileliste

•

Ständerzeichnung & Teileliste

•

EG-Konformitätserklärung

DE

SCHNITTZEIT

SCHNITTZEIT

HB350 – TECHNISCHE DATEN

Bohrerdurchmesser – 35 mm

Spannbereich d.

Bohrfutters – 13 mm

Leerlaufdrehzahl – 850 U/min

Leistungsaufnahme – 1050 W

Magnethaltekraft – 8.000N (815 kg)

L x H x B (mm) – 225 x 490 x 195

Gewicht – 11 kg

Spannung – 110/230 V

Schalldruckpegel – 89,13 dB(A)

Schallleistungspegel – 100,12 dB(A)

INKLUSIVE: Integriertes Kühlsystem, Garantie,

Transportkoffer, Innensechskantschlüssel, Spanngurt

und Schutzvorrichtung

• Diese Angaben unterliegen aufgrund unseres

kontinuierlichen Forschungs- und Entwicklungsprogramm

unangekündigten Änderungen.

DAS KONZEPT DES RÄUMSCHNEIDENS

Sollten Sie mit der Anwendung von

Ringschneidemaschinen (oder

Räumschneidemaschinen) nicht vertraut sein,

nehmen Sie sich bitte einige Minuten Zeit, um

diesen Leitfaden zu lesen. Sie werden von der

besseren Leistung und der längeren Haltbarkeit

Ihres Werkzeuges profitieren, wenn Sie das

Konzept verstanden haben.

Ringschneidemaschinen schneiden nur Material

am Umfang des Lochs aus, anstatt das gesamte

Loch in Späne zu verwandeln. Als Folge davon,

sind die für die Erstellung des Lochs

erforderliche Zeit und Energie geringer als bei

Verwendung eines herkömmlichen

Spiralbohrers.

Daher ist die Räumschneidekapazität einer

Maschine größer als die Spiralbohrkapazität. Der

nach dem Bohrvorgang ausgeworfene Kern hat

außerdem einen höheren Schrottwert als

Metallspäne.

Optionales Zubehör

Einzelheiten zu Optionen können dem Katalog entnommen oder in dem

Geschäft, in dem der Kauf getätigt wurde oder bei einem Makita

Vertriebsbüro erfragt werden.

Wenn Sie Hilfe oder weitere Informationen bezüglich dieser Zubehörteile benötigen,

wenden Sie sich bitte an Ihr örtliches Makita Servicezentrum.

• HSS-Schneidwerkzeug

• TCT-Kernbohrer

• Bohrfutter

VERWENDUNGSZWECK

Dieser Magnetbohrer ist zum Bohren von Löchern in eisenhaltigen Metallen bestimmt. Der

Magnet wird dazu benutzt, den Bohrer während des Betriebs in seiner Position zu halten. Er ist für

das Bohren von eisenhaltigen Metallen in der Fertigungsindustrie, dem Baugewerbe, dem

Schienensektor, der Petrochemie sowie allen anderen Anwendungen bestimmt.

Bei jeglichen Abweichungen vom Verwendungszweck erlischt die Garantie.

ALLGEMEINE SICHERHEITSHINWEISE FÜR ELEKTROWERKZEUGE

Allgemeine Sicherheitswarnhinweise für Elektrowerkzeuge

WARNHINWEIS Alle diesem Elektrowerkzeug beigefügten Sicherheitswarnhinweise,

Anweisungen, Abbildungen und technischen Daten sorgfältig lesen. Das Versäumnis, alle unten

stehenden Anweisungen zu befolgen, kann zu elektrischen Schlägen, Bränden und/oder schweren

Verletzungen führen.

Alle Warnhinweise und Anweisungen zur späteren Bezugnahme aufbewahren.

Der Begriff „Elektrowerkzeug“ in den Warnhinweisen bezieht sich auf Ihr netzgespeistes

(kabelgebundenes) Elektrowerkzeug oder Ihr batteriebetriebenes (kabelloses) Elektrowerkzeug.

1) Sicherheit im Arbeitsbereich

a) Arbeitsbereich sauber und gut beleuchtet halten. Unordentliche oder dunkle Bereiche erhöhen die

Unfallgefahr.

b) Elektrowerkzeuge dürfen nicht in explosiven Umgebungen wie in Gegenwart von entflammbaren

Flüssigkeiten, Gasen oder Stäuben benutzt werden. Elektrowerkzeuge erzeugen Funken, die Staub

oder Dämpfe entzünden können.

c) Kinder und andere Personen während des Gebrauchs des Elektrowerkzeuges fernhalten.

Ablenkungen können zum Verlust der Kontrolle über das Elektrowerkzeug führen.

2) Elektrische Sicherheit

a) Der Netzstecker des Elektrowerkzeuges muss in die Steckdose passen. Der Stecker darf in keiner

Weise modifiziert werden. Keine Adapterstecker mit schutzgeerdeten Elektrowerkzeugen

VORSICHT: Diese Zubehör- oder Aufsatzteile werden zur Verwendung mit dem

in dieser Bedienungsanleitung beschriebenen Makita Werkzeug empfohlen. Die

Verwendung von beliebigen anderen Zubehör- oder Aufsatzteilen kann zu

Personenschäden führen. Zubehör- und Aufsatzteile nur gemäß ihrem

Verwendungszweck einsetzen.

verwenden. Originalstecker und passende Steckdosen verringern das Risiko eines elektrischen

Schlages.

b) Körperkontakt mit geerdeten Oberflächen wie Rohren, Heizungen, Herden und Kühlschränken

vermeiden. Es besteht ein erhöhtes Risiko durch elektrischen Schlag, wenn Ihr Körper geerdet ist.

c) Elektrowerkzeug von Regen oder Nässe fernhalten. Das Eindringen von Wasser in ein

Elektrowerkzeug erhöht das Risiko eines elektrischen Schlages.

d) Das Kabel darf nicht zweckentfremdet werden. Benutzen Sie es nicht, um das Elektrowerkzeug zu

tragen, aufzuhängen oder den Stecker aus der Steckdose zu ziehen. Halten Sie das Kabel fern von

Hitze, Öl, scharfen Kanten, oder sich bewegenden Geräteteilen. Beschädigte oder verwickelte Kabel

erhöhen

das Risiko eines elektrischen Schlages.

e) Bei der Arbeit mit einem Elektrowerkzeug im Freien nur Verlängerungskabel verwenden, die auch

für den Außenbereich geeignet sind. Die Anwendung eines für den Außenbereich geeigneten

Verlängerungskabels verringert das Risiko eines elektrischen Schlages.

f) Wenn der Betrieb des Elektrowerkzeuges in feuchter Umgebung nicht vermeidbar ist, einen

Fehlerstromschutzschalter verwenden. Der Einsatz eines Fehlerstromschutzschalters vermindert das

Risiko eines elektrischen Schlages.

HINWEIS Der Begriff „ Fehlerstromschutzschalter“ kann durch den Begriff „FI-Schutzschalter“ ersetzt

werden.

3) Persönliche Sicherheit

a) Seien Sie aufmerksam, achten Sie darauf, was Sie tun, und gehen Sie mit Vernunft an die Arbeit

mit dem Elektrowerkzeug. Benutzen Sie kein Elektrowerkzeug, wenn Sie müde sind oder unter dem

Einfluss von Drogen, Alkohol oder Medikamenten stehen. Ein Moment der Unachtsamkeit beim

Gebrauch eines Elektrowerkzeuges kann zu ernsthaften Verletzungen führen.

b) Persönliche Schutzausrüstung verwenden. Immer eine Schutzbrille tragen. Das Tragen

persönlicher Schutzausrüstung, wie Staubmaske, rutschfeste Sicherheitsschuhe, Schutzhelm oder

Gehörschutz, je nach Art und Einsatz des Elektrowerkzeuges, verringert das Risiko von Verletzungen.

c) Unbeabsichtigte Inbetriebnahme vermeiden. Vergewissern Sie sich, dass das Elektrowerkzeug

ausgeschaltet ist, bevor Sie es an die Stromversorgung und/oder den Akku anschließen, es anheben

oder tragen.

Wenn Sie beim Tragen des Elektrowerkzeuges den Finger am Schalter haben oder das Gerät

eingeschaltet an die Stromversorgung anschließen, kann dies zu Unfällen führen.

d) Entfernen Sie Einstellwerkzeuge oder Schraubenschlüssel, bevor Sie das Elektrowerkzeug

einschalten. Ein Werkzeug oder Schlüssel, die sich in einem drehenden Teil des Elektrowerkzeuges

befinden, können zu Verletzungen führen.

e) Beim Arbeiten auf eine normale Körperhaltung achten. Sorgen Sie für einen sicheren Stand und

halten Sie jederzeit das Gleichgewicht. Dadurch können Sie das Elektrowerkzeug in unerwarteten

Situationen besser kontrollieren.

f) Tragen Sie geeignete Kleidung. Tragen Sie keine weite Kleidung oder Schmuck. Haar und Kleidung

von beweglichen

Teilen fernhalten. Lose Kleidung, Schmuck oder langes Haar können sich in beweglichen Teilen

verfangen.

g) Wenn Staubabsaug- und -auffangeinrichtungen montiert werden können, vergewissern Sie sich,

dass diese angeschlossen sind und richtig verwendet werden. Verwendung einer Staubabsaugung

kann Gefährdungen durch Staub verringern.

h) Wiegen Sie sich durch Vertrautheit mit dem Elektrowerkzeug nach vielfachem Gebrauch nicht in

falscher Sicherheit und setzen Sie sich nicht über die Sicherheitsregeln für Elektrowerkzeuge hinweg.

Achtloses Handeln kann binnen Sekundenbruchteilen zu schweren Verletzungen führen.

4) Korrekter und sorgfältiger Gebrauch von Elektrowerkzeugen

a) Überlasten Sie das Gerät nicht. Immer das für Ihre Anwendung bestimmte Elektrowerkzeug

verwenden. Mit dem passenden Elektrowerkzeug arbeiten Sie besser und sicherer im angegebenen

Leistungsbereich.

b) Kein Elektrowerkzeug benutzen, dessen Schalter defekt ist. Ein Elektrowerkzeug, das sich nicht

mehr ein- und ausschalten lässt, ist gefährlich und muss repariert werden.

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

La page charge ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

dans d''autres langues

- español: Makita HB350 Manual de usuario

- Nederlands: Makita HB350 Handleiding

- português: Makita HB350 Manual do usuário

Documents connexes

Autres documents

-

PROPOINT 8740144 Le manuel du propriétaire

-

Evolution Power Tools EVOMAG28 Guide d'installation

-

Ega Master 79633 Le manuel du propriétaire

-

Milwaukee 4203 Manuel utilisateur

-

Milwaukee 4203 Manuel utilisateur

-

Milwaukee 4203 Manuel utilisateur

-

Milwaukee 4203 Manuel utilisateur

-

Evolution Technologies BORA 2800 Manuel utilisateur

-

DeWalt DWE1622K Manuel utilisateur